Size matters

The greater the granularity of the sand, the larger the grains of sand, the stronger the building mixture will be with them in the composition. But at the same time, it will be less plastic.

That's why:

- Coarse grains are good for the production of high-grade concrete from B35 (M450). In private construction, it is used for paving slabs, curbs, well rings. It is also an excellent solution for a drainage device, because the more grains of sand, the better they absorb water.

- Sand of medium grain size is a universal solution for the production of bricks and commonly used grades of concrete B15 (M200). Such concrete is used for foundations, staircases, retaining walls; plots on plots, paths, etc. are poured with it.

- Fine-grained sand is a part of building mixtures, which have special requirements for leveling and finishing properties. We are talking about plaster, bulk field - wherever the fineness of application, evenness, smoothness are very important.

So when you purchase sand for the preparation of building mixtures, be guided by the manufacturer's recommendations for use.

What kind of sand you pour into a concrete mixer, you will get such a mixture

What kind of sand you pour into a concrete mixer, you will get such a mixture

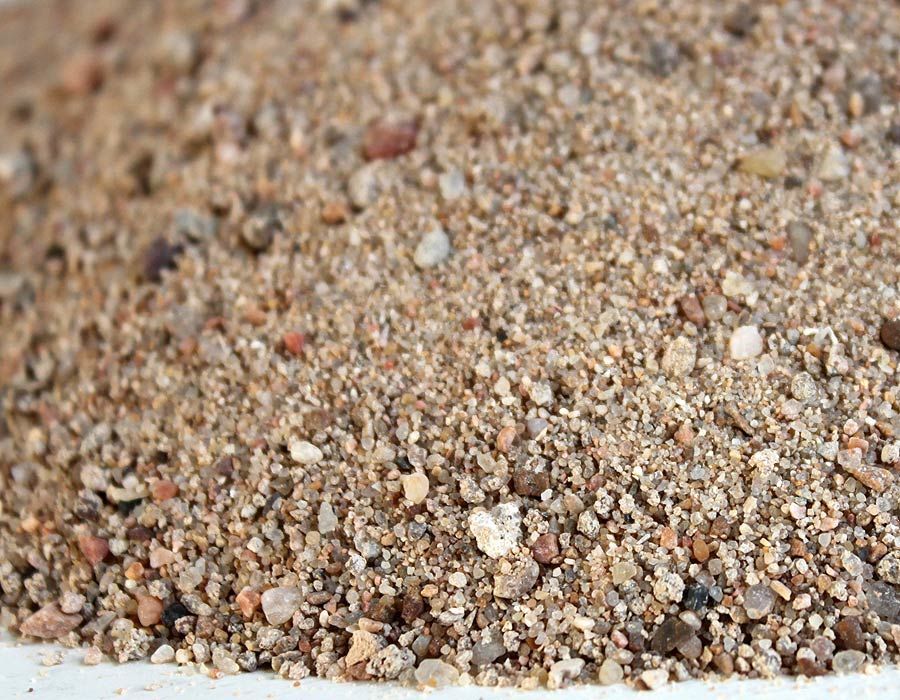

Can you determine the graininess by eye?

In general, yes. Large grains of sand in front of you or small ones can be seen with the naked eye. But it is better to measure, even if you decide to dig the sand yourself and will not use it in a responsible facility.

Place a small amount of sand in front of the ruler, and then check the grit values above. The main thing is that all the material is homogeneous, otherwise measure some fractions, and dig deeper, you will dig up grains of sand of a completely different size.

Also focus on color:

- yellow (towards beige) or beige;

- medium - brighter, more yellow;

- small - pale yellow, white, with a grayish tint.

Why not try to determine the grain size of the sand yourself?

Why not try to determine the grain size of the sand yourself?

What factors to consider when buying?

In the process of acquiring a river mineral, you should be as careful as possible. It must be remembered that the quality of the raw material has a great influence on the final result of your work (regardless of the purpose for which the material is used).

