Veneered furniture: recommendations for selection

Furniture covered with veneer must be chosen correctly. After all, it will depend on this whether it will become a decoration of the living room or spoil the interior composition. There are some general guidelines, let's take a look at them.

- When buying such pieces of furniture, carefully examine their facade. It is advisable to inspect from different angles. So that later it turns out that in the living room you have a piece of furniture with coating defects.

- The veneered surface should not have obvious defects: chips, cracks, scratches. Also inspect its edges, if the veneer is glued poorly, then you will notice this, precisely at the edges of the product.

- Be sure to find out who is the manufacturer of the furniture you like. Do not buy furniture from underground craftsmen.

- And one more tip, furniture with double veneering is of higher quality and looks closer to natural.

Thus, veneer furniture can also take place in the interior of the living room. If you want to design a living room in which naturalness and proximity to nature would be captured in everything, but the budget does not allow purchasing expensive solid wood furniture, then veneer-covered furniture in this case will be a good option. It will be a good imitation of luxury furniture, and will also contribute to creating a cozy and warm atmosphere.

Interesting:

Soft corner for the living room

Beautiful mirrors in the interior of the living room

Furniture from Spain in the living room

Bar counter, wardrobe and table in the interior of the living room

Black and white furniture in the living room - choose wisely!

German furniture in the living room

Luxurious and exclusive furniture in the living room

Classic living room furniture - choose yourself!

Furniture characteristics

The peculiarities of veneer furniture are determined by the materials used for the production, as well as by the manufacturing technology.

Affordable price. If we compare it with the cost of natural wood (especially solid wood), then it can be called more than moderate. And it is this dignity that attracts most of the buyers.

High-quality veneer can look almost the same as natural wood, and it is very natural. And this allows you to achieve the most aesthetic appearance of furniture made from this material. Objects obtained from wood have been valued at all times and still remain popular. And it is sometimes difficult to distinguish veneered furniture from natural furniture, even upon closer examination.

Veneer is an environmentally friendly material that does not emit any harmful substances into the environment. Of course, in the manufacture, adhesives are used that fix wood sheets on the base, but respectable manufacturers use high-quality glue. In addition, it is located under a layer of veneer, so that its components cannot evaporate unhindered.

The base is also environmentally friendly.

Veneered furniture is much lighter than wooden furniture, that is, it is easier to transport and move, and for many this is important.

Veneer is an almost universal material from which any furniture is made: for a living room, for a bedroom, a children's room and even a kitchen.

This material has a stylish design. Firstly, the surface has a unique pattern, characteristic of the natural wood texture.

Secondly, there is a colored veneer, and its shades can be very different, so the choice is very wide.

Furniture items of any complexity are made from this material. You can draw up a sketch yourself and place an order, then you will receive an exclusive and ideal model for you.

Practicality. No complicated maintenance required.It is enough to protect the furniture from rough mechanical and aggressive chemical influences, and also wipe it with a soft damp cloth, removing dust and dirt.

Durability. Veneered furniture will last a long time and will retain its original qualities, and this does not require much effort.

Durability and reliability. This material is durable, because, in fact, it is multilayer and has a solid base and no less durable wood coating.

Since the veneer is processed in a special way, the coating becomes resistant to high humidity, minor mechanical and other influences. From this point of view, wood can be called a more "capricious" material.

The material does not have any unpleasant odor.

- If you accidentally damage the veneered furniture facade, you will have to carry out a complete and rather complex restoration.

- Veneer can fade in direct sunlight, so furniture should be protected from this.

- Furniture cannot have smooth corners, since it is almost impossible to cover such areas with veneer.

- Veneer reacts to sudden temperature changes and may change some of its properties because of them.

- If there are wide surfaces in the object, then the joints may be noticeable, since each sheet has its own unique pattern, and it can be difficult to pick it up.

- Damage may remain on the surface after rough mechanical stress.

- Exposure to aggressive chemicals can also damage the surface. For this reason, do not use products containing acids or abrasive particles for cleaning.

- Poor quality furniture can have an unpleasant odor and even emit harmful substances into the environment, so you should be careful when choosing.

- Veneer made from expensive woods may not be cheap at all.

- Light-colored furniture can be contaminated by, for example, coffee, strong tea, wine or Coke.

Now you know everything about veneer furniture and you can decide if you should buy it.

