What is Serebryanka paint

So what is silver? Let's deal with this issue in more detail. The name should not be misleading - there is not a drop of silver in that material. Its formulation includes PAP-1 or PAP-2 aluminum powder, organic solvent, modifying additives.

Despite the fact that every year a lot of new products from manufacturers of paintwork materials (paints and varnishes) appear on the building materials market, silver paint for metal does not lose its relevance. For a long time this paint has been used to protect metal and wood surfaces. Those who are older surely should remember the water pipes in the bathroom, painted with this paint.

On the territory of our country, GOST 5631-79 Varnish BT-577 and paint BT-177 are in force. The technical conditions in it define the requirements for the composition, the requirements for the acceptance of finished products GOST 9980.1-86. These documents specify that each ready batch must be accompanied by accompanying documents, they must indicate:

- Manufacturer's company name. Its trademark is indicated, by the way, it is allowed to indicate only the trademark.

- Name and grade of finished products.

- Batch weight.

- The batch number of the finished product.

- Date of manufacture.

- Results of the conducted testing or substantiation of the conformity of the normative and technical documentation used in the production of paint

- Container type and number of packaging units in a batch.

- The name of the regulatory document.

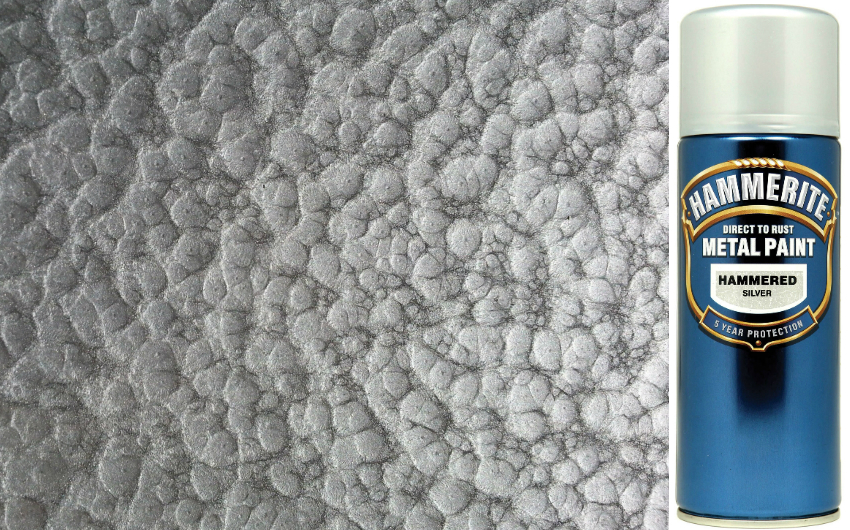

Manufacturing enterprises pack finished products in different containers, made of glass or thin sheet metal. The container capacity ranges from 0.5 liters to several kg. Recently, some manufacturers have been producing paint packaged in spray cans. This greatly simplifies its application to the surface to be protected.

For a long time this paint has been used to protect metal and wood surfaces.

Composition and properties, areas of application

Historically, it is most often used to protect metal from corrosion, in particular:

- Metal structures for industrial purposes (power transmission poles, pipelines for various purposes. Automotive products. It is used for tuning, protecting rims, etc.).

- Roof coverings are covered with silver, for example sheet metal, including galvanized iron. It is used to paint buildings made of sheet metal. The silver layer protects not only from corrosion, but from overheating in the warm season. Details in the boiler rooms.

In addition to the listed areas of use of this paint, they are used to paint products that are in constant contact with sea or fresh water.

In practice, several types of silver are used:

- Heat-resistant - this helmet is made on the basis of BT-577 type varnish or its analogs;

- This paint is used to cover heating radiators.

It is used for tuning, wheel rim protection.

It is used for tuning, wheel rim protection.

