Preparation - in what conditions and at what temperature to glue the film oracal

It should be borne in mind that the physical properties of the film depend on the temperature conditions in the room. Ideally, work with Oracal should take place at a temperature of + 10-30 degrees. At low temperatures, the film loses its elasticity, at high temperatures it becomes too soft.

Temperature requirements also apply to the surface to be glued.

Moreover, to achieve the best result, it is recommended to expose the film to temperature changes no earlier than 24 hours after the end of the work.

Before applying the film, the surface must be cleaned of dust and dirt and must be degreased. Too aggressive or oily solvents are not suitable for these purposes. Ethyl or isopropyl alcohol is preferred, and regular vodka will do.

You should also clean up all the smallest protrusions and irregularities on the surface to be pasted, since they will all be visible under the film.

To carry out work on rolling vinyl film, you will need the following tool:

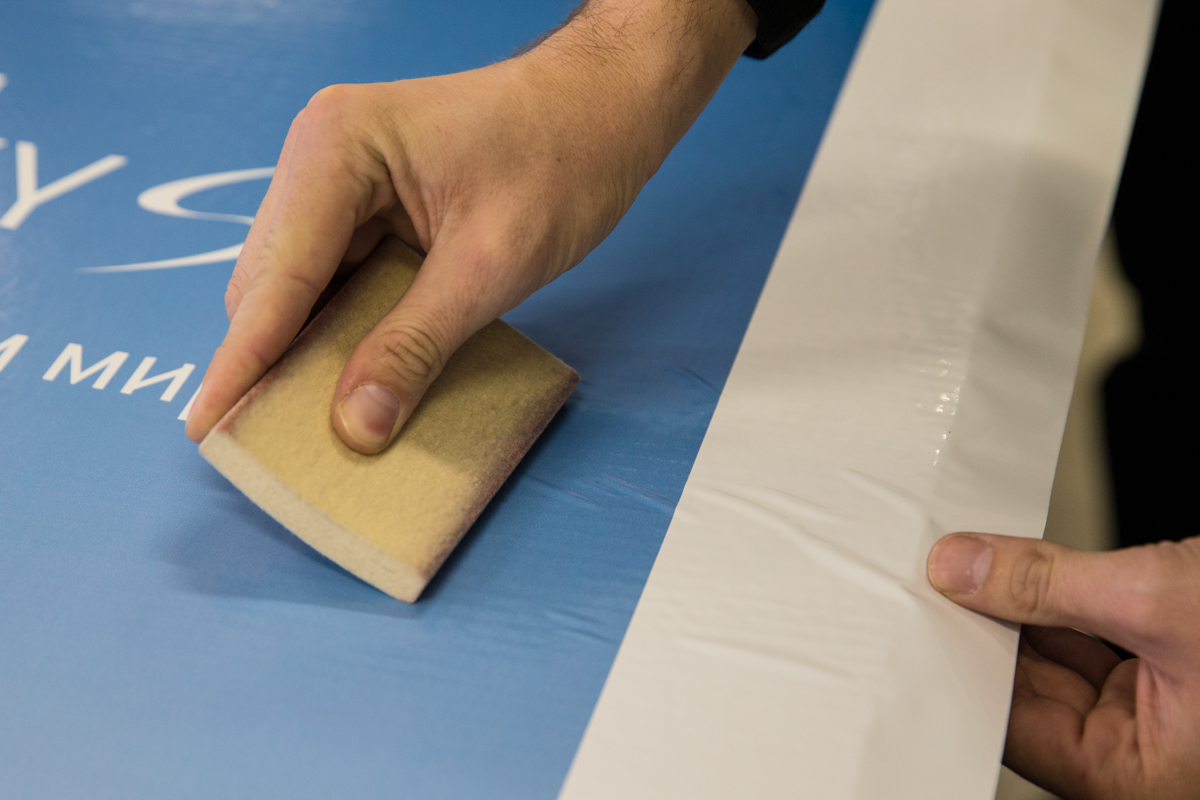

- squeegee - a plastic, rubber or felt squeegee for the application of films,

- stationery knife with replaceable blades,

- household water spray.

Correctly glue the oracle on plastic and glass - step-by-step instructions

There are two ways to apply vinyl film:

- "Wet" (with water);

- "Dry" (without water)

Experienced craftsmen work with "dry" technology. This is a more reliable way, but to glue the oracle smoothly and without bubbles, you need skill.

For beginners, we recommend that you first fill your hand, adopting the "wet" method, since it allows you to move the film over the surface during work, adjusting its position.

