Views

Innovative products do not appear very often in construction. Many of them become "sensations" a decade after they were launched into mass production. Interestingly, the most popular are new building and finishing materials, which have improved energy efficiency, reducing costs and shortening the time of work.

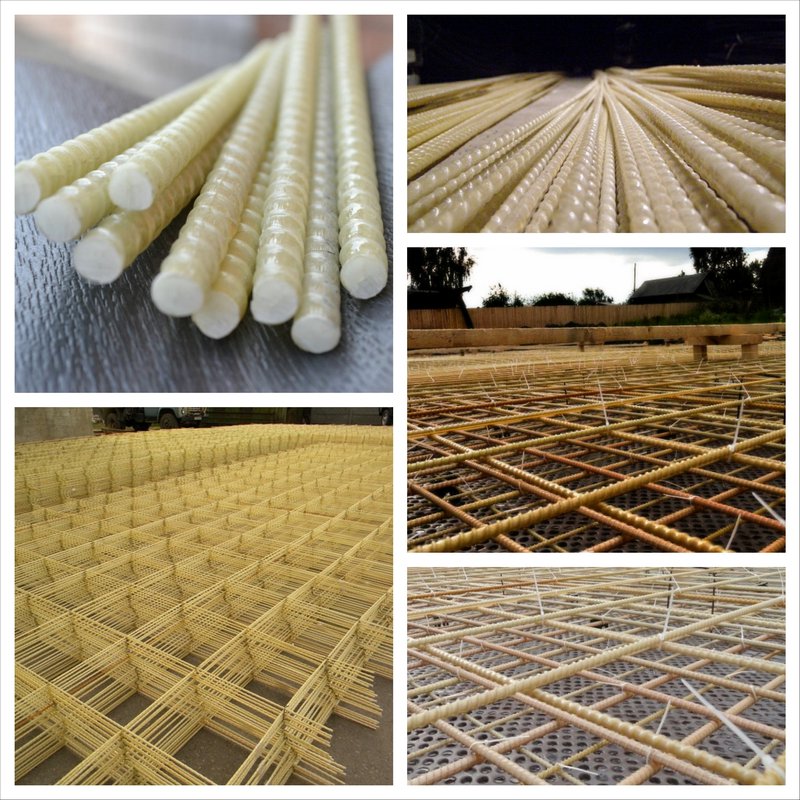

Coal concrete

The material has super-strong characteristics that are superior to those of reinforced concrete structures. It is distinguished by its high cost, belongs to the composite options that combine the properties of carbon fiber and artificial stone. The tensile strength of such a monolith exceeds that of the best steel grades by 4 times, while the weight of the structure is significantly reduced.

The production is carried out according to 2 technologies.

- With pouring into the formwork. Carbon fiber reinforcement is mounted in the mold, then the prepared solution is introduced.

- Layer by layer. In this case, a special carbon fiber fabric is used, which is laid between the layers of concrete. The procedure continues until the desired thickness is reached.

Aerated concrete

This version of an innovative building block is made using a cellular technology, based on Portland cement, fly ash, aluminum powder and ground boiling lime, mixed with water. Aerated concrete is widespread in low-rise construction. It is used to create single-layer and multi-layer walls, allowing to reduce material consumption when erecting walls and partitions.

Porous ceramic blocks

Wall structures made of these materials are of low density and high energy efficiency. The material is similar in its characteristics to aerated concrete, but surpasses it in terms of thermal conductivity. The difference is up to 28%.

Reinforced concrete panels with insulation

Ready-made wall structures with window and door openings, cast in the form of slabs. These are quick-assembly solutions, formed in the factory. Internal insulation allows you to refuse additional installation of thermal insulation. In some cases, slabs are produced as individual components assembled on site.

Wood concrete, or arbolite

This lightweight composite combines the properties of cement and wood chips. It has good heat-insulating properties, the material surpasses both brick and expanded clay concrete in its properties.

