Manufacturers

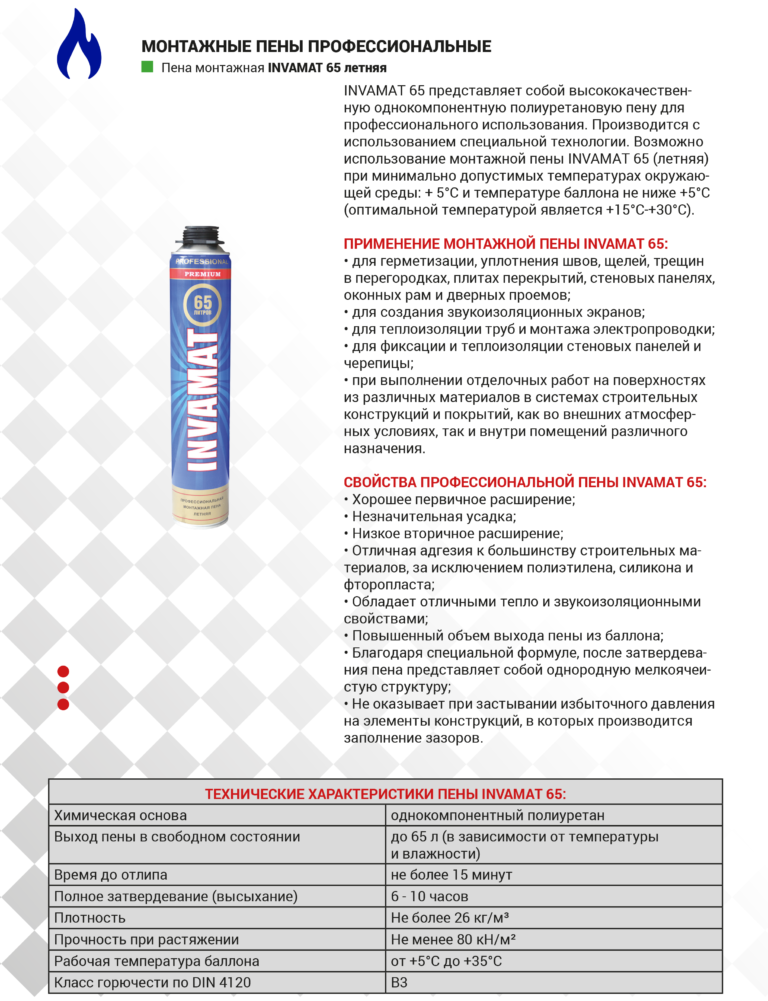

The presence of a large number of manufacturers contributes to the appearance on the market of an abundance of polyurethane foams with different characteristics. For example, DF foam (article number DF1201) is classified as combustible with a fire resistance of 150 minutes. It has a pink color, packed in a 0.740 liter can. At the exit, it forms about 25 liters of foam.

Unlike DF foam, CP 620. This material is thermally expandable, two-component. The foam output is 1.9 liters. It is used in hard-to-reach places and where it is necessary to create reliable insulation from smoke, steam and water. It is used for insulating cables.

Nullifire - professional foam with a red tint, has the highest fire resistance class B1. The period from the moment of exposure to open fire to fire is 4 hours. Formed on modified polyurethane and non-combustible gas.

It is used in the arrangement of chimneys, pipe and cable wiring, fire doors. It adheres perfectly to all surfaces. The mixture yield is about 42 liters.

Hilti 660 two-component foam is used in a variety of applications. It is versatile, capable of protecting any penetrations from fire and smoke. Fire resistance is maintained for three hours. The thermally expanding mass is red and is supplied in 325 ml cartridges. The material yield is 2.1 liters.

Rush Firestop Flex 65 is a single component, moderately flammable foam. Differs in the uniformity of the mixture exit from the cylinder, high heat-insulating properties of the seams.

The scope of this composition is translucent structures. Used to seal building structures. Low adhesion to fluoroplastic, polyethylene and propylene. High adhesion to brick, stone, concrete, wood.

Estonian foam brand Penosil is designed for sealing and insulating joints of fire-resistant structures. The product is suitable for sealing tile roofs. The material retains its tightness when heated for three hours. Recommended for installation of fireproof doors.

Nullifire FF197 is a one-component mixture of flammability class B1. It is used for insulation, sealing, filling and insulation of joints and seams of fire-hazardous structures. Suitable for surfaces made of plastics, including foam, cable sheaths, plastic. Perfectly adheres to stone, concrete, metal, brick, wood.

Profflex is a Russian manufacturer. The polyurethane foam of the same name is intended for both domestic and professional use. The material is all-season, can be applied at sub-zero temperatures (up to -15 degrees).

