Water stain “Anles”, oak color. - review

Stain for 29 rubles. What can she do?

I'm drawing. And I decided to hang some of my works in the apartment, but they had to be framed. The baguette I liked was expensive. The finished frames did not fit. But do not hang my works on pins ?!

I like antique classic frames, no gilding. There was no question of buying an old frame, but an aged modern frame would be fine. But it was also worth a lot of money. And since I cannot afford to buy such a frame, I decided to go the other way. Semi-finished, in the literal sense of the word I ordered half of my future dream frame (i.e. the baguette itself) in the baguette workshop, and I decided to decorate it myself with the help of ordinary stain.

After examining various offers and reading about what it is and how to use it, I went to the store. It didn't get any easier here, because I was overcome by a huge number of samples, among which there were many handsome. I understood that the color of the sample can (and most likely will) differ from my real object, since the tree can inscribe the stain differently, the application technology will be different, and so on and so on. I chose the water-based stain I liked. To be honest, it cost so little that I thought it wouldn't paint anything at all.

Material

Water stain (oak) is poured into the most common 0.5 liter plastic bottle. and has a coffee color.

Result

So, I used it on three pine frames. On the first frame, I wanted to see a barely noticeable shade, remove the whiteness of the pine and give it a slight dustiness. I wanted to see the second frame as dark as an old ship board. All of them were not supposed to shine, but they had to radiate the warmth of wood. The third frame (of which there are no photos), I made with the effect of "piercing".

A barely noticeable shade, the color of dried sand dust - so I would describe what happened after applying 2 layers of stain. The result suits me completely. No smudges were observed.

I fiddled with the second frame much longer, probably applied 7 layers. But the result was worth it.

Outcome

In all three cases, I was satisfied with the result of my work. For decorative work, it fits exactly, because it is almost odorless and does not require special tools and skills. Its price, in my opinion, is more than affordable, but not at the expense of quality

Therefore, I recommend that you pay attention to it if there is a need for this product.