First, you must make sure there are no impurities. Remember that cleanliness is the most important property of a material. Therefore, it is not recommended to purchase natural material if it contains elements such as clay or stones. In the event that there are no impurities in the sand, then it will be homogeneous, with high flow characteristics

Accordingly, when buying, you should pay attention to these qualities

You should be especially careful if you purchase sand by weight. The thing is that the mass index largely depends on the moisture content of the sand. Accordingly, even if you bought a sufficient amount of sand by weight, the material may not be sufficient in volume. When calculating the amount of sand required to perform certain jobs, use units such as cubic meters. Thus, you can make the most accurate calculations, which will make your work easier and have a positive effect on the final result.

Before you go shopping for sand, think about how to transport it. The point is that in some cases you may need special permission. Before direct purchase, ask the seller to show you quality certificates (or any other documents) that indicate the quality of the sand. Feel free to study them carefully, and, if possible, ask additional questions to the seller.

Classification

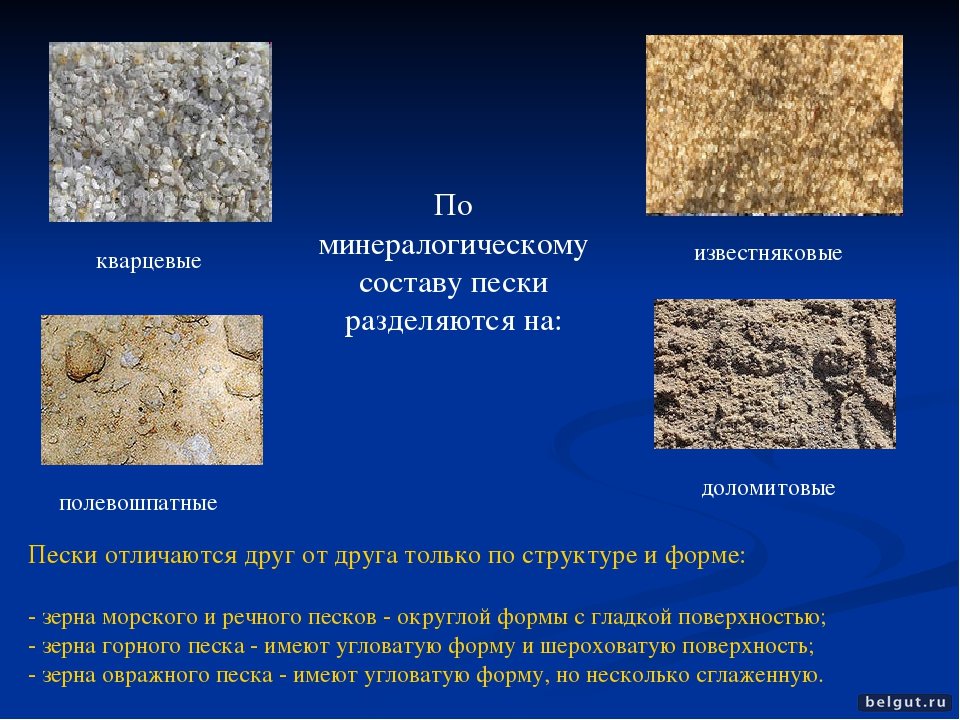

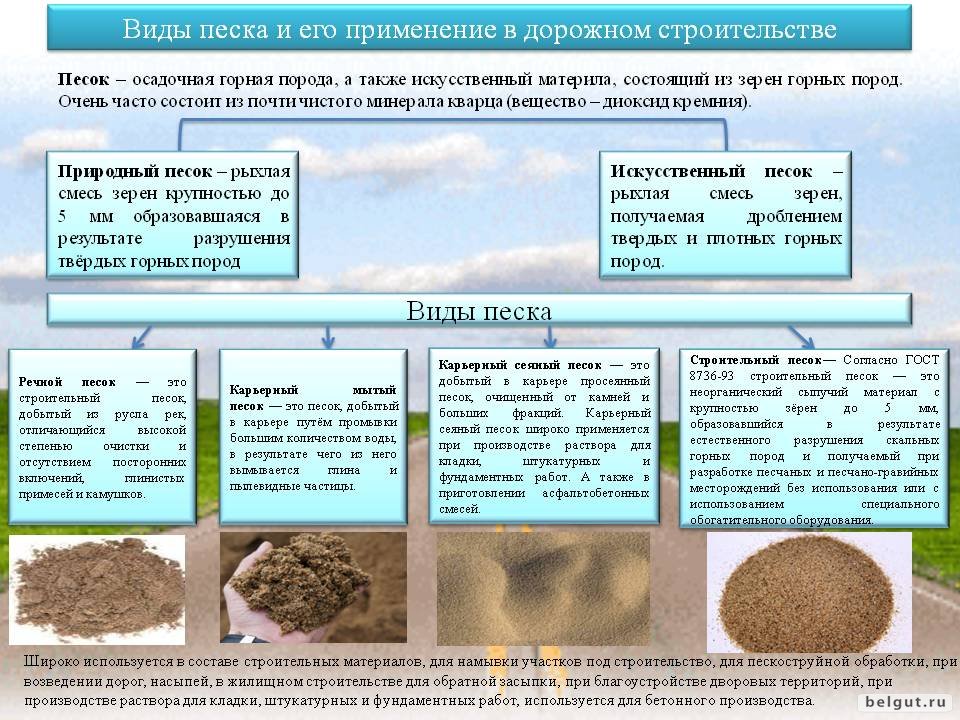

