Varieties

The product for different types of connection is available in different sizes and diameters. Differing in shape, direction of internal and external threads, combining inconspicuousness, it provides multiple disassembly of the product, preventing its deformation. A small part, which can be made of different materials, serves as a fastener and represents:

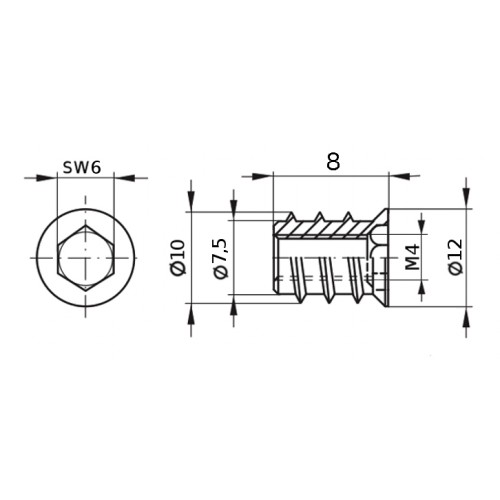

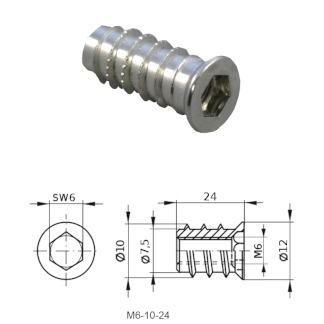

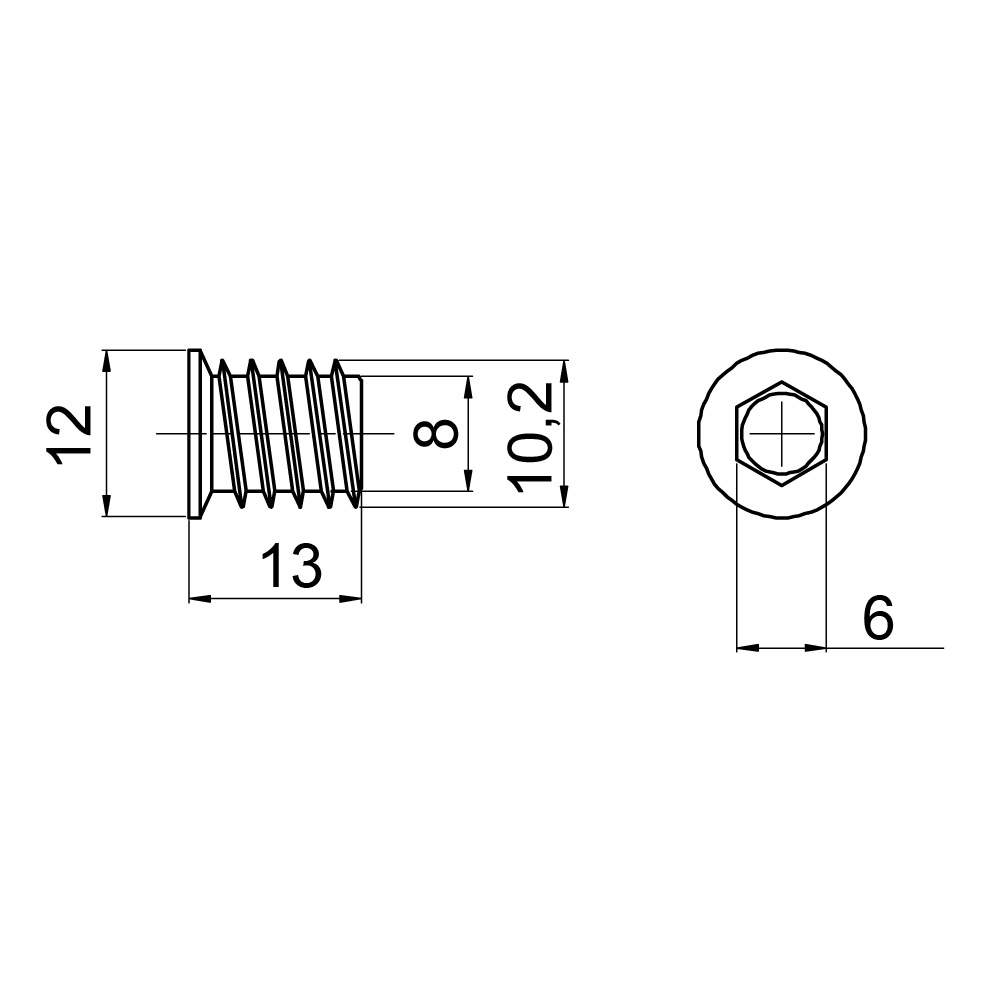

- hardware with a slot for a hex wrench or screwdriver;

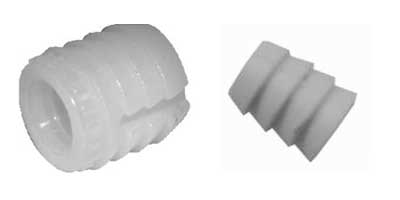

- expansion and spacer adapter, for self-tapping screws, nylon;

- a case with a latch for fixing furniture supports;

- hardware with a spacer ball, for eccentric, conical ties, using a rod, a screw.

