Pros of processing bricks with varnish

Paintwork materials (paints and varnishes) for bricks are currently the most widely used. All thanks to their properties. They can be used outside and inside the home for vertical, horizontal and inclined surfaces. In its own way, paintwork materials for bricks are universal - they are not only widely used, but also do not cause difficulties in application. It also does not roll or deform.

Under the influence of moisture, a brick that has not been varnished quickly loses its properties and begins to collapse. It is mainly the walls outside the house that suffer from this. With the help of brick varnish, you can several times reduce the negative impact of snow, rain, hail on the facade of the house, thereby prolonging the life of the brick, and avoiding major wall repairs.

Another noticeable advantage of the lacquer coating of bricks is its resistance to high temperatures. This is especially noticeable on fireplaces and stoves. To cover them, a heat-resistant brick varnish is used.

A fireplace or stove treated with varnish takes on a completely different appearance and looks very beautiful.

Varnish can also protect your home from salt and dust stains. Having processed the facade of a house or a fence with varnish for bricks, you can be one hundred percent sure that they are protected from such untidy phenomena as salt, accumulation of dust and fungus.

The variety of paintwork materials is very wide. Varnishes with enhanced shine will effectively emphasize the facade of the house against the background of other buildings, or simply make it look like a tower from a fairy tale. The varnished walls look very impressive.

What paint is right

Considering the range of manufactured and sold paints and varnishes, the question of how to paint a brick should not torment you much.

Otherwise, if this extremely important point is not taken into account, you will get a raw box, practically not suitable for living.

Composition properties

Let's decide what properties the paint on brick should have:

- The paint must have the property of vapor permeability;

- For it is necessary to choose heat-resistant, that is, withstanding a temperature drop from –50 ° C to 50 ° C above zero. This is especially true of the northern regions, where such temperature drops are natural;

- The composition of the material must be suitable for finishing brick surfaces. It should be taken into account in advance that not every composition is suitable for this purpose;

- Brickwork, as a rule, has a high content of alkaline compounds, and this, in turn, can adversely affect the finish that is not intended for these purposes. Conclusion: it is advisable to take these points into account when choosing a particular type of paint.

Brick, in fact, was not originally intended for DIY painting. Being manufactured in the factory, it can have different geometric and color parameters and does not require any design manipulations.

Choose the right materials yourself

If the question arises about finishing, then it is advisable to use only those materials that meet all the stated requirements to the highest degree.

Many experts strongly recommend using silicate, cement or acrylic polymer-based compositions when decorating brickwork. Also for external walls, a silicone-based composition is perfect, but it should be borne in mind that it is much more expensive.

When choosing, it is better to give preference to compositions that do not contain solvents, since such coatings dry much faster, and this is a very important point, especially when finishing facades.

Brick painting should not be done with such types of compounds as, for example, fire-retardant paints for metal Polistil or, no less well-known, electrically conductive paint Zinga, since these protective coatings are intended for metal elements.

For particularly complex coatings, when, for example, the question arises of how to paint a silicate brick, then a water-based acrylic composition is most suitable. Sand-lime brick painting requires a preliminary priming. If you do not follow this procedure, then the coating will last a very short time.

In some cases, when facing the outer walls of a house or any other building, decorative bricks are used for painting. The composition of this material includes components that interact well and firmly bond with paint and varnish coatings. Acrylic-based solutions are suitable for finishing such cladding.

The same compositions are used, for example, to paint a brick balcony or any other internal walls of buildings.

In general, compositions on an acrylic or silicone base are completely universal and can be used on almost all surfaces, both stone and wood, or covered with a plaster layer. They contain state-of-the-art polymer components that promote high-strength adhesion to bases even as complex as silicate ones.

The surface treated with these materials is smooth and easy to clean. Another advantage should also be noted - the maintainability of coatings. For repairs, it is not at all necessary to repaint the entire wall completely, but it is enough to update only the problem area.

The composition of the do-it-yourself oven plaster solution

You can prepare the oven solution with your own hands. Fortunately, practice has developed many simple compositions of mortar for plastering the oven. The above are the main formulations that beginners can knead.

Before mixing the clay solution, the components are prepared:

- The clay is soaked a day (preferably 4-5) before use. After that, it is poured with additional water, the floating debris is removed, the water is drained, or stirred, passed through a sieve, then allowed to settle and the water is drained. The remaining clay is mixed until smooth. Any lumps will cause cracks. The resulting mass of clay is combined with the rest of the components.