So, according to the place of origin, it is customary to classify sand into the following types:

River sand

River sand is mined from the bottom of the rivers. It is distinguished by its natural purity and good culverts.The size of grains of sand in river sand ranges from 0.3 to 0.5 mm.

This type is used for the preparation of concrete mortars, cement screeds, treatment filters, drainage structures. It is worth noting that when preparing a concrete mixture, this type of sand precipitates quickly, so the solution must be constantly mixed. The cost of river sand ranges from 600 to 800 rubles per 1 m3.

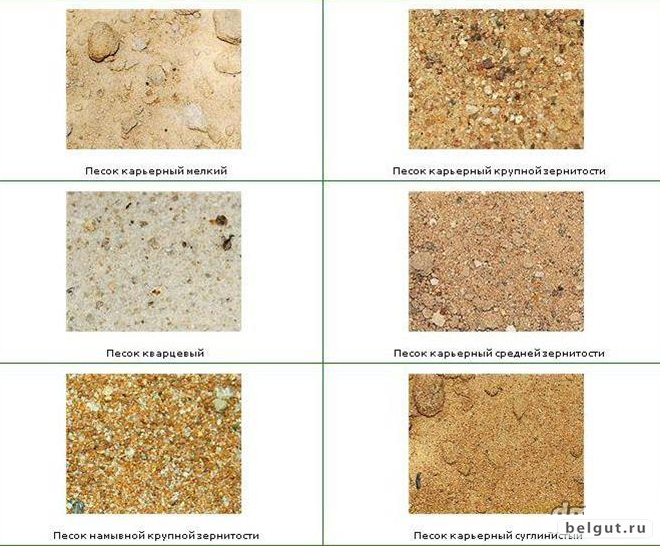

Quarry sand

Quite logically, quarry sand is mined by the open method and includes impurities: dust-like particles, stones. The grains of open-pit sand are much smaller than that of river sand, ranging in size from 0.6 to 3.2 mm.

In its original untreated form, the building material can be used for trenching or as foundation sprinkling. Usually the leading manufacturers wash and sift the quarry sand. In this case, it can be used when performing plastering and finishing works, to create an asphalt concrete mixture, to form a screed.

Sea sand

This non-metallic mineral is extracted from the seabed using hydraulic shells. There are practically no foreign impurities in it, and salt participates in the purification.

