Finishing: work in stages

First, preparatory work, consisting in the creation of a preliminary lathing

How to sheathe a house with cladding, let's figure it out in detail:

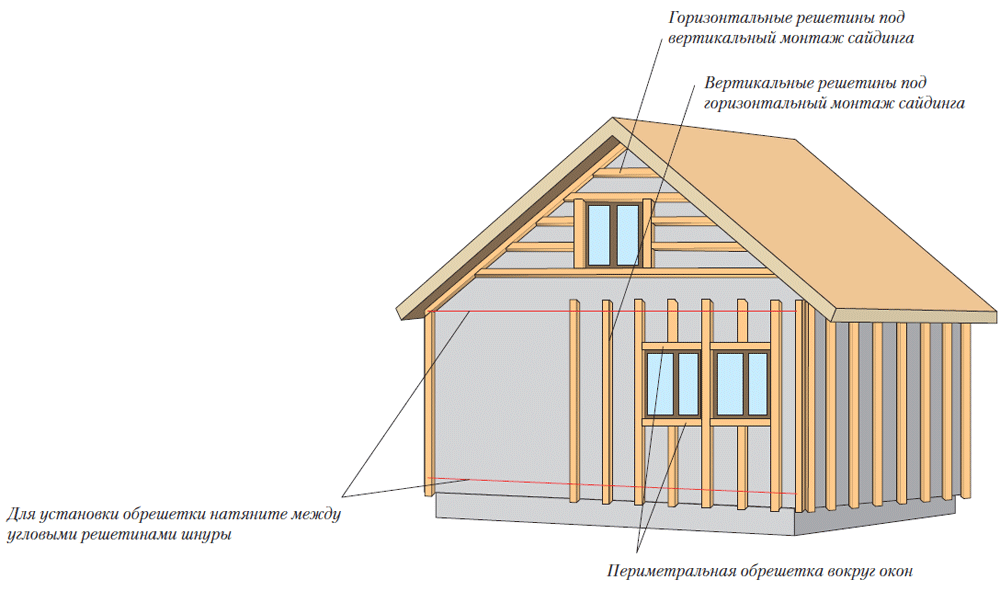

- First, preparatory work, consisting in the creation of a preliminary crate. It will come in handy both inside the house and outside, depending on what kind of areas are being finished.

- Square bars 30 * 30 mm are packed vertically in increments of 0.5-0.6 m, fastening can be done with nails, strips and do not forget about the processing of the bar.

- At this stage, it is worth deciding on the need for additional insulation and be sure to level the installation of the battens with a level.

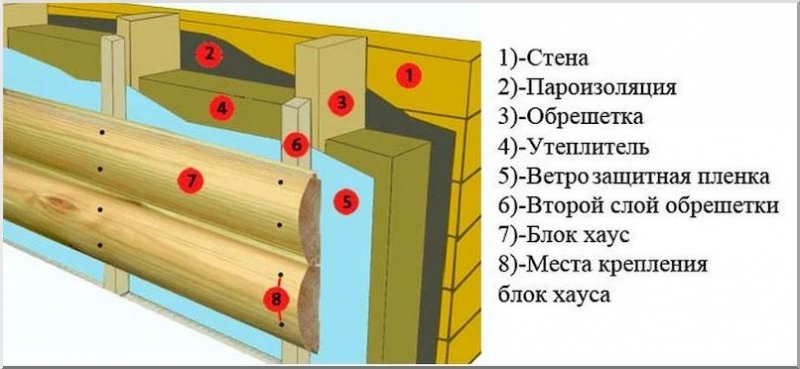

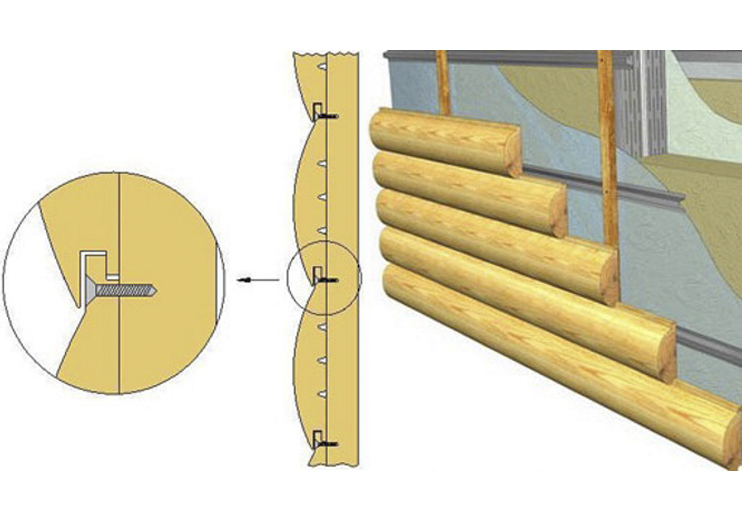

- As soon as the lathing on the walls is ready, proceed with the installation of the house block. Regardless of the type and type of panels, fastening always starts from bottom to top.

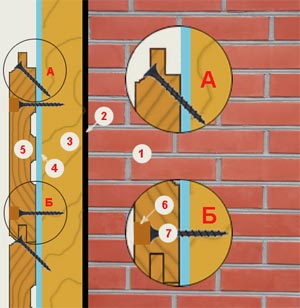

As for fixing the planks, there are two ways:

- The use of galvanized clay, which is bent into a groove with one part, the other is attached to the lathing bar using a screw. After that, the panel is linked to the next one and the process is repeated. The positive aspects of the type of fastening are the strength and reliability of the masonry. Sometimes it is permissible to use liquid nails to increase strength. At the same time, the panel itself does not require screws and nails, so the risk of panel deformation is reduced to zero. Watch the professional videos to understand the whole process in detail.

- The second option provides for fixing the panel to the lathing bar with self-tapping screws. To do this, make a hole in the board equal to half of its thickness. After that, a screw is heated into the hole, and then the hole will be caulked flush with the board, as shown in the video. The house block is now securely fastened, while the screw head is not visible. The method is laborious and there is a risk of damaging the lamellae during installation.

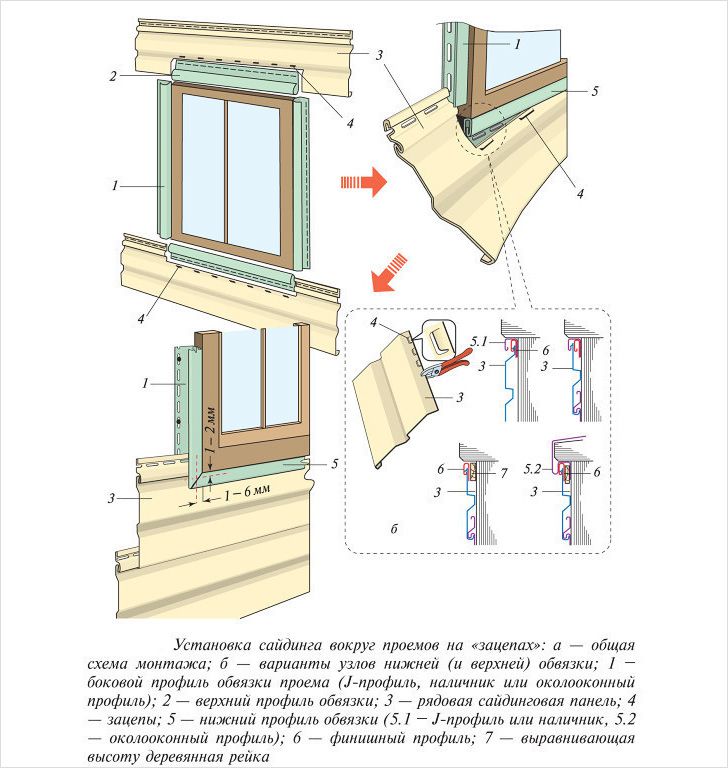

Window openings and doors require the use of special platbands

There are several difficulties that a home craftsman who wants to decorate the walls inside the house with a block house with his own hands may encounter:

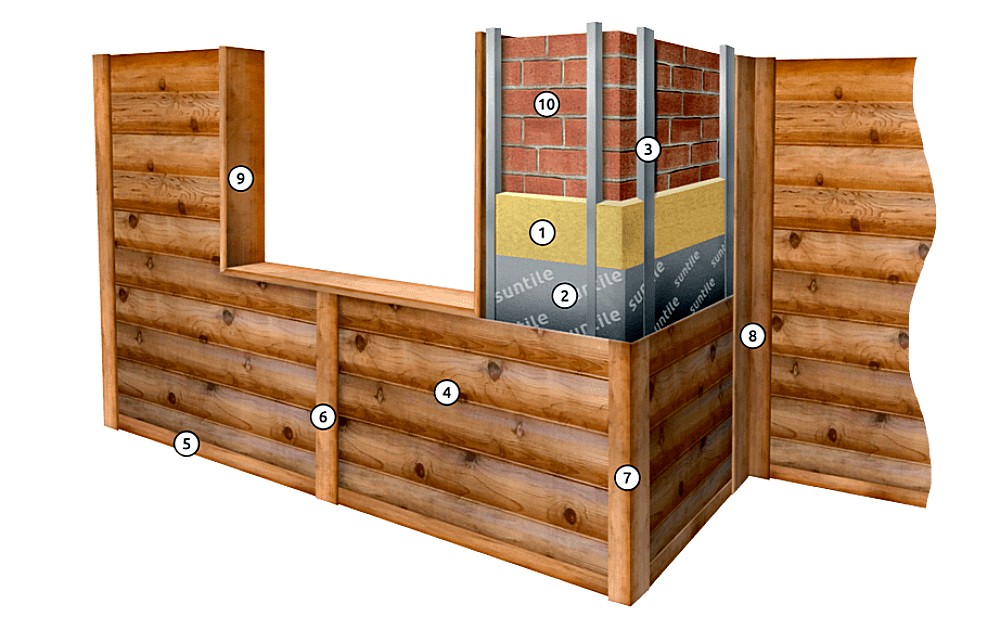

- Docking of panels in the corners. It is better to use special corners of the plinth, fitting parts of the lamellas under them. To do this, both walls of the corner are driven out, then the joint is hidden with a semicircular or flat element and fixed with liquid nails.