Remontix is a flame retardant material with a flammability limit of 240 minutes. It hardens in 10 minutes, completely polymerizes after application in a day. Requires processing, as it is afraid of ultraviolet radiation. Output at a temperature of +23 degrees can reach 65 liters.

Winter polyurethane foam - at what temperature does polyurethane foam freeze? - 2 answers

Winter polyurethane foam

In the Construction and Repair section, to the question at what temperature does the polyurethane foam freeze? given by the author Fleur the best answer is that there are two types of foam, summer and winter. Summer foam is designed for freezing temperatures. Winter foam can be used at air temperatures above -10, in extreme cases -15. Foam polymerizes by absorbing moisture from the air, therefore it is recommended to wet the surfaces before foaming. Do not wet at subzero temperatures. But even if the foam is winter, it may not cure, even if the work was carried out in the range of temperatures indicated on the cylinder. And there are two types of non-polymerization of foam: this is frozen foam, when it will not keep warm and needs to be re-foamed, and canned foam, this is when the foam in frost has passed into a state of conservation before the onset of heat and continues the polymerization process when warming.Therefore, the conclusion: you should try to work with foam at an air temperature of at least -10 degrees, while heating the foam cylinder as much as possible (put it in a bowl of hot water for a while), before foaming, you need to shake the cylinder thoroughly, and everything will work out, it should not freeze Evgeny Sinyatkin-Novosibirsk Thinker (8641) Thank you!

2 answers

Hey! Here is a selection of topics with answers to your question: at what temperature does polyurethane foam freeze?

The answer from Interstillar took all-season today, and nifiga does not go

Answer from Ѐuslan Averchenko Here I am working, I need to foam the seams between the concrete slabs, the temperature outside (from -4 to -7) is no less, the frost is winter foam BUT the trouble is barely getting out I am suffering very much balloons prematurely warming up, tell me maybe something like a balon mono insulate, because it is clear that the balloon is freezing and the foam stops first expanding and then coming out completely otkazyvaetya! PS Balon is not an empty penalty as it should be upside down)) It doesn't look like a marriage! what to do so as not to suffer? Changing the brand of foam does not get penalties than they give.

Answer from Saint there is summer foam up to 0 degrees, there is winter foam up to -10 degrees ... windows cannot be placed at -30 =)