Veneer furniture production

To make veneered boards, it is necessary to glue the thinnest cut layer of solid wood on MDF boards, which was cut and sewn before. Further, the surface must be covered in several layers with primer and varnish or oil, which will protect the wood from mechanical damage, dirt during use. In addition, such coatings give the final product a warm, pleasant matt finish or, on the contrary, an almost mirror-like sheen.

It is interesting that the choice of patterns and shades of veneer is much wider than the palette of natural wood and, of course, chipboard. No two trees are alike, the pattern of one piece of furniture will always be different from the other. This is a colossal advantage of both solid wood and its veneer.

When choosing a type of wood, you choose a texture, and the color itself can be different. For example, an object made of oak veneer can be tinted in the shade "Wenge" or, on the contrary, whitened.

Cons and pros

In appearance, doors with veneer are very difficult to distinguish from their counterparts made of wood, since they are covered with a natural cut of wood.

Such doors have many advantages:

- The product is 99% natural in composition, since it includes solid wood and a cut of valuable wood from the outside.

- Veneered doors are made from environmentally friendly materials, so they are often used not only for bedrooms or living rooms, but also for children's rooms.

- The attractive appearance of the product is achieved through the use of natural wood, which is characterized by an original and unique print and texture.

Wooden doors with veneer make it possible to create a good indoor climate. They perfectly pass air through micropores.

The lightness of veneered models allows them to be installed even on very thin walls. If the doors are installed correctly, then in rare cases they can sag.

A good combination of quality and price of the product. If we compare the cost of veneered and wooden models, then the option with veneer is much cheaper.

If a model with natural veneer is also expensive, then you can pay attention to options with eco-veneer or other artificial turf.

Models with veneer very often convey the texture of a valuable wood. Cherry, pine, wenge, mahogany or ash veneer looks beautiful

Expensive tree species include such as black walnut and madrona.

- Veneered models can be repaired if the canvas is damaged during transportation or operation. It is necessary to use a special compound for staining veneer or to polish the damaged area.

- The product with veneer is characterized by excellent sound insulation properties, as well as the ability to perfectly retain heat, if we talk about options made from solid pine wood.

- Modern manufacturers offer a wide range of veneered doors, among which you can choose not only the material, but also the color and the required dimensions. The doors are presented in natural colors. To give the veneer color depth, staining is often done.

Doors with veneer also have some disadvantages, which you should familiarize yourself with before choosing doors:

- Natural materials are always expensive, which is why veneered models are expensive. The popularity of the manufacturer also affects the price of doors.

- Natural veneer practically does not differ from artificial one, which allows fraudsters to pass off low-quality veneer as natural.

- To ensure long-term use of the product, careful care must be taken. To clean the doors, it is worth using special products developed on the basis of wax.

For the manufacture of laminated doors, a special laminate film is used. It perfectly conveys the texture of the array. Of course, such products are distinguished by affordable cost, increased wear resistance and reliable protection against moisture ingress.

Tips for choosing. Veneer against PVC

Based on all the listed characteristics of veneer and doors created with its use, we will try to highlight a few tips for choosing such products:

First, notice the texture of the door and the pattern on it. If you see two identical ornaments, you can be sure that the manufacturer used fake veneer;

To make sure that the veneer is glued properly, look at the end of the door

The edges of the coating should not protrude and pry off with a fingernail;

When choosing a door, pay attention to the quality of veneer gluing

- Examine the surface carefully. Neither the veneer itself nor the varnish covering it should have cracks and foreign objects;

- Sniff. Natural veneer created according to all the rules does not emit an unpleasant odor.

The veneer door has a beautiful look and is environmentally friendly

And finally, let's answer one more burning question, which doors are better: veneered or PVC? On this occasion, you can meet a lot of controversy, both in real life and on forums on the Internet.

Of course, it is impossible to answer unequivocally which door is better, since both veneered and PVC products are high-quality and low-quality models. In this case, the best door will be the one that is made in good faith.

The veneered door is perfect for eco-style

Sliding veneer door in the children's room

The main advice can be the selection of the door, depending on its purpose, as well as the style of the room.

So, for rooms with high humidity (bathroom, kitchen), experts recommend choosing PVC doors. It is better to install a door made of natural veneer in the nursery.Doors with artificial foil harmoniously fit into modern designs, such as high-tech and modern, due to the richness of their color palette. It is better to install veneer doors in rooms oriented to the classic style.

High-tech veneer door

Types of material

There are several hundred species of wood suitable for making veneers of various textures, colors and textures. Materials can be white, creamy, light brown, chocolate, golden, caramel, purple, bright red. From cheap raw materials canvases can be made, similar to expensive varieties of rose, red, ebony. There are ways to make the surface look like marble or stone.