- Particularly sharp corners should be hidden behind a wooden lath, it can be decorative if it is an internal finish and a single color if an external facade is faced.

- Fitting a panel to fit the ceiling can also complicate the process a little. If the ceiling is not finished, then in the process of facing all the irregularities will be hidden later, and if the ceiling is finished, the decorative cornice will skillfully hide the cracks.

- Window openings and doors require the use of special platbands. Thus, all cracks and backlashes are hidden, and the risk of snow, rain and wind entering the premises is minimized. Platbands can be mounted on nails, glue, screws.

Regardless of the choice of technology, the walls under the block house cladding, there is no need to cook thoroughly. The lathing can be stuffed on old paint, plaster, uneven panels, the main thing is that the frame holds well, and everything else will be covered with a house block.

After finishing the installation, it is better to walk the varnish over the surface. In addition to additional protection, the tint varnish will give the building the desired color scheme and complement the interior interior if the rooms in the house have been tiled.

Fastening the house block to the frame

Having made and fixed the crate on the walls, the main process of facing the house begins.When starting the installation of a house block with your own hands, you must remember that regardless of the material, it is laid only horizontally, from bottom to top.

Wooden panels

Installation of wooden panels is the most difficult and expensive. Basically, they use the following methods of fixing the board:

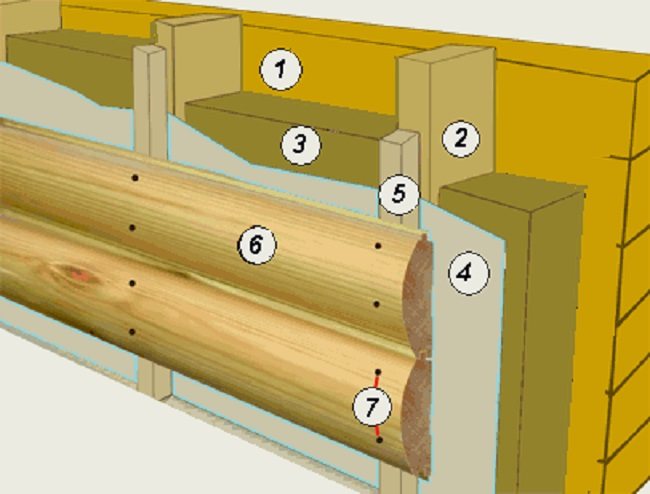

- Fixing the board with a cleaimer ensures a firm connection of the board according to the "thorn-groove" system. The kleimer is a metal bar, one side of which is inserted into the panel groove, and the other side is screwed to the lathing lag with a self-tapping screw. The gap between the boards formed from the kleimers is sealed with a special paste that imitates the color of the wood;

- The second method of fixing is performed with nails or self-tapping screws. They are carefully driven into the "spike" of the board and nailed to the log;

- A similar method of fastening the board in the "thorn" with a nail or self-tapping screw is done at an angle of 45 °. This option is characterized by increased strength of fixing the material but requires additional skills. Inexperience, you can break off the "thorn" and ruin the panel;

- The through fastening of the blockhouse is made with nails or self-tapping screws. A hole is drilled through the panel and fixed to the log so that the head of the fastener sinks into the wood. It is convenient to make “potay” for a hat with a countersink. You can make your own countersink from a drill sharpened at an angle of 90 ° or 120 °. From above, the hole is hidden with a wooden plug, which is then sanded;

- The outdated look of panels without the “thorn-groove” system is fixed through through holes or with a special adhesive inside the room.

To hide the joints in the corners of the log house, grooves are cut out for the panel board. A simpler option provides for the upper fastening of the decorative strips with glue. A nice connection is obtained by sawing the edge of the board at a 90 ° angle. The decoration of door and window openings is done with a variety of platbands.

Metal panels

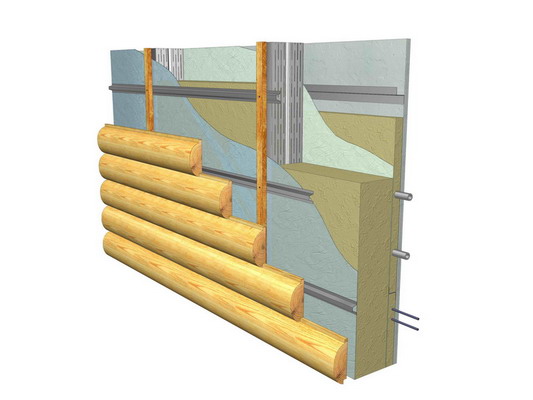

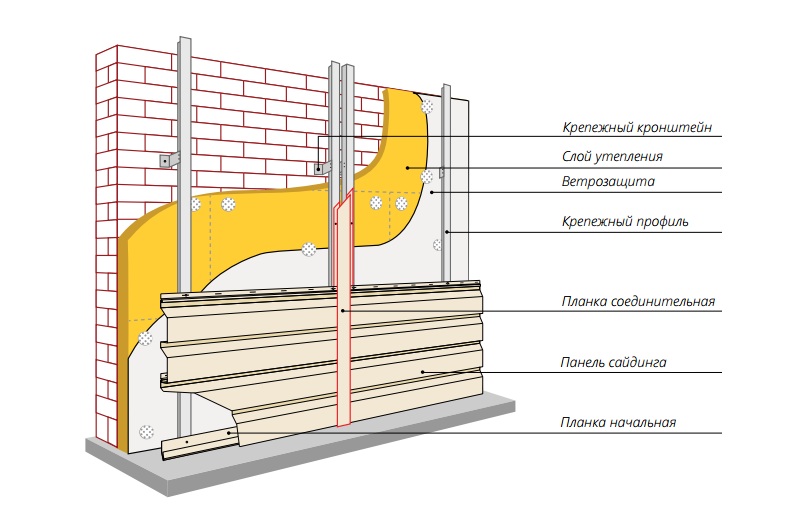

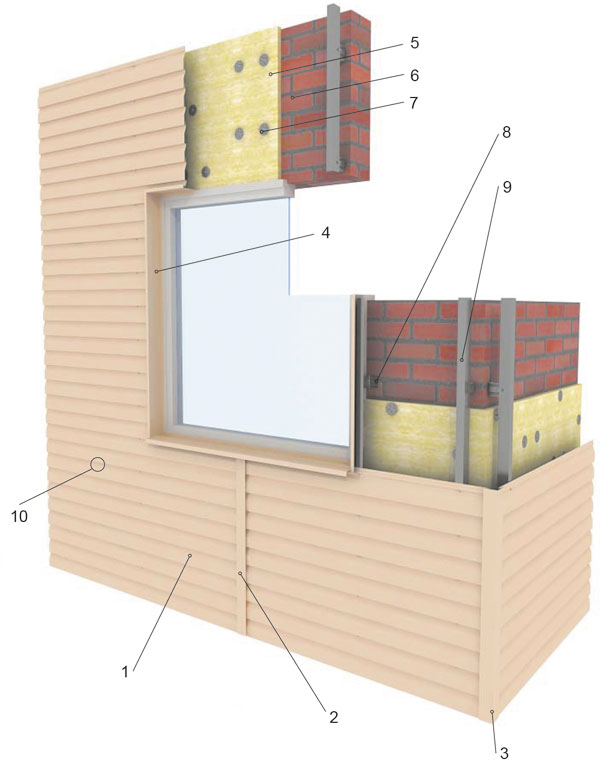

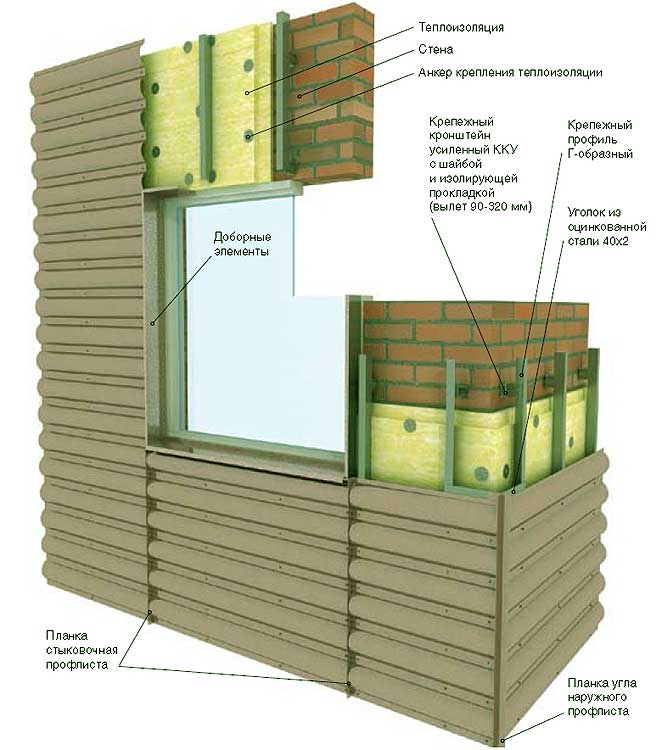

A good option for wall decoration is metal siding in the form of panels made for a blockhouse. It is generally accepted to mount panels from the outside to decorate the building. They are fixed on a frame made of a metal profile with stainless self-tapping screws through longitudinal holes. Mineral wool or foam insulation is placed between the elements of the crate. A film for vapor barrier is pulled from above and only then the panels are installed. Finishing of corners, hiding all joints is performed with additional additional elements.