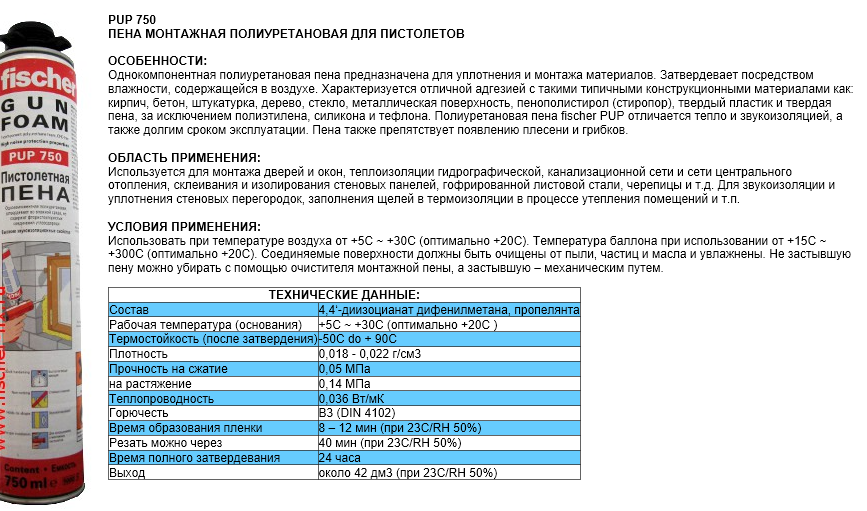

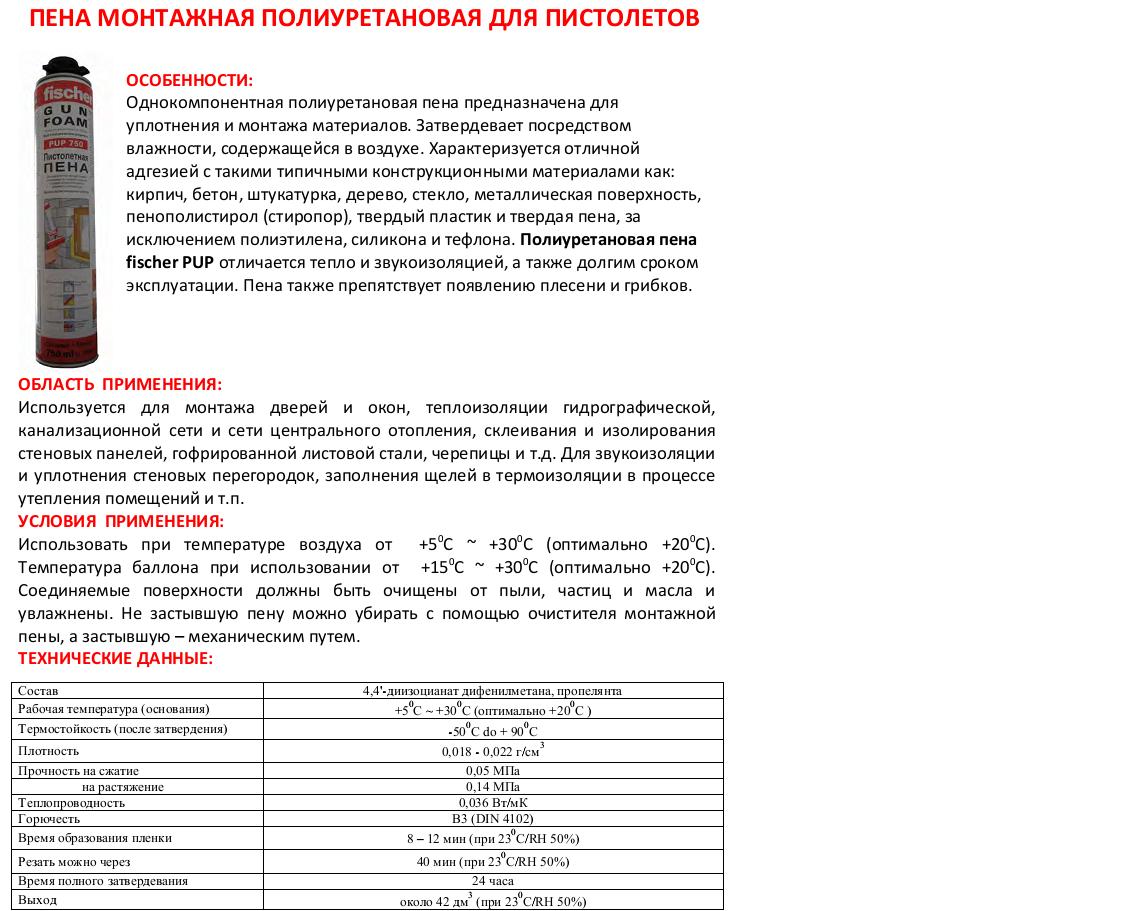

Answer from Ksyushik Savateeva Mounting foam standard 750ml-It is recommended to use at an air temperature not lower than +5 degrees. The foam surface dries up in 10-20 minutes. Fully cures within 24 hours. Heat resistance of the hardened foam from -55 to +100 degrees. Foam assembly std. winter 750ml-It is recommended to use at an air temperature not lower than -10 degrees. The foam surface dries up in 10-20 minutes. Fully cures within 24 hours. The temperature resistance of the hardened foam is from -55 to +100 degrees.

Answer from ValeryWorking T frost-resistant polyurethane foam -10. The decision on whether or not to carry out installation is made on site together with the window installer. An experienced installer keeps the window opening open for no more than half an hour. But whether he has this time or not, you decide , depending on the type and purpose of the room.

Answer from Just a grandfatherIn general, it should be written on the can at what temperature this foam can be used.

Answer from Kamil Volzhsky At what it freezes, such tests are not carried out. They are carried out for strength, moisture absorption, the presence of free pores, foaming time and tack-off time. This I mean that I do not know about it from the ceiling, I am an expert. Requirements for the use of foam - application temperature from +15 to +45 degrees.

Answer from Natulya At very low, because the installers will freeze! And as for the foam, there are frost-resistant ones - for low temperatures !!

2 answers

Hey! Here are some more topics with the answers you need:

Terms of use

Experts recommend adhering to several rules when working with polyurethane foam.

- Since it is not easy to remove foam from the skin, you should first equip yourself with work gloves.

- In order for the composition to mix, shake it thoroughly for 30-60 seconds. Otherwise, a resinous composition will come from the cylinder.

- For quick adhesion, the workpiece is moistened. Then you can go directly to the foam application. The container must be held upside down to displace the polyurethane foam from the container. If this is not done, the gas will be squeezed out without foam.

- Foaming is carried out in slots whose width is no more than 5 cm, and if more, then use polystrile. It saves foam and prevents expansion, which most often leads to structural failure.

- Foam from bottom to top with even movements, filling a third of the gap, because the foam hardens with expansion and fills it. When working at low temperatures, you can only work with foam heated in warm water up to + 40 ° C.