Today, a special place is occupied by a plastic case for furniture. Inexpensive hardware, easy to use, easily cuts into the hole of the surface, does not deform, due to the peculiarity of the location of the thread and its direction. The main advantage of the part is its reliability and high load capacity.

Hardware with a groove

Hardware with a groove

Hardware with a spacer ball

Hardware with a spacer ball

Expansion frame dowel

Futorka with a lock

Futorka with a lock

Manufacturing materials

Threaded products for various types of connections are made of corrosion-resistant steel, brass, non-ferrous alloys with nickel, anodized, zinc, chrome plating, high-strength plastic, aluminum. Most often, when disassembling, assembling, repairing furniture, steel furniture footboards are used. Being reliable elements for fasteners, they have a number of advantages:

- high strength throughout the entire operational period;

- increased resistance to corrosion due to the high content of alloying elements;

- ease of installation, which contributes to a hermetically sealed connection;

- have a small percentage of defects;

- parts are resistant to temperature extremes.

Today, in the furniture industry, plastic footwear is considered to be no less popular. Possessing high wear resistance, reliability, they can easily replace metal products. Plastic hardware has good impact and mechanical strength, low weight, density, can withstand various loads without changing its shape, without requiring special efforts in connection.

Plastic

Plastic

Steel

Steel

How to choose the right

The main task in the selection is to accurately determine the dimensions of the external and internal threads (union and nut, in the language of specialists). In addition, it is necessary to determine what type of thread is needed - metric, inch or pipe.

The most common thread options and their sizes

Plumbing is divided into two broad groups. The first of them is intended for installation in cast iron sanitary ware or pipelines, heating radiators, etc. Their advantages:

- relatively low cost;

- ability to withstand pressure up to 25 bar and temperature up to 300 ° C;

- the ability to use in difficult conditions, in contact with hot water, steam, oil, etc.;

- the presence of fittings with right and left threads.

The second group is used on aluminum or bimetallic products. As a rule, the material is galvanized steel, which is resistant to corrosion and other stress. The composition of the footwear of the second group has the following characteristics:

- maximum pressure - 16 bar;

- maximum temperature - 110 ° C;

- installation with a special tool that does not destroy pipelines or radiators;

- use of a special powder enamel coating.

A special table will help to determine the necessary parameters.

The diameter of the thread depends on its pitch and the number of threads per inch.

Products for cast iron elements of the system have great strength and are capable of experiencing high loads. Elements of the second group are designed for milder conditions, which must be taken into account when choosing a suitable fitting.

When buying, you should carefully inspect the products, trying not to miss mechanical damage, cracks or other surface flaws. The best option would be testing - trial connection of them to elements with a suitable thread. It should be done easily, without stress and over the entire length of the thread. Otherwise, use a different sample or type of fitting.

The use of this fastener allows you to solve many problems without the use of welding or complex technical devices. The purchase and installation is quite accessible even to an unprepared person, the main condition is the correct selection of an element in terms of thread and size. If no mistakes are made, the installed fitting can serve for many years without causing any trouble to the owner.

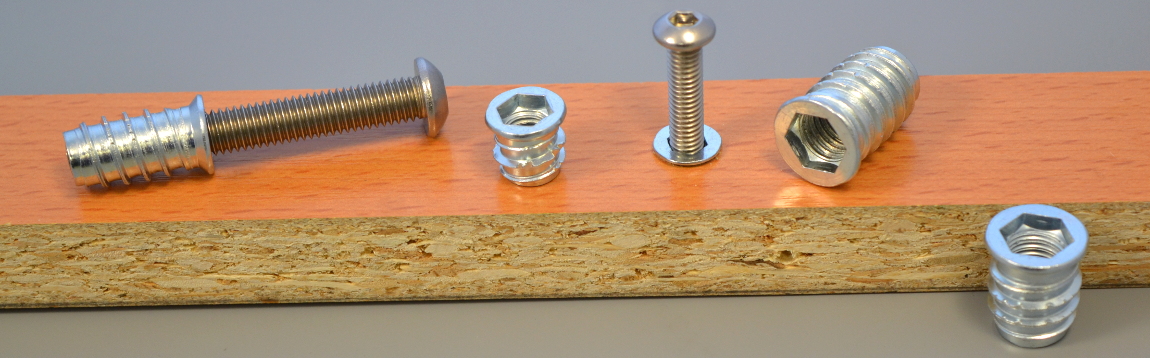

What it is?