Detailed instructions for gluing the oracle to plastic, glass or other smooth surface using water:

- We clean and degrease the surface to be pasted;

- We cut out the film, leaving 2-3 cm in reserve on each side;

- Using a household spray, evenly apply a small amount of warm water or a mild soap solution (water + 2% liquid soap) to the work surface;

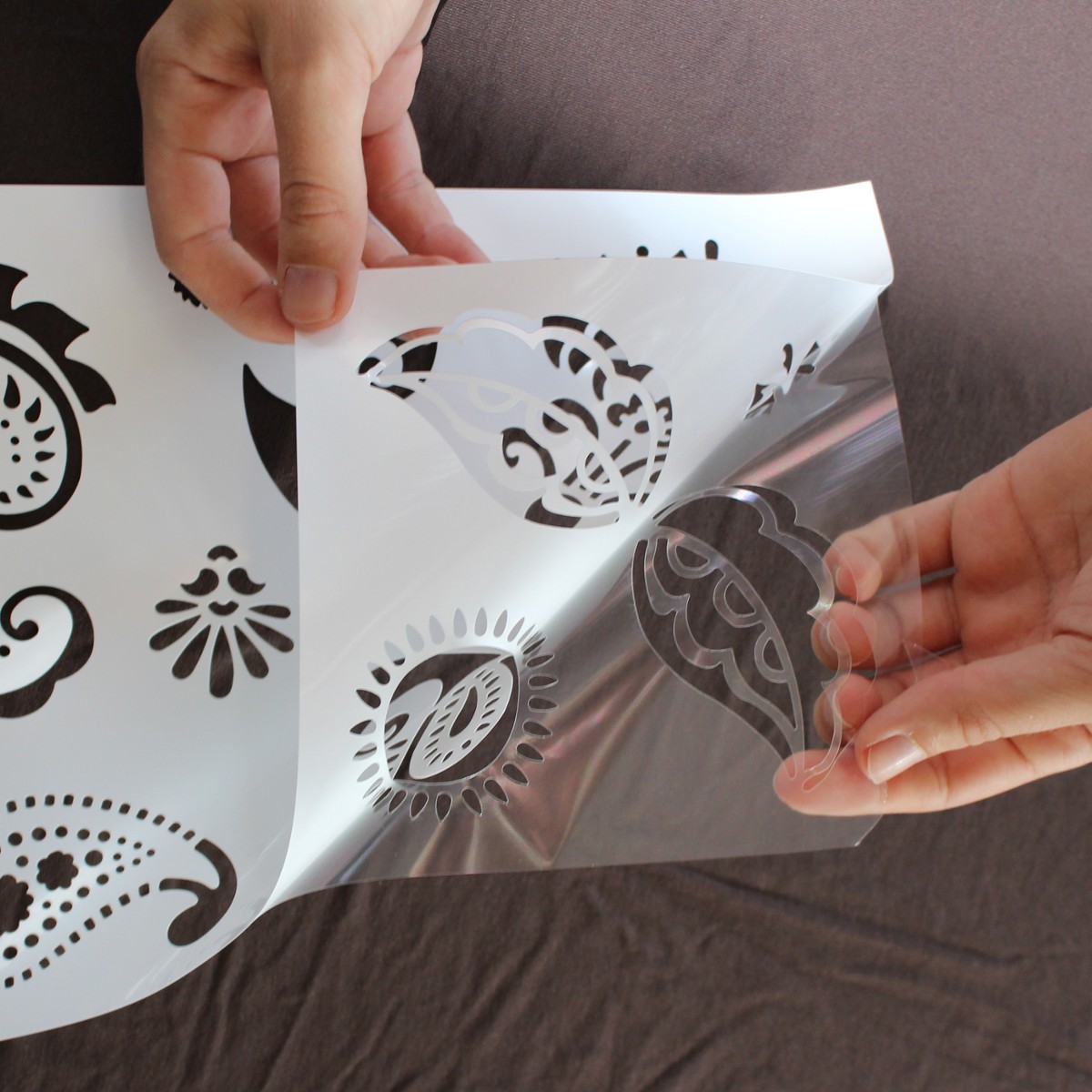

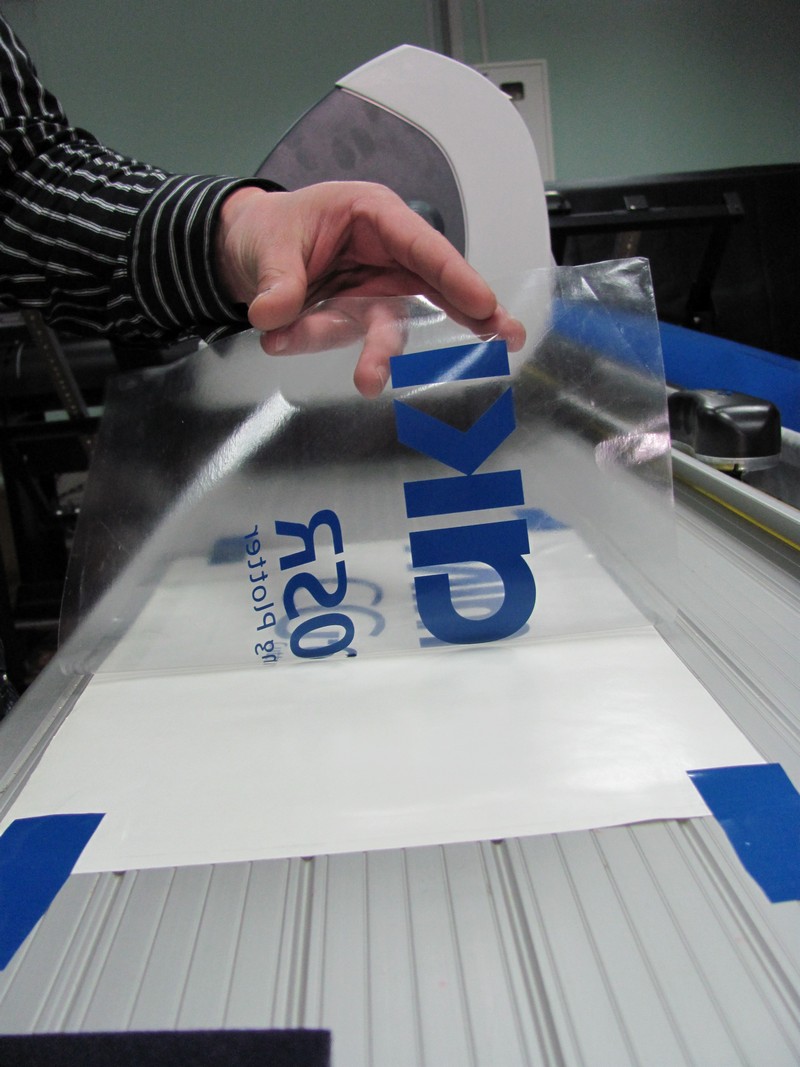

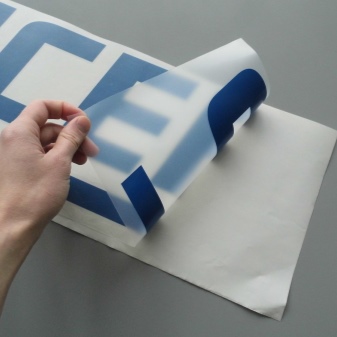

- Carefully peel off the backing of the film, while sprinkling the adhesive base with soapy water;

- We apply the oracle to the damp surface so that the film lies as flat as possible;

- Correct the position of the film if necessary. The final result depends on the accuracy of this operation;

- Moving from the center, we expel liquid and air bubbles with a squeegee to the edges, holding the material. This is the most crucial moment, so you should be extremely careful, smoothing movements must be done several times;

- If you use (have) the mounting tape, remove it with a smooth motion.

VIDEO INSTRUCTION

Important nuances - working with corners

On an industrial scale, the film is rolled onto large surfaces using special equipment - applicators. In this case, the film adheres perfectly evenly due to the uniform pressure of the roller.

When working by hand, special attention should be paid to corners and edges

So that the edges of the film do not peel off and wrap over time, several hours after rolling, it is recommended to carefully go through the squeegee again around the entire perimeter of the oracle, applying proper effort.

Some useful tips for rolling on self-adhesive:

- If, when smoothing the film, it is not possible to expel the air bubble, it is not necessary to press with force, it is not necessary to deform the oracle. It is enough to pierce a small hole next to the bubble with a thin needle and expel air through it.

- When choosing an oracle, it should be borne in mind that cheap films for the most part do not differ in high density. If the self-adhesive is very thin, all defects of the glued surface will be visible under it (scratches on the metal, stains, wood texture, etc.).

- Small radii and slightly convex surfaces are recommended to be pasted over with heated foil. For these purposes, you can use a regular hair dryer.

- The time for pasting can be shortened, and the quality can be improved if an assistant is connected to the work.