- For quick adhesion, it is necessary to spray the surface with water. Spraying at negative temperatures is prohibited, as it is impossible to obtain the desired effect.

- In case of accidental contact with mounting foam on doors, windows, floors, it is necessary to remove it with a solvent and a rag, and then wash the surface. Otherwise, the composition will harden and it will be very difficult to remove it without damaging the surface.

- 30 minutes after using the installation compound, you can cut off the excess and plaster the surface. For this, it is very convenient to use a hacksaw or a knife for construction needs. The foam begins to fully set after 8 hours.

Professionals recommend that you carefully read the precautions before working with polyurethane foam.

- The sealant can irritate the skin, eyes and respiratory tract. Therefore, it is recommended that the worker wear protective goggles, gloves and a respirator when there is poor ventilation. Once hardened, the foam is not harmful to human health.

- In order to avoid the purchase of fakes, you should use some recommendations: ask the store for a product certificate; examine the quality of the label. Since they try to produce fakes with minimal costs, the printing industry does not attach much importance. Defects of the label are visible on such cylinders with the naked eye: displacement of paints, inscriptions, other storage conditions; date of manufacture. Expired material loses all its basic qualities.

How to choose polyurethane foam for indoor and outdoor use

Quality products meet the following requirements:

- balloon weight - 850-920 grams (for 750 ml);

- high viscosity;

- low secondary expansion;

- high density after solidification.

The problem of choice is that the technical characteristics remain on paper - in fact, the quality often leaves much to be desired. On store shelves, you will find at least a few non-standard polyurethane foam. It happens that the composition uses gases that deplete the ozone layer. Actual cylinder weight may not correspond to stated net weight. Sellers do not hesitate to sell expired products.

The main criterion for the quality of polyurethane foam when performing work is its reputation in the market. It is difficult for an uninformed buyer to make the right choice. This is where the experience of others comes to the rescue. Today, the sealant market is represented by dozens of foreign and domestic companies. Moment, Macroflex, Tytan, Well, Penosil, Soudal, Dr. Shenk are just the tip of the iceberg. So which polyurethane foam is better? Two companies are most popular with consumers: Soudal and Penosil.

Soudal

Soudal is a large sealant company. It has been operating on the market for about 50 years. The production of polyurethane foams is a core business of the company. Soudal produces all types of foams, and the products are distinguished by low secondary expansion, good viscosity.

A large outlet volume (65 l) allows Soudal to be used for heat and sound insulation of a bathtub, insulation of an attic. It is waterproof, dense and odorless. The average cost of Soudal professional polyurethane foam is 300 rubles at an average market cost of 250 rubles (750 ml).

Penosil

Penosil is based in Estonia. This is the youngest company for the production of polyurethane foam, has been on the market for 18 years. It is engaged in the production of sealants, adhesives, cleaners and building materials. Like Soudal, Penosil manufactures its products for all types of work: winter, summer, all-season, professional, domestic and fire-resistant. It has good adhesion, it is suitable for the installation of PVC windows, joints between tiles and the bathroom, sealing cracks. The difference lies in the cost of production - the price for the Standard line is lower. Average cost of professional polyurethane foam Penosil - 285 rubles (750 ml).

Moment

Foam of the Moment brand is in high demand among domestic manufacturers. It is sold in a 750 ml aerosol and is intended for the installation of sound and heat insulation materials, PVC windows, doors, sealing cracks and cracks.

Compared to Soudal and Penosil, Moment has more modest characteristics. The maximum output volume for this brand is 45 liters, while for Soudal and Penosil it reaches 65 liters. The density of polyurethane foam Moment (750 ml) is no more than 28 kg / m³ versus 35 from Soudal.

Features and properties

Polyurethane foam is a substance released in an aerosol can.It contains a liquid prepolymer which is displaced from the cylinder by a mixture of gases. Thanks to this composition, the polyurethane foam, displaced from the container, foams and expands under the influence of moisture. Then, during the polymerization process, the product solidifies completely. The result is a fairly strong substance - polyurethane foam, which fills all the necessary cavities, seams and hard-to-reach joints. A fairly large amount of work can be performed with one cylinder, which is facilitated by a significant coefficient of expansion of the substance.

During the cold spring or autumn, the use of winter foams is mandatory. If the air temperature drops below +5 C, then summer foams are no longer suitable for installation.