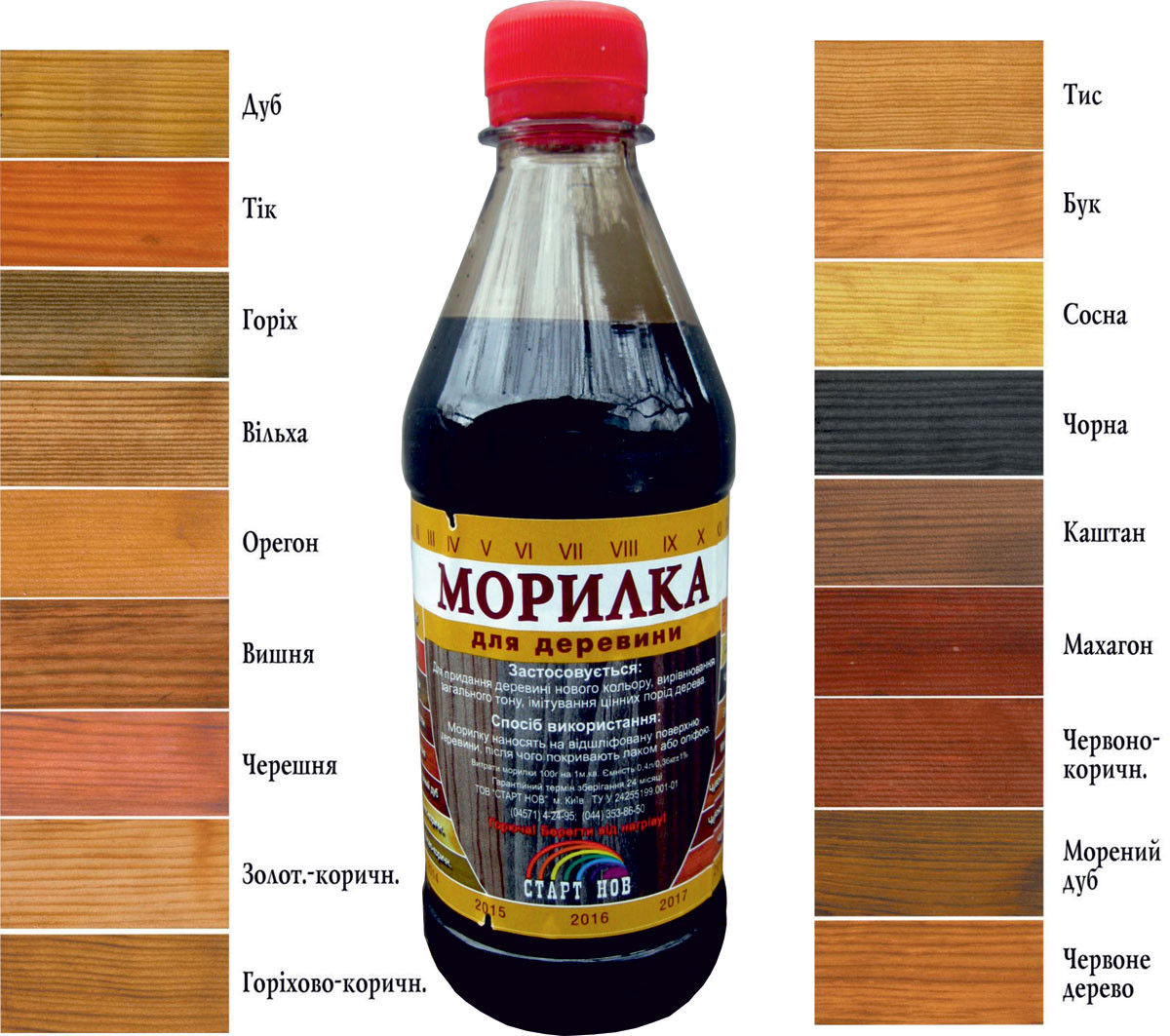

What color are wood stains, depending on the type of composition

The palette of available shades depends on the type of composition. Water-based wood stains come in a wide variety of colors. Manufacturers claim that such compositions can give the surface any shade. However, the palette of water stains mainly covers natural colors. This includes dark and light brown tones. When treating the surface, the water stain lifts the fibers of the material. Thanks to this, its structure becomes clearer and more pronounced, although the degree of protection against moisture is significantly reduced.

For very soft wood species, many manufacturers offer special stains-gels

Acrylic stains, which are a variety of water stains, have the most extensive palette of any product available. It's all about the improved composition, which expands the decorative possibilities of these solutions. Unlike water stains for wood, acrylic impregnation colors can be more exotic and atypical.These stains emphasize the structure of the material without lifting the fibers. Wax stains have similar properties, which also differ in a wide range of colors.

Among acrylic stains, there are also colorless compounds. Such impregnations are produced by the Tikkurila company. The color of the wood stain in this case will depend on the color that is added to the solution. The Tikkurila Pirtti stain palette includes 36 different shades.

The materials of the modern generation include gels stains. Like wax products, they have a thick consistency and are applied to the surface using swabs. As for the palette of gel stains, it is very limited.

Alcohol stains are characterized by a good color variety. However, due to the pungent odor in interior decoration, consumers prefer water-based stains, and for outdoor work, oil compositions with an impressive spectrum of colors and rich shades are often used.

Today stains are presented in a huge assortment

The color range of wood stains and the effect of the composition on the painted material

Water-based wood stains are available in a wide range of colors. These compositions allow you to quickly and easily give a wooden surface an expensive and noble shade or radically change the appearance of the material.

The color palette of wood stains can be conditionally divided into three groups:

- Neutral color scheme - this includes all shades of white, black and gray.

- Natural colors - includes natural shades of wood that are found in nature, for example, the color of wenge wood stain, walnut, maple, oak, cherry.

- Exotic colors - used to give wood atypical shades, such as blue or purple.