Polystyrene concrete

Material in blocks with finished exterior finish. Polystyrene granules are introduced into the aerated concrete mass during the production process. As a result, the material is warmer and more durable than aerated concrete or aerated concrete. The wall is lightweight, does not require additional installation of thermal insulation

Peat blocks

An environmentally friendly building material with excellent thermal insulation properties. Peat blocks are used in multi-storey residential construction.

Fixed formwork

Polymer blocks, similar to Lego bricks, are connected to each other right on the site. Easily assembled modules are reinforced inside, filled with concrete around the entire perimeter in 3-4 rows. Such structures are in demand in monolithic construction, provide high strength of the finished monolith.

Monolithic timber

An innovative solution that allows you to create walls from wood at once with a thickness of 100 mm or more. In low-rise construction, a monolithic beam makes it possible to reduce the depth of the foundation, reduces the load on the foundation.

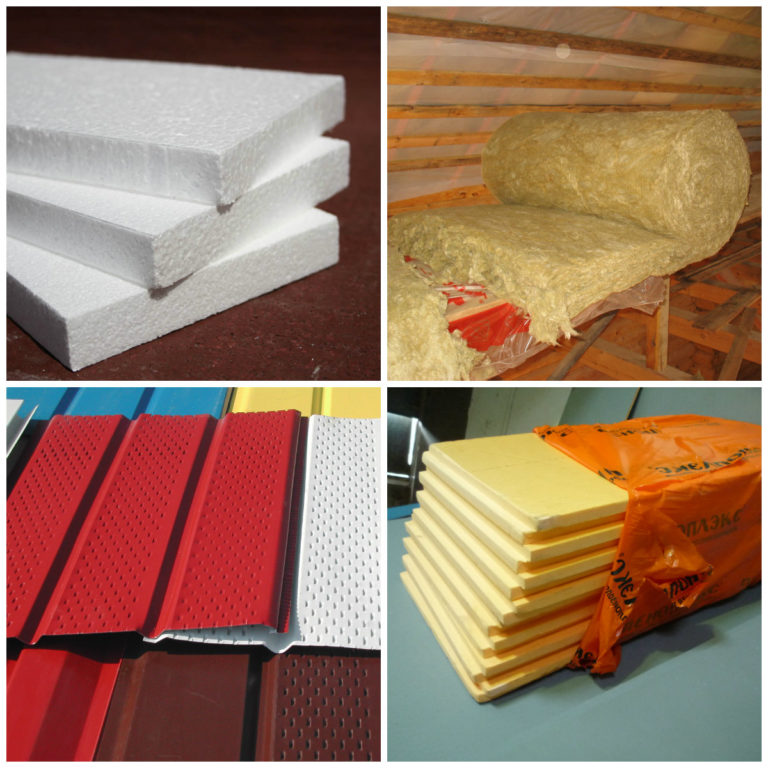

Basalt wool

It replaced other types of thermal insulation materials. Basalt mineral wool is fire resistant.The material has high heat-insulating and sound-insulating characteristics, resistant to deformation when atmospheric temperatures change.

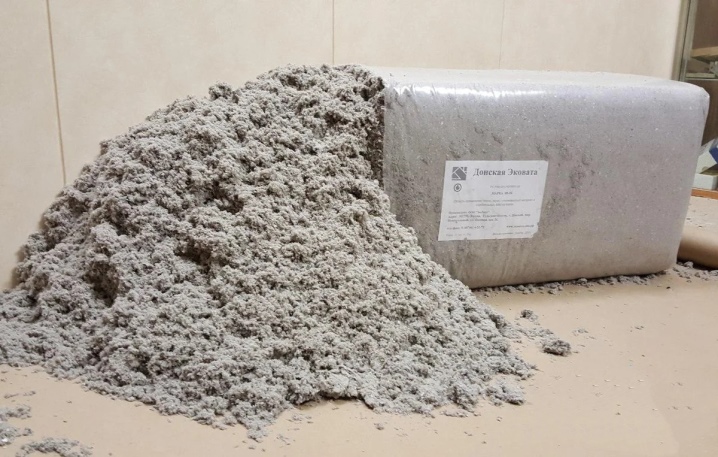

Ecowool

Thermal insulation material based on recycled materials. It has been used since 2008, it is distinguished by its economical consumption and high biological resistance. Fungus and mold do not appear in the material, it excludes the appearance of rodents or insects.

