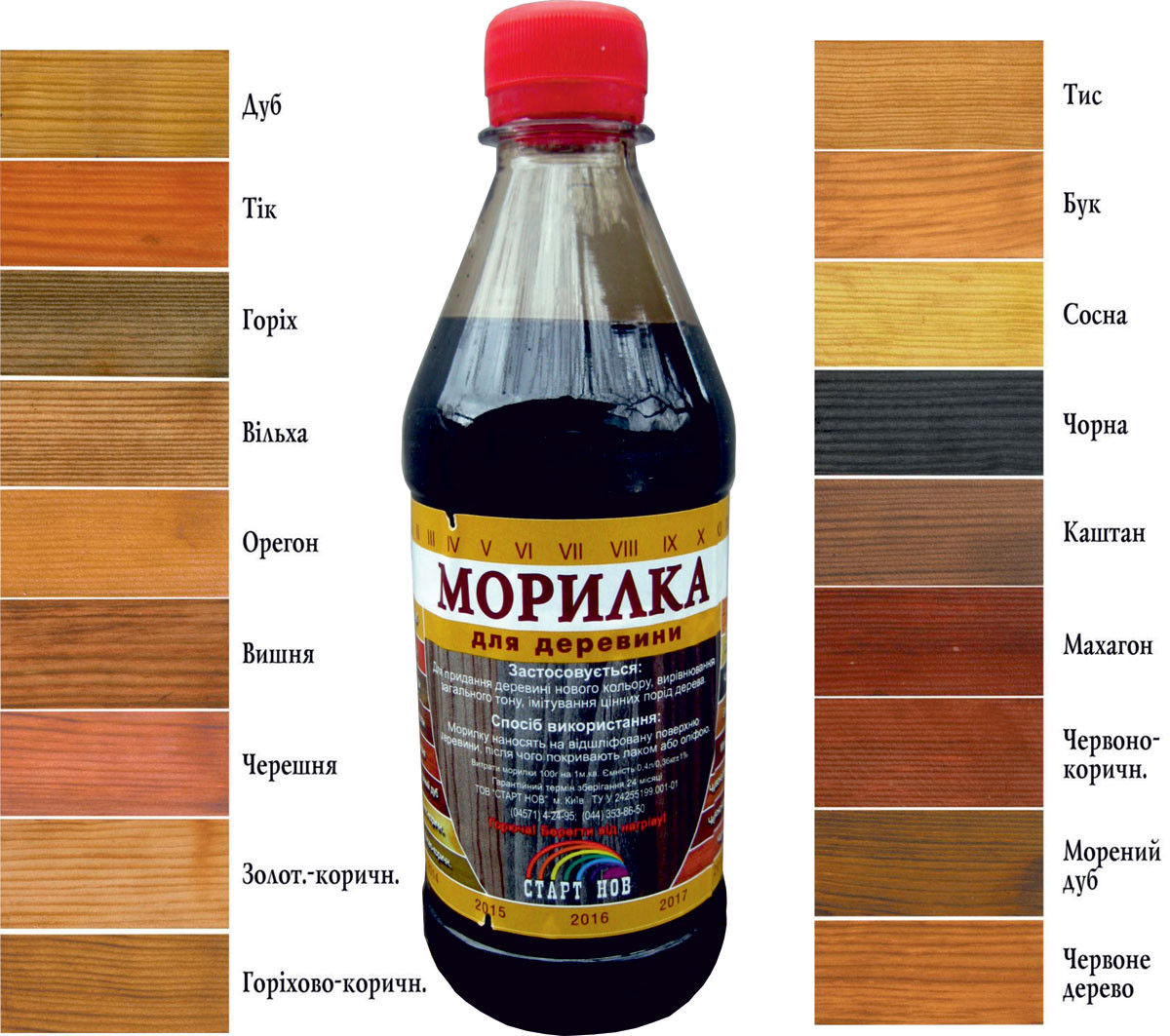

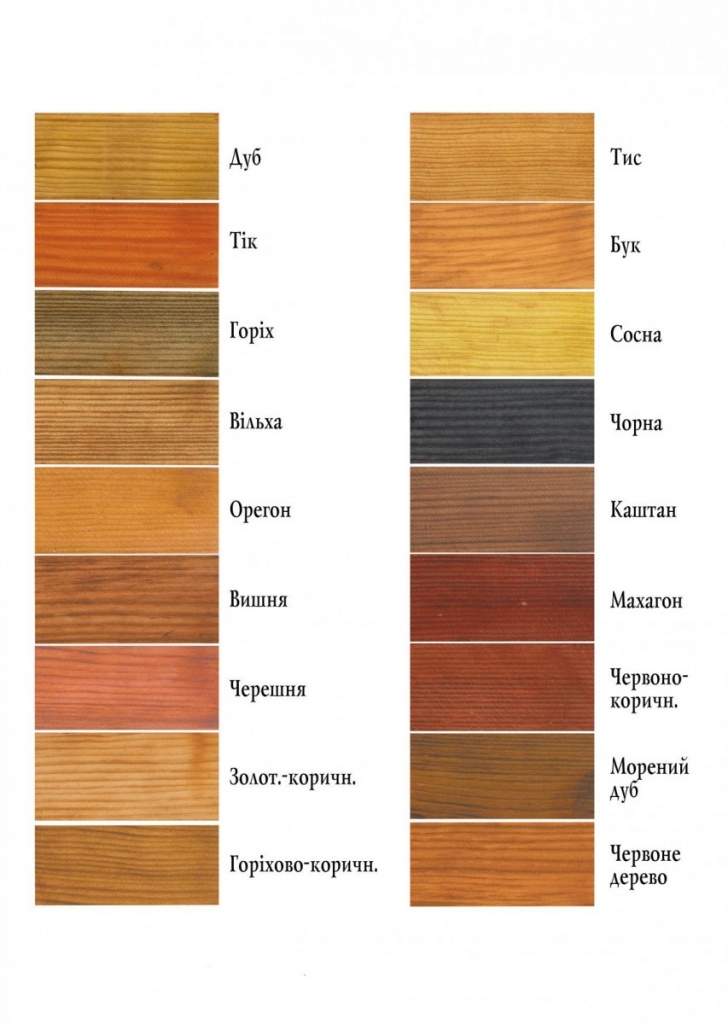

Choice of stain color.

Each color of the stain has its own code, which corresponds to the international classification, and the name coincides with the type of wood, the color of which is copied by the stain. For example, "Chestnut", "Walnut" or "Cherry" stain. But it is very short-sighted to choose a stain only by name or picture on the label, as you may get an unexpected result. There are special reasons for this:

1. If the stains of the same color and code were made by different manufacturers, then they may have different shades. For example, the water stain “Larch” from “Tsaritsyn Paints” has a pinkish-brown tint, and “Larch” produced by “Novbytkhim” has a pale yellow color. In various stores there are samples that have been painted with different stains. Such samples will reproduce the color of the stain much more accurately than the picture on the label.

2. The natural color, structure and density of wood can also affect the result. staining

... For example, a stain on mahogany will look much darker than on maple (if the stain used was the same tone). This is because mahogany wood has a darker shade than maple wood.

The same test with samples of pine and maple will demonstrate that pine wood is colored faster and more intensely. Pine has a softer and more porous wood, while maple is denser and harder. For this reason, it is easier for colorants to penetrate the pine wood.

The degree of staining is also influenced by the texture of the wood. Oak has a pronounced structure, so it quickly darkens from the stain, as the coloring substances penetrate into the grooves of the veins. But the bulk of the oak wood that is outside the veins stains more slowly and less brightly.

What color are wood stains, depending on the type of composition

The palette of available shades depends on the type of composition. Water-based wood stains come in a wide variety of colors. Manufacturers claim that such compositions can give the surface any shade. However, the palette of water stains mainly covers natural colors. This includes dark and light brown tones. When treating the surface, the water stain lifts the fibers of the material. Thanks to this, its structure becomes clearer and more pronounced, although the degree of protection against moisture is significantly reduced.