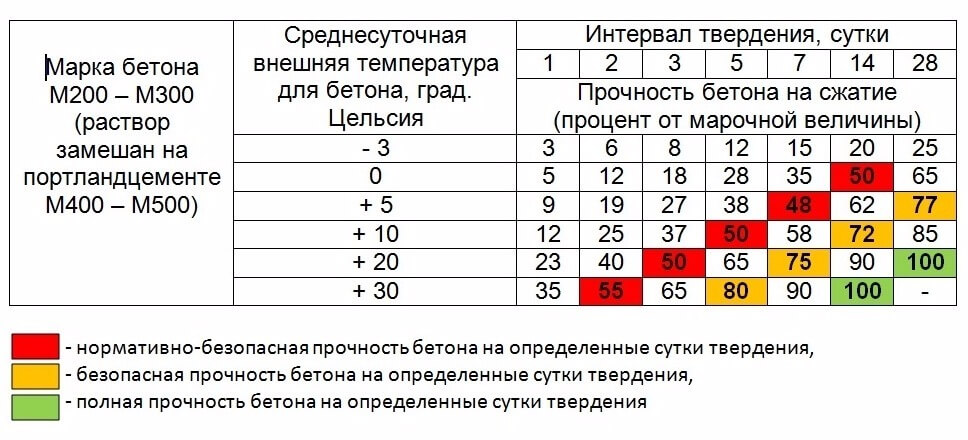

Material performance decreases with decreasing temperature. At negative temperatures, the amount of foam is reduced to a minimum. In addition, the layer may not harden properly, the substance during application will not be able to achieve the required consistency and will not form the required hermetic base. This problem can be solved by winter types of sealant, which ensure stable operation at temperatures down to -10 ° C. Therefore, in winter, it is necessary to use only special high-performance versions of polyurethane foam.

Winter polyurethane foam sealant differs from summer one mainly in the chemical composition of the propellant, the propellant, which makes the foam much more productive. According to the main characteristics, winter types of foaming sealants have the same adhesion and insulating properties as summer ones. At positive air temperatures, winter sealants work just as well, so they can be used in summer as well.

When using polyurethane foam, you should remember one important nuance. The curing time of polyurethane foam sealant directly depends on the ambient temperature and increases with each decrease in the degree

Experts advise not to proceed with further processing until the foam layer has completely hardened. In winter, this process takes longer than in summer. Failure to comply with the hardening time of the material leads to a deterioration in the properties of the polyurethane foam, as well as to a violation of the layer structure and dimensional stability.

It is interesting: Euro lining and lining "Calm" - differences and similarities

Terms of use and storage of polyurethane foam

Storage conditions for polyurethane foam and its use are quite clearly indicated by manufacturers. So, the use of this material requires a certain, moderate air humidity and a temperature range above zero, optimally from +5 ˚C to + 30˚C.

Even if the packaging indicates that the application is designed for all-weather conditions, it must be remembered that inappropriate humidity and temperature are factors that can affect the adhesion of the material to the surface and the curing time. For example, at temperatures below + 5 degrees, the quality of the foam will be cellular, transparent-bubble, when solidified, the color will be closer to brown, and the material itself will be brittle.

As previously stated, the ultimate factor in foam hardening is a certain moisture content. Thus, the application of water to the surface of the material and the foam itself from a spray can accelerate the formation of polyurethane - the hardening of the foam itself. The approximate consumption is 40 ml of water per 750 ml of the container with the mounting material.

It should also be remembered that a lack of moisture - can affect the hardening and lead subsequently, even after several months, to its expansion. And, conversely, high-quality solidified foam will subsequently be resistant to moisture, reagents, pests, but not to ultraviolet light!

You have probably already seen that fresh foam looks white, beige or light yellow, under the rays of the sun it turns dark yellow and soon begins to collapse, crumble, breaking the insulation, the tightness of the gaps and the durability of the built-in product (windows or ventilation, for example). This means that the assembled material also requires additional protection in order to serve longer and perform its insulating and insulating functions for a long time.

Most often, an unprotected layer of polyurethane foam begins to deteriorate within 1-2 years, maximum - four. To protect the foam layer, different methods are used - puttying (to choose from: frost-resistant plaster, liquid plastic or glass, putty), assembly tape (cheap, but ugly and short-lived), coating with paints and varnishes (acrylate compounds give good adhesion to this isolate) and protection other materials over the foam seams.

Foam shelf life

Storage of polyurethane foam has its limitations. The term for each manufacturer and type may differ. On average, the maximum shelf life is in the range of 1-1.5 years. At the end of it, the foam in the cylinder becomes thicker, becomes viscous, which makes it difficult to use.

When stored at subzero temperatures, the composition becomes more viscous, which makes it difficult to use, therefore, before use, it is better to hold the container in a warm room, warm it by placing it, for example, in warm (!) Water and shake it periodically. Heating by high temperatures is absolutely excluded - this can increase the pressure of the gas displacing the foam and lead to rupture of the package.

The expiration date is usually indicated from the date of manufacture, it can be viewed on the bottom of the cylinder.