Advice from the "facade"

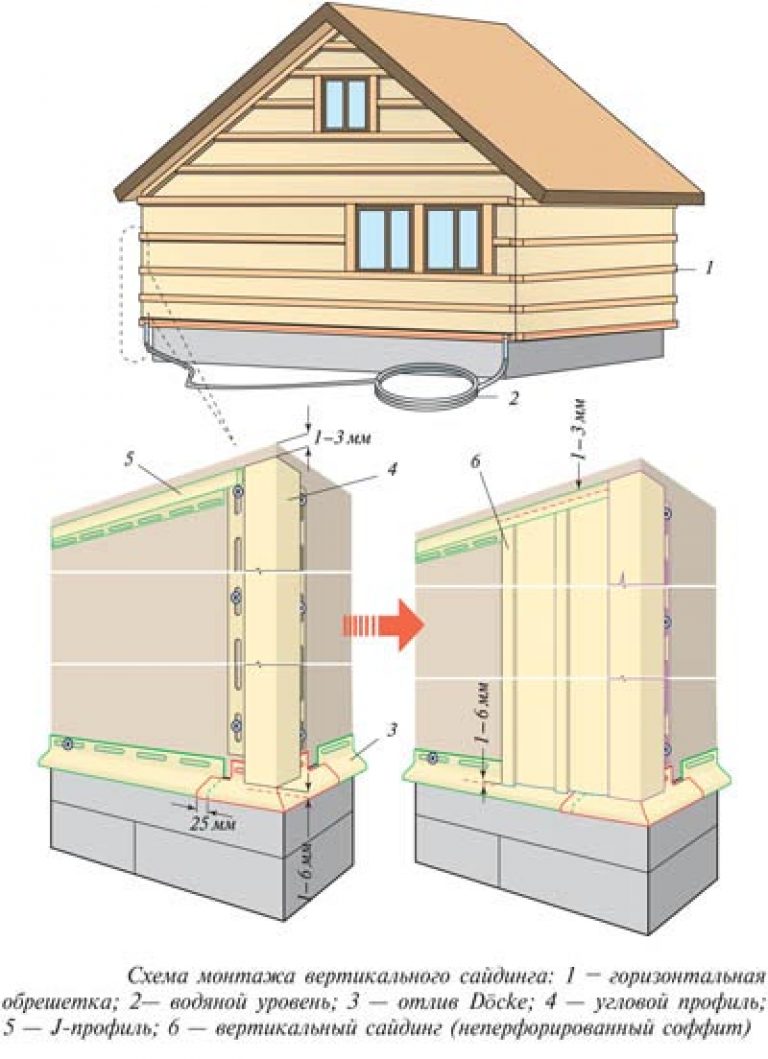

If you like the vertical direction of the cladding, then metal block house will be a way out of the situation. It can be mounted not only horizontally but also vertically.

Plastic siding

A type of plastic material for a blockhouse is made in the form of siding. A wide range of acrylic and vinyl panels makes it possible to arrange them when cladding a house. The plastic siding is fixed in the same way as the metal panels - with stainless self-tapping screws in special grooves that are on the purchased panels.

Choose those panels in the manufacturing process of which special materials were used non-combustion.

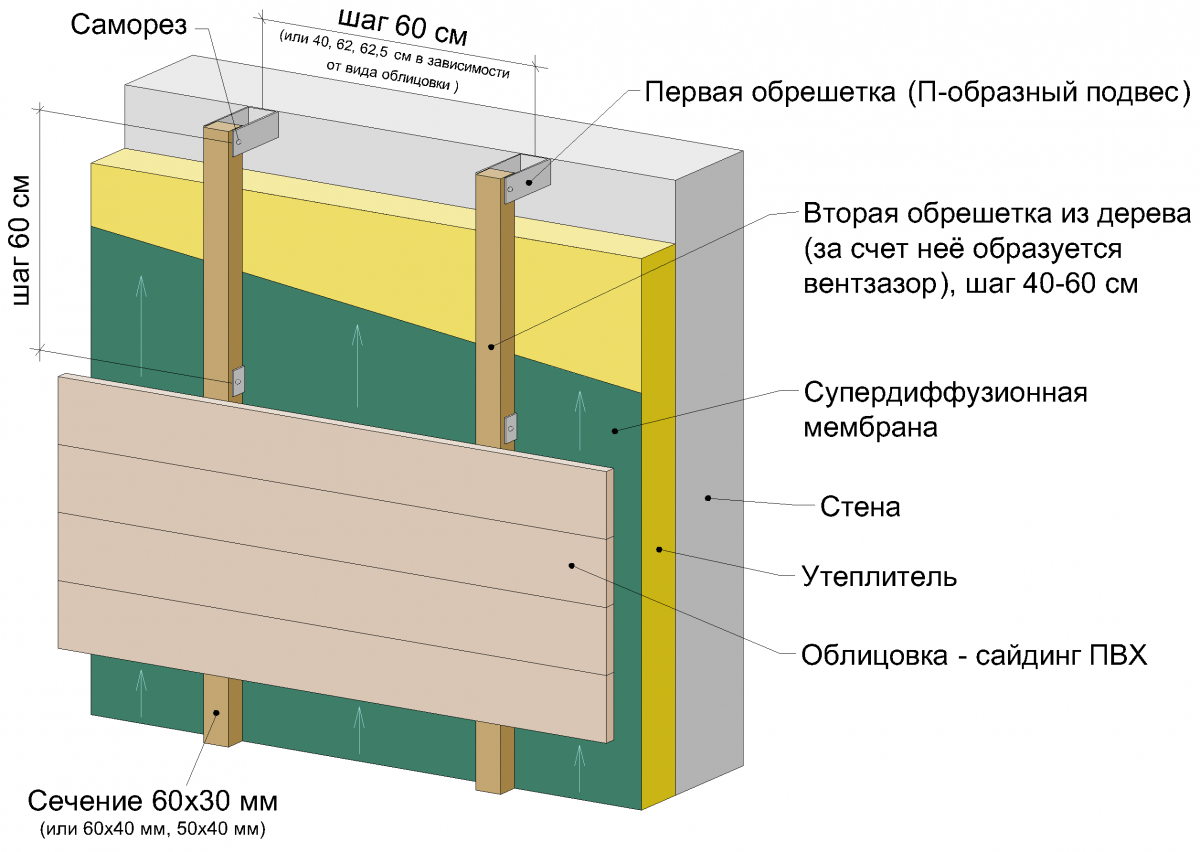

With external wall cladding, a temperature gap of about 2 mm is made between the siding elements. It protects the material from splitting during thermal expansion. This is due to the difference in weather conditions. The siding is screwed to the crate loosely, maintaining a gap of 1 mm. The presence of numerous gaps on the cladding negatively affects the insulation of the building. The use of plastic sheathing under siding will help to avoid this.

The plastic profile will deform from the temperature drop along with the siding. Therefore, they can be rigidly fixed without observing the clearances. To hide the gaps between siding elements, additional elements are used. Observing the instructions, you can easily make a crate yourself, make wall insulation and do the installation of a house block with your own hands.