For very soft wood species, many manufacturers offer special stains-gels

Acrylic stains, which are a variety of water stains, have the most extensive palette of any product available. It's all about the improved composition, which expands the decorative possibilities of these solutions. Unlike water stains for wood, acrylic impregnation colors can be more exotic and atypical. These stains emphasize the structure of the material without lifting the fibers. Wax stains have similar properties, which also differ in a wide range of colors.

Among acrylic stains, there are also colorless compounds. Such impregnations are produced by the Tikkurila company. The color of the wood stain in this case will depend on the color that is added to the solution. The Tikkurila Pirtti stain palette includes 36 different shades.

The materials of the modern generation include gels stains. Like wax products, they have a thick consistency and are applied to the surface using swabs.As for the palette of gel stains, it is very limited.

Alcohol stains are characterized by a good color variety. However, due to the pungent odor in interior decoration, consumers prefer water-based stains, and for outdoor work, oil compositions with an impressive spectrum of colors and rich shades are often used.

Today stains are presented in a huge assortment

The color range of wood stains and the effect of the composition on the painted material

Water-based wood stains are available in a wide range of colors. These compositions allow you to quickly and easily give a wooden surface an expensive and noble shade or radically change the appearance of the material.

The color palette of wood stains can be conditionally divided into three groups:

- Neutral color scheme - this includes all shades of white, black and gray.

- Natural colors - includes natural shades of wood that are found in nature, for example, the color of wenge wood stain, walnut, maple, oak, cherry.

- Exotic colors - used to give wood atypical shades, such as blue or purple.

This table contains information about what colors the wood stain is.

| Color name | Staining result |

| Beech | Natural shade, warm and well emphasizes the woody pattern |

| Oak | Dark brown tone |

|

Ebony |

Creates a visual effect of aged wood, emphasizes the relief of the material and its natural lines |

|

Cherry |

Can give the surface a rich shade of dark burgundy or paint in light red tones |

| Fern | The wood takes on a pleasant green tint |

| Mahogany | After drying, the treated surface turns brown with a slight shade of red |

| Black | Used to create an aging effect |

| Rowan | Slightly tints the material in a pale pink or transparent beige shade |

| Mocha | The painted surface becomes coffee |

| Bog oak | Gives a matte effect to the natural color |

|

Hazelnut |

Outwardly similar to a nutshell, it is used to deepen the structure of the material |

| Blue | Matches the color of wolf berries |

| Ash | After staining, a slight pink color appears on the surface |

|

Larch |

Has a wide range of shades from dark yellow to orange |

| Maple | Delicate shade of peach color |

|

Lemon |

Yellow, which can be made contrasting by repeated application |

| Plum | Dark pink |

| Wenge | Dark shade of brown with black streaks and blotches |

| Bleached oak | White shade |

| Light walnut | It is used to protect wood while maintaining its natural color |

| Red tree | Noble red |

| Kaluzhnitsa | The treated surface becomes darker |

| Pine | Transparent, almost invisible coating |

Varieties

Stains can be used to cover absolutely any wood surface - pine, oak, maple, birch, and so on. But you still need to know the types of this tool, because each type of stain has certain properties.

Water

The presence of water in the stain is considered the main ingredient. The group of water-based impregnations is considered to be the largest. Typically, these products are made ready-made or in powder form. The powder can be diluted in water on your own according to the attached instructions.

Positive traits:

- Due to the fact that this agent has a neutral base, it does not have increased toxicity and does not have a harmful effect on health;

- Available in a wide range of shades with natural texture. With these types of products, you can create shades from lightest to deepest, which will help to recreate the natural look and deepen the tone.And also this quality gives the surface expressiveness and noble appearance;

- It has an easy and simple application, while there is a minimum consumption of the product;

- Suitable for all types of wood - for pine, birch, oak, maple, walnut, cherry;

- Not high cost.

Alcohol-type stain

This product comes in the form of aniline dye, which is dissolved in denatured alcohol. Stain of this type is sold both ready-made and dry as a powder that must be dissolved.

This tool has the advantage of fast drying. However, this quality delivers some qualities when manually applying the mixture to the wood; after drying, greasy stains are often formed. Therefore, many builders recommend using a spray gun when using alcohol products.

