Where is it applied?

Due to its properties, Makroflex FR77 is widely used. First of all, this is the provision of fire protection for doors, walls and windows of structures, which must be fire resistant.

Also with its help:

- channels for cables and pipes in the wall or ceiling are sealed;

- cracks and holes in the ventilation ducts are filled;

- various seams and cracks are sealed;

- joints of roof structures are sealed;

- soundproof screens are created;

- the gaps near the pipes are sealed;

- construction details are mounted;

- insulating materials are glued;

- heating and sewerage pipes are fixed.

Description

Makroflex FR77 is a professional one-piece construction material. The product is sold in cylinders with a gun, prepared in advance for work. The volume of the package is 750 ml. The product complies with European standards, which are regulated by ISO 9001 / EN 29001.

The foam is intended for filling gaps and voids in the gaps between mineral and metal layers during the construction of buildings with specific fire safety requirements and evacuation times in case of fire.

Interesting: Mosaic in the style of Antoni Gaudí - in search of unique interior design

Rules for working with professional polyurethane foam

Let's consider the rules for working with Makroflex 750 ml.

Preparing the balloon:

The first step is to keep the balloon at room temperature for 12 hours. Shake the can at least 20 times before starting work. After removing the cap, secure the gun and check for a secure fit.

Preparing the surface for work:

The surface is preliminarily cleaned from dirt and dust. Porous - moistened with water from a spray bottle. The work is carried out at a humidity above 60%. If the air humidity is insufficient, then any surface is subject to humidification. Work on frosty surfaces or covered with ice is not carried out. To prevent foam from getting on other surfaces, they must be covered with plastic wrap.

Since the substance increases significantly in size, spacers are installed when installing windows or doors to avoid deformation of the structure.

Working process with Makroflex:

The balloon is held vertically upside down. The feed is regulated by the applicator gun. As much as possible, the foam should be applied in strips 4 cm wide and 10 cm deep. However, moist air is required for hardening. Therefore, if there is insufficient moisture, the size of the stripes is best reduced.

For a good connection between the layers, the previous one is sprayed with water.

At the end of the work, flush the gun with Macroflex Premium Cleaner 500/650 ml.

Precautionary measures:

For more information about the nuances of working with professional Makroflex foam, see the video below:

Safety is one of the main conditions when working with polyurethane foam

Do not use foam near open flames, hot surfaces. Remember that heating the cylinder over 50 ° C will lead to an explosion.

Due to the high quality, construction materials from the Finnish manufacturer Makroflex are respected and in demand among specialists and ordinary mortals. But polyurethane foam is especially popular, breaking stereotypes. It is created using the latest Buildtec technology. It is an extremely effective manufacturer's tool for a wide range of renovation and construction work. Construction of a wall, construction of a partition from blocks, installation of insulating and interior finishing panels, window sills and stair steps - with such a sealant, there is always a high result.

Product range

Varieties

Polyurethane foam Macroflex 750 is produced in professional and semi-professional versions.The difference lies in the characteristics, configuration and packaging.

Professional foam Macroflex has a reduced coefficient of secondary expansion, and the container is equipped with a mount for a specialized gun and holds 750 ml of material.

Semi-professional packaging comes with a straw to facilitate the release of the sealant. If you interrupt work with semi-professional foam for more than 30 minutes, you will have to clean the nozzle, which will require a cleaner.

Foam types are also classified according to the seasonal use of Macroflex. The foam is available for summer, winter and universal (all-season). The first is used at temperatures above +5 degrees. The winter one involves the use of up to -18.

The technical characteristics of these three types of foam sealant are different. The winter type of sealant is suitable for work at low temperatures, but this reduces the coefficient of expansion and material consumption. Winter Macroflex is allowed to be applied to damp materials covered with frost.

Spray nozzle - pistol

Properties

The main property of the product is increased fire resistance. When applied correctly, it is fire resistant and does not sustain combustion for four hours. Also, this foam has excellent heat and sound insulation parameters.

Makroflex FR77 adheres to all building materials. The exceptions are silicone, oils and greases (the foam simply drips off of them). Therefore, one of the conditions for preparation for work is the removal of such substances from the surface.

Foam can only be used at freezing temperatures. It should be stored in a dark room at a positive temperature, protecting the product from sunlight. Even short-term storage of the product at subzero temperatures is not recommended. After this, the properties of the foam may noticeably deteriorate, which in this case is unacceptable.

Cylinders should not be heated to high temperatures. If the cylinder is hot, it must not be shaken to avoid an explosion. It is better to gently dip the product in cold water for a while. After cooling, the cylinder can be used.

