Views

There are a huge number of sealants. The qualification is based on the type of composition.

- Silicone sealants are flexible, water-resistant, and resistant to temperature extremes. The composition is rubber, due to which this rubber sealant is durable and safe.

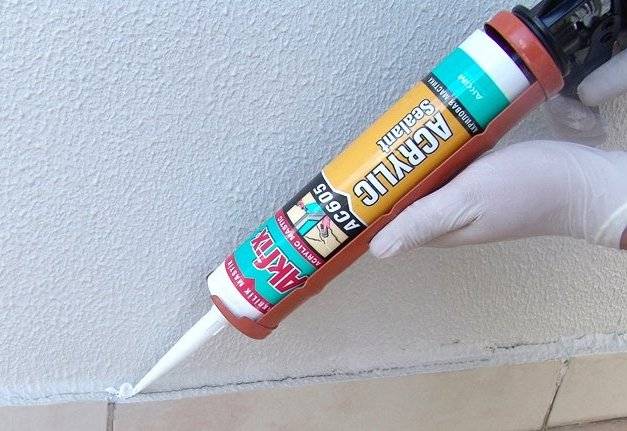

- Acrylic options are available in different colors and contain acrylic polymers. The water resistance of the product makes it suitable for outdoor use. For this sealant to "show" all its benefits, it needs dryness and warmth. Complete drying of the composition is carried out after 24 hours.

- Polyurethane models are durable, elastic, resistant to mechanical stress. They are suitable for working with different materials, do not emit toxic substances, and can also be dyed.

- Bituminous sealants are made from bitumen polymers, which are obtained as a result of processing residual oil products. They can even be used in drainage systems, as they are moisture resistant. The brown bitumen sealant is based on rubber and bitumen. Transparent formulations are also offered, which are more expensive, but they are suitable for all materials.

- Butyl variants are designed for sealing insulating glass units.

The adhesive sealant can be presented in different colors:

- white - used for work with plumbing and window profiles, as well as for sealing cable ducts;

- transparent - used for working with wooden windows;

- black is an outdoor product that is resistant to sunlight, suitable for facade and roofing works, and is also often used for vehicle repairs;

- brown - suitable for sealing various brown materials;

- colored - used for plumbing and windows, but you can select a product of the required shade.

Depending on the properties, the sealant is divided into several types.

- frost-resistant - designed for sealing joints at low temperatures. This is a "winter" product that can be used even in extreme conditions with sub-zero temperatures;

- moisture resistant - designed for use in damp rooms, for example, a bathroom or kitchen;

- heat-resistant - heat-resistant product, which is suitable for sealing elements of furnaces, heating systems and so on. It does not deform under high temperatures and retains its properties.

Usage

No matter how manufacturers care about the waterproof and frost-resistant parameters of their product, almost everything is in the hands of users.

It is not allowed to treat a non-uniform surface with a sealant. If the material delaminates, it is at least naive to hope for a strong bond with it.

Observe, of course, the manufacturer's instructions, especially regarding the exact application temperature.

The first stage is sometimes completed within 30 minutes after the release of the reagent to the surface. The second one lasts several days.

The two-component polyurethane sealant is almost 100% elastic. Storage of material should be organized in places known to be inaccessible to children and pets. Also, excessive heating during storage is unacceptable. When the normal, compliant handling conditions for the sealant are maintained, even in an open container, it will retain its properties for up to 10 months.

How to properly apply to wood

For,

in order for the sealant to lay down on the tree evenly and properly perform its function, you should

observe several rules for its application:

- wood

before applying the composition, it is required to clean it of debris, old paint and

treat with a degreasing compound; - to

the sealant did not hit the surface next to the seam, on both sides of the joint

sticking masking tape. It can be easily removed from any surface without leaving

traces and well prevents the ingress of sealant to the surface; - if

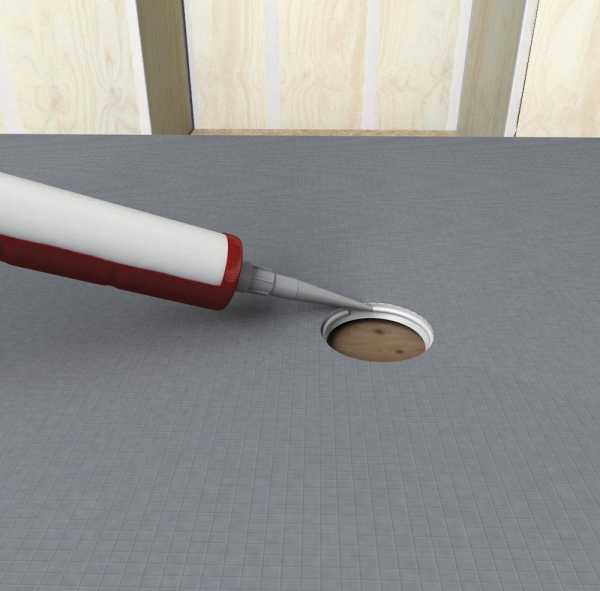

the sealant is purchased in a tube, then the container is inserted into a construction gun for

sealant and pour the sealant into the joint; - after

application of the sealant, the edges of the seam are leveled with a silicone spatula and left to

solidification.

In

time of applying the sealant on a wooden surface, it is necessary that

dry and warm weather was observed. Sealing joints in frost or rain

will significantly impair adhesion to the surface and may cause

discharge of the sealant.

Species features

Some features are characteristic of silicone sealants. Distinguish between neutral and acidic types. A neutral sealant is best used for restoration work in swimming pools, bathrooms or kitchens. A small amount of silicone compound may be needed for plumbing repairs.

Acid types are used for exterior decoration. They fit well on stone and interact with metal structures. You can also use acid analogs for working with wood.

It should also be noted that the frost-resistant silicone material cannot be painted or restored. For this reason, manufacturers produce facade sealants in various colors. The buyer can choose the color of the material that suits him best. For example, brown is suitable for wooden surfaces. White or transparent look is good for PVC window work. You can find colored compositions "under the stone".

Consumption

Before work, the approximate consumption of the sealant should be calculated in order to acquire the required amount of the composition. To do this, you need to determine the width and depth of the crack that you intend to seal. This indicator is influenced by the depth of the joint and the material from which the object is made. The depth is multiplied by the width, all this is calculated in millimeters. The result is the consumption of the product per 1 m of the joint in grams.

If the joint is triangular, then the result can be divided by two, because the costs of the train are significantly reduced. This is inherent in perpendicular surfaces, for example, for sealing a joint between a bathtub and a wall. If it is necessary to seal the crack, more material will be needed.

Consumption of the composition per meter depends on the material of the object. As a rule, during construction, a standard value of this indicator is set, often it is 6 mm, but there are exceptions. If the seam is larger, a silicone cord is used as a seal. This option is suitable for wooden surfaces.

The sealant is sold in stores in different containers. To select the required packaging, you must first perform calculations. For example, to seal a seam on a 10-meter surface, 0.25 kg of material will be needed.

In order for the purchased sealant to be enough for the entire surface, it must be applied according to the established rules:

- pre-prepare the object, degrease it and clean it from debris;

- on the area where the silicone will be located, masking tape is glued on both sides, which will prevent the material from getting onto the clean surface;

- the tube with the composition is inserted into a construction gun, poured into the seam, after which the mixture is leveled with a spatula.

Views

Based on the number of the main components that make up the silicone sealant, these compounds are divided into:

- One-component - the most common formulation in tubes or foil packs. It hardens when applying a layer with a thickness of 2 to 12-15 mm, it is widely used for small jobs.

- Two-component - capable of hardening in any volume, mainly used in industry.

According to the scope of application, sealants are:

- For metal work - used for various automotive work or for sealing the joints of downpipes and ebbs.

- For sealing joints - reliably protects joints and serves as additional thermal insulation.

- For woodworking - area of application - wood surfaces: window frames made of all types of wood.

- Construction - suitable for construction and installation work of any scale.

- Universal - suitable for all of the above jobs.

Another classification divides external silicone sealants according to their color.

The color depends on the filler component of the composition. Manufacturers are forced to produce colored versions, since after applying silicone sealant, it cannot be painted.