Oil

As part of these products, all oil pigments are dissolved in solvents or in White Spirit. This composition provides a number of advantages to this type of wood stain:

- When painting, it provides toning of wooden surfaces in all kinds of colors;

- It is convenient to use oil mixtures at home;

- The composition fits well on the surface, it can be applied with any tools;

- Oil stain evenly enters the area of the wood structure, while forming a protective film on the surface.

Acrylic and wax

Wood stain, which is made of an acrylic or wax base, is a novelty in the construction market. This tool has positively recommended itself among many consumers and professional builders. This is due to the fact that this mixture, after application, creates high protection of the base from negative influences and premature wear.

Features of the composition:

- After application, the impregnation of this type on the surface of the tree forms an insulating film through which moisture and other negative substances do not penetrate;

- Various color characteristics. Compared to other varieties, this composition has a variety of colors from natural to vibrant exotic tones;

- These types of wood stains are used by many designers of modern furniture. These products are used to paint the external facades of cabinets, tables, chairs from different types of wood.

Whitening effect

It is not always necessary for the wood to be dark in color, sometimes it is required that it, on the contrary, have a slightly whitish color. In these cases, impregnations based on hydrogen peroxide and acids are suitable. With their help, you can get a light, bleached color of a wooden bar. Typically, these solutions are used to prepare the surface for further painting.

Stain is simply a must for improving the quality of wood. This tool protects the base from rapid wear and tear. The main thing is to choose the right product and carefully read the instructions and characteristics of the composition. But which mixtures to choose, it all depends on what they will be used for - to improve color or for protection. It is better to first study the properties of each type of wood stain.

Using wood in your home interior, you think about how long it will last. The answer depends on whether you know how to choose stains and varnishes for interior woodwork. It is worth considering further use: for furniture, choose non-toxic compounds, for the floor - resistant to abrasion.

Advantages and disadvantages

Due to its composition, water-soluble stain has a number of advantages over other types of tinting mixtures.

Let's highlight the main advantages:

- small price;

- lack of smell;

- environmental friendliness;

- ease of application.

Water-soluble mixtures are not the most functional type of wood stains.

- They have a long drying time (fifteen hours).

- After processing and drying, pile may rise on the surface of the material. In this case, the wood must be sanded.

- Water stain applied in large quantities to the product, after drying, can provoke the appearance of cracks on the surface.

Modern manufacturers of building materials also produce universal tinting mixtures, which can be classified as a type of water stain. Water, alcohol, or acetone can be used as a diluent for universal formulations. The advantage of making an alcohol or acetone solution from a universal mixture is that it will dry faster.

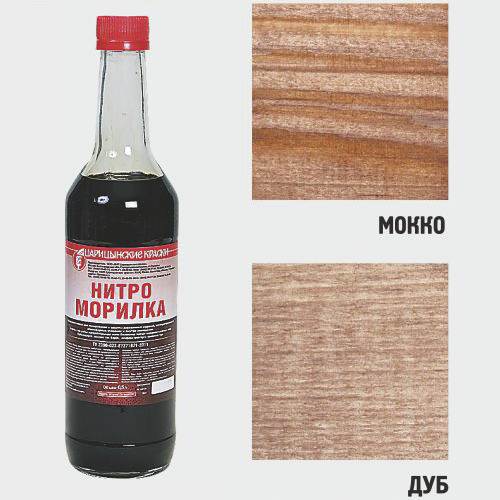

Consumption

The stain absorbs well into the wood. In addition, when buying the required amount of finishing material, it is necessary to take into account the porosity of the base. As a rule, 1 liter of ready-to-use mortar is sufficient for treating 12-15 m². However, the method of application and the type of building structures should be taken into account. For example, when applying stain from a spray gun, nozzle diameter and pressure are of great importance. The best option for aqueous solutions is 1.5 mm at a pressure of 3 atm, and for alcohol and nitromillocks - 1.3 mm at a pressure of 2-2.5 atm. The stain should only wet the surface to be treated, and not stand there in puddles.

Stain application

When staining, you should adhere to the correct technology. Wood placed vertically is painted from bottom to top. This will prevent splashing on clean places, and will not leave stains in the future.

The horizontal arrangement of the boards requires painting in the first stage along the grain. Next, brush across them and, at the third stage, repeat the original movement.