How much material can be stored in a cylinder

Polyurethane foam is a chemical substance, and even in a cylinder, immediately after release, polymerization processes begin in it, viscosity appears, properties are gradually lost.

High-quality raw materials do not lose their properties even after the specified periods have expired, but the manufacturer no longer gives a guarantee for this, therefore it is better to use freshly acquired material that will have all the properties that it should have.

Since the very qualities of this material are based on the current chemical reaction, carefully choose a product - read the instructions before buying, check the conditions of use, the date of manufacture. All this will ultimately affect the result of the work performed.

at what temperature can be used, expansion, types, instructions

Use summer foam to install interior doors (this foam is used to fill the gaps between the frame and the doorway), windows in the warm season. It is also suitable for strengthening the shower tray, which is described in more detail in the article "How to strengthen the shower tray". With its help, it is easy to fill the excess space in the holes in the wall or ceiling, where pipes are laid (water supply, sewerage, heating). This type of foam is used to fix additions and to mount the portal around the entrance doors from the side of the dwelling.

Winter

Winter polyurethane foam is designed for a temperature range from -20 to +30 degrees. This foam is used to fill the areas between building blocks and openings even when the heating is not working and there are no double-glazed windows in winter. Foam dries within 24 hours. Use winter foam to install windows in the cold season or metal entrance doors if the staircase is not insulated.

Universal

This type of foam retains an acceptable viscosity at temperatures from -5 to +30 degrees. Freezes within 24 hours. Suitable for use inside an apartment and for the same purposes as summer foam (sealing joints between concrete slabs in the ceiling, sealing cracks in the wall), but it will also help out in the absence of windows and heating. Suitable for outdoor wall sealing.For example, during the installation of the air conditioner in early spring and the sealing of the drilled channels for laying the freon line.

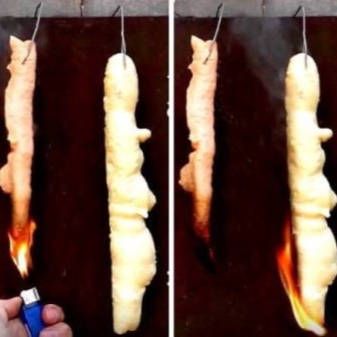

Fire resistant

Unlike the usual yellow polyurethane foam, the fire-resistant foam is painted pink or red. The sealant protects against open fire and smoke penetration. Capable of delaying ignition for up to 360 minutes. Fire-fighting foam is used where fire-resistant barriers are created (dividing buildings into zones in offices, shopping malls, hospitals, schools, etc.). In an apartment, it is suitable for the installation of individual heating and sealing the opening around the horizontal chimney facing the street from the boiler.

So, all types are used to seal openings and seal cracks, so when choosing foam, be guided by the ambient temperature during repairs in the apartment. Remember that polyurethane sealant dries up from direct sunlight, therefore, after hardening, it must be covered with plaster or add-ons.

Expansion coefficient of polyurethane foam

The polyurethane foam expands, which allows it to compact at the application site and provides an economical consumption. Primary or main expansion is a positive feature of the foam. The indicator varies from 20 to 65 liters. For example, the universal foam Ceresit Ts-62 from a 0.75 l bottle expands to 42 liters, and Tytan 65 (0.75 l) summer foam - up to 65 liters. The action takes place immediately, so you can immediately see by the occupancy whether additional application is needed or not.

Secondary foam expansion is a negative factor. Occurs over time and is not controlled. Such an increase in volume can lead to deformations of the structures (the door frame can bend inward, and the leaf of the sash will begin to wedge). High quality polyurethane sealants (eg Ceresit Ts-62 or Tytan 65) do not have secondary expansion.

Instructions for using polyurethane foam

Polyurethane foam can be professional and household. The first is applied from a gun and is suitable for reusable use (the valve closes the outlet from the cylinder, and the sealant does not freeze in it). You can work with this foam for a week. Household foam without a gun comes with a straw and must be used up immediately, otherwise the sealant will dry out.

Brief instructions for using polyurethane foam for beginners:

- Shake the can for 3 minutes to mix the polyurethane and filler gases.

- Invert and install the gun by turning the bottle neck clockwise.

- Use a brush to brush away debris from the gap or opening you will be filling.

- Moisten the area to be applied with water from a plastic spray.

- Bring the nozzle of the gun close to the slot and pull the trigger.

- Fill the space from the bottom up.

When using polyurethane foam for the first time, feed the material so that it fills the crack or joint between the boards by half. Monitor the expansion for a minute and then add foam as needed until the joint is completely closed. Polyurethane foam with a straw is applied in the same way. Hold the bottle with the valve down.