After application and hardening, the foam is able to withstand temperatures from -40 to + 80 degrees. The product loses its properties only with constant exposure to direct sunlight. In the absence of such an impact, the technical parameters of the foam do not change for decades.

Also, thanks to this, the highest possible speed of work is achieved.

Brand overview

The modern market presents a large assortment of polyurethane foam. To be sure to choose high quality material, you should purchase a can from a well-known and trusted manufacturer.

Ogneza

Fire-resistant polyurethane foam Ogneza is produced in Russia. Some characteristics:

- Fire resistance limit - EI 240;

- Application temperature + 5 ... + 35 ° С;

- Operating temperature -40 ... -80 ° С.

Fire foam can be applied at a slight cold of at least + 5 ° С, while it is necessary to heat the cylinder itself to + 18 ° С. The sealed material can withstand 2 freeze-thaw cycles up to 90 days without losing its original characteristics.

Fire is economical: 45 liters of foam comes out of a 935 g can! Affordable price is another advantage of the presented brand.

Macroflex

Makroflex presents a large series of polyurethane foams, including the fire-resistant Makroflex FR77. It has a wide range of applications:

- Seam sealing in the construction of panel houses;

- Fixing windows and doors in openings;

- Laying and fixing heating pipes, sewerage, etc.

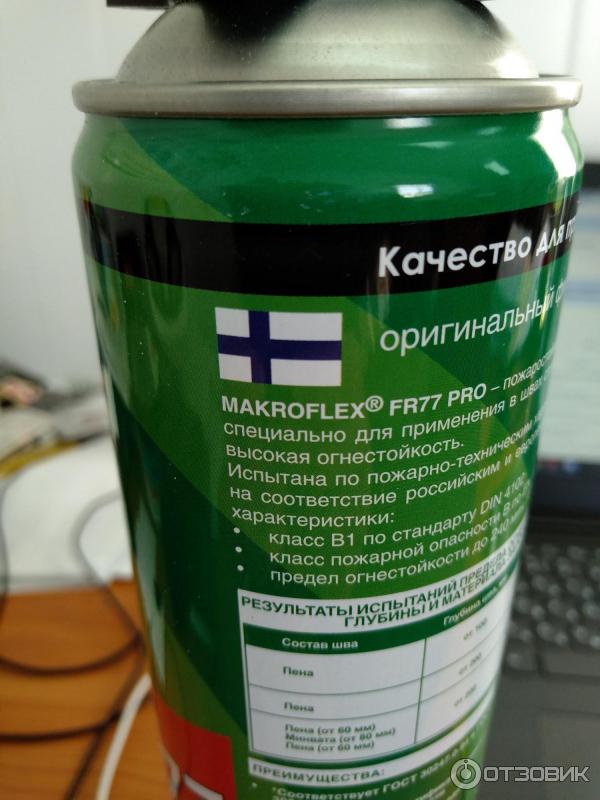

German developers' material has been tested in accordance with European and international standards. The brand is renowned for producing reliable building components that have stood the test of time.

Fire-resistant macroflex polyurethane foam is universal: its safety class is sufficient for use in public places, in residential apartment buildings and private houses, in industrial premises.

SOUDAFOAM FR (Soudal)

Fire-resistant polyurethane foam soudafoam fr is distinguished by an increased range of permissible temperatures in operation and a fire resistance coefficient of EI 360. This material will ensure maximum safety of the room and people in the event of a fire - the hardened foam does not support combustion and self-extinguishes after removing the fire source.

The applied foam polymerizes at a normal humidity of 60% within 2 hours at a layer of 30 mm.

The advantages of this insulator:

- High degree of protection;

- Effective consumption (from a liter cylinder, from 33 to 45 liters of foamed mass is obtained);

- High filling capacity;

- Increased adhesion to different surfaces;

- Stable layer without shrinkage and cracking;

- Available in different cylinders (with a tube or for a pistol).

DKC fire resistant polyurethane foam

A budget but practical foam insulator of an Italian brand originally from China. The material is used for instant insulation and fixation of window and door openings, electrical equipment.

Fire resistance temperature + 150 ° С. Such foam can only be used in passages with a low flow of people or in the back rooms of private houses. Operating temperature range -5 ... + 40 ° С. Suitable for indoor use only.

Recommendations for using Macroflex

The procedure for application is simple - the liquid substance of polyurethane foam, when the valve is opened, is released outward under the pressure of the gas in the can and gradually hardens, interacting with water in the atmosphere. The hardening of the material lasts a day. At the same time, the foam expands in volume from 50% to 250%.