In work, you can use a spray gun, brush or foam swab. The first option is suitable for large areas, as well as for alcohol and nitro-based stains. The pi nozzle does not exceed 1.5 mm.

Brushes can be with natural and synthetic bristles. Natural fiber is good for oil-based stains, synthetic fiber is water-based.

Before use, the brush should be checked for strength. If, upon contact with it, no pile remains in the hand, then the product is of good quality and suitable for dyeing. The width of the brush should be 100 mm.

Water stains

applied except for the two described more with a tampon or rag. The material should not crumble and leave marks on the wood, so cotton, foam rubber is worth choosing.

The wood absorbs the dye just as much as it needs. Do not be afraid that there will be an overabundance, you just need to remove the excess liquid with a napkin. The stain may look quite different after drying and the color is an order of magnitude lighter. In order not to take risks and get the desired result, you need to take a piece of the board and make a test.

To do this, sand it and cover it with the first layer - this will be the base. After complete drying, apply the second layer to a part of the board. Apply the third layer to the remaining part.

When the paint is dry, cover the entire surface with varnish. Now you can define the color. A test for conifers is considered relevant, since they do not absorb stain well and a problem with color may appear. The minimum number of layers is at least two. It is a good idea to prepare several samples with different colors.

Water-based stain has the ability to straighten wood fibers. After complete drying, sand the boards additionally with fine-grain sandpaper, but without much pressure.

Drying time from 15 to 24 hours. Alcohol stain works differently. It will not pick up fibers, but it dries very quickly, forms streaks, so for an even coating it is better to work with a spray gun.

If a brush is used, moisten the surface with warm water first. This also applies to the end parts of the board. They should be wetted, as they absorb a lot of paint, which will make them look darker. Drying time from 5 to 25 minutes.

Algorithm of work:

- the surface is sanded before painting; - cleaned from greasy stains, if spruce or pine - resin.You can use water (370 ml), combined with acetone (125 ml). Method 2. Add 25 g of caustic soda to 500 ml of water. Method 3 In hot water (500 ml), about 60 degrees C, dissolve 25 g of sodium carbonate. Treat the surface thoroughly with one of the mixtures obtained and leave for 30 minutes. Wipe dry with cotton cloth. Now walk again with clean water, preferably warmed up; - slightly warm the stain; - do not wet the tampon too much and apply to the wood; - if streaks appear, gently stretch them along the surface along the fibers; - the number of layers depends on the selected color on the test board; - as soon as the board is dry, wipe the board well with a cloth. It will remove dried dye that did not get into the pores of the object; - the final stage is varnishing in several layers. Sanding after each layer.

The wood can be painted in different colors. Today "bleached oak" is considered a fashionable color. In order to obtain this effect, 2 types are used. The first layer is applied white stain

, it bleaches wood.

Moreover, the dye is taken on a water basis. The second type on a wax base is the next layer. Not the other way around. Since after waxing oak stain

, you will not be able to achieve the desired effect.

Stain color

the top layer can be any: brown, black, gray. Only annual rings will be colored, the field will remain snow-white... Photo stains

of various types. Their contrast is clearly visible here.

Advice

The method of application depends on the type of stain and the size of the product. For these purposes, use a swab, brush or paint spray. For processing a large surface, it is not recommended to use a brush, since there is a high probability that traces of its villi will remain, and it will also take a long time to process.

With a large area, it is more convenient to work with a spray. To do this, it is necessary to choose a lighter shade of impregnation, since the applied layer will be thicker than usual. At the beginning of work, do not forget to cover the untreated surfaces with a film.

If you still want to apply the composition with a brush, then for water-based and alcohol-based stains, you need to choose a brush with synthetic bristles. It is necessary to buy only a high-quality tool that will not leave fluff on the wood.

After choosing a suitable shade and tool, you need to make a test painting. This is done in order to find out the required number of layers of stain to obtain a specific shade. This requires:

- take a small sample of wood material of the same species as the product to be painted;

- grind the board in the same way as the main product;

- cover it with impregnation and leave to dry;

- apply the next layer on two thirds of the tree;

- when the last layer dries, apply the stain on the remaining one third of the board;

- compare the color saturation and choose the optimal shade.

