Selection rules

Before you purchase the dowel fasteners, you need to find out in which surface it will be mounted. An important parameter when choosing is the diameter and length of the fastener. The larger they are, the more load it can withstand. It also takes into account the thickness, surface density and the presence of voids.

For example, the most popular universal dowels with a diameter of 0.6 centimeters and a length of up to 8 centimeters are suitable for a plinth. This is one of the reliable fasteners, but if the dismantling of the structure is required, problems can arise. It must be remembered that before installation, all the necessary markings are applied for mounting on the wall and under the holes on the baseboard, which will be drilled out in advance in the future. The diameter of the holes must be equal to the diameter of the dowel.

For a toilet with small dimensions, installation with dowels will be the most practical option. Complete with hardware should be rubber washers or gaskets. Here you also need to measure the surface and apply a markup where the fasteners will be inserted. Next, a hole is drilled in the tile with a drill, and then with a construction perforator in concrete. For insulation and foam, facade specimens are suitable, at their base there is a special toothed thread, thanks to which the dowel-nail is securely attached to the base.

As a fastener for a TV, for a wall hallway, for hanging a kitchen, shelves and other furniture that will be installed in a vertical plane, it is better to use metal nails for aerated concrete or frame nails.

In the next video, you will learn about the types, characteristics and features of the installation of dowel nails.

Fastener Specifications

Most of the construction and finishing works are not complete without the use of this part. It should also be noted that the dowel-nail is always supplied exclusively as a set, so there is no need to look for and purchase a separate "frame" for the nail.

Please be advised that in no case should you replace nails with screws, this replacement will be inappropriate, incorrect and inappropriate. The dowel-nail 6x40 mm, the characteristics of which are its advantages in comparison with similar types of fasteners, can be made of different materials (nylon, polypropylene, polyethylene).

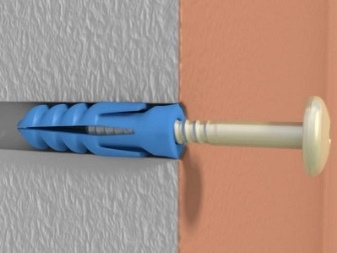

The fastener under consideration consists of several parts, directly from a double-spaced dowel (hence the name of this type of nail), on the surface of which there are no tangential fixing elements in the form of ailerons, or, for example, whiskers. The top of the part (hereinafter - the head) can be of several shapes - a cylinder, in the form of a mushroom and hidden.

The second element of the dowel-nail 6x40 mm is, directly, a nail in the form of a screw. It is usually made from carbon steel, but this is not the only layer to cover the screw. Among other things, a zinc layer is applied to the surface of the fastening element in question, which serves both for protection and for a decorative function.

A smooth part and a tip are located on the shaft of the fastener. It should be noted right away that the shape of the head of the element in question will ultimately depend on the shape of the inlet.

On the cut of this part, there is a so-called slot, which serves as a necessary element for the possibility of replacing the nail itself in case of such a need.

Do not forget about the calculated maximum load that can be applied to a 6x40 mm dowel-nail (for different materials, this indicator will be different):

- If fastening works on concrete, then the maximum load value should not exceed 15 kg, including on the cut itself - up to 12 kg.

- When working with a brick, the indicator in question should not be higher than 12 kg, in this case the maximum load on the cut does not change.

The size

Dowels, like any other fastening elements, have different sizes, because they can be used on different materials and in different conditions. Let's figure out the dimensions of the fastener in question:

- The length of the dowel-nail 6x40 mm is 40 mm (this is the second number in the name of the part in question);

- The length of the nail itself, which is screwed into the dowel, is 45 mm;

- The diameter of the dowel is equal to the value of 6 mm (the first number in the name) and the analogous parameter of the nail is 4 mm;

- The thickness at different ends of the part is different, the minimum is 10, the maximum is 50;

- Anchoring depth - 30.

How to fix the dowel-nail?