This type of sand is considered the most demanded. It is used everywhere, from the creation of concrete structures to the formation of finely dispersed dry mixes. But, despite the unique characteristics of this building material, there is a shortage in it, since it cannot be mass produced.

Sometimes construction sand is considered a separate species. But, as a rule, it means both river and quarry sand. River sand can be of two colors - yellow and gray, and quarry - brown and yellow.

But it turns out that in nature there is also black sand, which shines like metal. It can be found in different parts of the world. And this type of sand is formed as a result of geological processes.

This mineral is composed of dark colored heavy minerals and is formed by washing out light constituents. The main minerals are magnetite, ilmenite, hematite.

Such sands are characterized by high radioactivity - 50-300 microroentgens per hour, but sometimes this parameter can reach a thousand microroentgens per hour. Due to its high radioactivity, this mineral is not used in construction and economic activities.

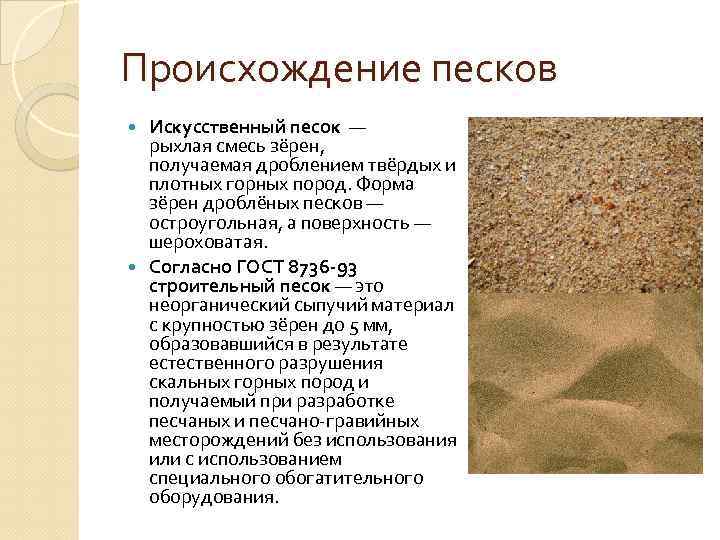

Artificial sand

It is worth noting that the above types of sand are natural, as they were formed by natural destruction of rocks. But, there is also artificial sand on the market, created by crushing marble, limestone, granite.

The most popular among artificial types of sand is quartz. It is made by grinding and dispersing the white quartz mineral until a homogeneous fraction is obtained. It differs from natural types of sand in that it does not contain impurities and has a homogeneous composition. These advantages make it possible to accurately calculate the parameters of a structure made on quartz sand.

It has found its application in the creation of decorative and finishing, welding materials. It is also used in the production of concrete, but rarely.

Sea sand: characteristic

This type of sand is the most expensive and high-quality of all, as it undergoes double concentration and has good technological characteristics. It is used for the construction of facilities under severe operating conditions, for reinforced concrete products with increased strength or special characteristics. But in general, it can be used in any type of work and in the manufacture of any building mixtures.

Specifications

There are several types of medium-sized sand. For example, there is a classification that is based on the method of obtaining it. Depending on this characteristic, natural sand can be natural, crushed, fractionated, quarry, alluvial, sea.This type of medium-grained material is called such because of the size of the grains of sand (fractions), the indicator of which is in the range of 2-2.5 mm (these data are recorded in the official and generally accepted GOST document).

Experts also distinguish classes I and II of medium-sized natural material. The material class depends on the content of grains of different sizes.

So, for medium sand, the residual amount should be about 30-40% of the total volume.

Medium-grained sand (like other varieties of similar material) has distinctive features and unique characteristics. So, for a material of this type, such properties are of great importance as:

- maximum bulk density (in the range of 1500-1700 kg / m3);

- specific gravity (indicator 2.55-2.65 kg / m3);

- bulk density (characterizes the material in its natural state, 1.5-1.8 kg per m3);

- deformation modulus (can be 30, 40 or 50);

- filtration coefficient;

- elasticity (120 MPa);

- the compaction index (is of great importance during the performance of repair and installation tasks, is about 0.95-0.98);

- angle of internal friction;

- porosity (sand can be dense, loose or of medium density);

- clutch;

- design resistance;

- size model, grain size composition;

- the presence of unwanted impurities and others.