The stain is applied to an uncoated wooden surface: it can be a completely new product or a part from which the previous coating has been removed.

Dry wood needs to be sanded with sandpaper. During work, you must not press hard on the tree, you only need to move along the fibers. This will avoid the appearance of small defects on the surface. If before painting they will be almost invisible, then after treatment with impregnation, the defects will be strongly emphasized. The sanding process takes about 30 minutes, this is enough to obtain a smooth surface and open the pores for the stain to penetrate.

After sanding, it is necessary to remove fibers and dust from the product with a vacuum cleaner. Using white spirit or gasoline, degrease the surface of the part. At the end, you should spray the tree with water, so the impregnation will fit correctly. For even mixing of the contents, the jars are thoroughly shaken.Then you need to warm up the stain to an average body temperature, so the composition penetrates deeper into the structure of the wood, then moisten a brush or swab for staining in the impregnation. For the sprayer, pour the stain into a special container.

During the processing of vertical products, they move from bottom to top. If the composition runs off, the smudges will remain almost imperceptible. For processing horizontally, brush along the fibers, then across, and then again along

It is important to distribute the stain carefully and to ensure that it is applied evenly. In order to avoid streaks, the composition is applied as quickly as possible.

Before applying the second coat of stain, it is imperative that the initial coat is completely dry.

After the composition has completely dried, the final wood processing process is carried out on the surface. With the help of washing, excess impregnation is removed, which remained without being absorbed into the surface. After this process, the product looks different: shine, texture appears. Washing is carried out with acetone using a volumetric brush as follows:

- tilt the product slightly;

- an absorbent cloth is placed under it;

- dip the brush into liquid;

- brush from top to bottom to drain excess impregnation;

- continue actions until the appearance of surface homogeneity;

- leave the products to dry and then apply varnish.

For information on how to make a wood stain with your own hands, see the next video.

Views

Stains are also called stains, they are used both indoors and outdoors. The stains are divided into groups, taking into account their chemical composition.

Water

The most common water stain is considered; it is made on a water basis. Thanks to water impregnation, you can give the product interesting woody shades. When working with this tool, it must be borne in mind that during application, fibers begin to rise on the surface, which will be exposed to moisture.

Alcohol

Alcoholic compositions are based on aniline dyes, which are dissolved using denatured alcohol. In hardware stores, you can buy powder stain or a ready-to-use composition.

A feature of alcohol stains is their ability to dry very quickly, this often leads to the formation of stains. Only two hours after application, the surface is completely dry.

Oil

Oil stains are considered the most convenient to use and are easy to apply to any surface. Unlike other options, oil impregnations have the most interesting colors, a large selection of shades.

Acrylic and wax

Taking into account all the shortcomings that were inherent in other generations of stains, acrylic and wax stains were created, which give the products bright colors, protect the surface from adverse factors. For those who love novelties and prefer exotic things, this type of stain will come in handy as possible, because thanks to its application, you can give the product unusual shades. Kitchen furniture with a blue wood texture will look very original.

In addition to store options, there are stains that you make yourself. For the preparation of such stains, various plants, decoctions from the bark, onion peels are used, and tea, coffee, vinegar are also added. It is worth dwelling on this issue and finding out what ingredients are used, and what the end result can be obtained when preparing stains on your own.

Stains that are made on the basis of decoctions from plants:

- to give reddish shades on a wooden surface, a decoction of larch bark is used, and instead of this decoction, onion peels can be used;

- to obtain a bright tone, a decoction of ground walnut shells is suitable;

- often black color is used for products, to get such a shade they take a decoction of willow and alder bark;

- to obtain a golden yellow hue, take a decoction of unripe buckthorn berries.

Stains can be made with tea, coffee and vinegar.

- To obtain a brown tint, brewed strong coffee with the addition of baking soda is used.

- For those who prefer tea instead of coffee, we offer another option using tea brewing. The shade after application also depends on how strong the tea will be. To achieve more blackening, light-colored tree species are covered with tea leaves, the tannin substances in the tea will provide the desired color to the product.