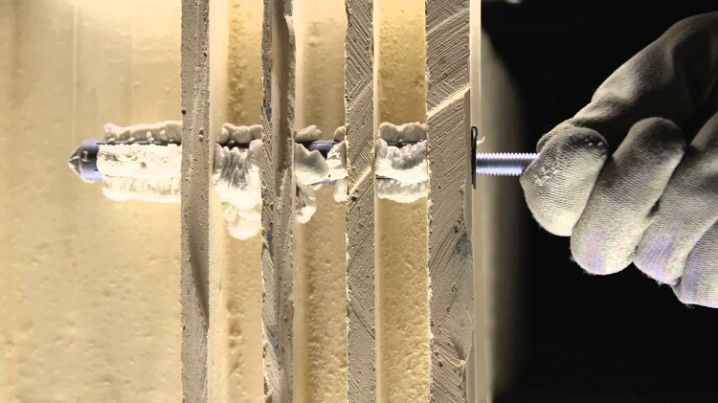

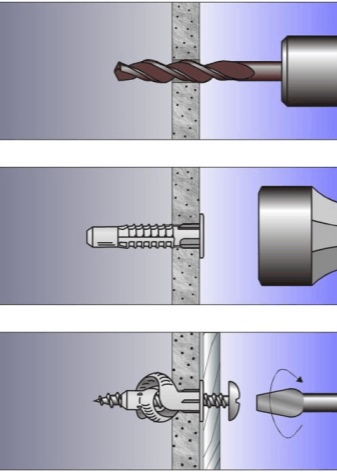

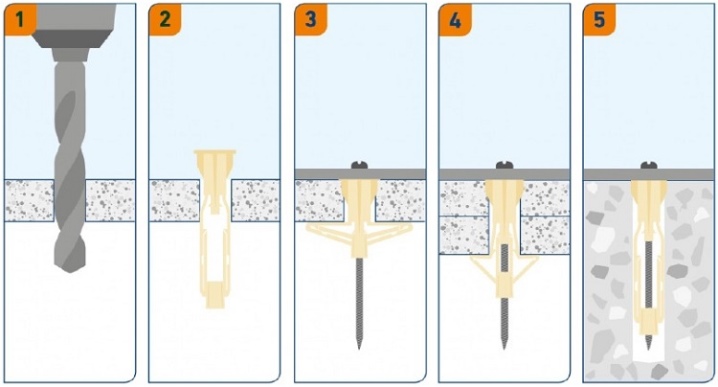

Having figured out the standard sizes, having learned how to use an impact drill and a perforator, it is very easy to install structures using this fastener. The instruction on how to use the dowel-nail is simple:

- Mark the center of the hole.

- We punch a hole of the required diameter with a puncher, taking into account the marking.

- The length of the hole should be 5-6 mm longer than the anchor used.

- It is advisable to clean the hole from dust with a vacuum cleaner.

- Carefully hammer in the expansion chuck of the dowel with a hammer.

- We hammer in a nail, if necessary, leaving 2-3 mm for attaching the suspension.

- In the case of fixing brackets or strips, the dowel is inserted from above through the mounting hole in the product.

Peculiarities

A dowel screw is a fastener for structures that has special antennae for fixing to the surface. When spaced with a screw or screw, a frictional force arises, which holds the dowel in the structure and prevents it from turning. Dowels are made from different materials, they can have different weights and sizes. Depending on the material of manufacture, self-tapping screws have their own characteristics. For example, polypropylene products do not withstand low temperatures. They are not recommended for outdoor use. Nylon elements are versatile. They can be used both outdoors and indoors.

The dowel can be with a retaining collar. The screw is made from nylon and is used for external installation work. Its peculiarity lies in special stoppers. They do not allow the self-tapping screw to fall into the hole.