This table contains information on how what colors are there wood stain.

| Color name | Staining result |

| Beech | Natural shade, warm and well emphasizes the woody pattern |

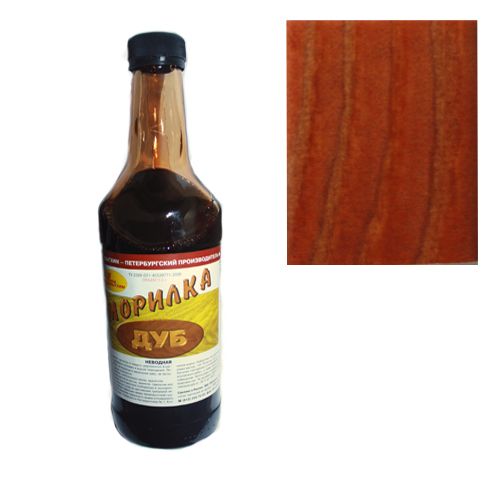

| Oak | Dark brown tone |

|

Ebony |

Creates a visual effect of aged wood, emphasizes the relief of the material and its natural lines |

|

Cherry |

Can give the surface a rich shade of dark burgundy or paint in light red tones |

| Fern | The wood takes on a pleasant green tint |

| Mahogany | After drying, the treated surface turns brown with a slight shade of red |

| Black | Used to create an aging effect |

| Rowan | Slightly tints the material in a pale pink or transparent beige shade |

| Mocha | The painted surface becomes coffee |

| Bog oak | Gives a matte effect to the natural color |

|

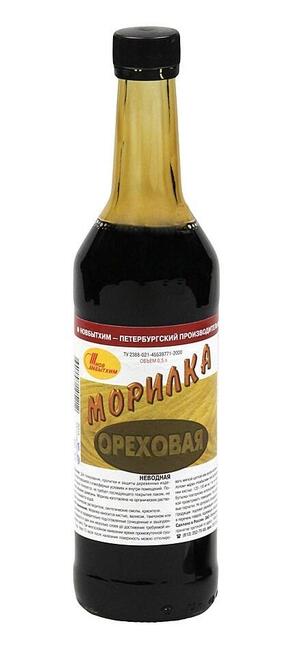

Hazelnut |

Outwardly similar to a nutshell, it is used to deepen the structure of the material |

| Blue | Matches the color of wolf berries |

| Ash | After staining, a slight pink color appears on the surface |

|

Larch |

Has a wide range of shades from dark yellow to orange |

| Maple | Delicate shade of peach color |

|

Lemon |

Yellow, which can be made contrasting by repeated application |

| Plum | Dark pink |

| Wenge | Dark shade of brown with black streaks and blotches |

| Bleached oak | White shade |

| Light walnut | It is used to protect wood while maintaining its natural color |

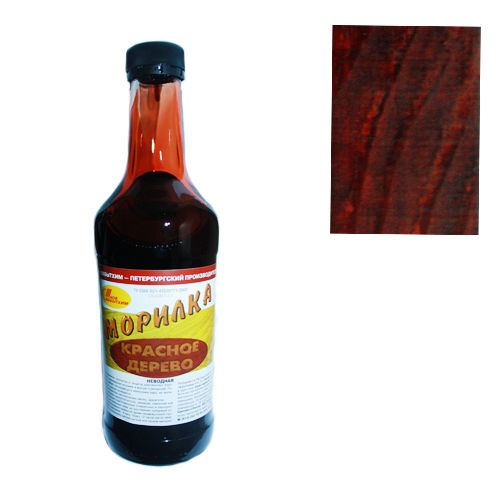

| Red tree | Noble red |

| Kaluzhnitsa | The treated surface becomes darker |

| Pine | Transparent, almost invisible coating |

Performance characteristics of wood stains by type, depending on the base used

The characteristics of the wood stains produced by the manufacturers depend on the formulations used as the base. We offer you to get acquainted with the distinctive features of the various compositions.

The effect obtained depends on the composition of the wood stain.

The effect obtained depends on the composition of the wood stain.

Water and alcohol

Manufacturers supply similar compositions in finished form or in powder form. They are environmentally friendly and available in a wide range of colors. The absence of a pronounced odor makes it possible to use them for the treatment of external and internal surfaces. Demonstrates high elasticity and adhesion to wood substrates.