- To get the effect of ebony, a mixture of vinegar and metal is made. For its manufacture, they take small iron parts, which are poured with vinegar. This solution is placed in a dark place for a period of 2 to 7 days, depending on the intensity of the shade that is planned to be obtained. When working with vinegar, it should be remembered that it has a very pungent odor, therefore, the composition is applied with open windows or in the yard.

- You can give the product a dark brown or cherry hue using a solution of potassium permanganate. For its preparation, take 50 g of potassium permanganate and dilute in 1 liter of water. After preparing the composition, it is applied to the wood. After a few minutes, wipe the surface with a sponge. For a more intense color, another layer is applied. After this treatment, the products are covered with protective compounds so that the potassium permanganate does not fade in the sun.

Alcohol stain: how to dilute an alcohol-based wood coating agent from manufacturers - Novbytkhim - and - Anles, how to dilute Expert stain with alcohol

Alcohol stain for wood allows you to protect the material from excessive moisture, prevent the reproduction of destructive microflora, and also give the product a beautiful intense color. The stain will renew the wood surfaces and give the whole room a new look.

Colored or transparent alcohol stain penetrates deeply into the wood structure and creates a special film on the inside and outside of the product.

Due to this, the wood fibers are lifted and the structure of the material becomes more prominent.

Alcohol stain can be obtained by diluting aniline dye in denatured alcohol. The substance can be purchased in the form of a powder or ready-made mixture.

The main advantage of alcohol stain is the quick drying time of the layer applied to the wood surface. But this property can also be attributed to the disadvantages of an alcohol-based substance.

In order for the surface to evenly absorb the applied tone, it is necessary to use a spray gun, otherwise (with the manual method of toning) greasy spots appear on the surface.

In order to maximally reveal the structure of the tree or "age" it, the surface can be treated with liquids of different colors. By diluting several varieties of wood stains, you can get the colors "Arctic oak" or "bleached oak".

Before applying alcohol stains on the surface, you need to try it on a small area of the board. This is how you can decide on the desired tone and the number of layers to be applied.

It should be borne in mind that hardwoods absorb stain well, and conifers, due to the presence of a large amount of resin, are worse.

- The choice of tools depends on the footage of the treated surface. For small areas, a brush or foam pad will work. For large surfaces, it is best to use a pneumatic spray gun. Using a spray can reduce the chance of oil stains and smudges.

- In order for the color of the tree to acquire a rich shade, it is necessary to apply a few words of tinting agent. The second and subsequent layers can be applied only after the previous ones have completely dried. The same rule applies to the finishing layer.

- The surface should be painted over wood fibers. Thanks to this, you can emphasize the pattern, avoid smudges and reduce the consumption of stain.

- The stain must be of the correct consistency.

- The varnish coating does not need to be applied twice on the same place, then too dark areas can be avoided.

- Alcohol stain needs a maximum of 3 hours to dry.

- The rules for applying the substance for external and internal decoration are the same.

Among the most popular manufacturers of alcohol-based stains, there are three companies whose products please customers with a price-quality ratio:

The products presented by the St. Petersburg company "Novbytkhim" can be used for tinting door panels, skirting boards and handrails indoors, as well as veneer and plywood products.

Among the advantages of the stain produced by this company, the following can be noted:

- does not require varnishing;

- is not washed off with water;

- easy to polish;

- emphasizes the wood pattern;

- prevents swelling of the coating;

- gives the wood surface non-combustible properties.

The company "Anles" produces alcohol stains, the main purpose of which is to give the wood protective properties and a certain color that imitates another species of wood. The substance does not form a film on the surface of the product, but penetrates into the structure of the wood, thereby emphasizing the natural pattern of the natural material.

When working with anles stain, certain conditions must be observed.

The room temperature should not be lower than +5 degrees, and the humidity should not be less than 80%. The wood surface must be completely dry before processing.

Liquid from the "Expert" brand is suitable for processing wood surfaces indoors and outdoors, for tinting furniture, railings, log surfaces, doors.

The substance penetrates deeply into the material, allowing you to recreate the imitation of valuable wood species.

Available stain colors: maple, mocha, oak, mahogany, larch.

For more information on wood stain, see the following video.

All rights reserved, 14+