Types and characteristics of glue

The characteristics of the adhesive solution directly depend on its composition.

Assembly adhesive

Assembly adhesive requires strict adherence to the instructions for its preparation. Manufacturers indicate this information directly on the packaging. Work with him is performed with a spatula. The composition is applied to the surface in a circular motion. The intervals between strokes should be 15 to 30 cm.

When gluing the gypsum board under special control, there should be a uniformity of their installation. For this, a building level is used. If necessary, you can correct the location of the drywall sheets, but no later than 10-15 minutes after the material is glued to the surface. Mounting adhesive for gypsum boards was originally used as a tile composition. However, due to its moisture resistance, environmental friendliness and resistance to low temperatures, the composition is considered universal.

Polyurethane foam

Work with polyurethane foam is carried out according to the following technology:

- make 8-9 holes in the sheet, drill around each;

- pieces of foam rubber are glued to the panel, leaving a gap from the holes at a distance of 10 cm;

- the sheet is attached to the wall with screws and washers;

- the composition is poured into the holes;

- the washers are removed;

- the screws are tightened all the way.

Plaster based mastic

The gypsum variety consists of glue and lime. To prepare such a mastic, you need to pour the glue with water for 15 hours, after it swells, lime, already diluted in water, is added to the composition. Typically, a steam bath or gas stove is used to obtain a thick consistency. Finally, gypsum is added to the solution. The advantages of this type of glue include the absence of shrinkage after complete drying and antibacterial properties. Therefore, such a composition is recommended to be purchased for premises with a high probability of mold and mildew.

With sawdust

There is a mastic with the addition of sawdust. Such an adhesive solution resembles sour cream in density. To prepare gypsum and sawdust mastic, you need to mix gypsum and sawdust in a ratio of 4: 1 and add glue to the composition (for 1 liter of water, you need 25 grams of dry composition).

Sulfate-alcohol mixture involves mixing water and vinasse in a ratio of 4: 1. The consumption of gypsum is determined based on the consistency of the resulting composition. Ready-made gypsum mixes are distinguished by good plasticity and provide additional sound insulation

A positive feature of such a composition is its ability to take the shape of a surface, which is especially important in situations where it is necessary to level the wall

Special formulations

Special glue for drywall is produced in cylinders. Usually it is enough for 15 squares of area. The application technology involves processing the surface composition along the entire perimeter with further smearing of the plane independently. In this case, strips of glue are made on the base every 30 cm.

The elastic polyurethane compound is produced in cylinders. It is designed for laying gypsum boards and pasting seams. In addition, he showed himself well as an adhesive for gypsum or ceramic tiles. Work with him is performed using a special construction pistol. Sometimes polystyrene fibers are included in the composition of polyurethane glue, which have a beneficial effect on density.

Advice

In order for the drywall sheets to stick better, the surface for installation should be prepared. This process consists of priming and cleaning. Preparing the glue for work (in the case of using gypsum powder compositions) involves diluting and stirring with a drill with a nozzle.

The technology for applying the mixture consists in laying the composition in the form of small cakes on the surface of the sheet at a distance of 20 cm. You can distribute the composition directly on the work surface. Then the gypsum board is applied to the wall and pressed well for high-quality gluing. Leveling the material should be done with a rubber mallet.

To glue the ceiling with plasterboard, it is more convenient to use a dowel for fastening. They will help hold the material until it dries completely, so that the sheet is glued as efficiently as possible. Drywall is a quality material for creating all kinds of structures, wall and ceiling decoration. However, improper sealing between sheets can lead to cracks.

It is important to carry out this work using plaster. The type of composition should be selected depending on how the finishing will be carried out further

After the composition has dried, the surface is completely ready for finishing: the walls are pasted over with wallpaper, painted or decorated in any chosen way.

For the intricacies of gluing drywall, see the next video.

2 Properties and characteristics - why is the composition better than a liquid solution?

Polyurethane foam is the only adhesive for the installation of foam. It reliably adheres extruded polystyrene foam to any surface. Before the advent of this composition, it was believed that this material is not suitable for adhesive installation. True, craftsmen came up with technologies for gluing foam to the walls, but its installation had to be carried out only at your own peril and risk. Foam glue is recommended for the installation of this insulation by the manufacturers themselves, for this it was developed.