How to age metal yourself

The choice of the method for creating an interior style, which assumes the presence of traces of antiquity in the design, is quite wide. For connoisseurs of this style, it is not always affordable to purchase real old items. The way out of this situation is to imitate ancient metals. How to properly paint semi-antique metal with your own hands? Staining is carried out in stages:

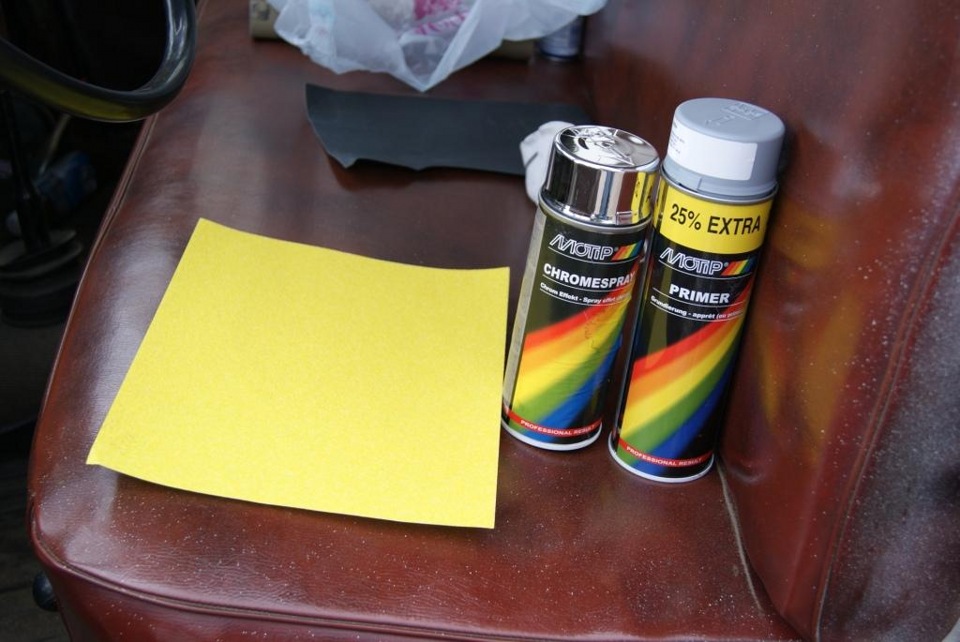

- Surface preparation for painting. We get rid of dirt, rust and traces of grease by grinding and solvent treatment.

- Metal priming. In this way, we achieve the formation of roughness on the surface for better adhesion of the paint. We choose a special primer for metal.

- Application of the selected metallized paint. Experts advise to carry out the process with a regular brush, so aging is achieved in the best way.

- Aging stage. When the paint dries, we cover the surface with a special craquelure varnish. It is after this step that the metal object is covered with cracks, which create the effect of an old product.

In the video: a master class on applying patina to forged metal.

Nitro-based paints - what is it

What is nitro paint, where can it be applied? Answers to these questions need to be obtained before deciding whether to choose it for painting. Nitroenamel paint is produced, both in cans and in aerosols. It is produced ready-made; there is no need to dilute it before using it. Used in spray cans to paint over small areas.

Used in spray cans to paint over small areas.

Used in spray cans to paint over small areas.

Characteristics of what is included

The constituent component of nitro enamel paint is cellulose nitrate, which is treated with nitric acid. In fact, it is an enamel product. It differs from many types of paints in its fast-drying properties. How long does nitro enamel dry? It takes only 10-30 minutes, while room temperature is enough to complete drying.

Previously, it was used for painting cars, but the durability of the coating did not force manufacturers to abandon its use. But for household painting of machine parts, it is quite suitable; it is also often used for various metal objects. It is used for wooden parts, it can be applied to walls treated with plaster, creating a beautiful glossy finish.

Room temperature is sufficient to complete drying.

Room temperature is sufficient to complete drying.

Advantages and disadvantages

Nitra enamel paint, like other products, has positive and negative properties. Knowing them will help you better understand what nitro enamel is. The benefits include:

- Fast drying rate, so it is popular to use a spray gun to paint surfaces with it;

- High indicators of resistance to moisture;

- Good ability to withstand UV rays;

- Creation of a reliable layer against rust formation;

- Getting a beautiful glossy coating, while to obtain a similar effect, you can do with the application of one layer;

- Possibility of use for external and internal works;

- Versatility of use, can be used on wood, metal, concrete, plastered surfaces;

- Low product consumption, per square meter requires from 30 to 120 grams, depending on the type of material being processed, the number of layers and color;

- A wide range of colors, nitro enamel is white, red, black, gray, green, all kinds of shades are produced;

- Acceptable cost.

It is popular to use a spray gun to paint surfaces with it.

It is popular to use a spray gun to paint surfaces with it.