Self-tapping screws without a collar also have their own distinctive feature. The product is made of polyamide and has a through hole with longitudinal ribs and a non-expansion top. The structure of the product makes screwing in the screw much easier and increases the expansion force. The unbreakable top protects the surface from cracking due to its immobility.

It is also worth noting that these dowels are weather-resistant. They can be used for outdoor facade work. There are types of dowels for a construction gun. The products are practical, effective and securely fix parts to the surface.

All fasteners are manufactured in accordance with GOST. Some specifications are subject to change. These include weight, diameter, length, structure. But the basic rules must be strictly followed. Manufacturers strictly adhere to the following GOST standards:

- material of manufacture;

- min and max are the curvature index of the rod;

- protection from a galvanized layer - galvanizing is carried out in compliance with the rules of galvanizing and passivated technology (coating thickness - 6 microns);

- diameter of washer and metal rod.

It is worth familiarizing yourself with the numerous types of products and their properties.

Varieties and sizes

Engineering thought does not stand still, and during the operation of nylon fastening rods, many types have been developed for various tasks and purposes. Let's consider the main options.

Normal. The main area of its use is internal work.It is used when working with bricks (ordinary and ceramic), gypsum and other materials, in general, where the load on it is insignificant.

You can find dowels of the following specific types: front, for scaffolding, for hollow bricks and many others.

The most common nylon dowels have the following parameters - 6x30, 6x40, 8x60, 8x40,10x50, 6x60 mm. These sizes are considered standard, there are also elongated ones.

Dowel-nail - characteristics

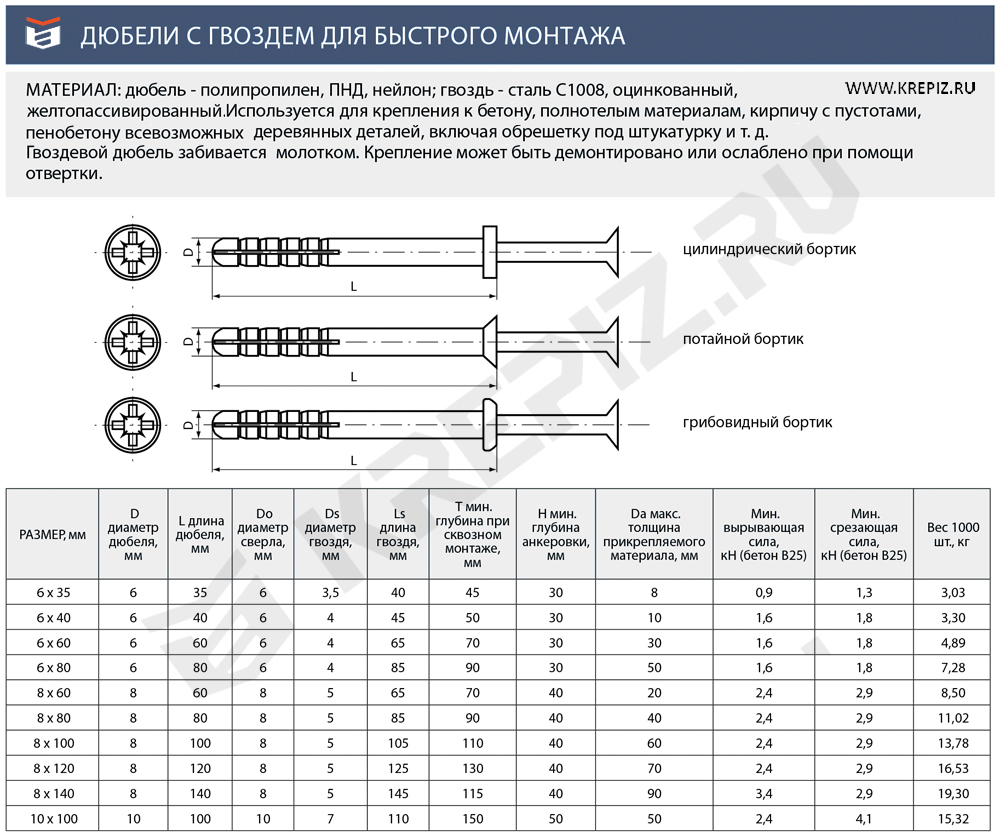

In preparation for construction work, you need to purchase a lot of consumables. The mounting dowel-nail, depending on the type and size, has different technical characteristics. Consider the main parameters of this fastener (minimum and maximum data) using the example of polypropylene products with a secret side:

- Dowel-nails designation - from 6x40 to 10x100.