The possibility of reliable adhesion of foam is associated with the ability of liquid polyurethane foam to adhere well to any surfaces, including the smoothest ones. In addition, thanks to the additives, the composition has high technical characteristics:

| Specifications | Meaning |

| Adhesion to concrete, MPa | 0,3 |

| Adhesion to expanded polystyrene, MPa | 0,1 |

| Application temperature, ° С | -10 +40 |

| Thermal conductivity coefficient, W / mK | 0,040 |

| Consumption of one cylinder, m2 | 10 |

| Setting time at a temperature of +20 ° C, h | 2 |

The table shows that the adhesive foam has not only good adhesion, but also a number of other advantages, such as:

- Low thermal conductivity - due to this quality, the composition is used to insulate the seams. Thus, you can get rid of not only cold bridges, but also glue the expanded polystyrene together. As a result, the likelihood of cracking in the plaster is reduced.

- High speed of solidification - already two hours after the installation of the plates, you can proceed to the next stages of work - grouting and reinforcement.

- The ability to carry out installation at negative temperatures. But not all types of glue have this property. Therefore, before buying a composition for the winter, carefully read the instructions.

Foam glue has other advantages:

- Increases the speed of work - unlike a cement-based mixture, the foam does not need to be dissolved with water and brought to a homogeneous consistency with a mixer. It is applied simply and quickly. Therefore, the process of fixing the plates to the wall is performed five times faster than in the case of using a liquid solution.

- It has a low weight - as a result, it simplifies the transportation of the material and reduces the load on the foundation. If the slurry increases the weight of the board by ~ 3 kg, foam has practically no effect on this indicator.

Therefore, it makes sense to use such glue not only for penoplex, but also for ordinary foam, especially if you need to perform installation work quickly. True, its big drawback is its high cost.

Operating instructions

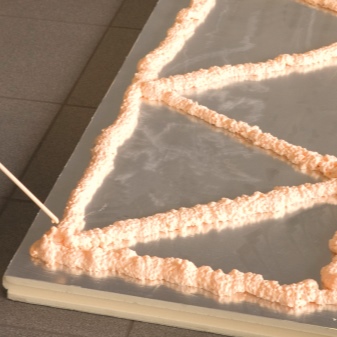

The method of leveling walls and ceilings with plasterboard depends on the linear differences in height and width. If the difference does not exceed 3 centimeters, then the sheets are glued to special glue or foam. In other cases, markings are made and profiles for drywall are installed.

When installing sheets on a metal profile, an inter-wall gap is formed. The air space can be filled with polyurethane foam, which will create additional sound and heat insulation.For this, 9-12 holes are drilled in each sheet, the diameter coinciding with the size of the assembly gun barrel.

A small amount of the composition is introduced through the holes under the sheet. To prevent deformation of the covering material, it is additionally reinforced from the outside with a sheet of plywood, holding for 10-15 minutes until the foam completely expands. On smooth walls, the sheets are glued directly onto the mounting foam. Getting the job done requires skill and careful preparation. Glue-foam is applied in zigzag lines over the entire sheet area and immediately applied to the wall. It is pressed with effort and held in this position for 10-15 minutes.

The choice of adhesive for extruded polystyrene foam

How to glue polystyrene foam? For fixing the plates, you can use different means that have different components. But there is a specificity of the use of mixtures. So, for gluing to a concrete base, it is better to use one, for fastening to a brick wall - others, for winter work - still others. There are adhesives that combine the properties of fastening material and insulation, and have low thermal conductivity.

Before buying, it is important to clarify that there are no substances that corrode polystyrene foam in the composition of the product. It:

- acetone;

- alcohol substitutes;

- toluene;

- ethers;

- other solvents.

The ideal option is to purchase specialized formulations, because their manufacturers have already taken into account all the important points. There are three main types of media that are suitable for bonding material. This is a plaster-adhesive mixture of different brands, polymer adhesives and bitumen glue (mastic).

