Specifications

Penosil polyurethane foam is almost not advertised, but professional builders invariably make a choice in its favor. The amount of mixture that comes out when using one cylinder is greater than that of well-known competitors. How exactly this is achieved is a deep commercial secret. There are a number of universal brands in the assortment, but it is even more correct to use them for internal work, since negative temperatures have a bad effect on the result.

Retention of consumer qualities is guaranteed in the temperature range from -45 to +90 degrees. A special formulation and manufacturing technology allows to reduce the susceptibility to moisture, heat leakage and make the setting faster. Drying time ranges from 10 minutes to a day, depending on the selected variety and on the conditions for using such a composition.

Provides excellent adhesion to the following surfaces:

- tree;

- plastics and polymers;

- metal parts;

- stone.

The Penosil developers make every effort to combine elastic and plastic properties in their product, because for builders and repairmen it is important not only to fill the gaps, but also to eliminate breaks. The foam has almost no smell and gives an attractive white color that can please any builder and owner of the premises.

How to use?

Those surfaces that need to be bonded or sealed are cleaned in advance: traces of dust and dirt are removed from them

It is very important to work only with protective gloves, because high adhesion will impair the removal of foam from the hands. Ideally, you should wear overalls or unnecessary household items.

People suffering from allergies should be even more careful, since the slightest contact with the composition can lead to serious consequences.

The area where a gap, crack or chip has appeared is filled with foam by 1/3. Acceleration of polymerization is achieved by spraying the applied mass with water. If after 30 minutes the expansion of the foam is not enough, then only then it makes sense to add a new portion.

Reviews of the Penosil brand polyurethane foam are quite favorable. Builders and repairmen emphasize that the mixture is always of high quality and gives a uniform foam. The likelihood of secondary expansion is small, and if it occurs, then only in insignificant volumes. The company's technologists managed to achieve the absence of shrinkage.

With regard to the power achieved, the proportions are as follows:

a 300 ml can gives 30 liters of foam;

500 ml corresponds to 40 liters of the mixture;

Gunfoam B1 750 ml, when released to the outside, forms approximately 50 liters of foam;

With the help of 1000 ml cylinders, up to 100 liters of active ingredient can be obtained, which is very important for large-scale work.

Insufficiently viscous material will quickly slide off the wall and lose its valuable qualities

It is important to take into account that even foams that are resistant to cold temperatures are best used in comfortable conditions, because in this case the mixture output from a cylinder of the same container will be the greatest. Household foam is equipped with a plastic nozzle and must be used in one go, while the professional version can only be applied with a construction gun.

For more information on the characteristics of Penosil polyurethane foam, see the video below.

Range and specifications

To date, the line includes 22 types of foam. Among them there are standard and economical materials that can process 1.5 or even 2 times the area without deforming the base.

Comparative characteristics are presented in the form of a table.