Safe and practical, water-based stain is not suitable for wood with high resin content. Dark spots may appear on the painted substrate. Also, the application of water-based stains provokes the rise of wood fibers. After processing, the tree needs mandatory grinding. With prolonged contact with water, moisture-resistant characteristics decrease, since the composition is gradually washed out.

Water stain is odorless

Water stain is odorless

Alcohol-based stains include aniline dyes and denatured alcohol. Supplied as a ready-to-use solution and as a powder. Due to the rapid penetration of the dye into the base, the surface dries quickly.

You can ensure uniform coloring of the tree using a spray gun. There are no characteristic spots and streaks on the surface. With their help, you can reliably protect wood from the weather. They can be used for processing substrates outside the building.

Alcohol stain can be recognized by its smell

Alcohol stain can be recognized by its smell

Oil and acrylic

The base of the oil-based stain is linseed oil or drying oil. It can be applied in any convenient way. Demonstrates good burnout resistance. Treated wood can be used in conditions of high humidity and temperature fluctuations. During the application of the oil composition, the wood fibers remain in place. They can be used for surface treatment inside and outside the building. Forms a moisture resistant protective film.

Oil stain can be applied internally and externally

Oil stain can be applied internally and externally

The base of acrylic stains is formed by the corresponding resins, which make it possible to form a special film and protect the base from negative external influences. The composition is environmentally friendly and fireproof. Can be applied to substrates made of various types of wood. Has no pronounced chemical odor. Dries quickly. Available in a wide range of colors. To ensure sufficient protection, the stain is applied in two layers, the maximum thickness of each is 3-4 mm.

Acrylic stain has antiseptic properties

Acrylic stain has antiseptic properties

Wax and rustic

Wax stain appeared on the market relatively recently. It is based on natural wax. Designed for processing previously painted surfaces. Provides reliable protection of wood from temperature fluctuations and exposure to increased moisture. A soft cloth is used for application. The stain is applied in a circular rubbing motion.

The wax stain is rubbed in in a circular motion

The wax stain is rubbed in in a circular motion

Rustic are also new generation compounds. Most often used to protect parquet flooring. By applying this type of stain, professionals create graceful color transitions, achieve unusual effects. The best result is achieved when painting oak boards.

The stain lay with a defect: ways to eliminate the consequences

Violation of the technology of work, the use of low-quality composition can cause defects, which sometimes can still be eliminated. If streaks have formed due to the large amount of stain applied and the excess removed in time, you will have to remove the impregnation layer. Subsequent application of the composition will soften the base coat. Remove excess stain with a rag.

Excess composition should be removed immediately.

If the coating turns out to be heterogeneous, for example, characteristic spots are visible, the composition is removed from the painted place mechanically, most often using a planer. You will have to remove all the veneer from the plywood.After that, the processing is repeated.

Stain application

When staining, you should adhere to the correct technology. Wood placed vertically is painted from bottom to top. This will prevent splashing on clean places, and will not leave stains in the future.

The horizontal arrangement of the boards requires painting in the first stage along the grain. Next, brush across them and, at the third stage, repeat the original movement.

In work, you can use a spray gun, brush or foam swab. The first option is suitable for large areas, as well as for alcohol and nitro-based stains. The pi nozzle does not exceed 1.5 mm.

Brushes can be with natural and synthetic bristles. Natural fiber is good for oil-based stains, synthetic fiber is water-based.

Before use, the brush should be checked for strength. If, upon contact with it, no pile remains in the hand, then the product is of good quality and suitable for dyeing. The width of the brush should be 100 mm.

Water stains

applied except for the two described more with a tampon or rag. The material should not crumble and leave marks on the wood, so cotton, foam rubber is worth choosing.

The wood absorbs the dye just as much as it needs. Do not be afraid that there will be an overabundance, you just need to remove the excess liquid with a napkin. The stain may look quite different after drying and the color is an order of magnitude lighter. In order not to take risks and get the desired result, you need to take a piece of the board and make a test.

To do this, sand it and cover it with the first layer - this will be the base. After complete drying, apply the second layer to a part of the board. Apply the third layer to the remaining part.