People often use "liquid nails" in a bottle, silicone sealants, frost-resistant tile adhesives, drywall products, and tiles for gluing the material. Can I use them? Experts say that the use of such adhesives is possible, especially if additional fastening of the structure with dowels is planned. But the cost of work can turn out to be much higher, so it is better to buy funds intended for EPSS.

How to properly and how to glue foam

Ideal - branded glue, based on polyurethane. The composition of the glue is selected in such a way that the connection is strong, the seam is neat, the structure of the foam is not disturbed. Polyurethane glue is exactly what you can use to glue the foam together. The adhesive composition does not react to changes in ambient temperature, is moisture resistant, and is not afraid of mechanical influences. Low consumption - 200-350 g / m2. Before buying, you should calculate the approximate amount of glue and lay 10% of the reserve, which will help to avoid problems during the repair.

For a high-quality repair, you need to think not only about how to glue the foam, but also about how to reduce the consumption of glue. It is better to use a fine-grained abrasive for surface treatment. Then gently apply the compound to the surfaces to be bonded and press them firmly together for a few minutes.

Depending on how you need to glue the materials (for centuries, if repairs are made at home or not, if you need to make a fake to school for a child), the method of applying glue and the requirements for the adhesive composition differ. Running a little ahead, we can say that in most cases ordinary PVA glue is suitable

Polyurethane glue is exactly what you can use to glue the foam together.

Choosing the right adhesive

Before gluing the extruded polystyrene foam together, you need to understand two important points that affect the complexity and efficiency of the repair. Foam boards are smooth, construction glue does not allow creating adhesive bonds. As a result, the materials do not stick. Construction glue contains various solvents from organic substances that corrode foam when it gets in, products deteriorate, and the final result cannot be achieved.

When buying a new adhesive material, you need to test it for compatibility with polystyrene: a substance is applied to a small piece or crumb and left for half an hour, inspect the material for deformations and defects. If they are absent, you can use this type of glue.

When purchasing a new adhesive, it is required to test it for compatibility with polystyrene.

When choosing an adhesive, pay attention to the following:

- The shape and structure of the foam, the surface;

- Conditions in the house where the renovation is being done;

- Composition price. An important point that will have a key influence on the choice;

- The conditions of the room in which the materials will be used.

The combination of the above factors determines the glue required for use. For fakes, ordinary PVA is suitable for school, it is available in every home, it costs a penny and is able to glue together any materials: from paper airplanes to cornices.

For fakes, a regular PVA is suitable for school.

What glue does not corrode

Not any glue is suitable for working with this material, most of the substances destroy it. The material dissolves and "burns through", which causes deformation. As a result, you have to look for new glue, buy additional sheets of foam, waste time and money. What kind of glue does not corrode foam? All those types that do not belong to those listed below:

- Acetone is used to make the glue. Such compositions are used to degrease surfaces;

- Oil derivatives are used for production: gasoline, kerosene, xylene, etc. Combustible substances destroy the foam;

- Alcohols.

Most suitable foam formulations are marked on the label. She informs that this glue is recommended to be used for working with expanded polystyrene and products made of this material.

Most suitable foam formulations are marked on the label.

Features of installation of expanded polystyrene

Extruded PPS is a high density foam material. It is with this indicator that it differs from ordinary polystyrene - foam. The density increases during the production process when passing through the extruder, this seriously increases the thermal insulation characteristics of the material. The resulting slabs are composed of polymer and fine air bubbles.

Due to their smoothness, EPSP boards have very poor adhesion to the adhesive composition. This is the main problem with gluing. It is solved by the selection of special adhesives, which themselves have high adhesion to any surfaces. Also, some products can partially dissolve the foam top of the boards, soaking into them.

The specifics of the installation of expanded polystyrene plates are as follows:

- if the material is purchased as insulation for the floor, it is laid on an expanded clay pillow or on a gasket made of other low-density material and poured with concrete;

- to insulate the foundation, the slab must be glued to the concrete of the basement and secured with mounting fasteners;

- the material is laid on the roof, then a layer of bitumen is placed, or a PPP is laid between the ribs of the rafters inside the layers of the roof;

- when insulating the ceiling in an apartment on the top floor, lay expanded polystyrene from the attic on glue, then concreted or covered with crumbs, gravel, expanded clay.