Depending on the technologies used, methods of sawing logs, there are several types of veneer:

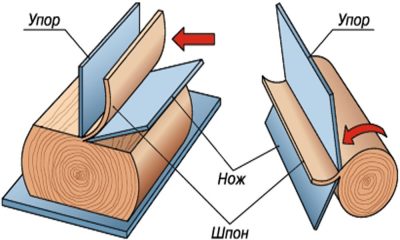

- Peeled. The cheapest, thinnest material, the thickness of the web is from 1 to 5 mm. It is obtained from round pieces of logs, which are rotated, clamped from the ends, into the grooves. A metal cutter removes the chips from the surface. Raw materials - birch, aspen, alder, oak, beech. The finished canvas is used mainly in the production of combined finishing materials.

- Sliced. The thickness of the finished sheets is from 4 to 10 mm. It is obtained by processing blanks with special knives. The angle of inclination of the bars during cutting is different, which makes it possible to obtain plates with different textures and patterns. The following types of raw materials are used: cedar, fir, pine, beech, hornbeam, birch.

- Sawed. The most expensive kind. It is produced by processing cubic or round pieces of wood with special saws. The resulting planks are 5–12 mm thick. A lot of waste remains, so the blanks are produced in small batches. Mostly conifers are used.

Sliced veneer is cut by guiding the knives along the grain or at different angles. Canvases are obtained in several types, each of which is marked:

- radial (P): with a pattern in the form of straight stripes of annual growth rings over the entire surface;

- semi-radial (PR): the stripes are parallel, located on 75% of the sheet area;

- tangential (T): annual layers form a silhouette of growing cones or curved lines;

- tangential end (TT): on the surface - closed circles or ellipses.

The reverse side is different from the front. The "wrong side" is in contact with the cutting surface, has microcracks, is loose, less even to the touch. The front side is smooth.

Another of the varieties is fine-line. It is sometimes considered plastic, but this is a misconception. This material consists of natural wood, it is obtained by reconstruction: pressing peeled plates into large blocks, followed by cutting into sheets. In the process, dyes and glue are used, which help to create imitations for expensive types of wood.

Production technology

To obtain the plates, high-quality raw materials are selected. Timber should not contain a large number of knots, resin passages, areas of deeply ingrown bark, wide cracks. Curliness is not a disadvantage, as it allows you to get a beautiful decorative pattern.

Preparation of logs includes removing the bark, cleaning the upper damaged layers, cutting into large ridges. Depending on the type of subsequent processing, the logs are divided into smaller fragments.

To soften the structure or correct the color, the workpieces are steamed for several days, or even weeks, then soaked in hot water. The exception is capricious breeds, for example, maple. There is a risk of losing the natural light color.

To get the canvases, the prepared wood is driven through the machines. Fresh leaves are dried, sorted, stacked and cut.

In the manufacture of fine-line, peeled veneer is immersed in containers with dye or etched with glue already assembled in piles. After a while, it transforms into a layered conglomerate.Then the glued material is placed under a high pressure press, where it acquires the required density. Then sheets are planed from the finished mass.

Fine-line is distinguished by high decorative qualities, is plastic, more resistant to moisture and temperature changes.

Selection of materials

For the manufacture of veneer coatings, only the most expensive and beautiful types of wood are used:

- ash - characterized by increased strength, has an unobtrusive cool shade;

- alder - this tree is distinguished by exceptional resistance to deformation, as well as to the adverse effects of moisture, gives a pleasant impression of a velvety surface;

- oak is one of the noblest and most expressive materials of the highest strength and strength, such a coating will be durable and will not change its original appearance for many years;

- cherry is a strong and sturdy tree, which has a pleasant reddish tint, over time it only becomes richer and deeper;

- walnut is a material with a spectacular texture, presented in the richest shade palette.

Thanks to the use of modern technologies, natural coatings have been repeatedly improved - they have become more uniform, durable and at the same time decorative. Thus, we got an eco-veneer or fine-line, which looks much brighter in modern kitchens. Although its perfectly smooth surface raises doubts about its natural origin, it is nevertheless the same ordinary wood, only before cutting it is painted and glued into blocks. Usually available and fairly soft poplar is used for the production of such material. Such a coating is much cheaper than natural veneer, at the same time it is inferior to it in density and durability.