Technical characteristics of Penosil polyurethane foam

|

Name |

view |

volume, ml |

output, l |

secondary expansion,% |

appointment |

t use |

shelf life, months |

|

"GoldGun 65 Plus Winter" |

winter |

875 |

65 |

up to 15 |

professional |

from -20 to +30 |

18 |

|

"GoldGun 65 Plus Summer" |

summer |

875 |

more than 65 |

up to 15 |

professional |

from -5 to +30 |

18 |

|

Max Gap Filler |

all-season |

750, 310, 435 |

up to 40 |

up to 200 |

household |

from -10 to +30 |

18 |

|

"Construction 70" |

all-season |

870 |

up to 70 |

up to 80 |

professional |

from -10 to +30 |

18 |

|

EasyPro All Purpose |

all-season |

750 |

up to 80 |

up to 80 |

professional |

from -10 to +30 |

18 |

|

EasyPro Window & Door Elastic |

all-season |

750 |

up to 75 |

up to 50 |

professional |

from -5 to +30 |

18 |

|

"GoldGun 65" |

summer |

875 |

up to 65 |

up to 15 |

professional |

from -5 to +30 |

18 |

|

"GoldGun 65 Winter" |

winter |

875 |

up to 65 |

up to 15 |

professional |

from -18 to +30 |

18 |

|

"GoldGun" |

summer |

750 |

up to 45 |

up to 15 |

professional |

from -5 to +30 |

18 |

|

"GoldGun Winter" |

winter |

750 |

up to 45 |

up to 15 |

professional |

from -18 to +30 |

18 |

|

"GoldGun Low Expansion" |

all-season |

750 |

up to 50 |

10 |

professional |

from -10 to +30 |

18 |

|

Premium Gunfoam 65 |

summer |

800 |

up to 65 |

up to 20 |

professional |

from +5 to +30 |

18 |

|

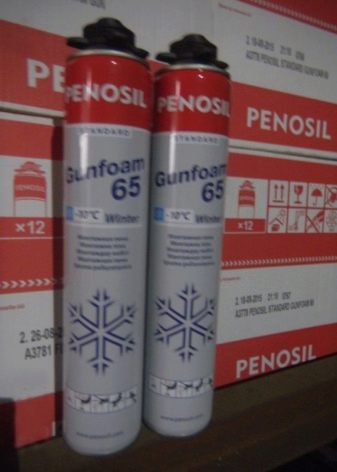

Premium Gunfoam 65 Winter |

winter |

800 |

up to 65 |

up to 20 |

professional |

from -10 to +30 |

18 |

|

"Premium Gunfoam" |

summer |

750 |

up to 45 |

up to 20 |

professional |

from +5 to +30 |

18 |

|

"Premium Gunfoam Winter" |

winter |

750 |

up to 45 |

15-20 |

professional |

from -10 to +30 |

18 |

|

"NewGun Foam" |

all-season |

750/500 |

45/30 |

up to 20 |

professional |

from -10 to +30 |

18 |

|

"Standard Gunfoam 65" |

summer |

875 |

up to 65 |

up to 30 |

professional |

from +5 to +30 |

18 |

|

"Premium Foam" |

summer |

750 |

up to 50 |

up to 70 |

household |

from +5 to + 30 |

|

|

"Premium Foam (340 ml)" |

summer |

340 |

up to 30 |

up to 70 |

household |

from +5 to + 30 |

18 |

|

"Premium Foam Winter" |

winter |

750 |

up to 50 |

up to 70 |

household |

from -10 to +30 |

18 |

|

Premium Fire Rated Gunfoam B1 |

fire-resistant EI 45 – EI 180 |

750 |

up to 45 |

up to 30 |

professional |

from +5 to +30 |

18 |

|

Premium Fire Rated B1 |

refractory EI 45 - EI 180 |

750 |

up to 45 |

up to 70 |

professional |

from +5 to +30 |

18 |

TOP 7 rating of the best polyurethane foam

Choosing polyurethane foam is not an easy task. Especially for ordinary consumers. That is why, we have compiled a rating that should help you:

- Makroflex Standart;

- Moment Installation;

- Penosil GoldGun65;

- Ultima;

- TechnoNicol 65 Constant;

- Soudal;

- Tytan O2.

Let's move on to the description of each model.

Makroflex Standart

Our rating opens with one of the most popular brands. She has long established herself both among professionals and ordinary people. Its main advantage is adhesion to any materials. The material copes well with temperature extremes. But you should be careful - there are many low-quality fakes.

| Seasonality | all-season |

| Cartridge volume | 500 |

| Appointment | standard |

| Gross weight | 0.598 kg |

Price: 350 rub.

polyurethane foam Makroflex Standart

- versatility;

- good adhesion;

- does not lend itself to temperature extremes.

Moment Installation

Probably, almost everyone was the first to hear about the Montazh company. Their products are renowned for their excellent quality. And foam is no exception. It copes well with any household tasks. You can work at any time of the year.

| Season | all season. |

| Cartridge volume | 750 |

| Appointment | standard |

| Gross weight | 0.750 kg |

Cost: 360 rubles.

polyurethane foam Moment Installation

- good stickiness;

- economical to use;

- suitable for indoor and outdoor use.

Penosil Gold Gun 65

This product is in high demand among professionals in their field. And for a reason! The absence of shrinkage and a variety of purposes make it unique and one of the best.

| Seasonality | all-season |

| Cartridge volume | 875 |

| Appointment | standard |

| Gross weight | 0.750 kg |

Price list: 275 p.

polyurethane foam Penosil Gold Gun 65

- no shrinkage;

- white material color;

- perfect for interior renovation work.

Ultima

One of the most budgetary and high quality foams. Has excellent adhesion. It is ideal for beginners as it is simple and straightforward to use. And the convenient applicator only makes the work process easier.

| Gross | 1.02 kg |

| Appointment | fixation of insulating and heat-insulating materials, filling of joints, installation of technical equipment. communications |

| Cartridge weight | 0,82 |

| Seasonality | all-season |

Price: 270 rubles.

polyurethane foam Ultima

- ease of use;

- dries quickly;

- excellent adhesion.