Block house assembly instructions

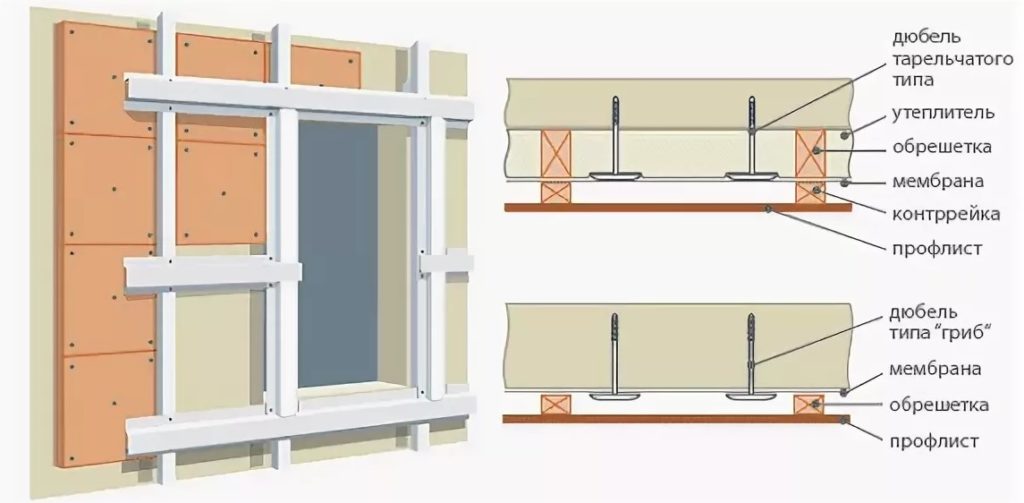

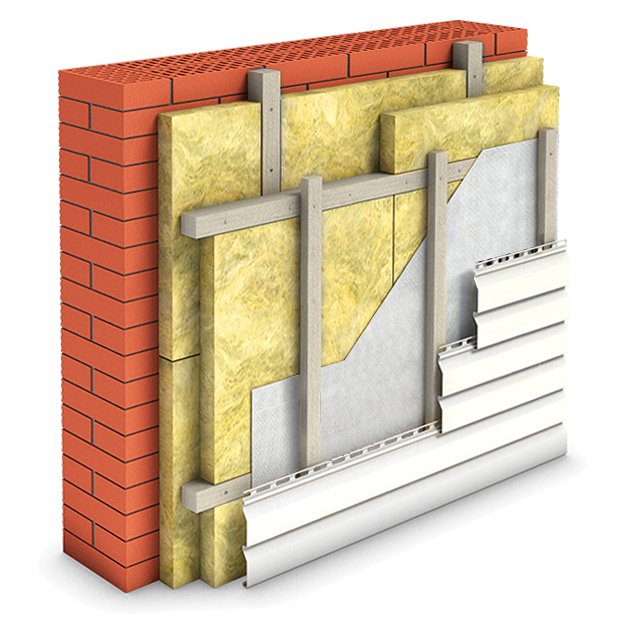

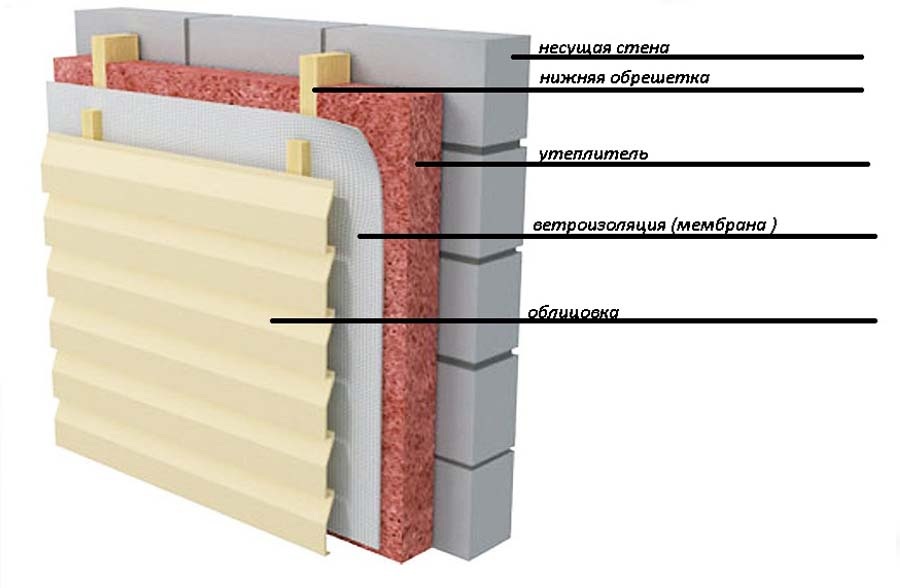

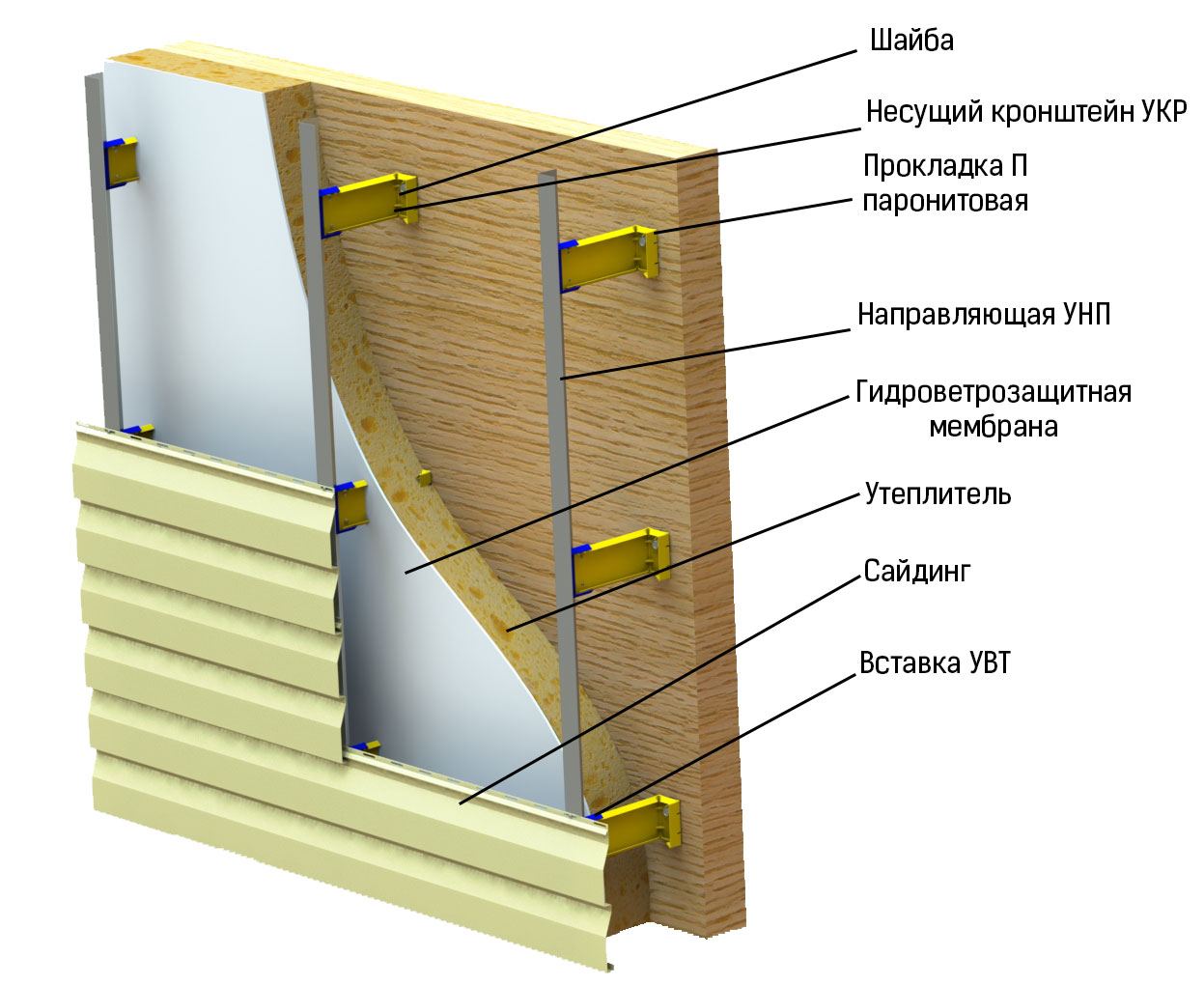

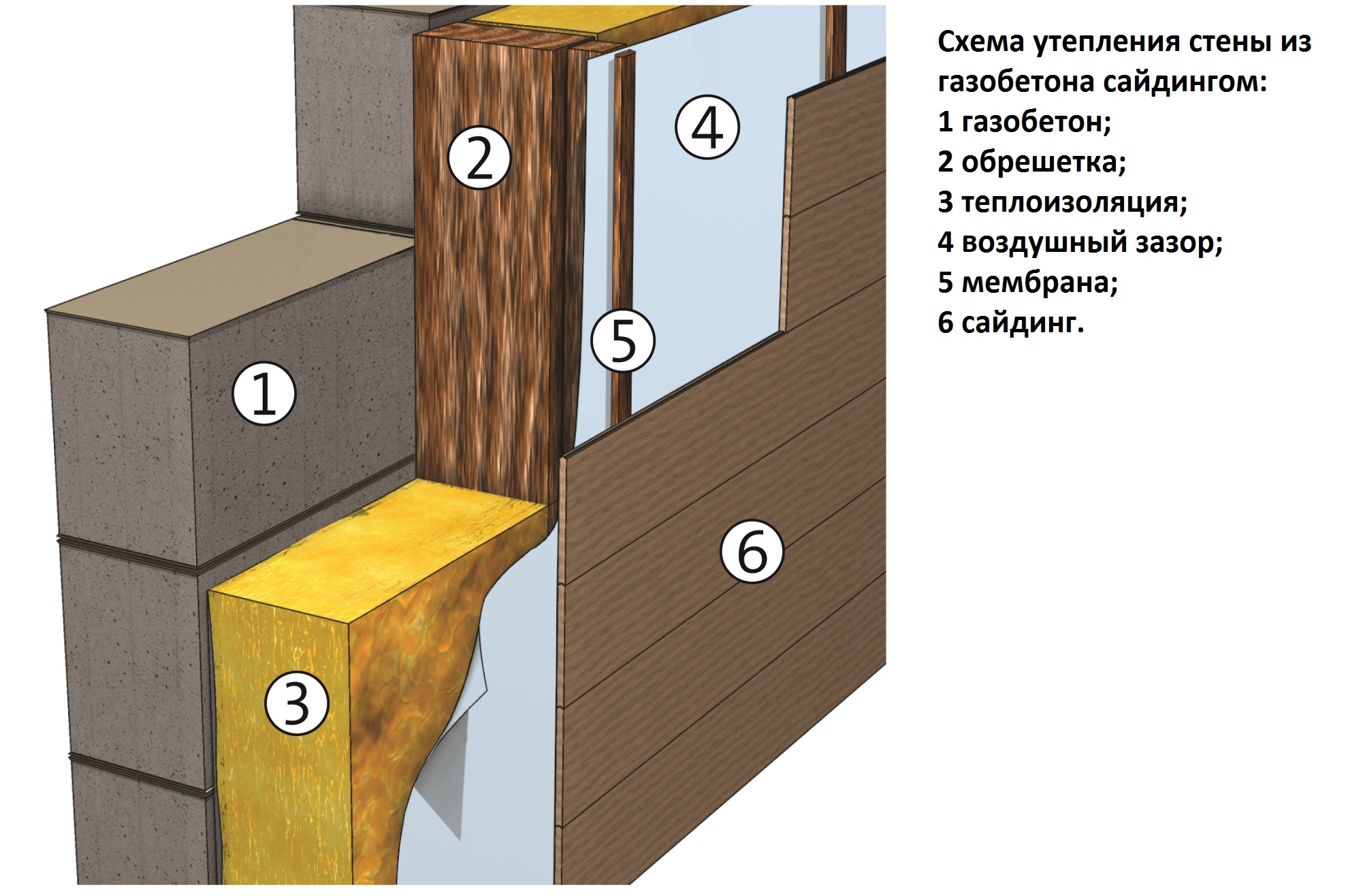

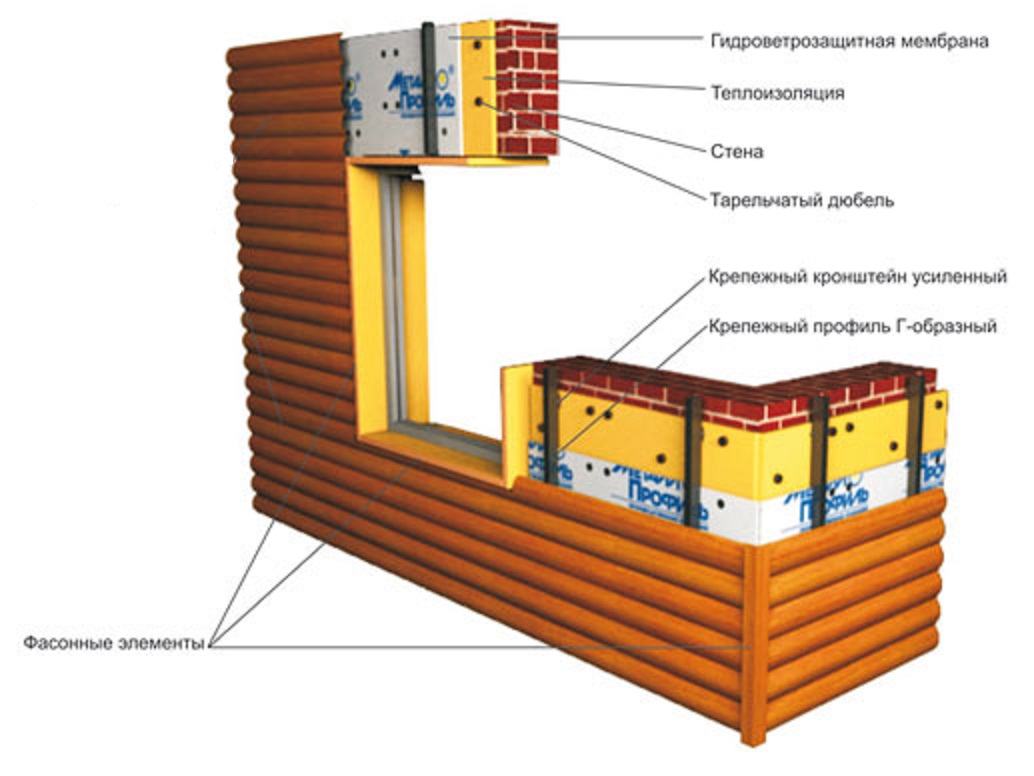

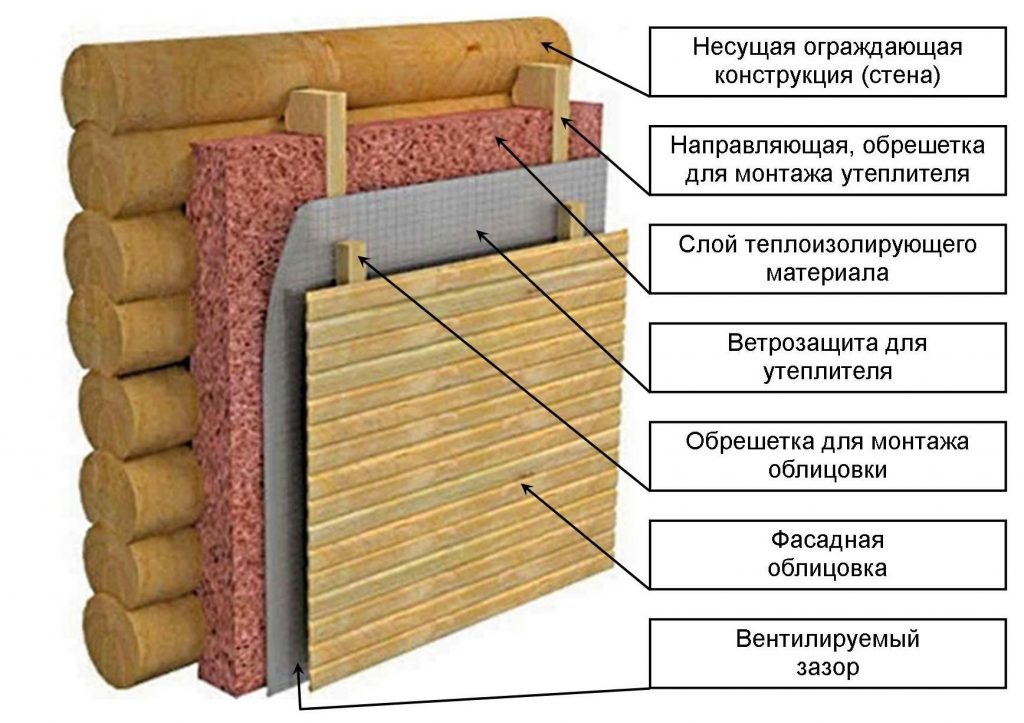

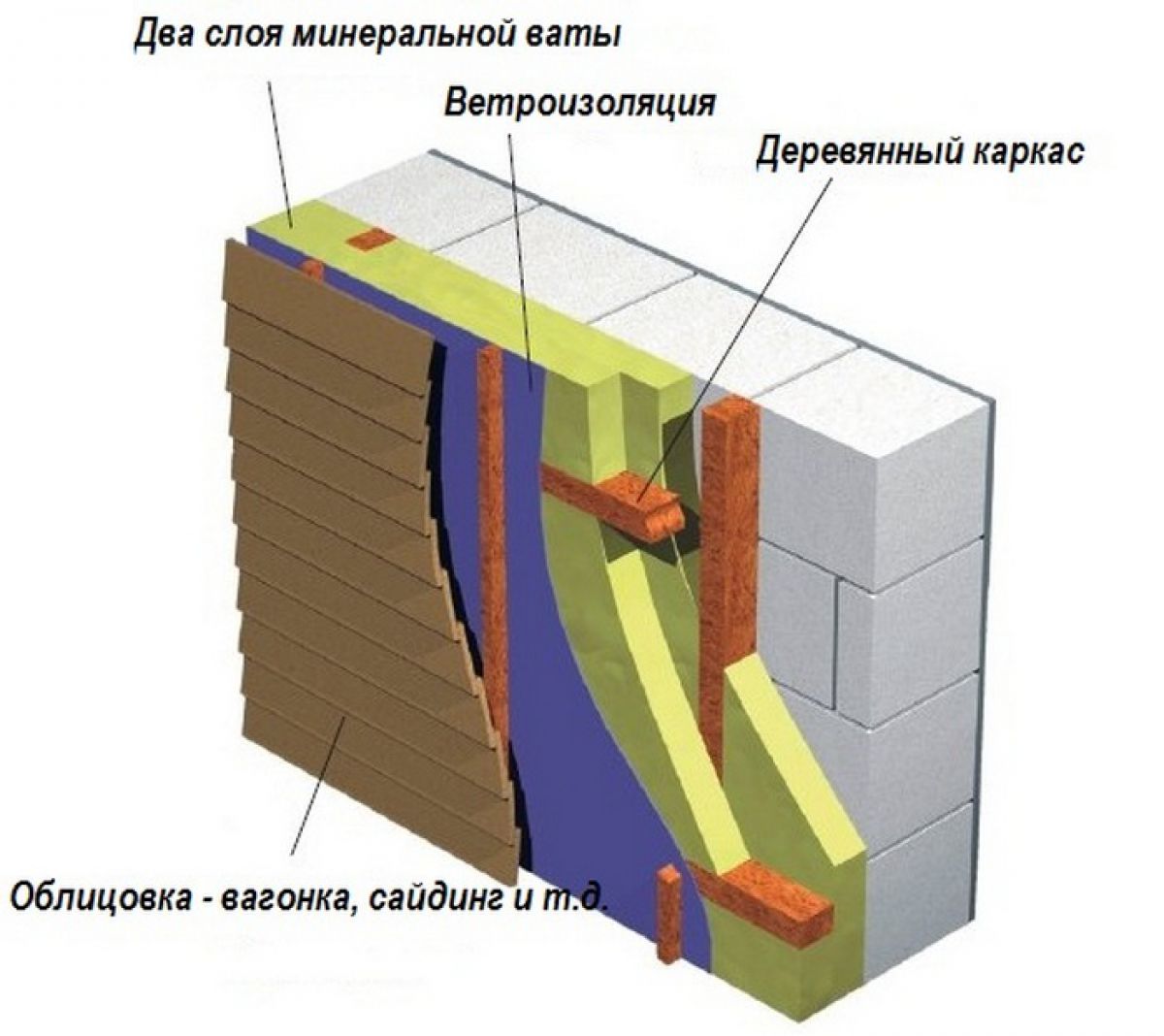

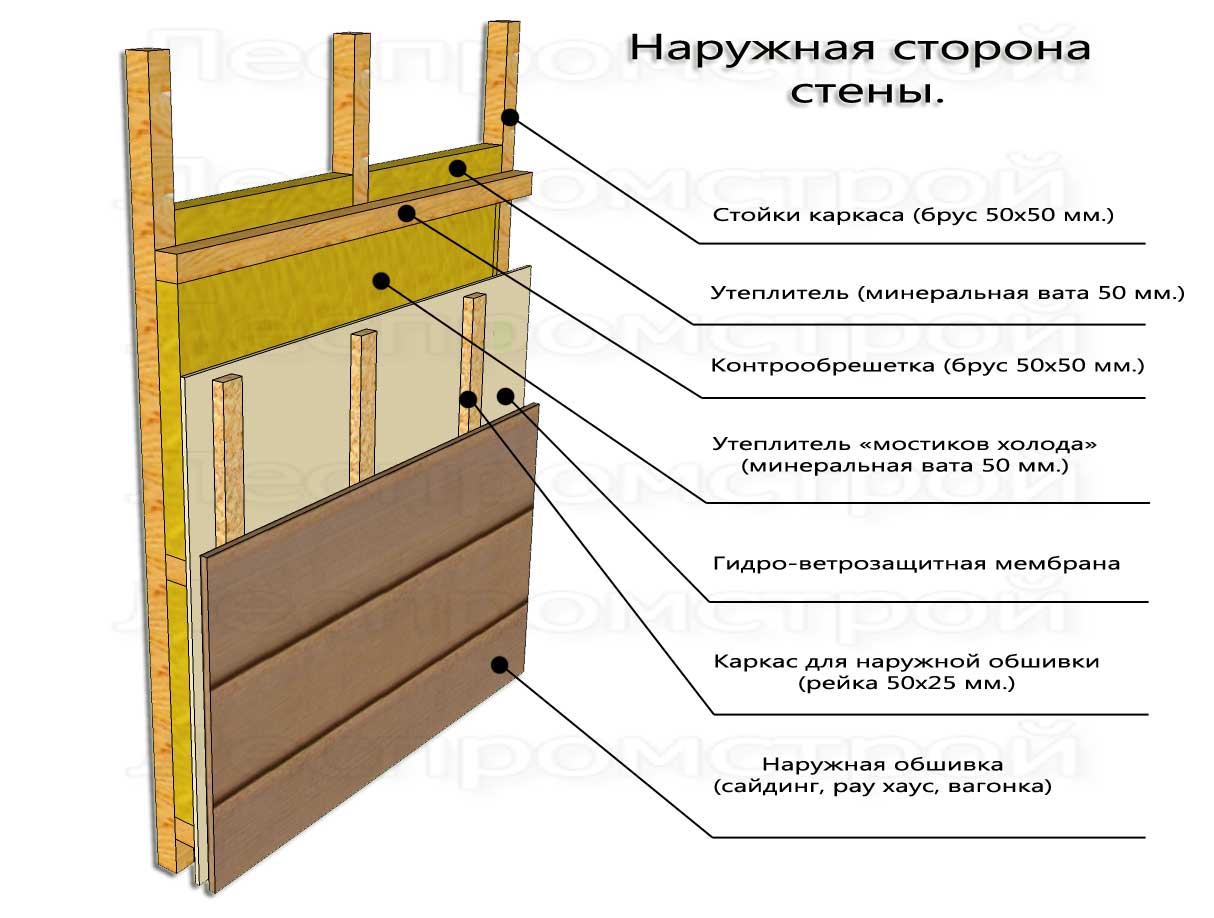

The cladding of the house with a block house, as the technology prescribes, is carried out by sequentially fixing the layers of the finishing and heat-insulating pie (photos will help you navigate this).

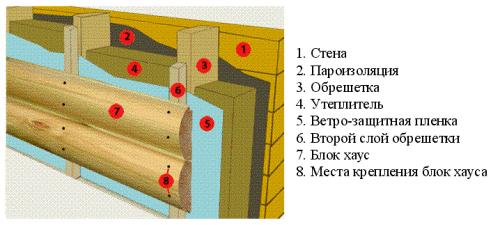

A waterproofing film is attached to the walls with adhesive tape, which releases moisture in one direction - from the house

To do this, the fleecy side of the material is directed inward, and the glossy side is directed outward (it is especially important to take this into account when cladding a wooden house with a block house)