Frost-resistant foam is used at temperatures above + 5 ° C. At a low temperature close to zero, before use, the can is kept at room temperature for at least 12 hours. When starting work, the container is shaken. To apply Macroflex to the surface, the can is held upside down, both in the case of manual foam application, and using a mounting gun.

Before foaming, the surfaces must be cleaned of dust and slightly moistened. Moistening the surface will increase the adhesion of the foam and accelerate curing. The amount of foam applied is controlled by changing the angle of the outlet valve. After filling with Macroflex, it is required to immediately clean up uncured stains using a special cleaner. Otherwise, the frozen pieces of foam will have to be torn off the surface with great difficulty.

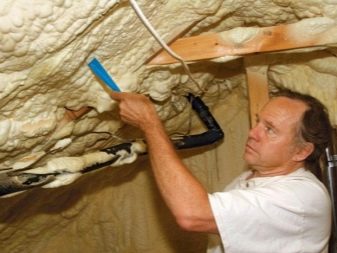

Insulation of the roof from the inside

MOUNTING FOAMS

Surface preparation

- Ensure the stability of the surfaces, clean them of substances that can impair adhesion.

- To improve adhesion, when working on mineral porous surfaces (brickwork, concrete, limestone), spray them with water.

- Cover the adjacent surfaces with foil.

Balloon preparation

- Application temperature (ambient) - from + 5 ° C to + 30 ° C.

- It is preferable to keep the balloon at room temperature for 12 hours before use. Temperature limits for cylinders: +5 ... +30 ° C.

- Shake the can vigorously before use (15 - 20 times).

- Remove the cap from the cylinder and screw it tightly onto the gun.

- Always hold the container upside down when handling the gun.

- The foam flow rate is controlled by pulling the trigger of the gun.

Application

Dispense foam sparingly to avoid excessive consumption. Shake the can periodically during application. It is not recommended to remove an incompletely empty cylinder. Shake the new can thoroughly before replacing. Install a new cylinder immediately after removing the used container to prevent air from entering the gun.

- Follow the guidelines for the fire test to obtain the correct level of flame retardation.

- If a new cylinder does not need to be installed, remove foam from the gun with a special cleaner. Hard foam can only be removed mechanically.

Recommendations

There are restrictions on the maximum joint width, taking into account the ambient temperature and humidity.In dry conditions (in winter, in rooms with central heating, etc.) to obtain the best structure and properties of the foam, it is recommended to fill the gaps and seams in several layers, applying thinner strips of foam (up to 3-4 cm thick) and slightly moistening each layer.

For best results, it is recommended to use an applicator tested and approved by the foam manufacturer.

This is interesting: Choosing a pneumatic gun for a sealant: lay out in order

Application nuances

Before starting work, it is necessary to completely clean the surface of dust, oils, various types of grease and other contaminants. It is necessary to remove all unnecessary elements, all porous areas must be grinded off. A coat of primer can be applied to increase adhesion between the surface and the foam.

When working, it is important to have a special cleaner or solvent on hand to immediately remove stains from accidental foam splashes on a clean surface

It is necessary to apply foam strictly according to the instructions. Recommendations for use are usually indicated on the foam canister and sometimes on the gun. The foam expands by about one third. When working, this fact must be taken into account. If too much foam is applied, sagging may occur. It is also necessary to monitor the level of moisture in the cavity that the product will fill. At high humidity, the foam "shrinks" and loses its properties.

The curing rate of Makroflex FR77 fire-resistant polyurethane foam is one of the highest among analogues.

Therefore, if you want to get a high-quality result, it is extremely important to monitor the cleanliness, the optimal amount of the applied composition and the conditions for carrying out all stages of work.

See the following video for the test of Makroflex FR77 fire-resistant polyurethane foam.

Soudal

Special mention should be made of the Soudal super-frost-resistant foam. Which successfully promotes its product to the Russian market, since such a sealant is in demand in cold conditions. Unique characteristics of "Soudal", with the help of which construction and installation work, replacement of windows and doors at temperatures up to minus 25 ° C are performed.

This material is durable, tensile and compressive resistance. The adhesive properties of the foam to basic materials (stone, metal, concrete and wood), even at extremely low temperatures, comply with European requirements. This type of sealant is fire-resistant, and in terms of other characteristics, Soudal is twice the requirements for such materials existing today.

Scope of application

Consider the main areas of application of foam from Makroflex:

For the installation of windows and doors

It is important to remember that the use of the material does not exclude the use of the necessary mechanical fasteners, much less replace them. To avoid the formation of defects, it is necessary to install spacers.