Furniture foot (threaded nut-sleeve, sleeve) is a fastener that allows you to make a socket for a standard metal screw or hairpin in a wooden or plastic surface. It looks like a small cylindrical part with a threaded hole and threads on the outside. Sometimes a retainer is used instead of an external thread. The thread (or retainer) on the outside serves for the most tight fastening in the material, and the inner one for screwing in the screw that attaches the second part.

The advantages of using a footwear are as follows:

the counter screw can be screwed in and out an unlimited number of times, which allows you to make furniture collapsible and transformable;

the connection is more gentle for the material than a self-tapping screw, and this is very important in furniture of soft wood, MDF, chipboard, plywood, plastic; it would be almost impossible to make collapsible structures from these materials without a futorka;

the aesthetic appearance of the connection - it turns out to be secret and neat, there are no protruding elements that spoil the appearance of the wooden surface;

allows you to speed up the assembly of furniture, while the fastening is highly reliable: the threaded bushing gives additional rigidity to the connection, absorbs part of the mechanical load; the furniture will not fall apart at the most inopportune moment, will withstand the required weight and will last for many years.

Appointment

The connecting product, due to its design feature, is an important element in the assembly and repair of furniture. The futorka furniture is a fitting with a metric internal thread and external screw... It is widely used when installing shelves in cabinet, kitchen furniture, as a base for hooks.

The part is well suited for joining complex planes, especially with an end rectangular screed, when assembling and disassembling furniture made of chipboard, MDF and soft wood. The part, providing reliable fastening, is quite technological, has the correct thread pitch, diameter size, a small degree of surface roughness, and tightness.

The main service purpose of the part is screwing or driving into a prepared hole on the surface. Hardware, coinciding with the passage in diameter, thread, provides an accurate, strong connection, does not allow gaps and distortions between fasteners. The product, even with an increase in the contact area, tolerates the load well.

The product is technologically advanced by its design features: it effectively reduces time costs, contributes to the quality of furniture manufacturing and repair. To improve the anti-corrosion resistance, the parts are plated with chrome or zinc.

Features of choice

When choosing a footwear, it is necessary to determine which type of footwear is needed, what dimensions and characteristics it should have, what loads to withstand and what material it should be made of.

It is especially important to choose the right size of external and internal threads and their type (metric, inch, pipe; right or left). To do this, you need to carefully study the characteristics of the counter thread on which the foot will be mounted.

It can be difficult for a non-professional to determine the type of thread in this way, so it is worth resorting to the accompanying documentation for the equipment for which the footwear is being selected, or using the advice of an experienced craftsman.

Here are some tips to help you when choosing different types of footwear.

- If we are talking about the installation of water or heat supply systems, then all the elements of the installed system, including fittings, are best bought in a set, from one line of a certain manufacturer. This ensures maximum hardware compatibility.

- For pipes made of some metals, not all adapters are suitable (even if they fit on the thread), but only from the appropriate materials. So, for copper pipes, only copper fittings with brass elements are suitable, for cast-iron radiators and pipes - only cast-iron ones. For plastic pipes, steel and cast iron fittings will be too heavy, plastic, brass or combined adapters are used here. But fittings from any materials are combined with steel pipes.

- In the catalogs of manufacturers for a metal pipe with a thread, the diameter is indicated, measured along the inner side of the pipe (excluding the thickness of the pipe itself), and for plastic pipes, along the outer (taking into account the thickness of the pipe). This must be borne in mind in order to correctly select the bore diameter and join pipes made of different materials.

- The repair spring sleeve must sink ¼ of the thread pitch into the hole. It must be selected based on the fact that in a free state, the length is slightly less than after installation. When designating such fittings according to the DIN standard, this feature is taken into account, and the final size is indicated (for example, an M8 2D insert in the installed state and with a broken shank will be a length equal to two diameters, that is, 16 mm). But when it comes to non-standard models, manufacturers can use their designations, and you need to be especially careful when choosing.