The above-described individual characteristics and properties of such a group of sand as medium-grained material suggest its use not for all repair, construction and installation work.

In addition, it is important to consider other characteristics of medium sand:

- environmental friendliness (thanks to this indicator, sand can be used without fear for your health, as well as for the health of those people who will use products made from sand);

- fluidity, which contributes to the filling of voids (which is why the material is in demand in the construction industry);

- lack of unpleasant odors (the material can be used even inside living quarters);

- the material does not burn (this property increases the safety of using the material);

- durability (products, in the manufacturing process of which medium-grained sand was used, will last for a long period);

- not affected by fungi, does not rot;

- strength and reliability.

GOST and basic parameters of construction sand

Construction sand is subdivided into quarry and river sand. This material is manufactured in accordance with GOST 8736-93. Depending on the purpose, quality and standardized indicators that determine the content of clay and dust particles, the material can be divided into two classes, each of which has its own grain size composition.

The chemical formula of sand was mentioned above, but it is not the only thing that professionals are interested in. Depending on the grain size, the material can be classified by size. The first class includes coarse sand, which is obtained by screening crushing. The second class of sand involves not only very coarse sand, but also fine, medium, and fine material.

The sand, the GOST of which was in the ones mentioned above, can also be alluvial. This material is obtained by flushing quarry sand. In this case, a large volume of liquid is used, which allows you to get rid of the material from clay and dust particles. Alluvial sand may imply the presence of fine fractions, the size of which is 0.6 mm. This type of sand is used for plastering work, where the presence of clay is undesirable.

Mining

As you might guess from the name of a particular type of material, it is mined from rivers. The specific mining method depends on how deep the river is.

For example, it is possible to take river sand from a deep river only by means of a special device - a dredger. Usually this mechanism is mounted on a specially designed barge.The design of the dredger traditionally includes complex hydromechanical equipment, which consists of pumps, tanks and screens designed to separate sand (however, the mineral can be separated by other methods as well).

The sand extraction procedure itself takes place in stages.

- To begin with, rippers are lowered to the bottom of the river. These devices will suck in sand due to their mechanical work.

- Further, along a slurry pipeline specially designed for this purpose, the sand will gradually rise to the surface of the barge. Here, the sand is piled onto a hydraulic dump, which, in fact, is an ordinary platform for material. Usually the dump is equipped with a drainage system.

- The next step is dry sand cleaning. The cleaned material is then transferred to a separate barge.

It should be noted that the extraction of river squeak from the channels of dried up reservoirs is organized according to the same method as the extraction of a quarry mineral.

The composition of the plaster

Any plaster solution includes several components. According to their purpose, the components are divided into binders (forming an astringent base), fillers (inert substances that do not enter into a chemical reaction), and modifying additives.

Binder

Cements are more common among binders. For plastering purposes, Portland cement is usually used (for special plasters, cements of a different kind can be used). For interiors, gypsum is used as a binder, less often lime, sometimes clay. These are classic mineral binders that can be used both alone and in combination, for example, cement-lime compositions. Polymers are used from modern materials for the base.

The type of binder depends on:

- the strength of the plaster coating;

- adhesion (tenacity);

- durability;

- setting time;

- water resistance;

- plasticity (for example, the addition of lime increases workability) and other characteristics.

Filler

The main purpose of the filler has long been to reduce the amount of a more expensive binder. For plastering purposes, sand has long been the main filler. Its amount in a solution is determined in parts of the amount (volume or weight) of the main binder. In addition to the sand filler, the composition of the plasters can include slag, artificial granules and fibers of various origins.

We also recommend a useful video on the topic of the article.