In the process of sealing joints, cavities, joints and seam elements.

For sealing joining lines during roofing work.

During the sealing of pipes in buildings.

For self-sealing cracks and holes.

Filling voids in building materials.

For thermal and sound insulation of premises structures.

The advantages of Makroflex foam are:

- no need for special preparatory manipulations;

- versatility and breadth of application;

- ease of use;

- affordable prices;

- reliability;

- fast hardening compared to cement composition;

- the ability to work with wood, stone, metal, PVC and chipboard coatings, concrete and foam concrete products;

- wide temperature range of application;

- elimination of the formation of dust and pollution during the production of work.

The disadvantages include the following points:

- Loss of material performance during prolonged exposure to ultraviolet radiation. To protect it, paint water-based compositions are used.

- The need for use in work with a substance of special.means of protection, since foam negatively affects the respiratory system, skin, irritates the mucous membrane of the eyes.

- Decent consumption of material.

The right choice of polyurethane foam

To avoid mistakes and alterations during repair and installation work, choose the right polyurethane foam. First, decide on the tasks of applying the sealant. What are you planning to pop? Where will the work take place - outdoors or indoors? At what temperature? Calculate the approximate amount of material required based on the specifications. Consider which cleaner to prepare.

Strengthening the window frame

Requirements for Macroflex, as well as for other types of polyurethane foam (for example, Soudal), include the following specifications and properties:

- Flame retardant packaging and aerosol sales;

- When applied to the surface, polymerization and hardening should occur within the time indicated on the package;

- The required level of adhesion (adhesion) to ensure installation work;

- When drying, the foam should be elastic, not crumble or collapse;

- The secondary expansion coefficient must correspond to that indicated in the certificate and on the packaging.

Polyurethane foam is the first assistant in repair and construction work, including the installation of windows and doors. These products have gained immense popularity among customers. Products from the Finnish company Makroflex are a bright representative in the line of all-season professional installation materials. Polyurethane sealant has both advantages and disadvantages. However, the latter is minimized if the rules for working with Makroflex polyurethane foam are observed.

Polyurethane foam of the Makroflex brand is in demand among buyers

Tips & Tricks

The following tips and tricks will help you to apply foam from the Makroflex brand qualitatively, productively and safely:

- Before using the product, we recommend holding it at room temperature for about 12-14 hours, this will allow the substance to take the optimal condition for use.

- Before starting work, the processed elements are cleaned of dust. Porous surfaces are moistened with water from a spray. The work is performed at a humidity of more than 60%. If the humidity is low, the surfaces are wetted. Working on frosty or ice-covered surfaces is not recommended. To prevent the substance from getting on other surfaces, they must be covered with polyethylene.

- The ready-to-use substance must have a uniform consistency, therefore it is recommended to shake the tube immediately before use.

- In the course of work, the can must be held upside down, regardless of the method of applying the material to the coating (manual or with a pistol).

Considering that the foam significantly increases in volume, when installing windows or doors, you need to install special

spacers to avoid deformation of structural elements.

If it becomes necessary to take a break for more than 15 minutes before starting again, it is important to clear the tube of dried pieces of foam.

Foam spots that do not have time to harden are easily cleaned with special means, but the already hardened part can only be cleaned mechanically (cut off).

Makroflex is best used when filling cavities and joints with dimensions of 0.5-8 cm, since in narrower places the substance may not get to the required depth, as a result, voids are formed. Larger seams and crevices may not support the heavy weight of the product.

In order to obtain the greatest foam yield, the tip of the cartridge should be cut off at a 45 degree angle.

- Avoid contact of the finished substance on the skin and organs of vision, this is fraught with severe irritation. If the composition gets in, it must be quickly washed off the skin, and the eyes should be thoroughly rinsed with warm water.

- It is not recommended to remove a completely unused tube from the gun. Replacement is done only if the tube is completely empty.

- Installation work must be carried out exclusively in places with effective ventilation, since substances harmful to the respiratory system are released during the spraying process. Don't forget about protective equipment!

- It is strictly forbidden to use the material on hot surfaces and old electrical wiring. This could lead to an explosion. Smoking is not recommended near sealing solutions.

An analysis of the available reviews and product reviews shows that the overwhelming majority of experts and those who independently used Makroflex foam for the first time recommend this tool for use, based on its very real advantages:

- practicality and ease of use;

- short hardening period;

- quite reasonable price;

- a wide choice for specific conditions of use;

- reliability and durability.