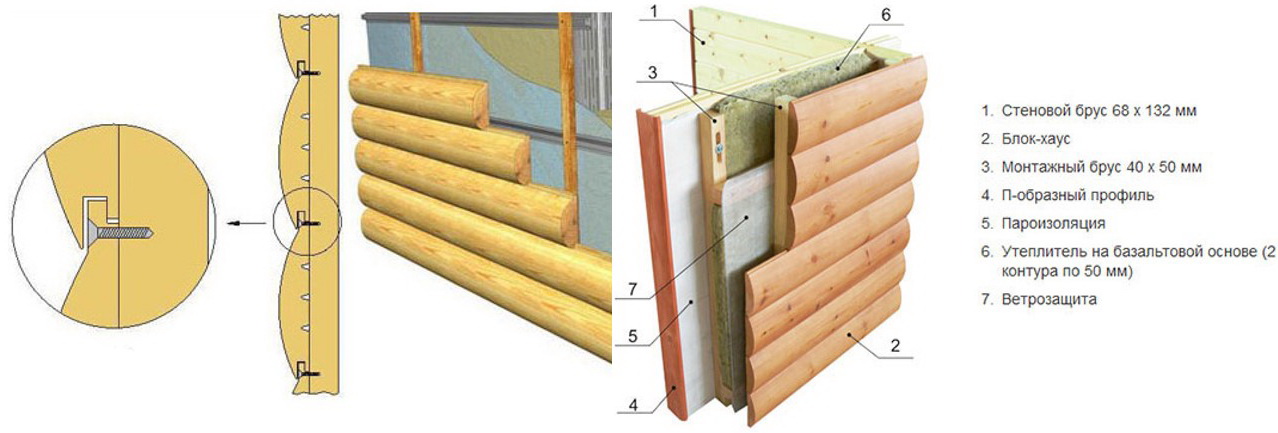

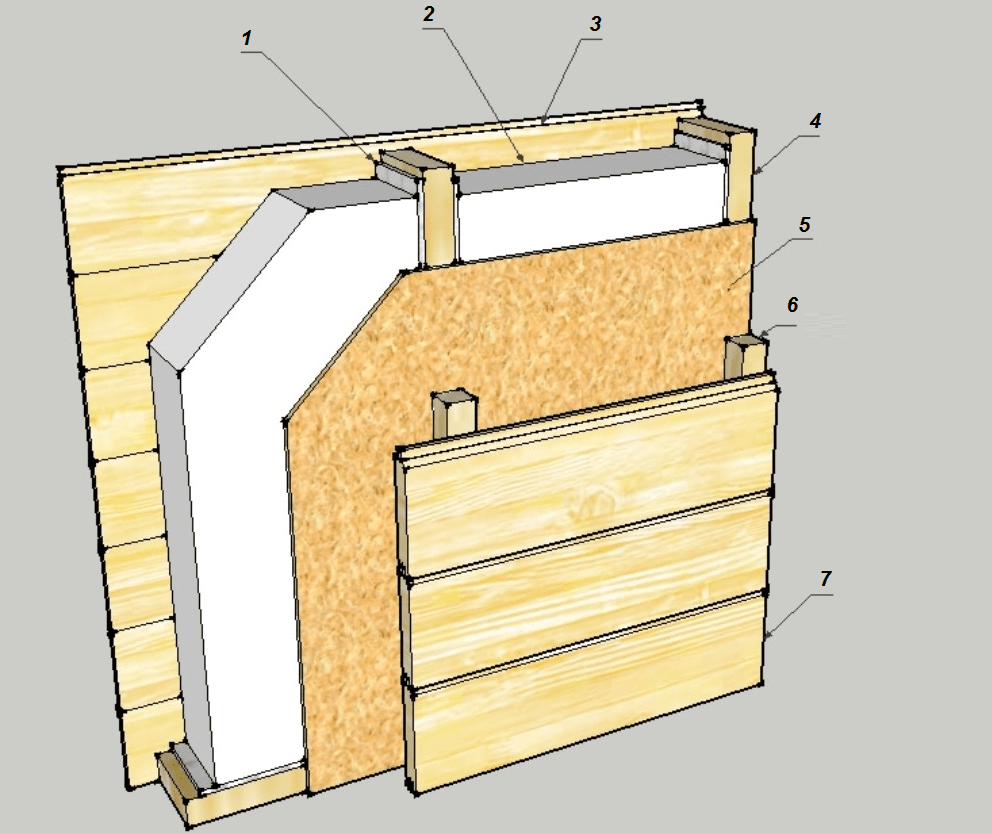

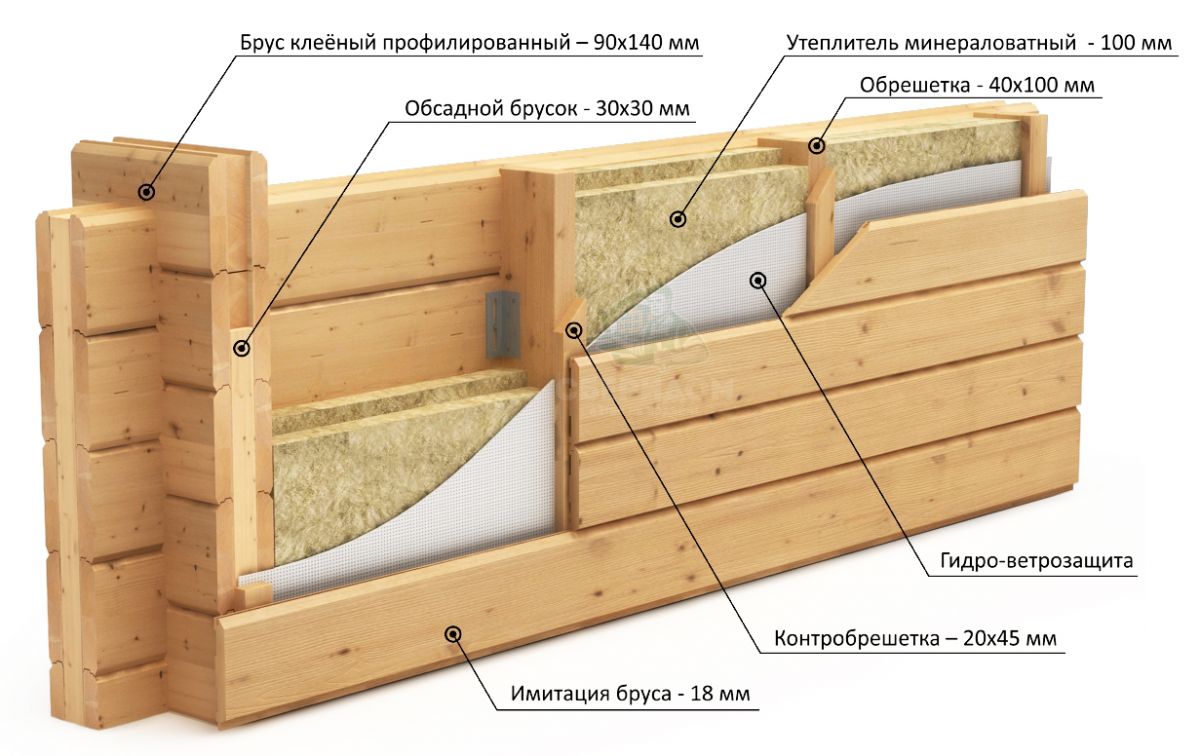

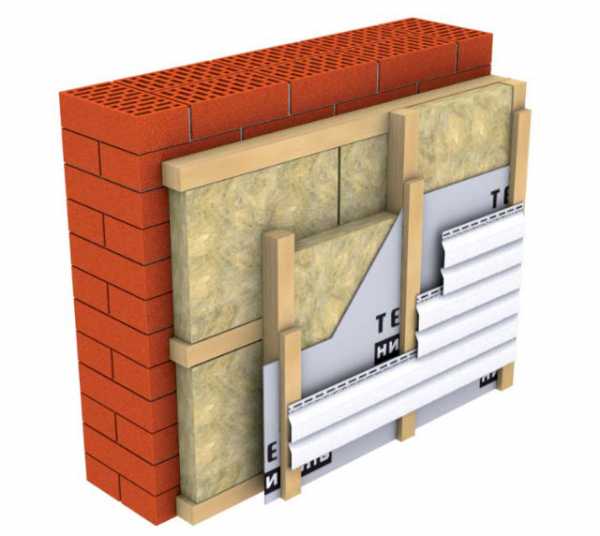

A vertical crate is installed with a step equal to the width of the mineral wool sheets (usually 50-60 cm), and the cross-section of the slats should correspond to the thickness of the insulation. The bars are pre-protected from fungus and insects with special solutions. Insulation is placed in the cells between the bars on the waterproofing (for reliability, it is fixed with umbrella dowels).

To protect the mineral wool from destruction by air currents during a strong wind, a vapor barrier windproof film is sewn to the crate with a stapler (always with the foil facing out). Through it, a counter-lattice with a thickness of 30 mm is nailed to the bars under the block house, which allows you to establish a gap between the panels and the wind barrier - due to this, the finish will be fully ventilated. In addition, air vents are left in the upper and lower parts of the facade for air intake.

Watching the video, note: the block house is being monitored in any convenient direction (bottom to top or top to bottom). The main thing is to achieve a strictly horizontal arrangement by checking the first panel with a level. Further, horizontality is controlled every 4-5 rows. When starting to do the work with your own hands and deciding how to sheathe the house with a block house, do not forget: the spike of the boards should be directed upward so that rainwater does not get into the grooves. The exterior wall finish is finished at least 30 cm above ground level, and the lower part of the house is faced with brick or special basement siding.

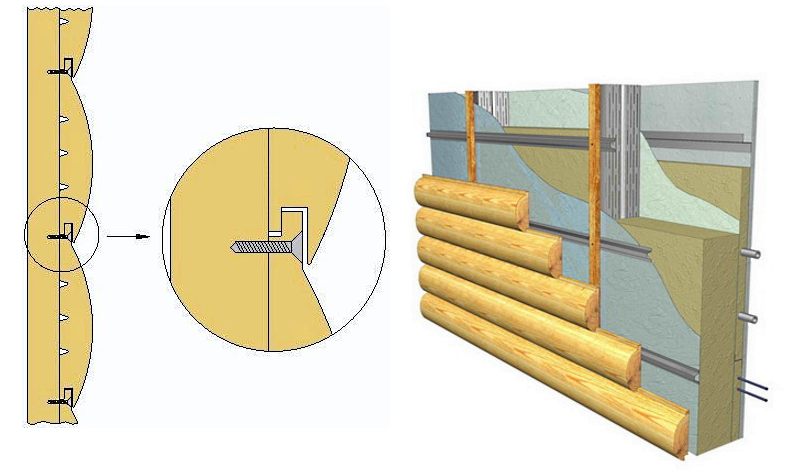

The question is often asked: what is the best way to fasten a wooden lining to the crate? In order not to damage the panels, clamps are used: the photo shows how to insert them into the grooves (this method is quite laborious). You can use nails, but only an experienced craftsman who will not allow damage to the lock connection can hammer them when doing plating with his own hands. The best and most common way is to fix the block house with self-tapping screws. To do this, holes are first drilled in the crate, corresponding to the diameter of the self-tapping screw and equal to half the thickness of the rail, and then the panels are mounted. The recess around the screw head is masked with a mixture of sawdust and glue.

In order to properly sheathe the outside of the house with a block house, special attention should be paid to the final stage. It is not necessary to connect the panels end-to-end in the corners: this requires careful marking of the ends of the elements for sawing, which entails unnecessary labor costs and makes it difficult to compensate for temperature expansions

Look at the photo: it is more rational to close the joints with special corners, putting them on glue. The decoration of window and door openings is carried out in the same way: defects and cracks are hidden behind the platbands.

Installation, fastening of the block house

When using a block house for exterior decoration, it is necessary to start with preparatory work. Initially, it is necessary to withstand the boards in the room, freeing them from the packaging. This is necessary for their "acclimatization".

It should be noted that the cladding of the house from the outside by the block house in its final form is a structure, the purpose of which is to provide warmth and comfort in the room. How it looks can be seen in a somewhat simplified form below in the figure (in section). Installation must begin with fastening the vapor barrier, after which the crate, insulation, wind protection, counter-lattice are placed. Installation is carried out in the sequence shown in the figure, in the direction from the wall to the cladding.After this work is done, you can proceed directly to the fastening of the house block. How some of the described works are carried out is shown in the video, how the installation of a board that imitates a bar is performed.