- Do - dowel hole (6 to 10 mm).

- L - dowel length (from 40 to 100 mm).

- Ds - diameter of nails (from 4 to 7 mm).

- Ls - length of nails (from 42 to 102 mm).

- T - the depth of the hole for the dowel-nail for through installation (from 50 to 150 mm).

- H - anchorage depth (from 30 to 50 mm).

- Da - thickness of the attached product (from 10 to 100 mm).

- The magnitude of the pulling out force (for concrete B25) - from 1.6 to 2.4 kN.

- The magnitude of the shearing force (for concrete B25) - from 1.8 to 4.1 kN.

- Weight 100 pcs. dowel-nails - from 3.3 to 15.32 kg.

What is better dowel-nail or dowel-screw?

In both cases, we have products consisting of two elements - a spacer part and a rod (nail, screw). The main thing that distinguishes the dowel-nail from the dowel-screw is the method of installation in the bearing surface. In the first case, it is required to drive in a nail, and in the version with a screw, the fasteners are screwed in with an electrical device or a screwdriver. Let's consider the advantages and disadvantages of each option.

Dowel nail:

- Installation is faster.

- Suitable for installation in any solid wall except drywall.

- Due to shock loads, the risk of fracture of the face surface increases.

Dowel screw:

- Installation takes longer.

- Dismantling is facilitated.

- The fastening is considered more reliable.

- Less risk of damage to the front.

What is better dowel-nail or self-tapping screw?

It is wrong to compare both types of fasteners, they are designed to work in different conditions. The dowel-nail is perfect for brick, concrete, dense foam block. The screws are recommended for plastic, chipboard or wood. In a pliable material, when screwing in, turns of an internal thread are formed, which keep the product from being pulled out. If you have to work with metal, durable plastic or wood species, then it is better to use self-tapping screws with a sharp tip or drill.