Scope of application

Finishing furniture and interior with veneered oak has long and firmly entered the fashion, which does not lose its relevance. The veneer can be used in the form of a solid canvas, or a collage is made from its pieces, choosing color shades that contrast with each other. A board made in the technique of marquetry with the use of various shades of veneer is used as an interior decoration, a door leaf or a facade for furniture.

Oak veneer is used for the manufacture of parquet flooring or platband and door leaf, a veneered window sill can be made from a natural cut of oak wood, a headboard is decorated, a rack is made. Oak veneer is used for inlaying arched openings and passages between rooms. This material is used to decorate staircases and steps. The high demand for natural oak flooring is due to the versatility of this material and its durability.

Colors

Veneered doors are available in a wide range of colors.

They can be selected for any room interior:

- For small rooms, you should give preference to light models. They will add light, make the room visually more spacious.

- White is versatile as it can be used in a variety of styles. Doors with white veneer look elegant, add softness and tenderness to the design. Options veneered with bleached oak look strict and restrained.

- Lovers of natural color solutions should take a closer look at the color of Milanese or Italian walnut. These shades give the veneer a natural look. Such doors are ideal for creating comfort and coziness in the interior of the room.

- Wenge doors are presented in a wide range of tones, from golden to dark brown. Models with wenge veneer are distinguished by excellent performance and fashionable appearance.

How is veneered MDF made?

The manufacture of such material is a rather laborious process, however, with the help of high-tech equipment and the skill of workers, excellent results are achieved.The factories use fully automatic mechanisms and high quality raw materials.

Natural veneer comes to factories in rolls or packs, packaging is carried out taking into account the required dimensions and properties that will differ in the final product. Experienced craftsmen put prepared veneer sheets on the prepared and treated MDF surface with a special adhesive. When using roll raw materials, gluing is carried out in one step. When gluing veneer, which is brought in in packs, a special technology is used. It consists in longitudinal and transverse gluing, which resembles a fish bone. There are other gluing methods. But all processes are necessarily strictly controlled by employees and using a computer that carries out measurements and settings. The veneer is glued to MDF boards with an adhesive. The next step is press drying, after which the surface still needs to be sanded and varnished. Today, many industries use a high temperature drying press. It makes it possible to glue veneer on many MDF boards in a short time, therefore, much less time and money is spent on warehouses for drying the final product. Provided that the surface of MDF is uneven, for example, on curly door plates, the technique of vacuum gluing is used. However, this process is more costly and time-consuming.

After all these procedures, the resulting veneer plate must be sanded first across, and then along. Only after that a perfectly smooth surface is obtained. In addition, in order for the varnish to lay down more evenly, the veneered surface must be ironed with a hot roller. This must be done because there is a possibility that the wood grain on the veneer will rise during the application of paints and varnishes. As a result of this painted surface, bumps or depressions can form, which greatly spoil the appearance and quality of the final product. For this reason, ironing technology is used, during which excess fibers are soldered to the surface, and it becomes completely smooth.

The slab is painted with transparent or opaque varnish, colored paint, as well as special wax.

Despite the fact that there are huge reserves of forest in the world, wood is still a valuable and expensive material. Therefore, veneering MDF profiles or panels is the most profitable solution than solid wood.

Veneer or solid wood: which is better?

Solid wood furniture is considered the most status, sound and reliable.

Products made from a single piece of wood have always attracted attention at a high price. Door leaf, furniture, solid parquet flooring belong to the number of luxury interior items and are an indicator of the wealth and status of their owner.

Interior items made of wood are always classics of the genre, they are beyond competition and fashion. If you decorate wooden furniture with semi-antique fittings, then you get a real work of art. At the same time, such furniture is very capricious and, without proper care with special wax compositions, will soon lose its outer gloss. In addition, wooden furniture is not recommended to be placed in rooms with variable humidity. Making furniture from solid wood is a costly procedure, which cannot but affect its price. In this regard, the popularity of veneer is growing every day. Veneer products are much cheaper than wood products and easier to handle, they are lighter in weight. In general, veneer furniture will look like solid wood and feel like wood. In order to prevent cracking of the veneer due to compression or expansion of the inner base, it is preliminarily pasted over with chipboards, and a layer of veneer is already fixed on them.Also in favor of veneered furniture is the fact that such furniture is not afraid of changes in humidity and temperature in the room, direct sunlight. And all thanks to the fact that after the product is veneered, it is covered with a special protective polyurethane varnish. Veneer products are not as bulky as wooden ones and can be easily rearranged. In case of damage to the surface of the furniture, it is enough to simply restore it by replacing the damaged element. Products covered with veneer also do not harm health, as they are manufactured using high-quality natural raw materials.