Peculiarities

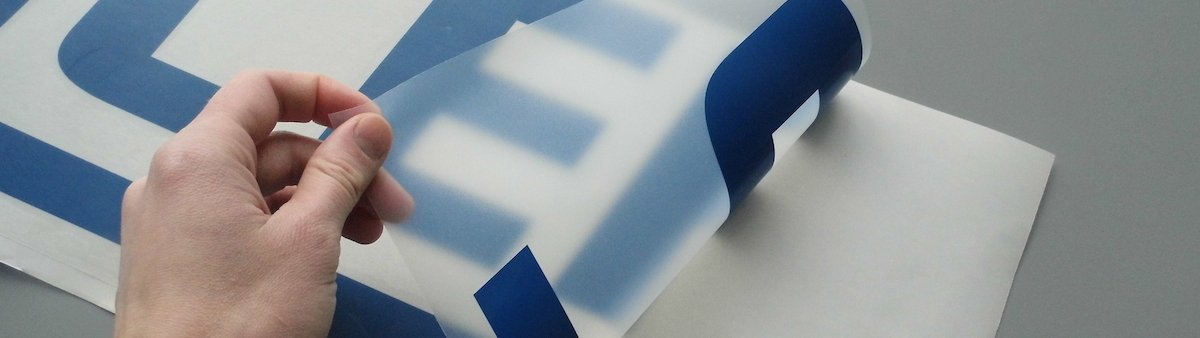

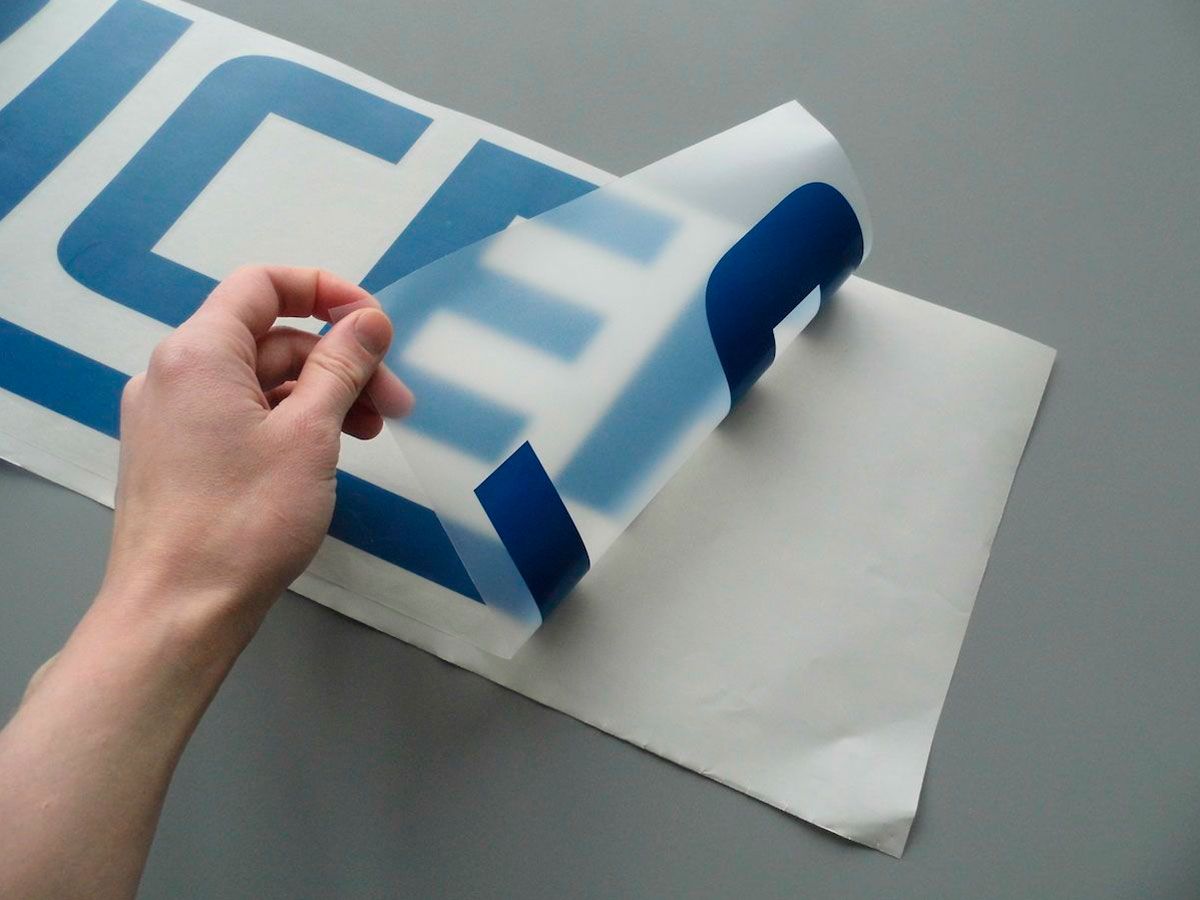

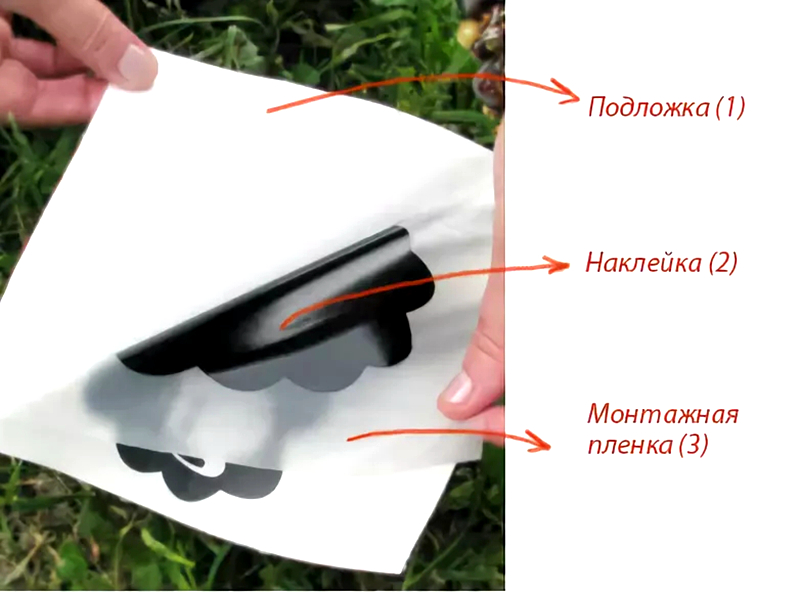

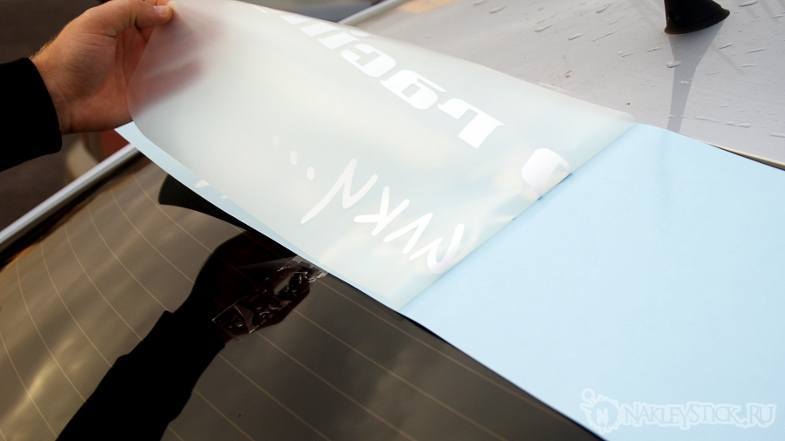

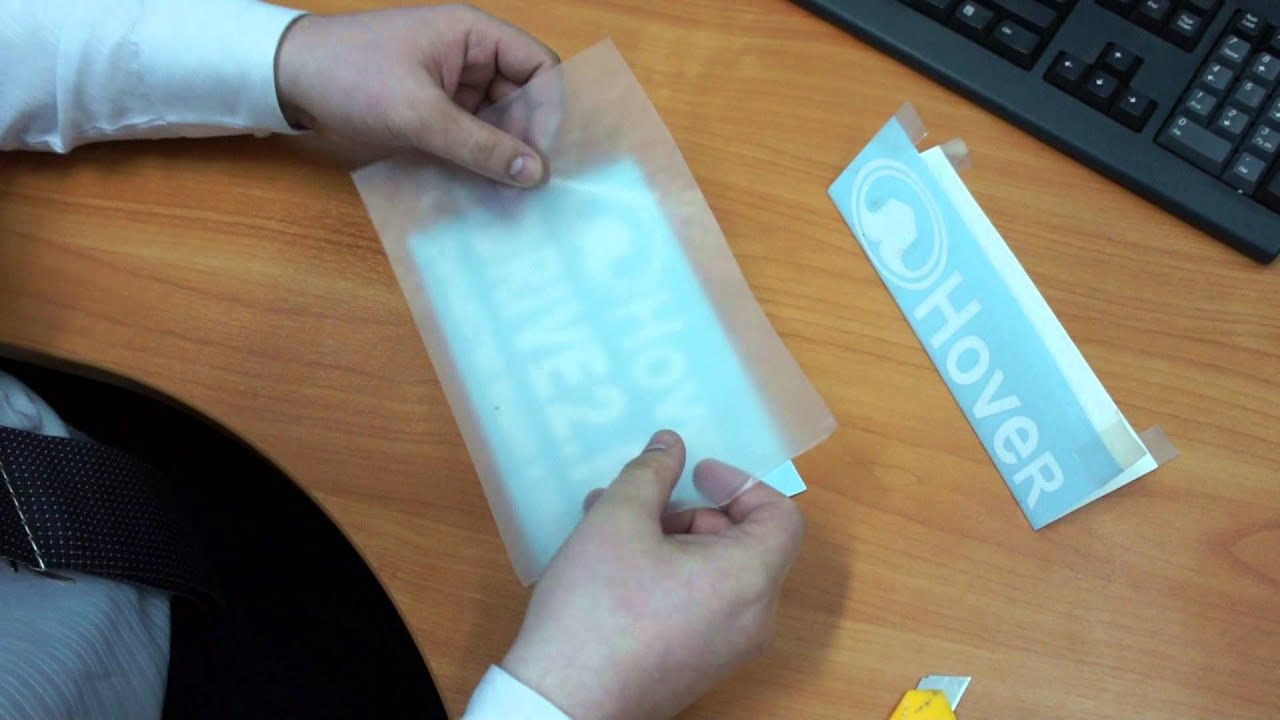

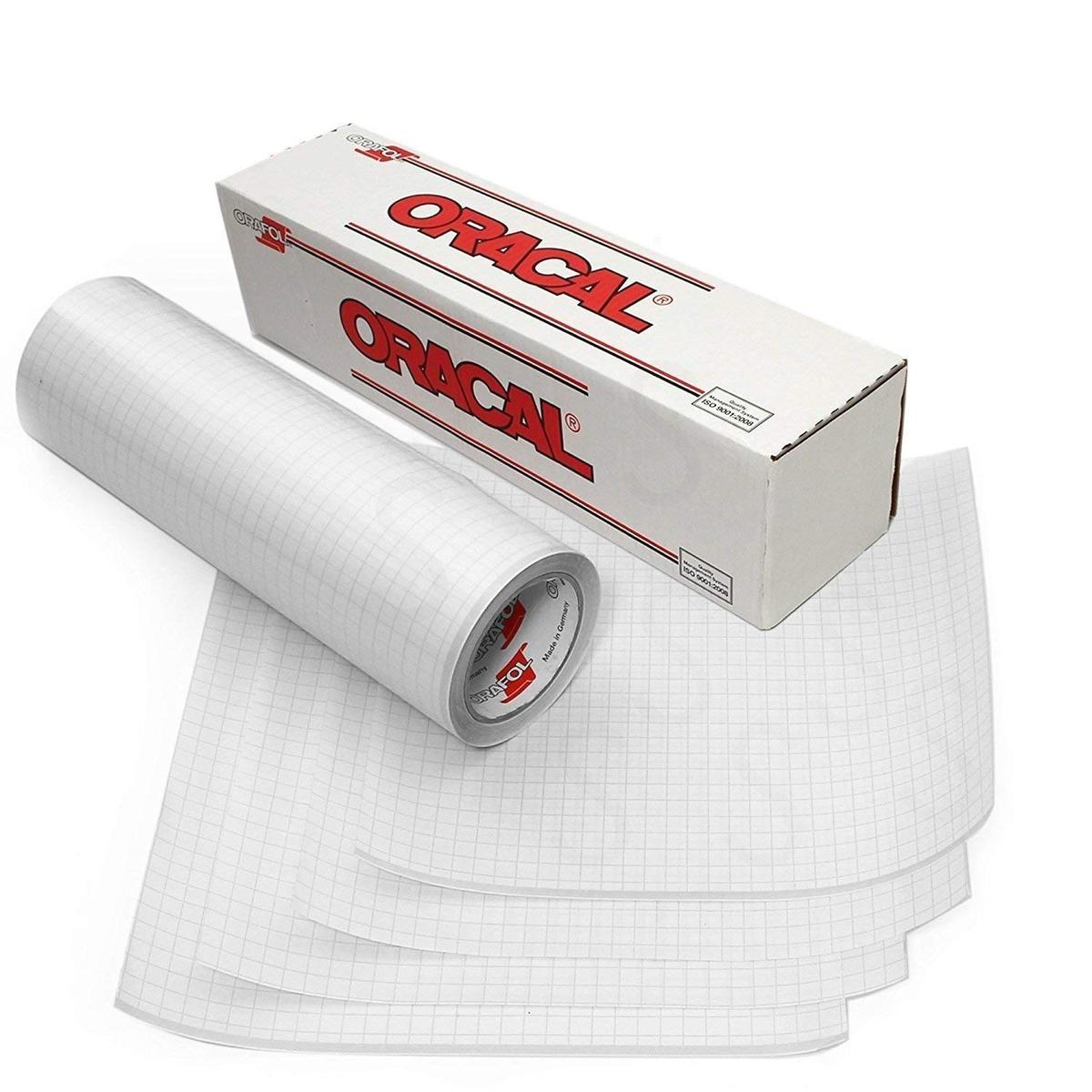