Applying a block house for exterior decoration, it can be fixed in several ways, the main ones are shown in the figure below. For fastening, nails or self-tapping screws are usually used, and it is necessary that they be with an anti-corrosion coating. In the case of fastening according to option B, shown in the figure, then additional wooden plugs will have to be placed in the holes for the self-tapping screws on the front panel, covering the holes.

When fixing the board according to option A, the self-tapping screw is screwed into the base of the spike and later, when installing the next board, it is completely masked with a groove. There are other mounting options, but those that are presented are the most common. Installation of the board can be carried out both from above and from below, it does not matter.

Regardless of the method of fixing the board, its location during installation is of great importance. It must be placed with the spike up, as shown in the figure. Such an arrangement of the board will avoid the accumulation of moisture, dust in the groove of the board and will contribute to its safety. An important role in this is played by the air gap formed between the thermal insulation and the outer skin.

Blockhouse finishing price

Now let's talk about the cost of such work.

Of course, you can do everything with your own hands - there would be a desire. But, if you are in doubt about your own abilities, or there is no free time for such classes at all, you can always negotiate with specialists.

Of course, material prices are not taken into account here - these are already separate costs.

The cost of the material is not great - for this it is also appreciated

When buying a blockhouse, it is best to look towards Finnish or American products. The long-term experience of the finishers suggests that such boards are of excellent quality, can be used for a longer period of time without any complaints, and the percentage of defective products is minimal.

Since decorating a house with a blockhouse is a task that not every family can afford, there is an alternative option - to sheathe the house with sadding, which imitates a blockhouse. Nowadays, metal and vinyl siding is in great demand - this material is ideal for finishing of facades of houses.

What are the advantages of vinyl as a cladding material:

- Extremely easy to maintain

- Fireproof;

- Not afraid of corrosion;

- Can always be repaired without complications;

- It weighs a little.

The pros of metal siding are:

- The material does not burn;

- It is very durable;

- Environmentally safe, does not emit any hazardous substances into the environment;

- Installation is easy, as is subsequent maintenance.

Among other advantages, finishing siding is not too expensive, has a very presentable appearance - the effect will be almost the same as finishing a house with a blockhouse. Another pros - the choice of colors is very wide. For example, you can easily find the following shades:

- Caramel;

- Banana;

- Pistachio;

- Cream;

- Eggplant, etc.

In addition, if you have chosen siding, please note: manufacturers accompany their products with accessories, including external and internal corners. Also, the set may contain initial strips - with the help of all this, wall cladding is done quickly, and at the same time very high quality.

To secure the material, watch the video: do-it-yourself vinyl siding house cladding. The effect is almost like a blockhouse, only cheaper and slightly faster.

Types: advantages and disadvantages

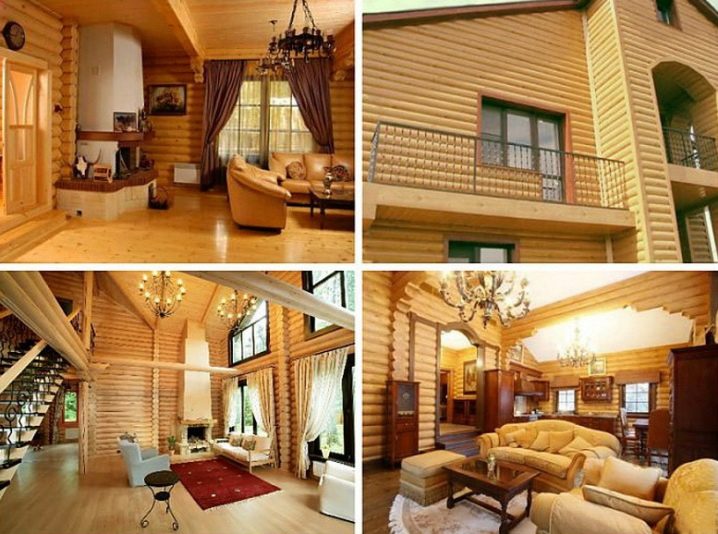

Since the block house is made from various raw materials, it is subdivided into several types. The most popular is the material made from natural wood. The main advantage of such boards is their environmental friendliness.The basis of a wooden block house can be spruce, pine or larch, so choosing it for external cladding at home, you can get an unusual decor with an imitation of a log cabin.