Types and technical characteristics

To obtain a reliable, tight seam, it is necessary to take into account not only the temperature regime, but also the humidity, the position of the working area, the width of the voids, and the amount of work. In order for the building material to cope with each task at hand, there are different types of it with certain fillers. Depending on the amount of work, foam can be:

- Household. Produced in small cylinders with a dispenser tube. Suitable for small repair areas, does not require additional equipment.

- Professional. It has a PRO article and is intended for a large installation volume. A special pistol is required to use it.

Seasonality of use:

- Winter. Designed for outdoor construction work at temperatures from -5˚С, high humidity.They have permissible lower temperature limits of use up to -60˚С.

- Summer. It is allowed to use indoors or for external installation in the temperature range from +5 to + 35˚С, humidity not more than 80%.

- All-season. The most versatile for outdoor work in harsh weather conditions. Permissible operating temperature from -10˚C to + 35˚C, relative humidity 75%.

By chemical composition:

- Two-component. The balloon is divided into two cavities: one contains the main composition, the other contains a polymerization reagent. Under pressure, both components are squeezed out and mixed directly in the tube. Opened packaging cannot be stored, therefore it is produced in a volume of no more than 220 ml.

- One-component. It is cheaper, has a shorter shelf life. The curing reaction takes place due to moisture and begins to take place already in the cylinder. Has a higher expansion ratio. After opening the package, it can be used several times.

By the degree of refractoriness:

- Category B I - non-combustible composition.

- Category B II - self-extinguishing when burning.

- Category B III - combustible.

Frost-resistant assembly foam for outdoor use has the following technical assumptions:

- Working temperature: from -10 to + 35˚С. Some materials remain functional at -30˚С.

- The coefficient of expansion of the volume of the working mass: usually this figure is 1/100. That is, from 100 ml. material in a cylinder can be obtained 10 liters. foam at the outlet.

- Porosity from 50 to 85%. The higher the porosity, the better the thermal insulation.

- Adhesive properties. Polyurethane foam materials have high adhesion to stone, wood, metal, concrete. Not suitable for Teflon and plastic substrates.

- The viscosity, the higher it is, the better the sealant holds its shape, does not drain from the base.

- Drying time. Depends on temperature and humidity. Winter foams set from 5 to 12 hours.

- Shrinkage should not exceed 5%.

Soudal

Professional polyurethane foam that can be purchased at most hardware stores. It has a low expansion and is suitable for thin joints where accurate application is especially important.

Soudal adheres well not only to brick or concrete, but also to metal or glazed surfaces. The tip is included, so the cylinder can be used not only with a construction gun.

Advantages:

- Dimensional stability;

- Uniform texture;

- Ease of application;

- Complete protective gloves.

Disadvantages:

Is not washed off.

Users note in reviews that they come across defective cylinders with a poorly working valve.

Fire-resistant qualities are especially important when applied in rooms with high temperature conditions: baths, factories, restaurants, nightclubs and other entertainment establishments. Flame retardants are added to their composition, imparting non-combustible properties to the entire composition. After analyzing this market segment, 3 leaders were identified that professionals prefer to buy.

This is interesting: Heat-resistant glue for metal - pros and cons

Winter foam - characteristics and application features

Since the expansion and polymerization of the MP depend on the temperature and humidity of the surrounding atmosphere, winter foam tends to solidify even at low temperatures, but its expansion during polymerization is weaker than that of summer foam.

Output volume - this indicator determines the amount of material obtained from one cylinder. In comparison with ordinary foam, it can be 1.2-1.5 times less.

Adhesion - Determines the bond strength of the substrate and foam. This indicator is practically no different from that of summer foams.

The holding time is the time during which the foam is completely cured. The subzero air temperature and the low temperature of the building structure itself require a longer exposure of the foam after application.Moreover, the lower the temperature, the longer the holding time should be.

This is important to consider, as less expansion of winter foam may require a seam to be processed in several passes. The next layer of foam is applied only after the previous one has completely polymerized.

- Before starting work, the cylinders must be kept in a warm room for at least half a day. Some manufacturers advise to heat the cylinder in warm water at a temperature of 30-50 degrees before use. However, the most advanced manufacturers may not give such recommendations - their foams already contain substances that increase the volume of the mixture coming out of the container. In any case, you need to carefully study the instructions on the bottle label.

- The surfaces to be treated must be cleaned of dust, debris, snow and ice. It is allowed to slightly moisten the surfaces with water using a spray gun (just before work).

- Before using the foam, the can should be shaken for 15-30 seconds - this promotes better mixing of the foam components and increases its yield.