TechnoNicol 65 Constant

The material of the domestic manufacturer is universal in application, not inferior to foreign ones in quality. There is no shrinkage. But it's worth trying a little with the purchase - finding foam is not so easy.

| Gross | 990 g |

| Appointment | sealing, insulation, construction and finishing works |

| Cartridge weight | 0,65 |

| Seasonality | all season. |

Cost: 302 r.

polyurethane foam TechnoNIKOL 65 Constant

- versatility;

- good quality;

- high yield.

- difficult to find in stores;

- sometimes crumbles.

Soudal

Belgian foam is fire resistant. Therefore, it can be used in the sealing of furnaces and chimneys.Retains color and does not crack, which is why it has earned popularity and a good rating.

| Gross | 750 g |

| Appointment | lat. |

| Cartridge weight | 0,75 |

| Seasonality | all season. |

Price list: 380 rubles.

polyurethane foam Soudal

- fire resistance;

- good texture (dense);

- durability (5 years or more).

Tytan o2

There are also winter foams. And this one is pretty good. Experts speak extremely positively about it, because its feature is its harmlessness. Therefore, it is used in hospitals.

| Seasonality | winter |

| Volume | 0,75 |

| Gross | 750 |

| Appointment | wide. |

Price: 410 p.

polyurethane foam Tytan O2

Technical characteristics of polyurethane foam Titanium

Product of the American company Selena. Launched in 1992. Today, production facilities are already available on all continents.

Specifications:

- the output of the polyurethane foam mixture from a 750 milliliter canister - up to forty-five liters (at an air temperature of 23-25 degrees and humidity - 50-70 percent);

- excellent adhesion to a wide range of surfaces;

- resistance to high humidity and mold formation;

- excellent sound and thermal insulation parameters;

- high accuracy of application;

- ready to cut within half an hour after surface treatment with foam;

- the duration of the complete polymerization is twenty four hours;

- density of finished polyurethane - 20-25 kg / m3 (very fine and dense structure);

- has a slight primary expansion;

- secondary expansion and shrinkage are absent;

- guaranteed shelf life - one and a half years;

- flammability class (according to DIN 4102) - B2 and B3.

Specifications

Penosil polyurethane foam is practically not advertised, but, despite this, professional craftsmen increasingly prefer it. This is due to a number of material characteristics that allow work to be carried out economically and efficiently.

The assortment offers a variety of tools that are best used for interior work. Masters note that at low temperatures it is more difficult to work with foam, which has a negative effect on the final result.

Features of Penosil foam from the manufacturer:

- Moisture resistance.

- The absence of toxic fumes, after solidification, the composition does not pose a danger.

- Low thermal conductivity.

- Elasticity combined with elasticity, which allows to fill the gaps as much as possible.

- Fast polymerization, setting occurs within 10 minutes.

- Complete hardening is noted after 24 hours.

- Heat resistance, ability to withstand from -45 to +90 degrees.

- Good adhesion to various surfaces, including metal, wood, plastic.

The foam is odorless, painted white, available in cans of 300, 750 and 1000 ml. The final output is 30, 50 and 100 liters, respectively. The cost depends on the capacity and type of material. For example, Penosil Premium 500 ml will cost from 200 rubles.

Penosil foam is good because it does not emit toxic substances after hardening, which allows you to safely use it indoors. A special manufacturing technology makes the material less susceptible to temperature changes and moisture. It sets quickly, but this will depend on the type of composition.

How to use

The algorithm for working with polyurethane foam is as follows:

1. The surfaces to which the foam will be applied are well cleaned of dirt, dust, moisture. They need to be degreased and then dried.

2. Wear gloves before handling foam. If it comes into contact with sensitive skin, the composition can provoke an allergic reaction.

3. A can of polyurethane foam is inserted into the gun.

4. The tip is guided into the seam in such a way as to fill the space by 1/3.

5.After application, the material can be sprayed with water, which will speed up the curing.

6. After half an hour, you need to check how well the foam has expanded.

7. After complete hardening, remove excess foam with a knife.

When working with polyurethane foam, professional craftsmen wear not only gloves, but also the entire set of overalls.The high adhesion of the material makes it difficult to remove it after hardening, therefore it is better to protect the exposed areas of the skin.

Models

There are three lines of Penosil polyurethane foam:

Gold.

"Standard".

"Premium".