Depending on the quality of the array, wood panels are divided into three groups.

- Class "C". The boards have a well-planed surface, without knots and other large defects. However, slight discoloration, chips and scratches are allowed for this product.

- Class "B". The canvases are characterized by a low price, therefore, traces of mechanical damage, light and dark knots may be present on their surface.

- Extra class. The boards are perfectly finished and free from any flaws. They are expensive due to their high quality, which is achieved by manual selection.

Regardless of the class of production, the following advantages of a wooden block house can be distinguished:

- good heat and sound insulation;

- presentable view;

- naturalness.

As for the negative properties, such boards are expensive, easily ignite and require treatment with antiseptics.

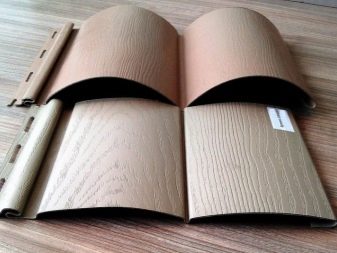

If you are planning a budget option for finishing, then vinyl panels will be the right choice. They are sold at an affordable price, imitate natural wood. The main advantage of the products is that they do not need to be additionally impregnated with antiseptics and varnished before installation. In addition, compared to wood, they have a longer service life and do not require special maintenance. Since the vinyl block house is lightweight, it does not put pressure on the structure of the building.

The advantages of vinyl panels include:

- a huge selection of textures and colors;

- ease of installation;

- durability;

- resistance to moisture and ultraviolet light.

This material has few disadvantages: it is sensitive to temperature extremes, requires adherence to a special installation technology, and the surface of such boards looks dimmer than the solid wood.

The steel block house is considered to be no less popular type. It is a bent profile painted to look like natural wood. Thanks to this material, it is possible not only to decorate the facades, but also to carry out high-quality thermal insulation. The main advantage of the product is its super strength, but similar to vinyl panels, the material is only suitable for external decoration, as it looks unpresentable indoors.

The pluses of steel panels include:

- long service life;

- affordable price;

- ease of installation work;

- moisture resistance and fire safety.

Blockhouse installation

Let's talk about what the installation of a blockhouse is.

If you follow the recommendations, there will be no problems with the installation of the blockhouse.

Requirements for materials and base

In order for the service life of the new blockhouse cladding to be as long as possible, you should adhere to some rules when doing the work:

- Blockhouse boards should only be laid on dry walls. In addition, the base is pre-cleaned from fungus, mold, old plaster is also removed.

- Before installing the panels, they are dried. If the humidity is too high, the entire future cladding of the blockhouse may warp when it dries, that is, the finishing will have to be done anew.

- The cladding of the house by Block House - with your own hands or with the help of specialists, is done on the condition that only galvanized elements are used as fasteners. If you ignore this point, rust streaks will ruin the entire upholstery.

This is what blockhouse boards look like when they are completely ready for use.

Preparation for styling

Before you tackle the cladding of the outside of the house, you need to wait a while - so that your new, recently purchased panels, slightly adapt to the climatic conditions of your future stay.

While the blockhouse is being "prepared", certain repairs should also be carried out, which include the following:

- First, a vapor barrier material must be installed - an affordable glassine or perforated film perfectly copes with this task. The vapor barrier when finishing with a blockhouse is overlapped; aluminum tape is also used in the work.

- Before sheathing the facade of the house with Block House, you should make a crate. It should be performed only from materials that have been pretreated with antiseptics. You can easily fix the timber to a wooden wall using self-tapping screws or simple nails.

When placing the lathing bars, they are guided by the following rule: in the future, a layer of thermal insulation should fit freely between them. As practice shows, a gap of 0.6 m is quite enough between the bars.

House block can be safely sheathed brickwork

- As part of the next stage, the thermal insulation material is laid. Excellent thermal insulation under the blockhouse - fiberglass. On the market, this material can be found in the form of mineral wool or slabs. Minvata is produced today, including in the form of rolls.

- Next, a waterproofing layer is laid. A waterproof film is ideal as this material. It is simply attached to the lathing bars - to make it easier, use a construction stapler in your work.

- After all the above operations, one more crate should be made. That's all - now the decoration of the house with a blockhouse from the outside can be done without any difficulties with your own hands.

Blockhouse on the walls - finishing technology

If during the work you decide that the material should be tinted, then it is advised in advance to paint the grooves and spikes of the board - it is possible that in the future its size will change, that is, stripes that have not been painted over will be visible. Often, materials that are used for facing stairs inside the house or outside (in gazebos, attics) are also tinted.

Blockhouse installation: instructions:

Laying the boards begins from the bottom row.

Pleasant color, impressive characteristics, ease of installation - this is why block house finishing is in great demand.

The house block is often fastened with self-tapping screws.

- In order for the blockhouse board to be securely fixed, it is best to attach it to two self-tapping screws at once. One should be near the groove, the other near the spike.

- The boards should be laid so that they are spiked up. This is due to the fact that moisture easily accumulates in the grooves. In addition, a small gap is left between the boards vertically and horizontally - this is necessary for ventilation.

- The next stage of finishing the house with a block house is the processing of gaps: here either putty is chosen, or wooden dowels are installed (attached to glue). The excess dowel is simply cut off, the edges are polished.

- When the work is done, the surface of the blockhouse is often treated with tinting compounds or special varnishes. This is done as follows: first one layer of the composition is applied to the boards, then grinding is done, then the composition is applied again - already in two layers.

Video: cladding a house with a blockhouse is a small lesson in order to consolidate all of the above. Be sure to look, perhaps you will find answers to those questions that we did not consider. In fact, everything is no more complicated than finishing a staircase with wood - if desired, any person can figure it out, even with minimal construction experience.

Material selection

Decorative finishing should start with the selection of material. House block is divided into several types depending on the type of wood and material class.

Wood species

Block house lamellas can be made from several types of wood, differing from each other in texture, color, technical properties and cost.

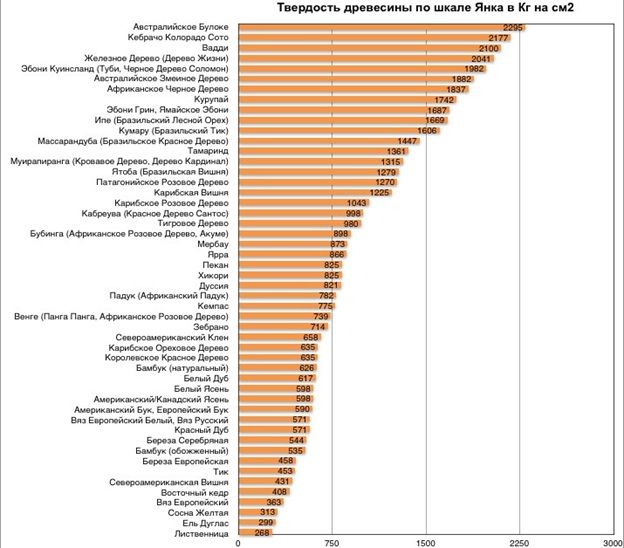

The table shows the comparative hardness of some types of wood used for interior decoration.

Use conifers for living spaces

Use conifers for living spaces

For living quarters - living rooms and bedrooms, it is recommended to use coniferous wood.The subtle pine scent that will emanate from the walls and ceilings will have a calming effect on the nervous system of the inhabitants of the house.

In addition, the resin of coniferous trees has antiseptic properties, preventing the development of pathogenic bacteria in the room.

For cladding interiors with a high heating temperature (saunas, baths), it is recommended to use deciduous wood, since conifers tend to emit excess resin when heated.

For finishing the bath, the use of larch will be optimal.

For finishing the bath, the use of larch will be optimal.

You should also take into account such a factor as high humidity, therefore, wall decoration with a block house in such rooms involves the use of wood that is resistant to moisture.

However, an important criterion for choosing a wood species is personal preference. After all, the main purpose of finishing a wall with a block house is to create an interior pleasing to the eye, therefore, if you like the openwork texture of a Karelian birch or beech, buy just such a material.

Panel size

Use thin panels for interior decoration

When choosing panels, you should also pay attention to their size. Usually the width of the lamellas ranges from 80 to 230 mm, but there may be exceptions to these rules.

Wider panels are used for finishing the facades of buildings, as inside the house they will look too massive, creating an oppressive feeling and "eating up" the space.

As practice shows, for interior decoration it is better to take thin lamellas, 8 - 16 cm wide. The lamella thickness can be from 20 to 50 mm. The length of the slats of the block house can vary from 2 to 6 m, therefore, when choosing a material, this parameter should also be taken into account so that production waste remains as small as possible.

Material class

Top class materials have a high price

In addition to the type of wood and size, the block house is also subdivided into classes depending on its quality.

It has enhanced decorative qualities, first of all, it is characterized by the almost complete absence of knots and other cosmetic defects. However, the cost of such a block of house is quite high.

The next class of material is "A" and "B". They have a greater number of knots, and some other defects are acceptable on their surface.

The next class of material is "A" and "B". They have a greater number of knots, and some other defects are acceptable on their surface.

The cost of such material, respectively, is much lower than that of the extra-class, but if you are not too demanding on quality, then you should pay attention to this option of the economy class. Moreover, sealing small chips or dents is not a big deal.