Microcement

Finishing material in demand in industrial style interior design. It contains polymer components, dyes, which make it possible to impart moisture resistance to the treated surface, and improved aesthetic characteristics. The fine structure of the cement dust provides good adhesion to various materials.

LSU

Magnesite glass sheets are used in the interior decoration of buildings and structures, suitable for wall and floor cladding, creating partitions. The composition of the material includes fiberglass, magnesium oxide and chloride, perlite.

Pros and cons of a brick house

Let's summarize all the advantages and disadvantages of brick buildings. The advantages of brick houses are:

- Durability. A brick building is rightfully considered one of the most durable. The service life of such a house can reach several centuries, since this material is not subject to decay, like wooden houses.

- A brick house retains its original appearance for a long time, so additional external finishing of such structures is not always required. Brick itself is a good finishing material.

- In our time, the loft style has become widespread, which involves the use of natural brickwork as the interior decoration of the room. Therefore, when building a brick house, you can also save on interior decoration.

- Resistant to fire. Brick walls are non-combustible, therefore, in this component, they outperform log or timber houses, as well as frame buildings. Often this advantage is decisive when choosing a material for building a house.

- Strength. Brick walls are among the most durable in private construction. They can withstand significant loads from the roof, and also allow the construction of multi-storey buildings.

- Environmental Safety. For the production of bricks, only natural materials are used - sand, clay and water, which do not emit harmful substances into the atmosphere.

- Frost resistance. Brickwork withstands much more freezing cycles than aerated concrete, so such houses can stand without external finishing in aggressive conditions for more than one hundred years.

The most frost-resistant type of brick is clinker brick, which is often used on the outer layer for cladding a building. - Investing in a brick house is a good investment, since this building material has proven itself well in all respects.

A few decades ago, brick had no competitors, but with the advent of new building materials on the market, the disadvantages of brick houses became obvious. Let's analyze the main ones.

- High material cost. Brick is not the cheapest building material, so not everyone can afford to build a brick house and choose cheaper analogs, such as frame houses.

- The need to attract bricklayers for the masonry of the house. The construction of brick walls is not an easy task, therefore, hired workers of appropriate qualifications are often hired for such work. The work of bricklayers is paid quite high.

- Terms of construction of a brick house. The construction of a building from this building material is slower than with the use of more modern construction technologies. As a rule, it takes several months to build brick walls.True, in comparison with wooden houses, brick houses do not have significant shrinkage, which allows finishing immediately after the construction of the box and bringing the house under the roof.

- Due to the heavy weight of a brick house, it requires a heavy monolithic foundation. Such a foundation will cost significantly more than for lightweight structures made of wood or SIP panels.

- To ensure sufficient heat capacity of a brick wall, it must have a significant thickness. This increases the consumption of materials and the construction budget. Houses made of modern building materials with the same heat capacity have a wall size several times smaller than that of brick buildings.

A brick house is perhaps the most durable and adapted to our weather conditions. It contains many positive qualities, such as strength, long service life, energy consumption and fire safety. In addition, the disadvantage will be the need to attract specialists for the construction site, as well as the need to equip a strong foundation.

At the end, we suggest watching a short video calculating the cost of building a brick house

Blooming (thermal) wallpaper

The main feature of this finishing material is the ability to change colors or show additional details of patterns in the event of a change in the temperature of the room or objects adjacent to the wallpaper. The effect is achieved thanks to a new technology for the manufacture of finishing materials using thermal paint, which is used to apply patterns to the canvas.