The Gold series belongs to professional products. They are used for assembly work in the construction and repair of buildings, as well as for the repair of industrial premises.

"Standard" can be used both by professional craftsmen and in everyday life. The range is represented by winter, all-season and summer foam.

Polyurethane foam of the "Premium" series is a universal tool for any work. It can be used in different conditions, at production facilities and in everyday life.

Representative GoldGun 65 has a high yield, but this composition does not react well with damp and very hot surfaces. The quality of the material drops significantly at temperatures over 30 degrees. The "Gold" line is purely professional and should be used only for major works.

Another special Gold Gun Winter squad is the winter option. This foam can be used at low temperatures. But Gold Gun Expansion All Season is suitable when you need to seal the smallest and most delicate joints, since its expansion is insignificant. The application of such a composition will not damage delicate structures.

Premium Gunfoam is just the kind of foam that's right for the hobbyist. It can be used for a very wide range of applications. Its use is permissible at temperatures from -10 degrees. Gunfoam B1 is fire retardant and meets the standards EN 1366-4 and DIN 4102-1.

Characteristics of individual Penosil products:

- Penosil Pro is a one-component expanding compound for heat and sound insulation, it is used with a pistol, the advantages are low secondary expansion and the ability to work under any climatic conditions.

- Foam for household use - a one-component mixture, used with an applicator, can be used to install windows and doors, to fill various gaps, has a low secondary expansion, it is easy for an amateur to work with it.

Penosil Polystyrol foam glue is used for gluing panels during insulation, it has good sound insulation properties, adheres to many types of surfaces, perfectly seals, and is not suitable for Teflon, silicone and polyethylene.

GG 65L summer is a foam with a high density, it can be worked with in winter and summer, has good sound insulation, does not require moisture after application, and gives excellent results at low temperatures.

- 65L summer PRO - has a favorable price, an output of 65 liters, an improved manufacturing formula, and is suitable for work at positive temperatures.

- NG universal - can be used with a gun and an applicator, all-weather, used at temperatures of -10 + 30 degrees, has a high performance.

Fire Rated PRO - fire-resistant foam, used for installation of windows and doors, provides heat and sound insulation, meets EN1366-4 standards.

Properties

The company's polyurethane foam is known among professional craftsmen, who note a lot of its important qualities.

The foam is characterized by different secondary expansion, as well as high resistance to moisture and mold. The solidification of the mass is determined by the humidity of the air. This happens quickly, filling all the voids, regardless of their shape. Complete polymerization occurs within 24 hours.

The mass is environmentally friendly and is intended, among other things, for technical communications. It helps to ensure the required level of heat and sound insulation, has a shelf life of more than a year, but needs protection from UV rays.

Some varieties are distinguished by the possibility of filling holes and voids up to 40 liters. Other types of polyurethane foam of the company can be used during rain and snowfall. They have an elastic structure and do not deform the base during expansion. You can cut off the surplus within an hour from the moment of use.

The range is designed for jobs that require a lot of foam.In addition, there are fire-resistant materials in the line, which is one of the advantages of this adhesive foam.

For convenience, the materials are divided into several branches, each of which has its own modifications. For example, one type of foam can be standard, winter, summer, and all-season. This variety allows the buyer to more accurately choose the desired option for construction work. The structure and density of the individual varieties are different, as are the required temperature conditions for using the foam.

You can use foam to perform work of any complexity. Polyurethane foam of the brand is non-toxic, therefore, harmless to health. It is characterized by a combination of elasticity and plasticity, is characterized by high quality and performance characteristics. For this reason, after filling the gaps with the composition, breaks are excluded.

Peculiarities

This brand of building materials has been in great demand among construction professionals for a long time. The reason is simple - it is distinguished by an unprecedentedly high quality of its composition.

The assortment of this brand includes the following compositions:

- products for household and professional use;

- foam cleaners;

- substances activating it;

- materials that have both a foamy and an adhesive effect;

- tapes to improve tightness;

- assembly pistols.

The brand is the property of the WolfGroup concern, more precisely, of the Krimelte company, which is part of it, a key manufacturer of sealing products on the European continent. Production facilities are located in the Russian Federation and the Baltic States, deliveries go not only to the post-Soviet space, but also to countries such as Japan, Israel, Germany, New Zealand. In total, polyurethane foam with this name goes to more than fifty different countries, which indirectly confirms its high perfection. Internal scientific and technical developments are actively underway, which helps to improve the main parameters from year to year.