- River sifted, washed, dried sand is suitable. It is dry sand that is given in the recipes. Using wet sand will require less water.

- The asbestos is fluffed up.

- Lime is used to prepare milk of lime or dough.

When plastering a stove with your own hands, it is important to maintain the proportions of the components. The clay solution can be different in the ratio of sand and clay, depending on the fat content of the latter. The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water)

The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water)

The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water). The standard procedure is the first-priority mixing of dry components followed by the addition of liquid components (clay or lime emulsion, water).

Experienced stove-makers add 200 g of salt to a bucket of solution. The additive prevents the appearance of cracks, slows down the setting of the mixture, thereby achieving uniform drying of the coating.

If the stove is planned to be heated with coal or peat briquettes, which give a high temperature, fireclay powder should be included in the compositions.

What Kinds of Oven Varnish are Best?

Siltek produces quality oven varnishes.

To correctly choose the best heat-resistant varnish for the formation of the decorative design of the stove, it is necessary to take into account a lot of parameters.

Despite the fact that a huge number of different types of varnishes for internal and external coating of fireplaces and stoves have recently been presented on the market, the most popular types are Ko 85, KO815 and Siltek-1.They have already gained popularity, since they are distinguished by their durability and durability of the surface.

The most commonly used varnish is KO 85, which is used not only in domestic conditions, but also in industry to create an extremely durable coating.

The finished coating can withstand temperatures up to 300 ° C, the composition is resistant to temperature extremes, including when they fall to -30 ° C. In addition, the material can be applied with a spray gun. The consistency can be adjusted by thinning the varnish.

Varnish KO 85 withstands temperature extremes well.

Heat-resistant varnish KO 815 can withstand temperature drops down to - 60 ° C and rise up to + 300 ° C. It allows you to form a high-quality coating with minimal material costs. One of the advantages of this type of material is that it can be used in areas of the furnace where contact with an open flame is unavoidable.

At the same time, the application of such a composition is carried out by the hot method, that is, the surface hardens when exposed to special infrared rays, which in some case complicates its use.

Heat-resistant varnish Siltek-1 allows painting the furnace surface without using a special primer. When applying varnish, the surface has an extremely aesthetic appearance, but at the same time, the material consumption is quite high.

To create a high-quality coating, the composition should be applied at least 3 layers of material.

What paint is right

Considering the range of manufactured and sold paints and varnishes, the question of how to paint a brick should not torment you much.

Otherwise, if this extremely important point is not taken into account, you will get a raw box, practically not suitable for living.

Composition properties

Let's decide what properties the paint on brick should have:

- The paint must have the property of vapor permeability;

- For it is necessary to choose heat-resistant, that is, withstanding a temperature difference from –50 ° C to 50 ° C above zero. This is especially true of the northern regions, where such temperature drops are natural;

- The composition of the material must be suitable for finishing brick surfaces. It should be taken into account in advance that not every composition is suitable for this purpose;

- Brickwork, as a rule, has a high content of alkaline compounds, and this, in turn, can adversely affect the finishing coating not intended for these purposes. Conclusion: it is advisable to take these points into account when choosing a particular type of paint.

Brick, in fact, was not originally intended for DIY painting. Being manufactured in the factory, it can have different geometric and color parameters and does not require any design manipulations.

Choose the right materials yourself

If the question arises about finishing, then it is advisable to use only those materials that meet all the stated requirements to the highest degree.

Many experts strongly recommend using silicate, cement or acrylic polymer-based compositions when decorating brickwork. Also for external walls, a silicone-based composition is perfect, but it should be borne in mind that it is much more expensive.

When choosing, it is better to give preference to compositions that do not contain solvents, since such coatings dry much faster, and this is a very important point, especially when finishing facades.

Brick painting should not be done with such types of compounds as, for example, fire-retardant paints for metal Polistil or, no less well-known, electrically conductive paint Zinga, since these protective coatings are intended for metal elements.

For particularly complex coatings, when, for example, the question arises of how to paint a silicate brick, then a water-based acrylic composition is most suitable. Sand-lime brick painting requires a preliminary priming.If you do not follow this procedure, then the coating will last a very short time.

In some cases, when facing the external walls of a house or any other building, decorative bricks are used for painting. The composition of this material includes components that interact well and firmly bond with paint and varnish coatings. Acrylic-based solutions are suitable for finishing such cladding.

The same compositions are used, for example, to paint a brick balcony or any other internal walls of buildings.