For plastering work, you can use any of the sands. But each type of sandy material has features that need to be considered. By choosing the right sand for plastering, according to its characteristics, you will avoid surprises in your work and get a good quality plastering coating.

Sand under the microscope

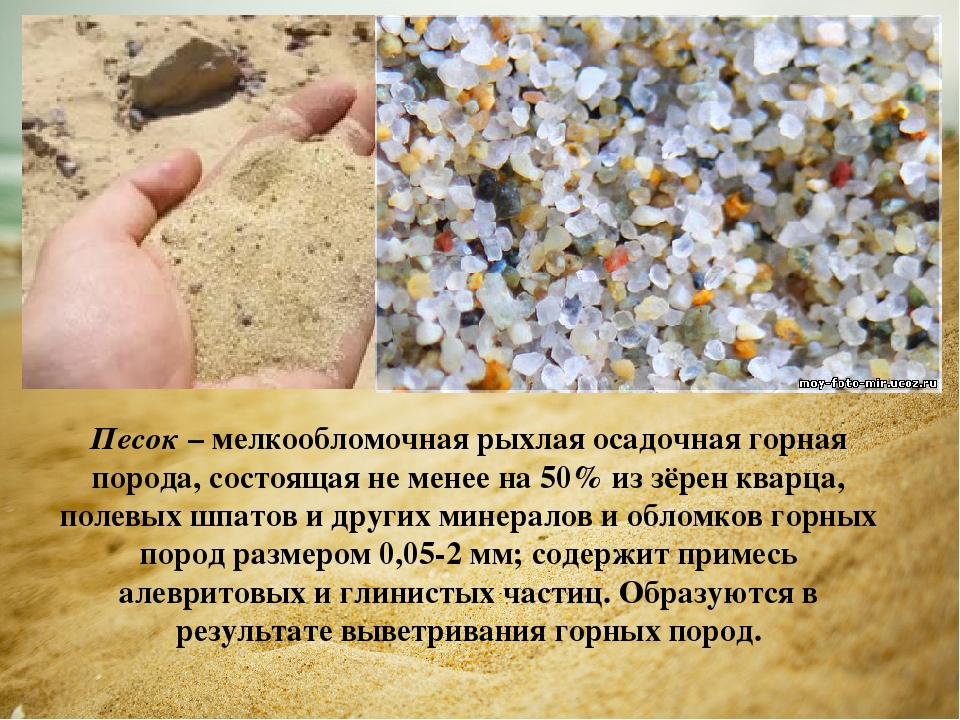

In trade, sand of various characteristics is presented. The main type of sand, the most demanded and irreplaceable, is construction sand, which has an additional classification. It is worth highlighting that, despite the rapid progress in the production of building materials, this inexpensive and widespread substance does not have full-fledged analogues today. For example, natural stone is quite successfully replaced by bricks, concrete products, blocks; iron and wood are giving way to more advanced alloys and plastics. And sand belongs to the unique and unsurpassed types of natural materials. Moreover, the amount available on the planet more than satisfies the needs of industry and construction.

It is interesting: Finishing the facade of a private house with a bark beetle: we cover in general terms

General requirements for fine aggregate

Sand concrete (PB), which is used to make a mixture of concrete, must comply with the GOST 8736-2014 standard. It is allowed for use when its recipe contains less than 10% of elements with a fraction of up to 0.15 mm and no more than 2.9% of dust, silt inclusions and clay.The presence of the last component in the structure has a very negative effect on the frost resistance and strength properties of the mixture. Clay envelops the cores, preventing them from combining with other components.

The developer, wondering what kind of raw material is needed, should know that in accordance with the norms, it is not allowed to contain large-sized fractions of more than 10 mm in the bulk, and the volume of parts of 5.0-10.0 mm must be in the range of 4.0-5.0%. Basic inclusions in the structure, in the form of humus or plant elements, should be absent.