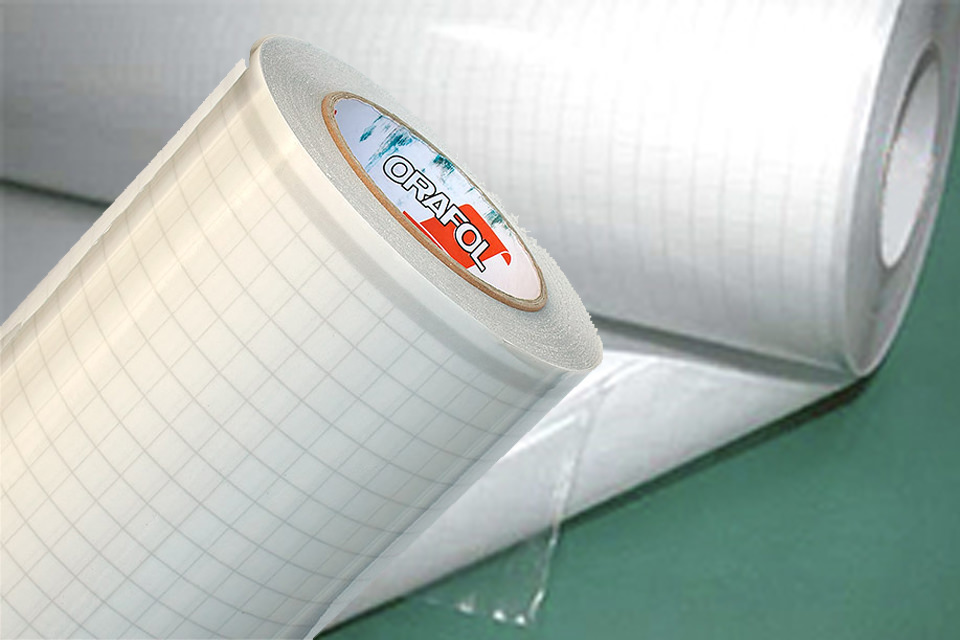

Mounting film is the type of product that has a layer of adhesive. It is used when transferring cut images from a substrate to a base, for example, glass, showcases, or a car. This product makes it much easier to design stickers with small details for advertising. With mounting tape, the craftsman can easily glue any applique, even on an uneven surface. In addition to all of the above tasks, transport film is able to correctly distribute image elements, as well as protect them from displacement and stretching.