In general, compositions on an acrylic or silicone base are completely universal and can be used on almost all surfaces, both stone and wood, or covered with a plaster layer. They contain state-of-the-art polymer components that promote high-strength adhesion to bases even as complex as silicate ones.

The surface treated with these materials is smooth and easy to clean. Another advantage should also be noted - the maintainability of coatings. For repairs, it is not at all necessary to repaint the entire wall completely, but it is enough to update only the problem area.

How to paint an artificial stone

With such a variety of materials, it is quite difficult to choose what to cover the decorative stone with.

The most popular options are:

- acrylic paint;

- vitriol;

- stain;

- various colored solutions.

Each of the materials has features of application and properties.

Acrylic paint

Water-based wall paint is popular, as it allows not only painting the walls, but also protecting the surface from weather.

Acrylic paint for decorative stone has a number of advantages:

- elasticity. Due to changes in temperature conditions, cracks and deformations can form in the surface. Due to elasticity, this problem is eliminated;

- vapor permeability. This material perfectly absorbs and gives off moisture;

- the ability to easily change the color by adding a color scheme.

- resistance to ultraviolet and moisture.

If it is necessary to increase moisture resistance, you can choose a mixture with the addition of silicone.

Vitriol

Iron and copper sulfate are used as impregnation for natural stone walls. Such compositions increase the strength of the parts. However, these compounds change the color of the treated surface. Iron vitriol paints the stone yellowish, and copper sulfate - blue. If this is exactly what is needed for decoration, the elements should be immersed in the solution for a couple of hours in this way. So that they do not touch each other.

Stain

Decorative gypsum wall covering for stone is treated with the same compounds as concrete. On sale, these mixtures are monochromatic, but if you want to diversify the palette, you can use wood stain. Acid stain is popular, but one plate should be tried before applying to all walls.

This is important because gypsum stones can vary in composition.

Other types of solutions

There are other solution options that can be used for staining.

Choosing how to paint the surface of the walls like a stone, you can pay attention to the following materials:

- varnishes;

- impregnations that can not only paint the surface, but also improve their quality. Wet effect mixes can create a shiny film on the stone and create the visual illusion of moisture on the wall;

- gypsum paints of any modification;

- compositions created by their own hands. In this case, the main thing is to correctly select the components.

Compositions that can imitate natural stone have appeared on the building materials market. However, their cost is not yet available to everyone.