The developer, wondering what kind of raw material is needed, should know that in accordance with the norms, it is not allowed to contain large-sized fractions of more than 10 mm in the bulk, and the volume of parts of 5.0-10.0 mm must be in the range of 4.0-5.0%. Basic inclusions in the structure, in the form of humus or plant elements, should be absent.

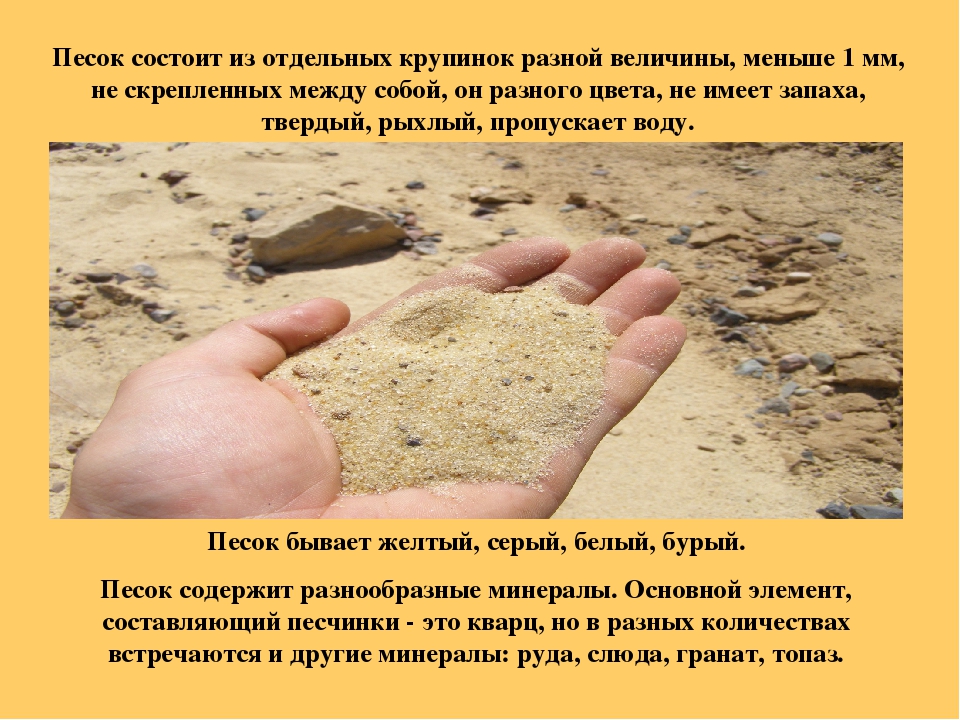

The origin of sand and its properties

What sand to use for brickwork from the point of view of origin? The very fact of extracting sand from a quarry or from a river is not fundamental. What matters is how it affects its properties.

On the one hand, river sand is cleaner and has a more homogeneous structure. Its particles are sanded with water to an almost perfectly spherical state, which increases the attractiveness of its appearance.

On the other hand, such grinding reduces the ability of the grains of sand to adhere to the cement particles and form a monolithic slurry. Quarry sand is devoid of such a disadvantage. The career option is also cheaper. But it requires washing and sieving.

Thus, what kind of sand is needed for masonry depends on the type of the latter. For load-bearing walls and rough work, treated quarry sand is the best option. For decorative cladding, river sand is more suitable due to its better appearance.

The mortar mixture is considered the basis for the construction of walls from bricks and other building materials. Whatever the solution, it always includes a fine aggregate, usually sand, less often clay.

Sand can be considered an indispensable component for brickwork, and there are reasons for this, which lie in the properties of the material. It is relatively inert, homogeneous in structure, has a fine fraction and the required specific gravity. In addition, the considered natural material is well wetted with water, has a significant bearing capacity, is inexpensive and affordable. There are several main types of sand in nature, and all of them are used to prepare mortars and concrete mixtures. In order to figure out which sand is better for laying river or quarry bricks, we will deal with its subspecies.