The mounting tape must always have adhesiveness so that the separation of the PVC layer from the backing is neat and not accompanied by difficulties. Compared to paper, this product does not curl, so it is ideal for graphics that require dimensional stability.

Features of the stained glass canvas and its application

The structure of the film traps the sun's rays in different ways, depending on the material. It can be in the form of a colored stained-glass film, or quite light with a delicate openwork pattern.

The film coating is reliably preserved on the surface due to the special polyethylene "Mylar", which is a transparent bonding element and allows the canvas to adhere firmly to the glass and save its configuration.

Thanks to this "protection", when hitting the glass does not fly apart in different directions. In this regard, the film for stained glass is often used in the transformation of design, decorating doors between rooms, as well as on glass partitions.

There are many varieties of such a canvas, and each of this series is used in several compositions. For example, experts advise applying matte stained glass film to glass doors and shower cabins.

Colored materials look great on windows, and light films with a light pattern transform simple mirrors into graceful decorations, forming a real imitation of an ornament.

Patterned stained glass film stands out for its waterproofness, which is why it is often used on the partition in the bathroom, as well as matte white stained glass film is used on the doors of shower cabins.

In the summer, to protect from the hot sun rays, one of the popular and inexpensive ways is to glue the decorative material onto the glass.

To reliably know how to decorate windows on a loggia with stained glass film, you need to take into account that these coatings are divided into four types, and which one to choose depends on the taste of the owner. Depending on how to stick the stained glass film, inside or outside, the illumination on the loggia will be determined.

Stained glass film on wooden doors is a design that allows you to make a certain compositional style and achieve the greatest balance in the interior.

As you can see, the use of stained-glass film canvas is diverse. It can be used both on windows and on partitions and doors. But wherever it is used, after its application, the interior in the room changes dramatically. With the help of films, you can make truly extravagant compositions, counterfeiting stained glass technology at the lowest cost.

Watch the video, which tells you how to stick stained glass film on the window and what you need to do this:

How to use?

In order to obtain a high quality sticker, the first step is to prepare the surface by making it clean, smooth and free of grease. Initially, the surface is washed with clean water, after which it is dried. Next, it is worthwhile to deal with its degreasing.

For the gluing process, the master should prepare the following inventory:

- squeegee;

- a piece of dry, clean cloth;

- simple pencil;

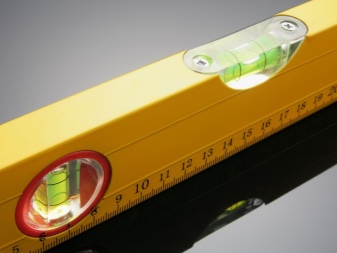

- building level;

- stationery knife;

- scissors;

- masking tape;

- a needle;

- sprayer filled with warm clean water.

The execution of the work consists of several stages.

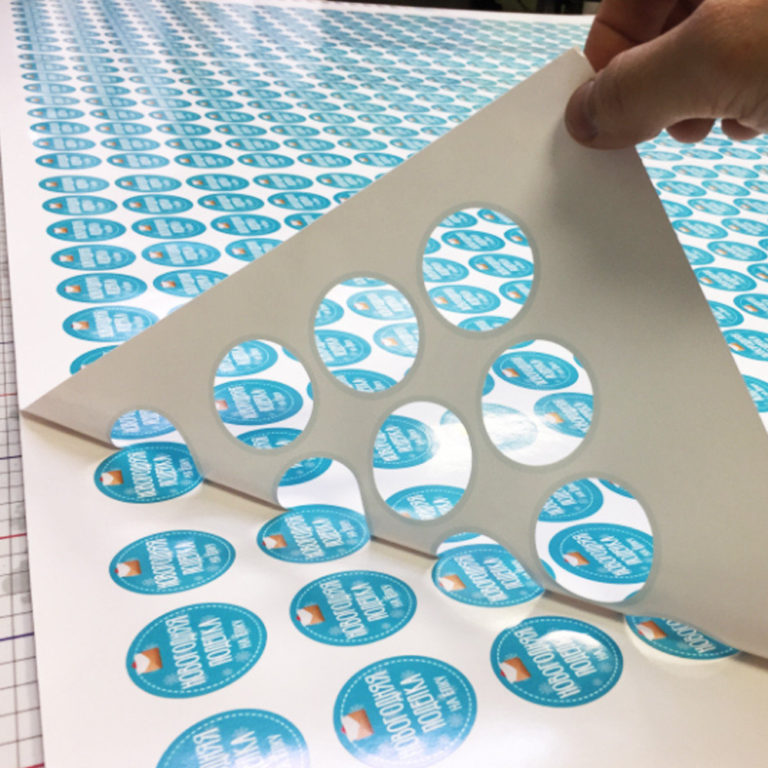

- The sticker must be applied to a clean surface and then fixed. Use a simple pencil to mark the correct borders of the picture. To horizontally and vertically align the decal, use a simple level.

- It is necessary to separate about 70 mm of the film with the image from the substrate. The area of the product must be applied to the marked place and smoothed from the center to the outskirts. If the size of the sticker is small, then it can be peeled off and glued completely.