- The work is carried out holding the cylinder upside down. Slots and seams must be carefully filled with foam to about 1/3 of the volume. Please note that the composition will expand during polymerization, so do not waste extra foam.

- If necessary, after hardening of the first layer of foam, subsequent ones can be applied.

- The use of winter foam in cold weather does not imply its subsequent spraying with water in order to improve adhesion (this is allowed in summer).

- Cured foam should be protected from light and sun as soon as possible, otherwise it may become porous and brittle, impairing its protective properties.

Most winter foams have a lower usage threshold of –10 degrees. But there are manufacturers who produce foams that can be used down to -25 degrees. One of these is Soudal - the product of this company is called "Arctic".

Most winter foams have a lower usage threshold of –10 degrees. But there are manufacturers who produce foams that can be used down to -25 degrees. One of these is Soudal - the product of this company is called "Arctic".

The usual winter foam of the Macroflex brand can be used at temperatures down to -10 degrees. Also, Tytan Professional 65 is an excellent winter foam used down to –20 degrees (cylinders with this material do not need to be heated before use).

During the installation of windows in the autumn-winter period, as well as in early spring, it is recommended to use winter foam. These polyurethane foams have high adhesion strength and good adhesion to a number of typical materials used in construction.

Freezing temperatures do not necessarily mean that construction or renovation work will need to be suspended until spring. The use of appropriate winter foam allows you to continue working, and the use of a heat shield - to protect the room from the harmful effects of frosty wind, snow, rain and low temperatures.

At what temperature can the foam be used?

Soft foam cleaners: PU Foam Cleaner Click (Soudal) (pack of 500 ml - 257 rubles). Photo: Soudal

Depending on the range of operating temperatures, polyurethane foams are divided into summer, winter, all-season. For the former, the range of permissible temperatures is in the zone of positive values: from 5 to 30 ˚C. Winter and all-season foams are used in a wider range: from –10 ° С (some from –25 ° С) to 30 ° С. In this case, it is worth considering the manufacturer's advice on the temperature of the cylinder. In the cold season, with low air humidity, the course of chemical reactions slows down, the viscosity of the mixture increases, and the pressure in the cells of the foamy mass decreases. For normal operation of winter foam, many manufacturers advise to warm up the cylinder to room temperature (23 ° C), keeping it in a living room for about a day or immersing it in warm water (about 30 ° C). However, there are products for which the use of a cold bottle is acceptable.

Winter foams contain components that help to better absorb moisture from the environment and maintain the desired consistency at low temperatures. Winter foams can be used in cold and warm seasons without any deterioration in performance.

Types and technical characteristics

All existing polyurethane foam can be divided into several types according to various criteria.

By its constituent components, the product is:

- one-component;

- two-component.

According to the ambient temperature during the application period, three types of foam are distinguished:

- Summer - marking on the package indicates the surface temperature at the time of application from + 5 ° to + 35 ° C, but at the same time the frost resistance of the hardened foam ranges from -50 ° to + 90 ° C.

- Winter - the temperature range, at the time of application, is mainly from -10 ° to + 35 ° C (some manufacturers were able to lower the lower limit to -20 ° C).

- All-season is the most versatile option, combining the properties of the two previous foams. Thanks to its special formula, the substance is able to expand in volume and quickly polymerize even in the cold.

According to the method of application, the foam is:

- professional, requiring the use of a special dispensing gun;

- household or semi-professional, which does not require special devices (a special adapter tube is used for application).

According to the flammability class, the foam is divided into:

- fireproof or refractory B1;

- self-extinguishing B2;

- combustible B3.

There are several main points to the technical characteristics and properties of winter polyurethane foam:

- The ability to grip various parts during assembly.

- Frost resistance. In the cured state, the foam layer is able to withstand low temperatures, retaining all operational data.

- Good sound and heat insulation characteristics.

- The ability to fill and seal air voids, cavities in hard-to-reach places.

- Excellent compatibility with most building materials (except Teflon, silicone, polyethylene, oily surfaces, etc.).

- Porosity capable of providing stability in various combinations.

- Good adhesion, ensuring the ability of the substance to adhere to any substrate. This property helps to ensure a fast and high-quality installation process.

- Shrinkage. The lower this value, the stronger the connection will be. The substance possesses this characteristic after solidification.

The quality characteristics of the assembly sealant depend on several parameters:

- Surface and ambient temperature at the time of use. In cold weather, it becomes more difficult to work with sealants, since cold air is characterized by low humidity. Under these conditions, the foam does not expand as well and does not harden quickly enough.

- Expansion - This property of the sealant affects the quality of the seal. If it expands too much, it can lead to deformation of building structures.

- Viscosity of the substance - this parameter characterizes the ability of the sealant not to slip from the surface at the time of installation.