Quarry sand is usually located at a shallow depth from the surface of the earth, and is mined using bucket loaders or excavators. The rock consists of small particles of quartz with admixtures of clay and various minerals. This type of sand is used for laying walls or building a foundation, but before preparing mortar or concrete, it is recommended to clean it from foreign impurities by washing or sieving. Quarry sand is also used for backfilling construction sites and leveling access roads.

Another equally widespread type of raw material is gully sand, it is also mined by the open method. The particle size of this raw material usually ranges from 0.3 to 3 millimeters, it is rough in structure, which makes it possible to improve adhesion to the brick surface. The value of the rock decreases due to the presence of various impurities in its composition, but the admixture of clay has almost no effect in the case of using gully sand for laying brick walls. If this sand is cleaned of foreign impurities, then it can be successfully used for the preparation of most mortars and concrete.

River sand is considered the cleanest of all the considered types of raw materials for solutions. It is mined from the river bottom and used for the preparation of all masonry mortars, concrete and other purposes. This natural material does not need additional purification. River sand can be divided into fractions:

- from 3 to 5 millimeters - large;

- from 2 to 2.9 millimeters - medium;

- less than 2 millimeters - small.

It is believed that sand of the middle fraction, river or quarry washed and sifted, is best suited for laying bricks.

Varieties

Raw materials of natural and artificial origin are used in construction. Both varieties play the role of a structure-forming framework. It is due to their presence in the future that the uniformity of the formation of internal stress occurs, the strength and durability of structures is guaranteed. Such a filler compresses the empty spaces that arise between the gravel. Interacting with the adhesive components in the form of a water-based cement slurry, it guarantees the creation of a strong mixture with a homogeneous structure.

To perform construction and installation operations, 2 basic types of raw materials are used by education - quarry or ravine and river, which is washed out from river beds. In areas near the seas, it is mined from the seabed, but since its transportation is a very expensive undertaking, it is often used at the place of the alluvium. In the center of the Russian Federation, river composite is much cheaper. Industrial chippers of the lake and quarry options have completely different characteristics.

Sand treatment

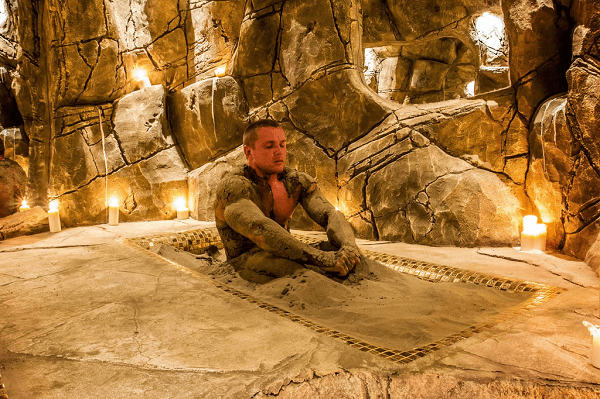

In medicine, sand is also actively used. The ancient Sumerians knew about its medicinal properties - such information is found on their clay cuneiform tablets. Despite this, it was only in 1889 that the Russian doctor N.V. Pariyskiy, after conducting experiments, was able to create a high-quality treatment system, which has survived to this day practically unchanged.

Sand treatment is called - psammotherapy. The general principle is simple enough. Sand perfectly accumulates heat and can give it off evenly for a long time. In addition, the edges of the grains of sand are sharp enough to provide a quality massage. The combination of these factors formed the basis of the treatment method. The heated sand is applied to a specific area of the body, heats it up and massages it with high quality.

Psammotherapy helps to cope with diseases of the musculoskeletal system, joints, sciatica and neuritis. It also promotes weight loss and has a positive effect on kidney function.

Thanks to the undoubted benefits, the availability of sand and the simplicity of the treatment procedure, psammotherapy spread throughout Europe and Russia almost instantly.

Thanks to the undoubted benefits, the availability of sand and the simplicity of the treatment procedure, psammotherapy spread throughout Europe and Russia almost instantly.