- The used film should not be thrown away immediately, as it can be useful for gluing small elements of the sticker that did not fix properly.

- After completing all the above activities, it is necessary to re-iron all parts of the picture, thereby checking the quality of the work performed.

To maintain good image quality, experts recommend not to wash the sticker for several days, and also not to forget the following rules:

- prevent the appearance of bubbles;

- do not stretch the picture;

- use a vinyl roller to smooth the surface after gluing.

Mounting film is an irreplaceable material for gluing pictures and stencils on different types of surfaces. Consumers should choose the right product and not skimp on quality.

For information on how to use the mounting tape correctly, see the next video.

Criterias of choice

The mounting film is in the form of a thin polymer material equipped with an adhesive base. When choosing a product, it is recommended to give preference to the manufacturer whose product is well adhered to the vinyl trimmed tape on one side. In addition, a film is considered the best option, which can be removed without problems.

The transport film with a paper backing is in the form of a vinyl film. This product is characterized by the presence of a siliconized cardboard core. Transparent tape is easy to apply and is considered the best choice for projects with small characters and images. If you have a limited budget, you can buy mounting film without a backing, which is inexpensive.

The most popular application products for transferring images include the products of several popular brands.

- Avery AF 831. The film from the German manufacturer is characterized by transparency, stability and ease of embossing on the backing. Due to the rigidity of the material, the product does not create difficulties in use. However, at the same time, consumers note that at low temperatures, the film can break.

- Oratape MT-95 is one of the best assembly films produced in Germany. The product looks like an almost transparent non-toxic material with a yellowish tint.

- TransferRite 1910. Unlined film of this type is manufactured in the USA. Good transparency and optimal rigidity are inherent in the product. Budget material is difficult to stretch, but it cannot be reused.

- The R-Type AT 75 is a linerless conveyor belt. The material is characterized by good external embossing and a whitish shade. Due to the presence of the adhesive layer, the film can be used repeatedly. The disadvantages of the product are high elasticity and the ability to curl after removal.

- FiX 150TR and FiX 100TR - these products are manufactured in Ukraine.The film is in the form of soft polyethylene with an adhesive base. Due to its high elongation, the tape should not be reused.

Since at present a large number of companies are engaged in the sale of mounting film, the consumer may have difficulties with the choice of this product.

Material features

For even greater convenience of working with such material, it is processed during manufacture with an antistatic agent. The film, intended for showcases and billboards, has a solvent base for greater paint durability and a more colorful image (up to 3 years warranty).

For even greater convenience of working with such material, it is processed during manufacture with an antistatic agent. The film, intended for showcases and billboards, has a solvent base for greater paint durability and a more colorful image (up to 3 years warranty).

Scope of application

Despite the fact that the film for laser printer or inkjet is expensive, the limitless possibilities of this direction and the impeccable quality of the finished image make it more and more popular.

The most common areas where images applied by a printing or copying machine to film are successfully used:

- making slides;

- printing of advertising materials;

- production of color separation forms;

- for raster and hatch projects;

- creation of original layouts;

- for transferring pictures to dishes, fabric, various computer devices, any surfaces (magnets, rubber, etc.);

- decoration of cars and motor vehicles using aquagraphics;

- showcase decor;

- production of posters, billboards, signs;

- issue of stickers, labels, stickers, etc .;

- transfer of temporary body tattoos;

- production of protective stickers, warning stickers for office equipment, etc.

The basis for the adhesive films is kraft paper with a silicone coating on one side and an adhesive, water-soluble layer on the other.

In the manufacture of advertising slates and presentation materials, a two-layer film is usually used, it allows you to use one side for applying an image on pigment printers, the other on inkjet printers.

The film intended for stickers and similar products is produced with a special adhesive coating, due to which the paint adheres very well, provides accurate color rendition and even borders of the picture. The image does not fade, does not spread, dries very quickly. Most often it is suitable for use with pigment and water-borne paints. Naturally, they are heat-stabilized and treated with an antistatic agent.

It is important to select the correct type of film for the printer you are using. Then the clarity of the picture, the realistic color reproduction and the quality of adhesion to the toner will cause a real delight.

When choosing a printer and film, you need to take into account the printing method and temperature conditions.

Varieties of films

According to their properties, they are conditionally divided into the following groups:

- one-, two-sided;

- matte, glossy;

- transparent, opaque, translucent;

- white and colored;

- self-adhesive and non-adhesive;

- waterproof and without resistance;

- siliconized and with other types of special coatings;

- thermal transfer and for printing at normal temperature, etc.

The most popular among users of transparent film for the printer is produced by very many manufacturers, both little-known and mega-popular, such as LOMOND, XEROX, WWM.

The produced film can be used in inkjet and laser printers and apparatus, in color and black and white. There are universal options and special ones, only for laser or inkjet printing.

Thin film (up to 100 microns) is designed for technologies with normal temperatures, and everything thicker than 125 microns can be used for thermal printing.

In free sale, usually A4 film size is found, roll versions (1.05, 1.60 m) or large-format versions are sold in specialized stores. Custom-made material of non-standard width and any type of winding.