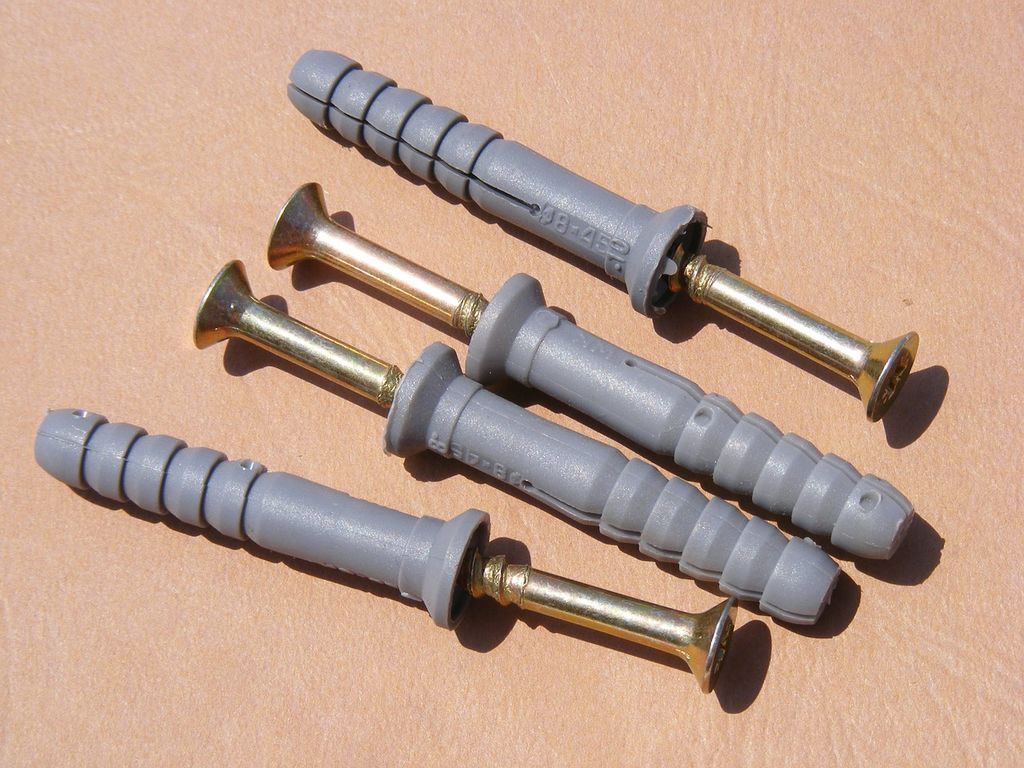

Photo of dowel-nails

We also recommend viewing:

- Threaded hairpin

- Wedge anchor

- Nails

- Cable ties

- Fasteners for wires

- Shelf brackets

- Screw nails

- Driven anchor

- Metal dowel

- Roofing screws

- Drywall dowel

- Sink mount

- Furniture fasteners

- Hex bolt

- Antenna bracket

- Wood grouse

- Steel chain

- Grover

- Wood fasteners

- Expansion dowel

- TV mount

- Construction shackle

- Dowel screw

- Self-tapping screws for metal

- Eaves bracket

- Metal fasteners

- Fasteners for windows

- anchor bolt

- Foundation bolt

- Plastic dowel

- Dowel clamp

- Wood screws

- Rigging bracket

- Crab system for shaped pipes

- Pipe bracket

- Clamp for cable

- Fasteners for pipes

- Chemical anchor

- Load hooks

- Self-tapping drill

- Plastic clamps

- Toilet mount

- High strength bolt

- Concrete screw

Size range of species

According to the standards, the dowels are made with a diameter of 5, 6, 8, 10 mm. There are also less common ones, for example 4 mm. The length varies from 20 to 150 mm, The size of the dowel-nail is selected according to the design parameters. For a symbol, two values are indicated in the marking, the first is the diameter, the second is the length.The most popular size range of fasteners is 4x20, 4x40 mm, 5x30, 5x40 mm, 6x30, 6x35, 6x40, 6x50, 6x52, 6x60 mm, 6x70 mm, 6x80 mm, 6x100 mm, 8x40, 8x50, 8x60, 8x80 mm, 8x100 mm, 10x50, 10x60, 10x80, 10x100 mm, 10x120 mm, 10x160 mm, 12x60, 12x70, 12x80 mm.

Dowel-fasteners are divided into types.

- Umbrella (or front). Differs in a cap of a large size and length. Designed for fixing large layers of insulation. The nail can be made of steel or impact resistant plastic.

- Chemical. Fastening takes place by means of a glue capsule. There is a chemical dowel of ampoule and injection types.

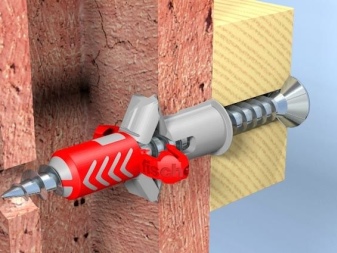

- KBT (or fasteners for aerated concrete). During installation, threading occurs, but the base material itself is not destroyed. It can withstand loads from 400 to 600 kilograms.

- Universal. Designed both for surfaces with voids and for solid surfaces. When installing the nail, the sleeve "twists" and forms a kind of knot, which provides reliable adhesion and fixation.