Features of natural veneer

This is a living material, which makes the presence of features inevitable: knots, waviness, stripes, sapwood, curls, eyes, created by nature itself, which is not a marriage, but only emphasizes the naturalness of the material. Especially vividly these features are demonstrated by veneers produced from old wood trunks, such as Retro oak veneer.

Features of working with natural veneer

The wood cut pattern is as individual as a person's fingerprints. The uniqueness of the pattern and color of the veneer of even one type of wood determines the peculiarities of working with this material:

- there is no way to make a sample, because a product made from veneer of a different trunk will differ from it;

- there is no way to create a warehouse program, because veneer in different locks and knols is different;

To emphasize the beauty of the pattern and create a harmonious piece of furniture or interior, consisting of individual parts, faced with natural veneer, we suggest using the option of selecting a veneer pattern, which ensures the transition of the pattern over the entire surface of the product from detail to detail, from element to element. The drawing can be picked up both horizontally and vertically.

When ordering products in natural veneer with or without pattern selection, it should be borne in mind that additional ordering of parts is impossible, because newly made veneer parts will differ in color, texture, pattern

We will not be able to find a veneer that completely matches the main order.

Classification

Depending on the method of obtaining the material, veneer is distinguished:

- shelled;

- planed;

- sawn.

Rotary cut veneer

Produced on special machines by peeling. Its thickness is 0.1-10 mm. It is a cheap veneer as it is produced in the lowest cost way.

Peeled birch veneer

To begin with, a blank is prepared - the tree trunk is cleaned of branches, twigs, etc. Then they place it in the machine. Further, the primary processing of the trunk is performed with a cutter: the bark is removed and the workpiece is leveled along the length. After that, a layer of veneer of the required thickness is removed along the entire length of the trunk at the same time.

The resulting semi-finished product is sorted by quality, appearance, etc. This type of veneer, in comparison with others, is not beautiful enough. Therefore, so that it can be glued to the door, it is processed, for example, dyed or hot-printed.

Sliced veneer

It is obtained by planing bars perpendicular to the wood fibers on veneer planing machines, in contrast to peeled, which is obtained by cutting off the wood layer from a rotating log.

Production of rotary cut and sliced veneer

Veneer is made from hardwood and softwood such as birch, maple, pear, elm, oak, linden, mahogany, etc. The thickness of the material obtained in this way is 0.2-0.5 mm.

Beautiful veneer for interior and exterior doors is made of twisted wood. In a twisted tree, the fibers inside the trunk do not run smoothly, but intertwine, forming patterns in the form of knots, bundles, etc.

In the production of veneer from such a blank, a layer is removed simultaneously along, across and at an angle to the fibers. This gives a beautiful pearlescent shine to the material. Karelian birch and sugar maple wood are valuable for such veneer.If you stick such veneer on ordinary wooden doors, then they will look much richer and more beautiful.

Sawn veneer

It is made by cutting blanks. Get a quality product with a thickness of 0.1-1mm. However, this type of production is the most uneconomical, since about 60% of the timber goes into sawdust.

By the texture of wood veneers are distinguished:

- radial (the pattern of annual layers is parallel lines that are located along the entire plane);

- semi-radial (the pattern of annual layers is parallel lines that occupy at least ¾ of the plane);

- tangential (annual layers create a pattern of a cone, angles or curves);

- tangential-end (annual lines create closed curved lines).

According to the material used for the production of veneer, they are distinguished:

- natural;

- fine-line;

- multi-veneer;

- eco-veneer

Natural veneer

Made from a natural solid tree trunk. At the same time, the structure of the tree is preserved. The cost of natural material is in the middle price category.

Fine-line veneer

It is also made from inexpensive and fast-growing natural wood species, but has a high porosity of the structure. The appearance resembles plastic. By dyeing, fine-line veneer can imitate natural veneer made from expensive wood species. This material is often used to decorate interior doors. It is made as follows. First, natural veneer is produced. Then the veneer sheets are dried, sorted and dyed in a certain color. After that, the sheets need to be glued together.

Fine-line veneer

As a result, the resulting block of veneered sheets is sent under the press. From the finished dried pressed block, very thin sheets of fine-line veneer are cut, which are glued to the surface to be decorated. According to its composition, it consists of 92-94% natural wood. The rest is glue and dye.