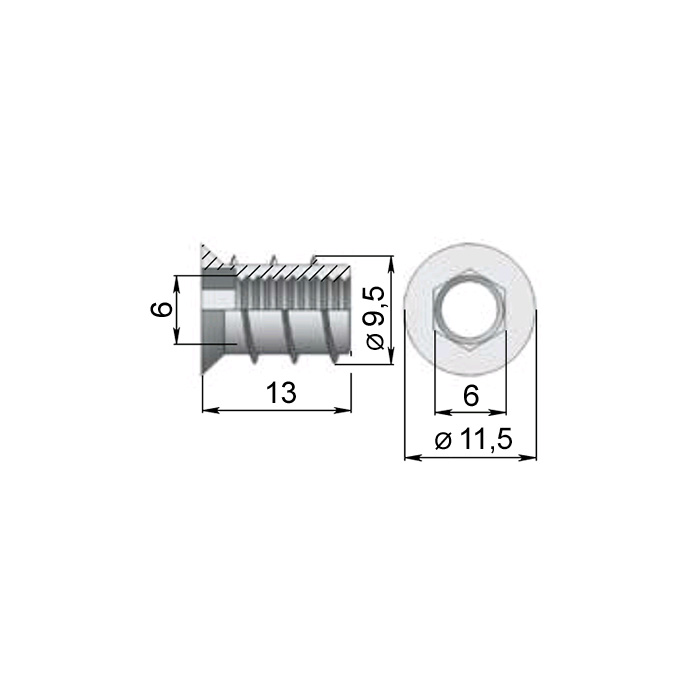

- When installing the furniture footboard, the edge of the hole and the top edge of the footboard must exactly match, and the length is selected so that at least ½ thread pitch remains from the bottom edge of the footboard to the surface (the hole is usually not through).

In any case, it is better to choose universal parts made according to GOST / DIN standards. They do not require special tools to install, they are compatible with other typical equipment. What mechanical loads a part can withstand, in what environmental conditions it can be used and other important characteristics can also be found from the corresponding standard.

When buying, you need to make sure that the thread is smooth, and there are no cracks or damage on the body of the part. To ensure the quality of the threads, you can "test drive" the fitting by connecting it to a suitable mating thread.

The following video provides an overview of the stainless transitional outer case.

Attachment nuances

An adapter with a through hole, regardless of the material of manufacture, allows the rotary action to be carried out evenly, progressively, without much tension. The main difficulty in mounting a part is maintaining high accuracy when drilling a hole.

When using a part, special attention is paid to its outer and inner diameters, thread pitch. When in contact with threaded hardware, they must be aligned

When installing the footboard, it is necessary that:

the centers of the bore and the part to be connected were coaxial so as not to break the hole, not to worsen the strength of the connecting elements;

when manually drilling a non-through hole, care was taken not to damage the face of the formation;

When screwing the part into hardwood, a special lubricant or wax was used to facilitate screwing. The tightening force is adjusted according to the protruding excess of the substance;

the hole was drilled perpendicular to the surface of the panels to be connected to prevent them from creeping during the installation of the screed .. When working with a fastener, an electric drill with a soft start function is usually used, a furniture jig for drilling, which is very popular among furniture makers

With the help of a unique device, drilling for fasteners, fittings are performed with high accuracy and speed, which makes it possible to correctly fix the footboard

When working with a fastener, an electric drill with a soft start function is usually used, a furniture jig for drilling, which is very popular among furniture makers. With the help of a unique device, drilling for fasteners, fittings is performed with high accuracy and speed, which makes it possible to correctly fix the footboard.

The main structural element is the bushing for guiding the drill. The tool is made of wood, MDF, chipboard, plastic metal, which greatly facilitates the installation of threaded fittings made of various material groups.

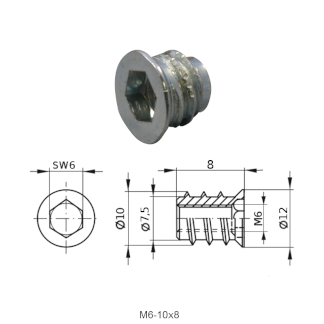

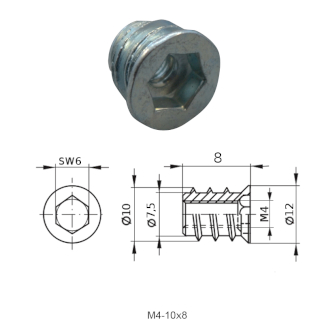

Mounting features

Installing the footwear is a task that you can handle yourself. The main thing is accuracy and attentiveness. The hole for the foot is made using a conventional drill with a drill of a suitable diameter. You can mark the drill with colored duct tape to see how much you need to immerse it in the material. You need to drill a hole, keeping the diameter accurate to the millimeter. If the hole is larger, the sleeve will not be able to hold, if it is too small, it will be impossible to screw it in. Therefore, you need to accurately measure everything and choose the right tool.