For an overview of Makroflex building glue-foam, see the next video.

Peculiarities

The brand began manufacturing these products 30 years ago. During this time, he mastered the production of polyurethane foam, glue, cleaning fluids, tools and sealants of various types. The production takes place at factories in Finland and Estonia, and it is in demand throughout Europe, as it is famous for its excellent quality.

The brand cares about consumers, therefore, it constantly develops new products using the latest technologies, trying to achieve uncomplicated use and improve their performance properties.

One of the great products is Makroflex FR77 fire-resistant polyurethane foam. It is available in 750 and 1000 ml cylinders, is suitable for many types of work, provides heat and sound insulation, and also has a good level of adhesion to most materials. Since foam is a fire-resistant material, it is advisable to use it for sealing joints in structures where fire safety must be observed. These can be public places, residential apartment buildings and private houses, industrial premises.

This one-component professional foam is used with a gun for more precise dosage and flow control.

You should know that filling large voids must be carried out in several stages, since complete hardening occurs in about 24 hours, and the initial treatment can be carried out in 20-30 minutes. Moisture is required for curing. If the ambient humidity is less than 60%, then the surface must be moistened. When there is ice or frost on the surface, work cannot be performed.

The surface must be cleaned before applying the foam.

Before starting work, the balloon is kept for 10-12 hours at a temperature of 18-20 degrees. Shake it several times immediately before use. An open bottle must be used within a month. It is unacceptable to heat the cylinder up to +50 degrees and above - it is explosive.

When working with foam, use personal protective equipment for skin and eyes.

Characteristics and properties

Macroflex is in fact a liquid polyurethane that hardens when combined with moisture from the air. Specifications are the benchmark for similar products. The consumption of the mixture depends on the weather conditions, but is considered the minimum possible. Polyurethane foam Macroflex characterized by such data:

- Expansion - 2 times (error - 5%);

- Curing time - 1 hour;

- Density - 25-35 kg per cubic meter meter;

- Fire resistance - B3 (according to DIN 4102);

- Compressive and tensile strength - 3 N / cu. cm for one-component and 5 n / cc. cm - for a two-component composition.

Premium foam is more resilient and more durable than standard foam.

Foam Macroflex Pro

The foam hardens under the influence of air humidity, is easy to use and safe. There is a faint smell, but it quickly disappears.

At an air temperature of + 20 degrees. and humidity not less than 30%, setting time - 15 minutes. At 100% humidity, this takes an hour. Under difficult conditions, complete curing occurs in a day. Resistance to temperatures - in the range from - 55 to +90 degrees.

The material is not flammable; melting requires a temperature of over 400 degrees. The recommended shelf life in the package is 15 months.

Macroflex White Technology

Macroflex White Technology gets rid of most of the disadvantages of other types. This new generation foam is created on the basis of polymers with high purity and a fine-pored structure with four times as many cells. Pure polymer guarantees correct hardening, snow-white color, cellular structure with great strength and elasticity. She is immune to ultraviolet light. The hardened foam provides excellent thermal and acoustic insulation performance. White Technology is characterized by low expansion pressure, which provides ease of installation and compensates for joint movements - over 25%. Due to its thermoplasticity, it guarantees long-term insulation and sealing.

The ShakeTec technology has been implemented - a metal ball inserted into the inside of the cylinder improves the miscibility of the components when shaken. The bottle is equipped with a new valve that retains the properties of the product. The composition does not contain freons.

A little about the content of the spray

Peculiarities

It was from the beginning of the production of Makroflex foam that the history of the manufacturer of the same name, popular in many countries of the world, which is now part of the Henkel group (country of origin - Estonia), began. Today the company is renowned for its extensive line of sealants, adhesives, cleaning fluids and tools. Such a variety of products, and most importantly, its quality, makes the Makroflex brand highly rated in its segment of the world market.

Foam for mounting Makroflex or polyurethane sealant is available in tubes with different volumes. The substance, consisting of a prepolymer and a propellant gas, solidifies upon contact with air, which ensures high-quality filling of cavities. For this product, in accordance with its main purpose, the following features are characteristic, which led to its widespread use in construction work:

- a high degree of adhesion (adhesion) to most building materials (wood, concrete, stone, metal and other building elements, etc.);

- high heat-insulating and sound-insulating qualities;

- maintaining strength for a long time;

- high filling qualities;

- the hardened material is non-toxic and non-flammable;

- dosage accuracy (when using a pistol) allows you to save on material consumption when using it;

- the possibility of organizing work breaks.