When the paint is dry, cover the entire surface with varnish. Now you can define the color. A test for conifers is considered relevant, since they do not absorb stain well and a problem with color may appear. The minimum number of layers is at least two. It is a good idea to prepare several samples with different colors.

Water-based stain has the ability to straighten wood fibers. After complete drying, sand the boards additionally with fine-grain sandpaper, but without much pressure.

Drying time from 15 to 24 hours. Alcohol stain works differently. It will not pick up fibers, but it dries very quickly, forms streaks, so for an even coating it is better to work with a spray gun.

If a brush is used, moisten the surface with warm water first. This also applies to the end parts of the board. They should be wetted, as they absorb a lot of paint, which will make them look darker. Drying time from 5 to 25 minutes.

Algorithm of work:

- the surface is sanded before painting; - cleaned from greasy stains, if spruce or pine - resin. You can use water (370 ml), combined with acetone (125 ml). Method 2. Add 25 g of caustic soda to 500 ml of water. Method 3 In hot water (500 ml), about 60 degrees C, dissolve 25 g of sodium carbonate. Treat the surface thoroughly with one of the mixtures obtained and leave for 30 minutes. Wipe dry with cotton cloth. Now walk again with clean water, preferably warmed up; - slightly warm the stain; - do not wet the tampon too much and apply to the wood; - if streaks appear, gently stretch them along the surface along the fibers; - the number of layers depends on the selected color on the test board; - as soon as the board is dry, wipe the board well with a cloth. It will remove dried dye that did not get into the pores of the object; - the final stage is varnishing in several layers. Sanding after each layer.

The wood can be painted in different colors. Today "bleached oak" is considered a fashionable color. In order to obtain this effect, 2 types are used. The first layer is applied white stain

, it bleaches wood.

Moreover, the dye is taken on a water basis. The second type on a wax base is the next layer. Not the other way around. Since after waxing oak stain

, you will not be able to achieve the desired effect.

Stain color

the top layer can be any: brown, black, gray. Only annual rings will be colored, the field will remain snow-white... Photo stains

of various types. Their contrast is clearly visible here.

How to make wood stain at home

Most stains are made up of solvent and natural pigment, so you can make your own wood stainer.

Homemade stains are of several types:

- based on herbal ingredients;

- based on synthetic materials;

- food-based.

It is easy to make wood stain with your own hands from improvised means

In addition, chemicals can be used to stain wood at home. For example, slaked lime will enhance the brown color of oak. If you treat a nut with this tool, the wood will acquire a greenish tint.

How to make a plant-based wood stain with your own hands

The pigments contained in plants are suitable for toning wood. If you apply a decoction made from larch bark to the surface, it will acquire a reddish tint. The lighter the wood, the more contrasting and brighter the result will be. Best of all, the shade manifests itself on products made from birch. A golden hue can be obtained with onion peels. This option is only suitable for light wood species.

Walnut shell is a universal toning agent. With its help, you can get different shades. The color depends on the amount of this ingredient in the stain. To begin with, the shell is finely ground to a powder state. Then it is added to boiling water and simmered over the fire for 12 minutes. The resulting broth must be filtered and baking soda added to it.

With the help of walnut shells, you can get different shades

If a dichromate solution is also applied to a surface soaked in a decoction of walnut shells, a reddish tint can be achieved. Treating painted wood with acetic acid will give a grayish color. To obtain a black color, decoctions are used made from the bark of alder and oak or willow. Buckthorn fruits give a golden yellow hue. They must be unripe.

A brown tint can be obtained by mixing the following components:

- oak bark;

- alder earrings;

- willow bark;

- walnut shells.

All ingredients are combined in equal proportions. To prepare the stain, they must be soaked in cold water and then brought to a boil. For some time, the broth should simmer over the fire, then soda is added to it, after 10 minutes. it is removed from the stove.

There is another way to make brown stains. For this, a decoction of walnut shells and apple bark is used. If you add alum to it, you can get a richer and darker shade.