No. 2. What are the varnishes in composition

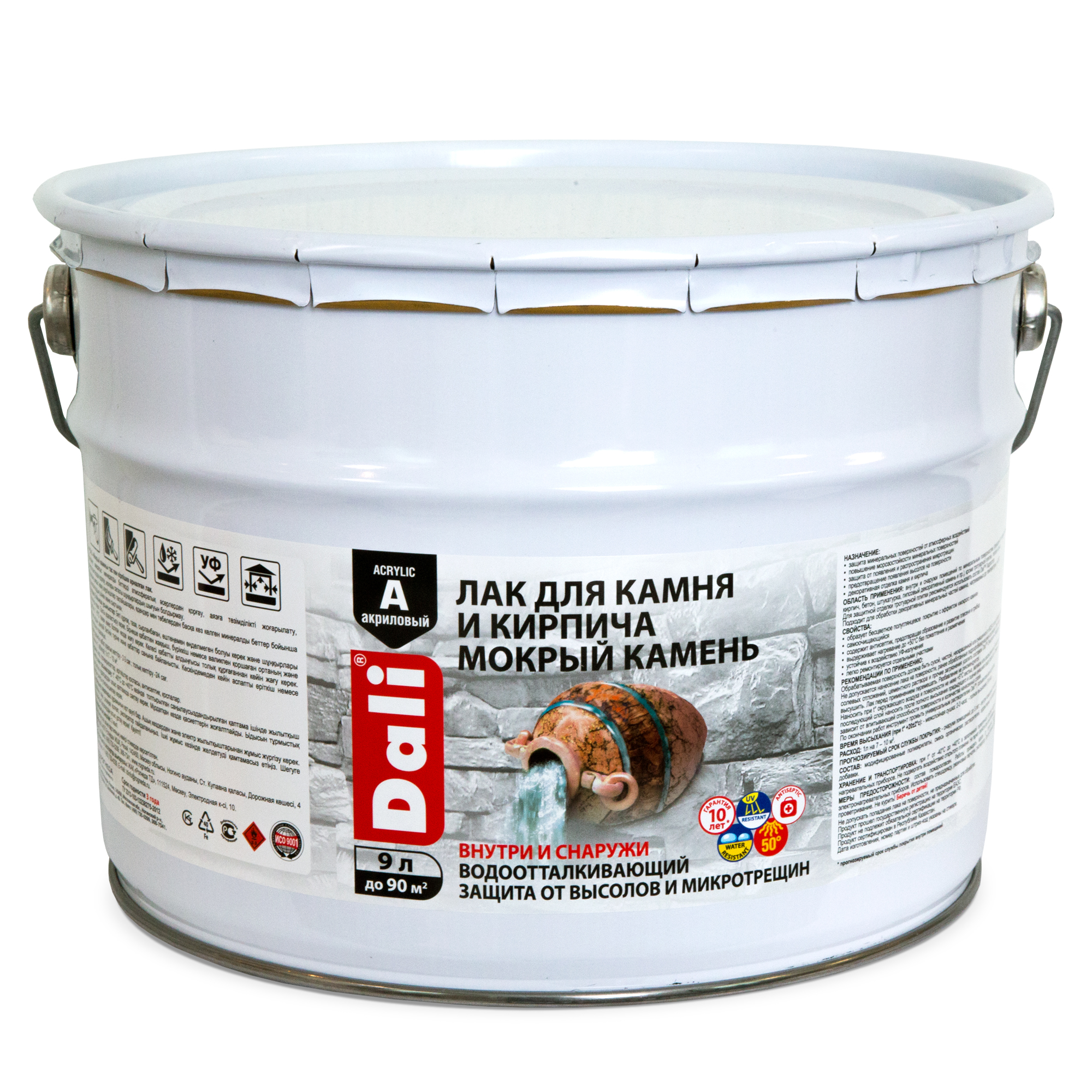

Brick varnish - a universal product for protecting brick base

But in order for the varnish to lie flat on the material and fully perform its functions, it is necessary to choose it correctly, paying attention to its composition

Polymer varnishes

This is the most popular type of paintwork materials. The demand for this product is due to its versatility. It can be used on brick and concrete substrates. Polymer varnish can be applied at sub-zero temperatures and in rooms without heating. It is easy to apply, dries quickly and reliably protects the material from scratches, cracks, moisture and dust. The mixture can be used to protect interior and exterior walls. Due to the ease of application of the polymer composition, it can be used by both professional craftsmen and beginners. Polymer varnishes are affordable.

Silicone acrylic varnishes

This type of paintwork is suitable for interior walls. Silicone-acrylic mixture can be used to cover not only bricks, but also concrete, ceramic tiles, drywall, metal. The composition is often used for application to decorative items.

Due to the presence of special polymers in the mixture, the varnish can be of various shades. In addition to the protective layer, the wall treated with this compound can be transformed into any color, depending on your wishes.

Silicone-acrylic varnish protects the base from alkalis, acetone, oils. The only disadvantage of such mixtures is the price, which is much higher than polymer analogues.

Polyurethane varnishes

It is a versatile product that can be used to coat interior and exterior walls. It is the polyurethane varnishes that create the “wet” effect on the brick base. They have excellent moisture-repellent characteristics, which is why they are most often purchased for treating external walls. The popularity of polyurethane varnishes is also explained by the fact that they can be used to process not only brick, but also concrete bases.

Heat-resistant varnishes for fireplaces and stoves

This is a separate category of paint and varnish materials, which differ in the characteristics of heat resistance, fire resistance. They are designed to prevent condensation from forming on the walls of stoves and fireplaces. Due to their high moisture resistance, such paints and varnishes are also purchased for decorating and protecting building facades.

Solvent varnishes

These formulations are based on silicone resin and solvents. When penetrated into the material, they create a strong protection, preventing cracking and discoloration

But, at the same time, such varnishes are easily flammable, and it is necessary to work with them extremely carefully, observing safety rules

Impregnations

In order to strengthen any paint and varnish, you can use special sealing impregnations. They are made on the basis of silicone and acrylic resins with the addition of aromatic, aliphatic solvents. Due to this composition, maximum protection of the paint and varnish for the brick base is provided. When using impregnation, deep penetration of paintwork materials into the building material is guaranteed.

In addition, sealants provide an extra layer of protection against seasonal rainfall, chemicals and UV rays. Many manufacturers also offer decorated options with a "wet stone" effect. The negative side of such impregnations is their use only for external or internal walls; they cannot be used in work with stove and fireplace installations.