For example, at low temperatures, only green stems with small buds can be seen on the wallpaper, but when the temperature rises to 23 °, the buds increase, and at 35 ° C, lush bright flowers appear on them. This amazing novelty will bring zest to any interior and will not bother the owners of the house for a long time. The disadvantages of this type of finish include the high price, as well as certain requirements for the room: thermal wallpaper should be glued where it is possible to create conditions with temperature changes (near heat sources, in rooms accessible to sunlight or with a controlled temperature).

Piles and beams built with closed cell insulation

Pile houses today are mainly built with hollow piles and beams. Meanwhile, this space can also be used for additional insulation of the foundation of the house, which allows achieving a higher R (thermal insulation) value.

A pile foundation insulated with insulators can solve many problems. In addition, massive piles and beams made from lumber at least 120 centimeters long will also allow you to build a stronger and more stable floor that will not sag, creak, and will not deteriorate as quickly from adverse weather conditions.

Piles and beams with closed cellular insulation are the key to building rugged houses that are not afraid of severe frost and floods. Closed cell insulation is far superior to fiberglass wool and is currently the industry leader in insulation value.

Of course, for Russian developers, who have every ruble in their account, additional insulation of piles or foundation frames sometimes looks too expensive. However, in Western countries, where there are no alternatives to electric heating, at the same time, electricity is much more expensive than ours, this technology has already become in demand.

Liquid tree

German experts decided to take an unexpected step at all and created an innovative material: bending wood is not such an easy task, so why not immediately make some kind of liquid composite from polymers and shredded wood?

The polymers in the composition can be organic or synthetic, and various modifiers are also added. Wood is found as wood flour and makes up 70% of the bulk of the composite.

Organic modifiers include casein, grain starch and paper waste. The inclusion of such organic components can reduce the final price of the product.

If the composition includes antimicrobial components, temperature stabilizers or substances that make the material shockproof, then the price increases accordingly, as does the quality.

Dye

The market offers a truly huge number of all kinds of interior paints. Water-borne ones are considered the safest and most non-toxic, and solvent-borne ones, when dry, form a denser, shiny layer. You can choose a moisture-resistant paint that is suitable for the kitchen, and vapor-permeable, which will be in place, for example, in the hallway. As for the decorative properties, the paints are glossy, matte and even embossed. The former are suitable for immaculately flat surfaces, and the embossed one is capable of hiding roughness and small errors on the walls.

As for the decorative properties, the paints are glossy, matte and even embossed. The former are suitable for immaculately flat surfaces, and the embossed one is capable of hiding roughness and small errors on the walls.

- Water-based paints have the softest chemical composition. Their other advantages include an attractive price and a huge selection of colors and shades. The disadvantages are instability to abrasion and high humidity.

- Acrylic paints are more tolerant of fumes, but droplets or jets can destroy them. The most durable among water-soluble paints are latex paints. They are even allowed to be washed, but they are not too UV-tolerant, and they are more expensive. Walls covered with acrylic-based paint are not afraid of sunlight, are non-toxic and do not fade for 15-20 years. The disadvantage of such paints is the long drying time.

- Alkyd paints are inexpensive, easy to use, have a wide color range and dry within an hour of application. True, alkyd-based dyes are short-lived - a year later, the walls may become stained and lose their original brightness. They also do not like sunlight, and most importantly, they are quite toxic. Due to the last point, these paints are not recommended in bedrooms and nurseries.

- Silicate paints are created on the basis of water glass with the addition of pigments and fillers. Most often they are used on verandas, balconies, in basements - where exposure to moisture and temperature extremes is required.

- Silicone paints are vapor-permeable, have dirt-repellent qualities, are not afraid of water and create a sufficiently strong coating layer. It is not surprising that their service life is equal to a quarter of a century. Silicone paints can be used to decorate the walls of the bathroom, use them in the hallway, in the kitchen. However, it should be remembered that the bumps and depressions on walls covered with this relatively new type of paintwork will become more noticeable.

- Oil paints with linseed oil in the base are rarely used for interior decoration today. The reason is the harmful components that are used in their production. In addition, oil formulations dry for a long time, do not allow surfaces to "breathe", they can bubble and crack. The merit of oil paints can be attributed, perhaps, to their affordability. Because of this, oil paints can be useful in utility rooms, utility rooms - they are used to paint pipes, window frames, radiators.