To obtain black stain, use oak bark

How to make your own food and synthetic wood stain

Coloring pigments are also found in food. You can use coffee to give the wood a brown tint. The stain is made on the basis of ground grains and baking soda. The use of instant coffee is allowed. To prepare the stain, it is necessary to firmly weld the grains or granules, and then thoroughly saturate the wood with this agent.

A brown tint can also be obtained with a tea pot. Tea contains theanine. This component gives the wood its natural brown color. Moreover, the saturation of the shade depends on how strong the tea is brewed.

The ebony effect is obtained using vinegar.Metal parts are required to prepare the solution. Small pieces of metal are poured with vinegar, after which they must be left in a dark place for at least 48 hours.

A dark stain can be made with baking soda and coffee beans.

Dark shades of cherry and brown at home can be obtained with a solution of potassium permanganate. To do this, dilute 50 g of powder in 1 liter of warm water. After 5 min. after processing wood with this solution, its surface is wiped with a soft cloth. To get a richer and darker shade, this procedure must be repeated. Potassium permanganate quickly fade in the sun. If it was used as a wood stain, the surface of the material must be covered with a protective agent.

Wood stain - classification by composition

Depending on the composition, the performance and application technology of the stain can vary significantly.

Water

The most common and affordable type of stain. Has a wide range of colors. It is produced both in the form of ready-made compositions and in the form of a water-soluble powder. In the second case, the intensity of the color depends on the amount of powder added to the water during the preparation of the composition.

Advantages: no pungent odor and toxic emissions, recommended for indoor use.

Disadvantages: when applied, slightly lifts the wood grain, which increases the material's susceptibility to moisture. Long complete drying time, which is about 12-14 hours.

Various shades of water-based stains

Alcohol and nitromorilac

It is an alcoholic solution of aniline dyes. Denatured alcohol is used as a solvent. Also produced as a ready-made solution or powder. A distinctive feature is a high drying speed - 20-30 minutes, which is both an advantage and a disadvantage.

For applying nitromorilac from alcohol-based formulations, it is recommended to use spray guns

High humidity and inaccurate brushing during application can lead to uneven pigmentation of the treated surface. Therefore, in order to obtain a uniform color, it is strongly recommended to use vacuum or pneumatic spray guns.

Advantages: fast drying, affordable cost;

Disadvantages: high likelihood of stains when applied manually, pungent and unpleasant odor, toxic discharge (especially nitromorilac).

Oil

It is one of the most convenient for manual application. Dissolving the different segments in oil results in a wide range of colors and a fade-resistant shade. White spirit is used as a solvent, the base is industrial linseed oil.

Applying oil stain with a brush

Advantages: does not form stains, does not raise fibers, provides a high degree of protection of wood from external factors, dries up in 2-3 hours;

Disadvantages: an unpleasant odor that disappears after a rather long time after application: from several days to several weeks.

Acrylic

It is produced in the form of aqueous dispersions of acrylic polymers with the addition of pigments. Such compositions have practically no drawbacks, except for the high cost.

Acrylic stain has vibrant colors

Advantages: dries up in 2-3 hours, has no odor, does not emit corrosive or toxic fumes during application and during further operation, forms a uniform coating without stains, provides reliable protection of wood.

Disadvantages: high price.

Wax

The composition is represented by an aqueous suspension of wax. It has a high density, it is applied with a cloth. Does not absorb into the material. Forms a relatively thick protective layer on the wood surface.It is used as a base "primer" for various paints and varnishes and for polishing the product with beeswax.

One-component stain based on wax "Borma wachs"

Advantages: Uniform pigmentation, reliable protection of the base, does not reduce moisture absorption.

Disadvantages: high cost, laboriousness of application.

Color selection of wood stain

In accordance with the international classification of color, each stain is assigned its own code, as well as a name identical to the species of wood, the shade of which you will receive using the composition. But, choosing a stain based only on the name on the label, you run the risk of encountering an unexpected result. This can happen for a variety of reasons.

Made by different manufacturers, stains of the same color can produce different shades. Specialty shops have wood samples painted with various types of stain. They convey color as accurately as possible, unlike the picture shown on the label, so it is better to focus on them.