- Molly (or folding spring) dowel. It is made of steel and when installed "folds", it is mounted in thin and hollow walls. Also popularly it can be called a butterfly dowel.

- Spacer. It has additional fastening whiskers, it can be three-spaced, four-spaced and six-spaced. A threaded nail is driven in with a hammer.

- Frame. Its distinctive feature is the shape of the non-expansion part, it is elongated.

- Metallic for concrete. It is best to use a special gun for fasteners, but manual installation can be done. Holes must be prepared in advance.

It is worth noting that some models come with a sealing washer.

Fastening to various surfaces

Dowels are used to install curtain rods and ebbs. For work, they take products with locking collars that prevent full passage through the surface. Nail dowels are used when repairing skirting boards and for fastening window frames before using foam. When fixing the frame, it is necessary to take into account the ratio of the non-spacer and spacer parts. For drywall, it is better to use plastic or metal screws. Plus, these screws are great for quick installation. There is no need to pre-drill the wall. At the end of the products there is a drill and a thread. To mount the self-tapping screw, use a screwdriver that screws the dowel into the surface.

The dowel "butterfly" or "molly" is used for fastening to a plasterboard surface, since the self-tapping screw expands only in a complete void. Plastic and metal dowels are suitable for fasteners in foam concrete... For fixing large-sized products with a large weight, polyamide dowels are chosen. They have a through hole and a top without spacers. Screwing in a self-tapping screw is quick and easy. The thrust increases. Due to this, the structure is able to withstand a lot of weight.

To install TVs and air conditioners, it is recommended to use standard dowels that come with the fasteners. The products are already designed for the weight of the device. The only caveat is the base of the material. If the equipment is mounted on a brick or concrete wall, then there will be no problems with fixation. To install chandeliers and sconces, it is better to use long self-tapping screws with reinforced spacers. Corrugated dowels are able to withstand the weight of massive chandeliers when installed under stretch ceilings.

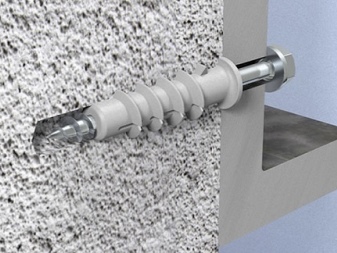

For heavier structures, anchor dowels are used. They are equipped with several parts - threaded bushing and spacer. The spacer is screwed into the sleeve. The thrust force is increased, due to which a reliable and rigid fastening is carried out.

For the repair and installation of pipes, it is better to use a dowel-clamp, which has a special screw for fixing. It is also used for fastening wires.

During repair and installation work, you cannot do without dowels. The choice of screws depends on the material of the products and the surface on which the structure will be attached.Each type of self-tapping screw has its own characteristics, weight and size. This article introduces the reader to the characteristics of the screws, will help determine the choice of dowels for a particular material.

In the next video, the types of dowels and their application are waiting for you.

Peculiarities

The dowel is a sleeve made of any material with ribs located on the outside of the product for reliable fixation and prevention of rotation during operation.

The main distinguishing feature of the nylon plug is a longer service life. It can last more than 10 times longer than polyethylene. They have been in operation in European countries for more than half a century. They are made of a special material - polyamide, which does not age over time and does not shrink. These properties of this type of plastic make it possible to use nylon plugs for many years without fear of their reliability.

Another feature is a rather wide temperature range at which such fasteners can be used - it ranges from –40 to +80 degrees Celsius. It should be noted that it can be used at lower temperatures at your own peril and risk: deformation and rupture may occur, or the dowel will not fully enter into place. But, as practice has shown, it will still hold better than ordinary polyethylene.

Due to the high degree of strength and reliability, this type of fastener is able to withstand loads about 3 times higher than the fastening rods made of simple plastic. The only drawback compared to the rest is the higher cost due to the fact that a higher quality type of plastic is used.

Nylon fasteners have another interesting feature: when placed in water, they will sink, unlike their other plastic counterparts.