- White - mainly used for plumbing work, sealing window profile joints. In addition, it is widely applicable for sealing cable ducts.

- Transparent - found its application for sealing a window opening with wooden frames, such a composition will not stand out against the background of wood and be striking.

- Black - a sealant of this color is resistant to ultraviolet rays, so it can be used for facade and roofing works. It is also in demand for car repairs.

- Brown - this type of sealant can be safely used to seal or glue surfaces of the same shade.

- Colored - designed for the same work as white, but allows you to select a silicone sealant for use to match the surface it is processing.

According to their characteristics, silicone-based sealants are:

- Frost-resistant - serves for sealing joints and gluing surfaces at sub-zero ambient temperatures, up to extreme.

- Moisture-resistant (waterproof) - used in rooms with high humidity: for work in the kitchen or in the bathroom.

- Heat-resistant - used at high operating temperatures: finishing furnaces, elements of the heating system, etc.

Advice

In order to purchase a high-quality frost-resistant and moisture-resistant sealant and use it correctly, you need to know certain nuances:

When purchasing a tube with a composition, it is worth examining it and checking the expiration dates, because even high-quality material will not be as effective after the expiration of its service life.

When choosing a tube with a sealant, it is important to study it well for mechanical damage, because this will negatively affect the contents, and you should not expect a good result from using such a tool.

It is important to choose the right silicone for a certain type of work. Frost-resistant is taken for a facade that will be exposed to cold, but not used near stoves, and vice versa.

When choosing a sealant from a number of similar ones, you should give preference to a proven product and a well-known brand

The price for it is often slightly higher, but you can be completely confident in the quality of the product.

When planning a trip for building materials, it is better to choose a construction supermarket than a market, because the store has special conditions for storing any goods, everything has certificates and a guarantee, which can hardly be seen from a market trader.

If the repair with the use of a sealant is to be done for the first time, it is worth taking care of the availability of the required amount of the composition, calculating the consumption per m2, which will significantly speed up the process. Sealing any areas should be done slowly and with complete confidence in what needs to be done. If there is no experience in using silicone, it is worth reading about the intricacies of its use and watching visual video tutorials, then patching up any defects inside and outside the room will not be a problem, whether it be interior walls or finishing the passage between them.

It is possible to use frost-resistant and water-resistant sealant options indoors, but often the scope of use refers specifically to facades, roofs and foundations, which are subject to negative influences. Construction and renovation has become much easier with the advent of these mixes that even the layman can use.

For information on how to choose a quality sealant, see the next video.

Are acrylic sealants for indoor use only?

Pure acrylic sealants really have a very small operating temperature range - from -20 ° C to + 70 ° C. Builders do not risk using them for outdoor work, since winters are much colder in most climatic zones. Acrylic is mainly used for indoor work when sealing fixed or inactive joints. They cost an order of magnitude cheaper than silicone ones.

Acrylic compounds are in excellent contact with various types of surfaces, be it wood, glass or concrete, which makes it possible to use them when sealing joints formed by different materials, for example, in the place where wood adjoins cement. Compared to the same silicone, acrylic has a very noticeable advantage - this sealant can be painted and plastered.

Acrylic has a fairly high elasticity and can withstand prolonged vibration, but in the cold it becomes hard and prone to cracking. It is not recommended to use acrylic grouting compounds in places with constant humidity. This is all about pure acrylic, but there is also a combination of acrylic resins and silicone polymers on the market today.

This arrangement allows you to take advantage of the following formulations:

- acrylic sealants with siliconized modifiers have the qualities of silicone, and the price of acrylic;

- the combination of acrylic and silicone increases the operating temperature range to -40 ° С and +80 ° С;

- the composition is highly resistant to deformation;

- tolerates prolonged exposure to moisture due to low water absorption;

- not afraid of exposure to UV radiation;

- contains antifungal additives, which makes it suitable for use in bathrooms;

- after drying, the joints can be painted with latex or oil paints.

Such formulations can become an excellent alternative to classic silicones, because most of the proposals on the market are not the highest quality formulations. For the same money, you can buy excellent acrylic with a silicone modifier and use it for outdoor work as well.