Any wood has its own special color, density and texture. All these factors affect the final result, and staining may not give exactly the effect you expected.

Consider porosity as well: the softer the wood, the more intense the staining result you will get. The composition will penetrate deeper and faster into the porous structure

If we compare, for example, pine and maple - pine is more porous, respectively, and the staining results will be different.

The structure of the wood in the form of a natural pattern (veins) is also important for staining, affecting the intensity of the result. For example, when dyeing oak, the pigments easily penetrate deep into the veins, due to which they darken faster than the rest of the wood. The shade on the veins will appear richer.

Before starting work, it is advisable to test the color on a separate board, treated in the same way as the material for painting. First, process the entire board in one layer, then apply a second layer on 2/3 of the part, and a third on 1/3. You will be able to see how the composition is suitable for a particular surface.

What is the stain for

In a professional environment, wood stain is called "stain". This liquid agent allows you to give the desired color to wood without changing its texture or pattern. On the contrary, stains emphasize the entire aesthetics of natural wood, enhancing it, ennoble simple species: after processing, even pine can be "made" of dark oak or other expensive varieties of material.

Any wooden products, despite their strength, are subject to various adverse factors. Wood stain can be used to protect wood from damage by putrefactive fungi. There are different types of wood stains, the properties of which depend on the composition.

The main qualities of the beytsy:

- protection of wood from ultraviolet radiation;

- destruction of woodworms and other pests;

- increased surface service life;

- clarification of wood;

- moisture protective function;

- the possibility of restoration of old products;

- compaction of the material structure;

- preparation of wood for further processing - painting, varnishing.

Some stains should only be used indoors - for covering floors, countertops, furniture, interior doors. Others are suitable for outdoor use - for example, for treating the floor on an open veranda. Some products are used only on the surface layers of wood, others are distinguished by the possibility of deep penetration. Many modern stains can not only be applied to the base, but also perform various interesting effects - combine tones, create shades uncharacteristic for wood.

The difference between stain and varnish, paint, varnish

Stain is a means for imparting texture to wood.It penetrates deeply, tints the wood from the inside, without closing its natural pores and preserving the pattern, while protecting it from decay and destruction. The drying oil also protects the material from moisture and putrefactive processes, but after its application, a film appears on the surface.

The drying oil weakly penetrates into the deep pores of the tree, but clogs them from the outside. If the stain can become an independent finishing agent, then drying oil is used only to prepare wood for further work to improve the quality of staining, reduce the amount of paint.

Varnish is also very different from stain-impregnation. Varnish is a film-forming agent, and a protective film from it is formed after the solvent evaporates from the surface. Oil varnishes form a super strong elastic film that is not easy to wipe off even with white spirit. Again, the varnish layer will have to be updated over time, first removing the previous one. Usually varnishes are used where there is a strong influence of atmospheric factors, and the stain will have to be applied too often.

Paint is another popular finishing material for wood. You can paint absolutely any wood product: from the floor to window sills or furniture. After painting, a dense, opaque film forms on the surface, which completely hides the natural wood pattern - this is the cardinal difference from the stain. Usually the color range of paints is far from natural: more often white, black, brown, green paints and varnishes are sold. After 2-3 years, many types of paints lose strength, snap off, after which you will have to completely remove the old layer and apply a new one.

Step-by-step staining technology

Despite the numerous preparatory steps, the immediate process of applying the stain is not complicated at all. Perform it according to the following scheme:

1. The stain is slightly warmed up to enhance the penetration rate into the wood.

2. A swab, rag or brush is moistened with stain. Strong moistening should not be allowed, otherwise the occurrence of streaks and uneven coloring is inevitable. When using a spray bottle, pour the stain into the reservoir.

3. Apply the stain along the wood grain. Try to work quickly, without interruption, to avoid stains. When streaks form, wipe the surface with a soft cloth, "pulling" excess liquid along the fibers. Leave the stain to dry completely.

4. In a similar manner, apply several more layers to obtain the desired shade (usually 2-3 layers).

5. Finally, the stained surface is varnished in several layers with sanding of each intermediate layer with fine-grained sanding paper.