Plaster and adhesive mixture

Such mixtures are suitable for gluing PPP to gypsum plasterboard, brick, concrete, cinder block substrates. They need to be bred by ourselves, since they are sold in the form of a dry mass. The composition includes mineral components, plasticizers, Portland cement, and a number of auxiliary additives. The mixtures are suitable for outdoor use and indoor decoration, they will hide all the unevenness of the base. The downside is the need for preliminary deep priming of the surface.

Ceresit CT-83

"Ceresit ST-83" is widely used for pasting the facades of buildings. It has excellent frost resistance, adheres well to wood, concrete, plaster, brick. After drying, ST-83 is breathable. Consumption per 1 sq. m is small, because it is enough to apply a mass of 1 cm thick (this is done with a notched trowel).

The company also produces high-quality Ceresit CT 85 glue, which is considered universal. High strength and ductility are due to the polymers included in the composition. But this tool costs an order of magnitude more expensive than the previous one, so builders prefer ST-83. Both materials are applied in intermittent stripes, slightly receding from the edge for better air release.

Bergauf ISOFIX

Bergauf Isofix glue is a mixture of minerals, fillers, cement, sand, plasticizers, special additives. It is used for any premises and for outdoor use. Average consumption - up to 5.5 kg / sq. m, a thin layer (3 mm) is required. After dilution, the mixture is viable for 1.5 hours, it is possible to change the position of the slab on the wall within 25 minutes. The glue is sold in bags of 25 kg, it can glue extruded polystyrene foam with all types of surfaces.

Manufacturers

Thanks to modern technical capabilities, products of a huge number of manufacturers for repair work are presented on the shelves of building supermarkets. These products are represented by well-known world brands and domestic firms.

Knauf

Knauf remains in the list of leaders in the production of construction products. Many experts prefer this particular product. The adhesives presented by the company are of excellent quality with a minimum consumption level during the installation of drywall.

The main advantages of German products are:

- guarantee for all types of goods;

- small rock shelf life of mixtures;

- excellent compatibility with gypsum board made by other manufacturers.

Volma

The plaster mix of the Volma brand is also in demand. It has the best plasticity characteristics of the material. This series is more affordable than the German Knauf PerlFix products. But the consumption of the adhesive is about the same.

"Titanium"

The series of universal adhesives "Titan" is very popular in the Russian construction market. The product has good adhesion. It is compatible with many materials including drywall.

Henkel

Henkel manufactures a line of Ceresit brand building adhesives. The mixtures are popular in Europe and the Russian market due to their high quality products. For drywall, Ceresit CM 11 glue is used, which is recommended for installation in rooms with high humidity levels.

Peculiarities

Mounting adhesives used in everyday life are most often used for fixing mirrors, baseboards, wall panels, window sills and various building structures.

They are designed for gluing products from the following materials:

- plastic;

- glass;

- expanded polystyrene;

- metal;

- drywall;

- ceramics and polymers.

6

Photo

The main features of assembly adhesives include the following:

- high rates of adhesion to any materials;

- rust resistance;

- excellent strength - depending on the modification of the composition, the indicator reaches from 14 to 80 g / cm²;

- ease of use - no need to purchase additional tools and equipment;

- weak non-toxic odor in most types of formulations;

- fast "setting" of the fastened products;

- economical spending.

When using liquid nails, repair and construction work is carried out without dust and dirt. Most of these formulations are manufactured in accordance with GOSTs, which allows the consumer to purchase quality products.

In order to make durable repairs using glue for installation, it is important to know what types of materials manufacturers produce, how to choose the right tool for specific types of work

Types and description

On the shelves of hardware stores, you can purchase several types of TekhnoNIKOL polyurethane foam:

- 500 Professional;

- 70 Professional;

- synthetic polymer adhesive for expanded polystyrene boards.

Glue-foam 500 Professional is a modern universal fixing solution for installation of heat-insulating sheets made of expanded polystyrene.Scope - thermal insulation of walls, floors, roofs, foundations and plinths. This adhesive can be used to fix aerated concrete (aerated concrete blocks), sheets of plastic, drywall, iron and wood.