Tips for working with varnish

In order for a high-quality adhesion of the composition to the surface to occur, it is necessary to take into account a number of points:

- the optimum temperature for applying a heat-resistant composition is 15-20 degrees Celsius, although many manufacturers claim that their products are resistant to more extreme temperature conditions (from minus 40 to plus 40 degrees);

- before starting varnishing, the composition must be thoroughly, but slowly stir;

- it is necessary to thoroughly clean from dirt and dust, dry and degrease the surface to be processed;

- paintwork can be applied in different ways - with a brush, roller, spray;

- parts insignificant in size can simply be dipped into a jar of varnish;

- when processing porous materials with a couple of layers, you cannot do it - you will need three or more layers;

- heat-resistant varnish is excellent for fireplaces made entirely of metal, as well as for metal parts of stoves (including doors, hobs, decorative forging, etc.);

- LMC should be kept cool, out of direct sunlight, in a place that meets fire safety standards;

- a jar of varnish should be stored only in an upright position;

- a general rule: for compatibility purposes, all varnishes and additives should be from the same manufacturer and, even better, from the same series;

- Before you start varnishing, it is best to do a small test in an inconspicuous place to see what the finished surface will look like.

The most popular way to apply varnish is with a brush

The most popular way to apply varnish is with a brush

Material selection

Since the oven and its components are constantly exposed to high temperatures, the varnish must meet the following requirements:

- heat resistance;

- heat resistance;

- moisture resistance;

In addition, the varnish must:

- help prevent washing out of the oven seams;

- help strengthen the masonry;

- protect the firebox from moisture, condensation;

- prevent premature cracking and destruction.

The most popular brands are KO-85 and KO-815. They can be used both outdoors and indoors at air temperatures down to -35 degrees. Suitable for their application are brick, concrete, stone, plasterboard, wooden surfaces, paving slabs.

For the manufacture of these stamps, an organic basis is used, so that they do not pose a danger to people and animals. The product is certified.

Characteristics of KO-85:

- Protects external and internal cladding and masonry of ovens.

- Gives water-repellent properties to the seams of the clay oven masonry, prevents them from drying out and sprinkling.

- Strengthens the seams of masonry stone, brick, concrete ovens.

- It can be used at low temperatures.

- The ideal solution for stoves in baths and saunas.

- When used, it does not form a peeling film.

- Quick drying.

- No smell after 30 minutes.

- It can be used to protect the masonry of a stove or fireplace at temperatures from -40 to +350 degrees.

- Prevents moisture absorption and swelling of bricks between fireboxes.

Characteristics of KO-815:

- It is used to cover the surfaces of the furnace inside all types of stoves, both indoors and outdoors.

- The varnish protects metal, concrete, glass, ceramics.

- Gives hydrophobicity, frost resistance and corrosion resistance to surfaces.

- Dries completely at temperatures over 150 degrees Celsius.

- Not subject to subsequent detachment.

- Protects brickwork at temperatures from -40 to +350 degrees.

- Can withstand particularly aggressive conditions.

- Prevents crumbling and cracking of brick oven joints.

- Like KO-85, it protects against moisture absorption and swelling of bricks between fireboxes.

Work process

How to apply varnish correctly, what rules to adhere to?

-

First of all, prepare the necessary tool of your choice:

- flat brushes;

- a spray gun with a nozzle size of 1.8 - 2.5 millimeters; the distance from the nozzle to the oven surface must be at least 20-30 cm;

- roller.

-

Then prepare the surface for painting:

- putty cracks and chips;

- remove dirt and dust from the oven;

- dry the surface;

- degrease it using a solvent.

- Apply varnish. Generally, three coats are recommended on brick surfaces. Because, due to its structure, the brick is able to absorb varnish. The first is applied directly on top of the oven bricks, it will fill in the uneven areas. The second one enhances the protective qualities and smoothes the surface. The third one improves the aesthetic appearance of the stove. If you apply two or more coats of varnish, the oven surface will become glossy matte.

Recommendations for the use of VEPOX epoxy 2-component water-based enamel

Base requirements:

The concrete base must be clean, free from traces of oil, old coatings and dirt that hinders adhesion. Fill defects and cracks with a repair compound, sand and dust. Application on damp concrete is allowed. New concrete floors must be at least 2 weeks old. Work can be carried out at an air temperature from + 10 ° C to + 35 ° C and a humidity of no more than 80%

Asphalt base:

The surface must be clean. Free from oil, grease, be dried. Apply the material only if there is no deformation of the base during operation. When applying to asphalt, do not add water, do not prime!