Representatives of the best frost-resistant compounds

Based on the positive feedback from the masters, the frequency of purchase, a list of the best frost-resistant sealants has been compiled:

- Ettrilat PU25 is a multi-component, low modulus polyurethane material. It is used in the absence of a primer, providing high adhesion to construction surfaces. Easy to use, resistant to water, moisture, solar radiation. After drying, staining is permissible. It is used for outdoor work in construction: butt concrete parts, ceramic, wood, etc. Not used with polypropylene, polyethylene, Teflon.

- Titan Wild is a universal silicone that provides reliable adhesion to concrete, stone, brick and other coatings. Perfectly fills seams and cracks. Increased resistance to weather conditions, temperature extremes from -40 to 80 degrees. The surface, after complete drying, can be painted.

- Sikasil-C is a water-frost-resistant acriplast. It is used for sealing construction joints, for non-porous surfaces, as a putty when installing windows, etc. Sealant 100% neutral silicone. Contains components that prevent the formation and reproduction of fungal formations. Produced in a palette: white, gray, black, brown, transparent.

- Rubberflex is a white, unary polyurethane sealant.It is used for external, internal work in the construction of roofs, swimming pools, sewerage, etc. Work on the application is carried out from -10 to 40 degrees. Working temperature from -60 to 90 degrees, briefly up to 120 degrees. Adhesion to all construction surfaces.

- TENAX TENALUX 112 is a one-component acrylastic for roofing work. Has a high viscosity, does not spread when applied vertically. No shrinkage, no smell. After complete drying, staining is possible. Resistant to climatic changes. Used with an assembly gun. The main production color is gray.

- Sazilast 24 - produced on a polyurethane base. Not affected by alkalis, acids, sunlight, moisture, vibration. The service life after complete polymerization is 15 years. It is used for laying, repairing roofs, walls, floors. Complete polymerization after two days. It tolerates temperature changes well. Adhesion to any building materials.

Description

Polyurethane sealants used outside buildings and structures effectively seal various cracks, gaps, seams and splits that appear during the operation of houses and other buildings made of concrete, reinforced concrete, bricks and blocks. Even if the building was erected by experienced specialists, after a few years cracks still appear on the outside of the building. These defects are best repaired during outdoor work with polyurethane sealants.

These compositions are made using polyester resins; they tolerate the effects of adverse natural factors much better than rubber or plastic. Polyurethane compounds used for sealing joints in concrete and brick are waterproof, they can be used in any climatic region of our country. Even under the influence of sudden temperature changes and changes in humidity, polyurethane sealants are not damaged and retain their original technical characteristics.

One of the significant disadvantages of polyurethane products is the rather high cost; these materials are an order of magnitude more expensive than silicone or any other sealants. In addition, polyurethane formulations have little resistance to UV rays, but the many advantages of these products completely outweigh all the disadvantages. For example, butyl substances tolerate temperature changes much worse. Protect from ultraviolet rays hardened polyurethane sealants applied to the external seams of a building are quite easy and simple, and any other sealants that are afraid of frost are almost impossible to hide from the cold weather of Russia.

If we compare polyurethane-based sealants, for example, with bituminous compounds, then polyurethane materials are much better suited for external joints, since they can withstand both high and extremely low temperatures. They also come in a wide variety of shades. Here are the main properties and benefits of polyurethane-based sealants:

Scope of application

Frost-resistant and water-resistant sealants are used in the winter season, because other options will not cope with the peculiarities of the climate. In construction, this material is used to seal roof joints, especially if it is made of modern materials, because they need additional protection along the joint line. Facade sealant will help hide any flaws on the front side of the building, and the ability to paint this material makes it invisible, which is very convenient.

For panel houses, cracks are a very common problem, which cause drafts, especially noticeable in winter. With the help of only one sealant, you can get rid of this situation, but only if the gaps are small.

In addition to the upper part of the building, it is worth paying attention to the lower one, because the whole foundation is the key to the stability of the building and its reliability. The sealant, due to its versatile properties, is able to stop cracking of the base and strengthen it for many years

Outside of both new and old buildings, there are always some flaws that need to be dealt with in the early stages, as long as the destruction is minimal and can be dealt with with simple means. With the help of a universal silicone sealant, you can connect parts of concrete and metal, fill in voids and correct what initially did not work out or deteriorated over time.