Some points to know

This type of special fastener has long been used in a variety of works, where fastening becomes a necessary process, according to technology. Below are some important points to consider:

The two main parts that make up the element are the nail and the dowel itself. Such a connection allows without destruction to carry out the fastening of objects to such materials as concrete, brick, stone.

Other materials, which are classified as corpulent, with a high density, lend themselves to fastening. It is possible, among other things, to give the types of appropriate fasteners suitable for installation processes, where fiberboard, chipboard, drywall are used as the main materials for connecting to the bases.

As for the length, it varies from 30 millimeters. The longest specimens reach 160 millimeters in length. It is this kind of dowel-nail that is used for thermal insulation. The wide pressing cap has given rise to the fact that sometimes such a dowel is called a disc-shaped dowel.

Where is the Dowel-nail 6x40 used

The fastener parts in question are used universally and are considered universal nails. The range of their application is wide enough, they can be used to attach various kinds of structural elements to such materials as: stone, brick of various types, reinforced concrete, etc.

Experts do not recommend using dowel nails for hollow-type materials and porous surfaces. The dowel-nail 6x40, the technical characteristics of which will be discussed below, are hammered in with a hammer, but before that, do not forget about the preliminary preparation of a special hole, where the fastener in question will be inserted.

The high demand for the element in question is due to three criteria and at the same time the advantages of such a nail, namely: an extremely simple design, low cost and practicality. Popular dowel-nails 6x40 are during the installation of supporting structures, because, in this process, you simply cannot do without them.

Types of dowel-nails

Builders have to use different tools depending on the conditions. For example, fastening an object to a concrete or plasterboard wall has a significant difference.

In some cases, the reinforced strength of the rod is important, in other places - thermal conductivity and moisture resistance. Even a simple seemingly driven dowel-nail has several varieties that differ not only in size and material, but also in the method of installation

Common types of dowel nails:

- Dowel-nail for manual installation.

- Dowel-nail for pistol - installation is carried out using an automatic device, which greatly accelerates the progress of work. He has no spacer part. The nail is made of the strongest steel (hardness 53-56 HRC, bending no more than 0.1 mm).

- Acoustic dowel-nail - in the manufacture of fasteners, not metal is used, but plastic and fiberglass, which prevents corrosion or the passage of cold. Consumables of this type are used for the installation of thermal insulation, sound insulation, cable ducts, decor.

- Dowel-nail "umbrella" - has a wide head and a long body, used for fixing thermal insulation.

Plastic dowel nails

The plastic cup has a spacer and non-spacer surface. The plastic dowel-nail is equipped with a collar that prevents the fasteners from falling into the surface. The presence of toothed elements prevents the product from scrolling in the hole. We list the common types of plastic fasteners:

- Universal dowel - used together with wood and chipboard screws, screw-screws, suitable for hollow and solid materials.

- Expansion plug S - nylon fasteners have a double-sided spacer. The absence of a stubborn edge allows you to hide the dowel inside the plaster.

- Expansion plug M-S - Suitable for working with standard bolts or threaded rods.

- Dowel for aerated concrete GB - the presence of spiral ribs allows to provide the strongest fit in soft material.

- Dowels for mounting TV / TVV steps - have a good surface geometry to prevent squeaking, vibration. Fasteners of the TV brand have a small spacer for installation in a steel profile.

Metal dowel-nails

The use of a steel spacer sleeve increases the cost of the estimate, but allows an increase in the design load. A metal dowel-nail for a foam block, brick structures or concrete structures is installed in the same way as plastic fasteners. We list the advantages and disadvantages of such a product:

- High load-bearing capacity.

- Metal does not stretch over time.

- Galvanized or stainless steel sleeve is corrosion resistant.

- Large selection of fasteners.

- Simple installation.

- The cost of metal dowel-nails is higher.

- It should be borne in mind that steel fasteners can create more stress, so it is better to place them further from the edge.