Technical features:

- adhesion period - 16 minutes;

- curing time - 1 day;

- colors - light blue;

- high fire level;

- temperature regime for installation - from 0 degrees to +40 degrees.

Polyurethane foam 70 Professional is a fixing composition consisting of one component in an aerosol can, which has an improved formula to increase the volume of foam output.

Advantages:

- high percentage of primary expansion;

- large volume of composition output;

- fire resistant;

- high adhesion rates.

The TechnoNIKOL trademark produces two types of these products:

- all-season;

- winter.

Technical parameters of all-season foam:

- density - 30 kg per 1m3;

- adhesion period - 11 minutes;

- curing time - 1 day;

- temperature regime during work - from -10 degrees to +35 degrees.

Features of winter foam:

- density - 30 kg per 1m3;

- the beginning of hardening - 10 minutes;

- full adhesion period - 24 hours;

- temperature regime during work - from -18 degrees to +35 degrees.

Polyurethane adhesive is a special type of mortar for fixing expanded polystyrene sheets, XPS boards, ceramic tiles, polystyrene foam. The base component is polyurethane, which releases isobutane after reaction with air.

Specifications:

- setting period - 20 minutes;

- color - gray.

Before applying the foam, a surface degreasing cleaner must be used.

Tips & Tricks

Before gluing drywall to walls and ceilings, surfaces should be properly prepared. It is necessary to remove wallpaper, paint, peeling plaster. It is necessary to sweep away dust from the walls, ceiling, it is better to vacuum it. For better adhesion of the glue to the surface, it is primed. Immediately before pasting, the surfaces are moistened with water using a spray bottle.

The choice of adhesive depends on the condition of the surface to be smoothed. For smooth walls, choose foam glue that has a small coefficient of expansion, for example, for expanded polystyrene. In case of significant defects, foam is used that can fill the cracks and recesses in the wall.

It is necessary to accurately calculate the amount of glue applied to the wall or sheet so that it does not squeeze out between the joints and complicate their further sealing. It is impossible to lay electrical networks in the polyurethane foam due to its high flammability. In addition to igniting, when heated strongly, it gives off a large amount of toxic gases.

2> How to choose?

To make the right choice when buying drywall glue, you should take into account the type of surface you need to work with. More often, specialists have to work with concrete, brick walls

Sometimes in the work you have to deal with penoplex, which insulates surfaces. Gypsum plasterboard is glued to the penoplex using a gypsum composition. Brick walls, aerated concrete, aerated concrete and shell rock suggest the installation of gypsum plasterboard sheets on a gypsum mortar. This option is the most economical and effective, since on average 5 kg of the mixture will be needed per 1 m2.

For concrete foundations with a minimum curvature, it is recommended to stop at one of the following options:

- polyurethane foam;

- gypsum glue;

- cement composition for tiles;

- putty on an acrylic or gypsum base;

- polyurethane adhesive.

To glue drywall sheets to polystyrene foam, acrylic putties and glue foam are suitable. You can glue the gypsum board on a plasterboard surface with almost any type of glue. However, for a small seam between the materials and maximum preservation of the area of the room, it is worth using a silicone compound or liquid nails.You can use silicone sealant or tile adhesives to adhere tiles to drywall in your kitchen or bathroom. If you have to work with window slopes from gypsum plasterboard, most experts advise to glue the surfaces together with acrylic putty.

Decorative ceiling elements will adhere better to the base if they are glued with liquid nails or synthetic glue (they will allow you to carefully attach the surface of the skirting board or baguette)

When choosing glue for work in large rooms, it is important to rationally treat the expense item, therefore, you should opt for mixtures in bags. Many people call gypsum plasterboard "dry plaster", because after the installation of the material, you can immediately start finishing work

Main manufacturers

When choosing an adhesive, it is better to focus on the brand of the already purchased drywall. One manufacturer of gypsum board and assembly mixture takes into account the peculiarities of materials during production, which gives an additional guarantee of the durability of cosmetic repairs.

Let's take a look at the products of the most popular manufacturers.