It is especially easy and effective to use the sealant during the installation or repair of windows

Inside, it is important to finish everything so that no traces of the presence of this substance are visible, but at the same time so that all the cracks are reliably closed. Outside, you can pay more attention to protecting the window opening by filling all the cracks with a sealant

By choosing a transparent option, you can achieve the fact that it will be difficult to find places on the facade where the work was carried out, and the use of color options will help to mask the area where the repair was carried out.

The scope of use of the sealant is large and it is difficult to imagine the repair of any room, both inside and outside, without the use of this building mixture.

What temperature can it withstand?

Construction work is most often not carried out in the winter, but there are always exceptions. There are emergency situations when you have to repair the house outside in any weather, solving a sudden problem

In such a situation, the temperature outside the window can be very different, which depends on the region, therefore it is important to use building materials and mixtures correctly

To work in negative temperatures, you need to purchase a frost-resistant version of the sealant, which does not lose its properties even at -60 degrees. Low and extra low temperature readings can affect the quality of work. That is why the use of a suitable sealant will help to cope with the situation quickly and get a good and high-quality result that will not collapse by the next season.

If we talk about the high temperature indicators that thermo-sealants can withstand, then the maximum is +200 degrees Celsius, which can occur when working with heating facilities or appliances. In addition to choosing a heat-resistant composition, it is worth taking care of protecting the body from exposure to high temperatures.

Any season dictates its own characteristics and it is important to know and take them into account, then there will be no problems with repair or construction. Waterproof, heat-resistant and frost-resistant sealant options will be able to cope with rainy weather, heat or high temperature indicators and freezing temperatures, while ensuring the proper result when working with seams, joints and cracks anywhere on the facade

It is worth focusing on the surface temperature indicators on which the work will be carried out. It is best that it be within the range of +4 to +30 degrees, while the ambient temperature can be from -40 to +120 degrees

Knowing the surface temperature is important in order to be able to calculate the time it takes for the sealant to dry completely, after which it can be painted and renovated. If the average layer thickness is 10 mm, then the temperature of the surface on which the composition was applied should be at least +25

The optimal indicators of the drying time of the composition will be one day.

If the surface has not been prepared, then the adhesion to it will be worse and the silicone will dry much longer.

When preparing the surface for work, it is important to clean it from dirt and dust and dry it, otherwise the result will be much worse.

Silicone sealants: invisible touches

Consider now silicone sealants:

Depending on the vulcanizer, they are divided into neutral and acetate:

- Neutral sealants are used on porous and smooth substrates. For example, in order to close the joint of roofing materials and protect ventilation ducts from leaks.

- Acetate sealants are more durable because they release acid. Therefore, it is allowed to use them only on those materials that are resistant to an acidic aggressive environment. It is clear that they are definitely not suitable for plastic, and therefore they do not seal ventilation pipes with them. By the way, a few days after application, such sealants no longer emit anything and are safe for humans.

Siliconized sealants are similar in their properties to acrylic, only they have a wide range of advantages. So, silicone is added here, which means that this composition is more elastic, it tolerates temperature changes more easily and is more durable:

Transparent silicone sealants are especially appreciated:

In total, silicone sealants have the advantages of resistance to aggressive media, elasticity, water resistance, good heat and frost resistance, and excellent adhesion to most materials.

Their use in the process of roof repair allows you to create a dense, but, at the same time, elastic base of the seam. In addition, after drying, such places can be safely painted with oil and latex paints.

Siliconized compounds (acrylatex)

If you need a frost-resistant compound and a strong waterproof base, you should choose siliconized compounds. Basically, a sealant for stone, plaster, glass, wood and siding has the same characteristics as acrylic.

A durable and reliable composition perfectly tolerates temperature extremes, humidity, prolonged exposure to ultraviolet rays. Acrylatex sealants are suitable for all types of sealing: both external and internal.

As always, the current colors are: dark brown, light brown, close to the beige palette, white, black. Many would prefer a transparent option that suits all occasions.