Material preparation:

The ratio of the mass parts of components A: B 100: 17

Open the buckets with components A- (large bucket) water dispersion of epoxy resin with additives and pigments. B- (small bucket) hardener. Mix component A with a low-speed drill with a nozzle, lifting the pigment and fillers sediment from the bottom for 3 - 5 minutes. and pour into a clean bucket, making sure that there is no sediment left in the bucket from under component A, which has caked on the bottom, otherwise repeat mixing. With the drill running, pour component B (premixed) into the same bucket and stir for 3-5 minutes. Pour the resulting mixture into the vacated bucket and stir for 3-5 minutes. Allow to stand for 10 minutes. The life time of the material after mixing the components is 4 hours at a temperature of + 20 ° C during this time it is necessary to carry out application work and therefore you should not prepare more than it can be worked out !!!

Application method:

To improve wetting, the surface can be slightly moistened, but without puddles. Apply with a short-haired nylon roller (8-12mm) in a thin layer at a rate of 200g / m². When performing the 1st (primer) layer, it is allowed to dilute the material with water (the recommended amount of water is 5―10% of the total mass), but only on the primer layer.

Interlaminar drying 16 hours, but should not exceed 24 hours at t + 20 ° С and not more than 18 hours at t + 25 ° - + 30 ° С. Recommended number of coats 2. If the temperature of the air and the substrate is below + 15 ° C, a slower reaction and an increase in the curing time must be taken into account.

Pedestrian traffic is possible after 24 hours. Full loads after 5 days.

VEPOX can be used as a primer on wet concrete and surfaces with capillary moisture inflow under: PU-555 soil, Monourethane, PU-555 floor and similar PU materials. They can be applied 24 hours after applying VEPOX

At the same time, it is important to remember that an impermeable moisture barrier will be formed and it is necessary to provide for ways to drain water from the concrete body. Provide room ventilation

Tool cleaning:

Tools should be cleaned immediately after work with water. In the future, with a solvent R-646, and after complete curing only mechanically.

Security measures:

When carrying out work, use personal protective equipment, goggles, rubber gloves. Provide ventilation. In case of contact with eyes and exposed skin, rinse with plenty of water. After curing, the material is safe.

Storage:

Store in its original packaging in a cool dry place at a temperature not lower than + 5 ° С. Shelf life - 6 months from the date of production.

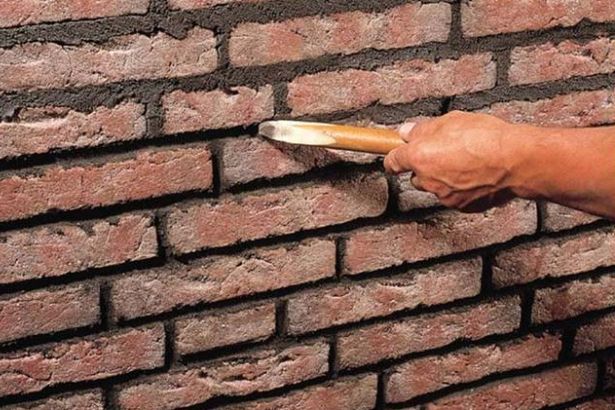

Painting process

The preparatory part of the wall decoration process is mandatory and includes the following steps:

All peeling and interfering parts of brick and masonry mortar are cleaned from the wall and, if necessary, the joints are partially renewed;

- It is advisable to reinforce the base with an acrylic primer before painting. To do this, use a wide enough brush or, even better, apply one layer of primer evenly over the entire surface with a spray gun. Often a single layer will be sufficient.

- Dry the substrate thoroughly after priming.

Paint application

It is more advisable to apply paint with an electric spray gun, especially if a sufficiently large wall area is being processed. If you don't have a spray gun, a regular wide brush or a large paint roller with a shaggy working base will do.

The technology itself and instructions for applying paint and varnish coatings are practically no different from applying to any other base.

It is advisable to apply semi-matt latex paints in two layers in order to paint over the surface completely and evenly.

It is advisable to use lighter compositions for the decoration of the facade or interior walls. This will visually expand the interior space and soften the dark shade of the stone wall outside.

Weather conditions when performing work on the decoration of external walls must be taken into account first of all. So, for example, the most favorable time for such events is early autumn, it is also called "Indian summer", when the sun's rays are not so scorching, and the wind will not blow the newly decorated facade with dirt and dust.

It must be remembered that when decorating brick walls with paintwork, sooner or later it will still have to be updated. In order for the coating to last as long as possible, it is necessary to choose only the appropriate types of paints, the price of which can be significantly higher than usual.