Multi-veneer

Refers to the reconstructed type of veneer, like fine-line. Geometric patterns are most often applied on its surface.

Eco-veneer

It is a polymer film with the addition of wood fibers. Its surface imitates the surface of natural wood. It is resistant to abrasion, changes in temperature and humidity. Veneered doors using eco-veneer are durable and do not lose their performance for a long time.

Eco-veneer doors

Types of veneer for furniture

There are three types of veneer - peeled, sawn and planed. Sawed veneer from 1 to 12 mm is obtained by sawing wood blanks into thin planks. The butt or burl is cut into boards of 4-6 mm. Most often, this type of veneer is made by the master himself.

Sliced veneer is created by planing with special knives on machine tools. This results in a veneer with the width of the workpiece. This type of veneer is made from coniferous and deciduous timber, as well as from burls.

The rotary cut veneer is cut in a spiral from a rotating workpiece, which is called a churak. Such material is made from popular and not very expensive varieties, for example, wenge, zebrano, oak, ash, cherry. When peeling twisted wood, the veneer will have a highly decorative structure. The front and back surfaces of the veneer are distinguished. Microcracks are often present on the back surface.

Why veneer furniture is good

- in an assortment variety of textures and colors, since both pine wood and expensive wood species are used for their production. The appearance of veneered furniture depends on the type of wood used to make the veneer. Depending on the varnish or paint used, veneered surfaces can be matte or glossy, in addition, they are often combined with enamel and film facing materials;

- in ease of processing, which allows you to obtain veneered blanks of various shapes for the manufacture of furniture for kitchens, living rooms, etc.;

- in the visual appeal of veneered furniture. Gluing precious wood veneer on a MDF or chipboard base gives the products a beautiful noble look. Its naturalness is palpable and clearly visible up close;

- in practicality. High-quality veneer kitchens are reliable and durable, as they are resistant to high humidity and temperature fluctuations - factors that have a destructive effect on furniture facades. Veneered furniture does not crack or deform during operation, therefore it is often chosen as the lower part of the headset;

- in maintainability. Minor scratches on veneered surfaces are removed by grinding, deep damage - with veneer patches;

- in availability. The cost of veneered headsets is much less than products made from natural solid wood.

Veneer, as a facing material, has certain disadvantages:

- under the influence of the sun, such a coating can change color;

- it does not tolerate cleaning with aggressive chemicals that cause bubbles and flaking on their surface. The exception is made of eco-veneer products - they can be cleaned with various means, but without abrasives and solvents;

- the unique pattern of each natural veneer sheet complicates the selection of patterns at their joints;

- higher cost of products made of oak, ash or beech veneer.

Frame types

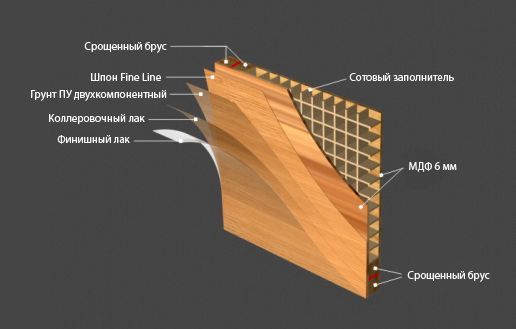

In interior veneered doors, a hollow frame is used or one that has a base of laminated veneer lumber.

Spectacular veneered interroom door

To create the frame of a hollow structure, well-dried pine beams are used (moisture content not higher than 8%). In cases when it is planned to mount glass in the door, a frame is also made around the perimeter of the future insert.

MDF sheets are nailed on top of the frame, the cavity inside is filled with honeycomb cardboard or expanded polystyrene.

Sliding veneer doors

Contrasting combination of dark door and white interior

Before veneering, sheets of the desired size are created from the veneer strips. They are selected according to their texture, soldered together on special machines, and excess glue is removed.

Fitting the sheet to the size of the frame, it is glued. After that, the product is sanded and varnished.

Veneer door structure

In a solid construction of beams, not only the frame is created, but also the entire base. Further processing procedure (MDF coating, veneer gluing) is the same as for hollow structures.

Glued laminated veneer lumber door with glass inserts

Hollow structures are lighter, but also less durable.

For entrance doors, as a rule, metal frames are used, upholstered with MDF, and then covered with veneer.

Interior doors and a wall finished with the same veneer look very interesting

Veneered interior door in a family room made of laminated veneer lumber