It is recommended that you use a drill designed for the wood or material you are working with. So there is less risk of damaging the material. The drill bit for metal is too tough, it is better not to use it for working with soft wood or DPS. The size of the hole is usually made equal to the outer diameter of the foot or 1–2 millimeters smaller (when screwing in, the thread of the foot cuts the material additionally, the adhesion is tight, without gaps). How many millimeters to throw in each case depends on the material in which the sleeve is fixed and on the method of attachment (thread, notch, additional spikes).

When the hole is ready, you need to insert the foot into it. Threaded furniture couplings are installed by screwing in with a screwdriver or a hex key, if there is a slot, a screwdriver can be used. When working with hard types of wood, wax or a special lubricant is used to facilitate screwing. The protruding excess of the substance also allows you to control the tightening force. Fittings without thread are hammered in with a hammer.

For an overview of furniture fittings, see below.

Appointment

The furniture foot is used in those areas of fixation where maximum reliability is required. It allows you to create the following:

- dismountable screw connections, fastening of furniture supports, for example, dismountable tables, chairs with unscrewed legs;

- non-separable screw connections - fixing vertical posts for railings, joining wooden panels, assembling cabinet furniture, assembling shelf supports;

- fastening mechanisms for opening furniture doors at different angles - an all-metal canopy on the footboards;

- fastening small functional or decorative parts to the furniture body - hooks, shelves, handles;

- connection of planes at complex angles, long wooden products - fastening parts of handrails at an angle, front panels;

- as a fastening element for eccentric couplers;

- replacement of broken or loose threaded connections.

Views

Fasteners with a through hole are widely used in the furniture industry, while furniture nuts can vary in shape, as well as in the parameters of the internal thread. The most common hardware is a hex nut, its technological design allows for rotational movement progressively, evenly, without requiring special physical effort when tensioning.

Nuts can be made in a multi-faceted shape, have a trapezoidal or metric thread. Different diameters make furniture nuts unique - this allows them to be used in any work, even when the weight of the structure is strictly limited.

There are several popular types of nuts on sale that are used in the manufacture of furniture.

Spherical - the model is a typical hex nut with a cap outer surface and a plug on one end of the threaded hole. It is used in detachable mounts. The cap helps to close bolts and other protruding elements, thereby reducing the risk of injury during product use, as well as giving the structure an aesthetic appearance.

Hammered

Such nuts are mainly used in automated furniture production; they have not found widespread use in everyday life. In the factory, a hole of a suitable diameter is formed in the structure, after which the nut is hammered in with a hammer.

This ensures accurate assembly and high speed of work.

Mortise

These furniture fittings are manufactured from corrosion-resistant, zinc-plated stainless steel. Outwardly, this design resembles a sleeve, while the internal thread remains flat. A metal disc with a hole at the end is provided. This design allows you to firmly hold the hardware in the material and prevent the risk of twisting during the tightening process. Widely demanded for unilateral fixation.

Hidden

Hidden furniture nuts play a special role among the entire assortment of hardware. Their structure provides the most durable fastening when assembling furniture blocks of any type. A countersunk nut looks like a small bar with a metric type female thread. The hat is semicircular, decorative. All elements are manufactured from corrosion-resistant galvanized steel. Models are indispensable for assembling tables, as well as beds and cabinet furniture, it is distinguished by a decorative look - hardware is almost invisible on the outside of furniture, therefore it is often used in the manufacture of cabinet furniture.

Materials (edit)

Furniture frames are made of metal or plastic. Metal is made of corrosion-resistant steel (carbon steel, steel grade A2, A4), brass, aluminum, non-ferrous metal alloys. For increased resistance to the environment, it can have an anti-corrosion coating - nickel, zinc, chrome, anodized. Metal hardware is used for important fasteners that must constantly withstand increased loads. They have increased wear resistance, but they are not suitable for products made of soft wood and for fastening miniature parts - they are too heavy, there is a high risk that the wooden surface will crack when screwing them in. In these cases, plastic fasteners are ideal.

The plastic case has the following advantages:

- modern plastics make it possible to make very durable and high-quality parts;

- they are not afraid of moisture, resistant to various environmental influences;

- cheaper and easier to manufacture;

- easily cut into surface holes, do not deform, provide a good connection tightness.

Therefore, plastic footwear is widely used in modern furniture fasteners.