Knauf

Knauf-Perlfix

Knauf-Perlfix

Perhaps the most popular gypsum glue for gypsum plasterboard in our country is KNAUF-PERLFIX. It is used for interior finishing of concrete, brick and plaster surfaces. The advantages of this adhesive mixture include the ability to use on uneven surfaces, the use in the production of only environmentally friendly materials.

This glue is for 1 sq.m. holds the five-kilogram weight of the gypsum board.

Volma

Glue "VOLMA-Montage" for drywall

Glue "VOLMA-Montage" for drywall

VOLMA-Montage glue for drywall is sold as a dry mix. Its basis is gypsum with chemical and mineral additives. The special composition provides, according to the manufacturer, high water retention and adhesion, facilitates the preparation of the final product.

Volma mounting glue is used at temperatures from +5 to +30 for interior decoration in rooms with an average level of humidity. Suitable for gluing gypsum plasterboard on gypsum, brick, concrete and plastered surfaces.

Titanium

The dry building mixture TITANIUM, which consists of gypsum and modified additives, can be used for installing drywall on foam and aerated concrete bases. Also suitable for gluing gypsum plasterboard on gypsum, concrete, brick and plastered surfaces.

"Grabs" in 50 minutes. Consumption of dry mix per square meter is from 3 to 5 kg. (with the manufacturer's recommended layer thickness up to 3 mm.).

Henkel

For drywall, use CM 11 - tile adhesive

For drywall, use CM 11 - tile adhesive

This assembly adhesive is made on the basis of rubber and is characterized by fast "setting" (it takes half the time for gluing the gypsum board than standard adhesive mixtures). Also, Henkel glue can be applied at sub-zero temperatures (up to 12 degrees below zero). Wide and temperature range of use: from -29 to +60 degrees Celsius. Better known by the Ceresit brand, and for drywall they use CM 11 - tile adhesive

Polyvinyl acetate adhesives

Polyvinyl acetate is a transparent elastic polymer that is obtained by polymerizing vinyl acetate. Such glue is considered universal, since it can hold together any hydrophilic materials. These adhesives do not rot, they prevent the appearance of fungus.

"Moment Joiner"

Universal polyvinyl acetate adhesive, widely used in renovation work. It is packed in containers of 0.1-30 kg, so you can easily select the required weight. "Moment Stolyar" dries quickly, does not corrode surfaces, and holds the expanded polystyrene sheets very reliably.

PVA-MB

Do not confuse the product with ordinary PVA glue. This material is a reliable polyvinyl acetate emulsion with a number of plasticizing additives in the composition. PVA-MB dries slower than Moment, but the seam is considered to be stronger. You should not buy too cheap adhesives, PVA is often counterfeited.

Recommended manufacturers

The most popular among consumers are building materials from German companies with a high reputation.

"Knauf"

The German company "KNAUF GIPS KG" was founded in 1932. The headquarters is located in Northern Bavaria (Iphofen city). Currently, the company is the world's leading manufacturer of gypsum-based building materials and components for work.

Volma

Russian manufacturer working on its own raw material base. The headquarters is in Volgograd. The leader in the production of gypsum boards, dry building mixtures in Russia and the countries of the Eurasian economic community.

Henkel

German chemical company specializing in the production of cleaning and adhesives. The headquarters are located in Düsseldorf. Subsidiaries operate in 70 countries, with a total of 340 enterprises.

Criterias of choice

In order for the result of the repair to meet expectations, it is necessary to take a responsible approach to the choice of mounting adhesive. When choosing the optimal composition, you should take into account a number of important recommendations from professional builders:

It is worth paying attention to the components contained in liquid nails. The presence of toluene or acetone indicates a toxic, pungent odor

Such materials can only be used in well-ventilated rooms or outdoors. The chalk in the composition will tell about poor adhesion, therefore it is better to refuse from these adhesives, if necessary, to fix heavy elements.

It is necessary to clarify the information about the initial setting time: for some products it can be up to 30 minutes

Such compounds will not work if instant adhesion is important in the work.

- When carrying out repairs in the kitchen, bathroom, bathrooms or other objects with high humidity, you should give preference to moisture-resistant materials.

- If you need a mirror mount, you need to refuse to purchase adhesives with corrosive components.

- For heavy structures, it is recommended to choose special purpose liquid nails.