- Enamel is often called for help when renovating it. Among the advantages of enamel dyes are budget price, aesthetics (it forms an even, glossy film), strength exceeding the strength of oil and alkyd paints. Enamel is called a universal coating because it easily adheres to any surface, be it brick, concrete or wood, and dries up within 24 hours. The paint resists moisture well, therefore enamel, it happens, is used to cover the walls of the bathroom. But do not forget that enamels are fire hazardous, which is why they should not be used near the stove. The durability of enamel paint depends on the type and ranges from 10 to 15 years.

No. 3. Facing brick

Brick has always been one of the most popular materials for facade decoration. Of course, for these purposes, not ordinary building bricks are used, but special decorative bricks, which are called facade, facing or front bricks.

Depending on the composition and method of production, facing bricks are divided into the following groups:

- clinker;

- ceramic;

- hyper-pressed;

- silicate.

Each of these types has its own operational qualities, but they are united by their excellent appearance, a wide variety of shades, textures (can be glazed, with mineral chips or matte surface) and shapes (there is a brick in the shape of a parallelepiped, and there is a shaped one in a figured shape). In addition, all bricks have excellent resistance to negative environmental factors.

Clinker brick

Quite expensive clinker bricks are obtained from special plastic types of clay by pressing and firing. Natural dye can be added to the mass. In terms of the aggregate performance, this is the best option for facing bricks.

Advantages:

- high mechanical strength;

- durability;

- frost resistance. The material easily withstands up to 300 freezing / thawing cycles without losing its basic properties;

- resistance to direct sunlight and high temperatures;

- resistance to aggressive substances;

- low coefficient of water absorption;

- environmental friendliness;

- aesthetics and a large selection;

- special care and maintenance is not required - the facade is easy to clean.

Among the disadvantages are the high price, considerable weight and complex installation. An alternative to this material is clinker tiles, which are made in almost the same way, can have a lot of relief and color options, but at the same time have a small thickness, which means less weight.

Ceramic brick

Ceramic bricks made from clay by firing it are familiar to each of us. Its facing variety is striking in a wide variety of colors and textures, but this is not the only advantage of the material.

Advantages:

- durability;

- environmental friendliness;

- good sound and heat insulation characteristics;

- resistance to temperature extremes, sunlight, fire;

- relative cheapness.

Disadvantages:

- not always accurate geometry;

- there may be inclusions of limestone in the presence, which, absorbing moisture, will stand out in a darker color;

- the possibility of crumbling or destruction, if mistakes were made in the choice of solution, product brand or installation;

- a high level of water absorption, which can reach 10%, reducing the frost resistance of the product.

Hyper pressed brick

Such material is obtained using cement, shell rock and some special additives by the method of semi-dry pressing. Outwardly, it resembles a ceramic brick, but in many respects it is ahead of it.

Advantages:

- durability and strength;

- good geometry;

- frost resistance;

- a large assortment;

- ease of processing.

The water absorption of such a brick is at an average level - about 5-6%, and the obvious disadvantages of the material include high thermal conductivity, the ability to change color over time and a large weight, which affects transportation.

Silicate brick

Facing silicate brick is made from a cement-sand mixture by autoclaving, special additives can be used. Due to the simplicity of production and low cost of raw materials, silicate brick is considered one of the most affordable materials among other types of bricks.

Advantages:

- high strength;

- precise geometry;

- environmental friendliness;

- good soundproofing qualities;

- low price.

Disadvantages:

- in comparison with other types of facing bricks, silicate bricks do not have the best decorative qualities;

- heavy weight;

- low thermal insulation qualities;

- high level of water absorption (more than 15%);

- low frost resistance.

Teplosten

Another innovation in

the area of bricks is a block called "heat wall". It was invented in 1999

year. The heating wall is presented in the form of a block, which consists of three layers. First

layer is a load-bearing block that holds the main load, the second is a layer

insulation, usually polystyrene, less often mineral wool, and the last one -

decorative facade layer. In terms of thermal conductivity, such a block is 6 times higher than

ordinary brick. The heating wall is mounted using tile adhesive, which

is applied in a thin layer, which eliminates the appearance of efflorescence on

wall surface. This material has a wide variety of configurations and

design options. It is also possible to manufacture blocks to order. By

the thermal conductivity of these blocks is unmatched, they can hold as heat in winter,

so cool in the summer. Teplosten can be truly called

material of the future, thanks to its economy, speed and ease of installation and

a wide variety of facade design options.

How to choose materials for wall decoration?

Each room needs an individual approach to the choice of finishes. For example, for kitchens, it is not recommended to choose a coating made of flammable materials, and moisture-permeable textures are not suitable for bathrooms.

So how to decide on the material for finishing? Pay attention to the following characteristics:

hypoallergenic - wall cladding should not provoke the appearance of allergic reactions, diseases of the respiratory tract and skin in people and pets;

environmental friendliness - the product must be harmless to the environment and safe for human health; ease of installation is an important criterion if repair work is carried out independently;

compliance of the material with the interior of the apartment - an organic combination of texture and color of decoration will create the effect of completeness, thoughtfulness of the interior;

the cost of the material is determined by the expectations of the buyer

However, it is important to remember that more expensive types of finishes remain in pristine condition longer than cheap ones. Guided by these principles, you can choose a laconic option for decorating the walls of an apartment, which will become an indicator of the taste and style of its owners.

Guided by these principles, you can choose a laconic option for decorating the walls of an apartment, which will become an indicator of the taste and style of its owners.

Rubber roof tiles

Well, the last one

a novelty in the construction market, which will be presented in this review,

will become a product that is practically impossible to get anywhere else - this

rubber tiles from obsolete car tires. This is invented

product in the European company Euroshield. Come up with such an original way

recycling of old tires of the inventors of these shingles was forced by the fact that all

landfills and trash cans are littered with unnecessary tires. Rubber roof tiles

has amazing strength, can withstand both hail and heat, not

subject to temperature changes and has an original appearance.

Recycled tire shingles are more durable than anything

renowned roofing materials due to their ability to stretch and

shrink. Rubber shingles are mounted, like ordinary flexible shingles, on

glue, or with screws and nails. The warranty period for this

new items are set at around 50 years old, but in reality it will last much

longer. Even after the end of its useful life, the product may be reused

redesigned to produce new shingles, so it's essentially a perpetual roof.

All presented in

in this material, new items are new only now, but soon

time, they will tightly enter our life, taking the place of outdated and less perfect

materials that were used in construction before them and finally

will displace the building materials familiar to us.And these novelties will be replaced by others,

and this will continue as long as man lives on Earth. His inquisitive

the mind is constantly striving for discoveries and the desire to improve its life,

finding the most amazing solutions to the most non-standard problems.

More articles about primary building materials:

- Types of roofing materials

- Cement

- Heat resistant paint

- Alkyd enamel, its feature and application

- Hammer paint

- Homemade glue at home

- Polyurethane foam

- All about bricks

- Materials for building a house

- Natural stone

- Comparative analysis of materials for pipelines

- Types of primers

Clinker

First, let's imagine

for acquaintance with new products such material as clinker. Clinker is a brick

but brick with a number of advantages that ordinary brick lacks. His

the main advantage over other facing materials is the price.

Compared to, say, decorative facing stone, clinker is significantly

cheaper and saves a significant amount of money spent on finishing

facade. Another advantage of clinker is the variety of shapes and colors.

Clinker brick does not contain chemical impurities in its composition, and consists

only from water and clay with the addition of dyes. This is another advantage of this

facing material, it is natural and environmentally friendly. Well, the last thing

I would like to note about clinker brick - this is its frost resistance and

resistance to various natural phenomena that have a destructive

influence on ordinary brick.