Nitro paint for wood and metal, in addition to many advantages, has several disadvantages:

- Working in high humidity conditions leads to the appearance of white spots on the product, the reason is the use of acetone in the composition, it evaporates under such conditions. Therefore, staining under 70% humidity is not recommended;

- Toxicity, to maintain health. Work should be carried out in a room where good ventilation is provided, the master must wear a respirator;

- Fire hazard;

- Incompatibility with a number of paints and varnishes that can be applied to the surface;

- Poor resistance to mechanical stress.

Work should be carried out in a room where good ventilation is provided, the master must wear a respirator.

Work should be carried out in a room where good ventilation is provided, the master must wear a respirator.

How to use heat-resistant silver paint for metal, painting features

As noted above, heat-resistant silver is made on the basis of heat-resistant varnish, for example BT-577 or its acrylic or other analogs. Before starting work, it is necessary to complete certain preparatory work.

Heat-resistant silver is made on the basis of heat-resistant varnish.

Heat-resistant silver is made on the basis of heat-resistant varnish.

Preparation and breeding

If we are talking about using ready-made paint, then you only need to prepare the surface. That is, remove the old coating, dust, debris and other foreign objects from the surface.

If we are talking about applying paint to wooden parts, then it is necessary to carefully grind it and remove dust from it after the end of the work.

Degrease the surface immediately before painting. For this operation, it is permissible to use white spirit, solvents, degreasers based on complex alcohols. The paint can be applied only after the surface has been prepared.

Degrease the surface immediately before painting.

Degrease the surface immediately before painting.

If there is no ready-made paint, then you can make it yourself. To prepare the finished paint, you will need to prepare dry silver (powder) and varnish for silver. All of these can be purchased at a home improvement store. Domestic enterprises produce two types of powder PAP-1 and PAP-2, the first powder contains larger grains, the second smaller. But, for paint preparation, it doesn't matter. The only difference is that after drying, the surfaces will be slightly different.

Since the task is to prepare a heat-resistant paint, then, accordingly, to dilute the powder, it is required to use a special heat-resistant varnish, for example, BT-577 or its analogues.

The cooking process is as follows:

- Pour the required amount of powder into a dry, clean dish.

- In the powder, carefully pour the varnish. As the varnish is added, the paint begins to stir. Construction workers, for this they use a mixer, in a domestic environment a stick is quite suitable, but it will take about 15-20 minutes to stir.

- The ratio of powder to varnish is 2/5.

- As a result of mixing, a uniform mixture should be obtained.

- If the mixture is thick enough, then it can be diluted by gradually adding white spirit.

To dilute the powder, you need to use a special heat-resistant varnish.

To dilute the powder, you need to use a special heat-resistant varnish.

Safety precautions require special attention. In the course of work, personal protection means must be used. In particular, eyes must be protected. Hand protection requires the use of rubber or latex gloves.

In the course of work, personal protection means must be used.

In the course of work, personal protection means must be used.

Principles of application to a metal surface

There is nothing particularly difficult in painting with silver. Above it was said that the paint should be applied to a clean surface. The paint can be applied in a variety of ways. And by hand, and with a roller, and with a brush and using a spray gun. When choosing a tool, it must be borne in mind that the silver dries quickly enough and a little confusion can lead to the appearance of irregularities.

If, during the work, a drop of paint falls in the wrong place, then it can be removed using the solvent used to create the paint. You can also use "folk" methods. For example, drip a few drops of sunflower oil into the place where the paint gets into and then wipe it off with a dry cloth. Alternatively, you can use acetone-free nail polish on the stain.

When painting, it is advisable to keep in mind that the paint consumption rate is 140-170 grams per square meter. m. This figure will also be required when calculating for procurement. The paint is applied in one layer and only after it has completely dried, it is possible, if necessary, to apply a second one.

Silverfish dries quickly enough and a little confusion can lead to unevenness.

Silverfish dries quickly enough and a little confusion can lead to unevenness.

In fact, silver is a versatile paint used to protect metal and wood parts. If the technological regimes for the preparation and application of the coating are observed, one can be sure that it reliably protects the metal from rust, and the wood from biological damage.

Types and composition of silver

In fact, the paint got its name not because of the presence of silver particles, but because of the corresponding color. Serebryanka is a finely dispersed aluminum powder of a light gray steel shade. This powder is used for diluting and coloring various surfaces. Thus, the base for the paint is obtained from aluminum waste by crushing. There are no other components in the silver itself.

There are two types of silver - PAP1, PAP2. Difference in particle size, dilution ratio of the material. The first option is made from larger particles, the second - from the smallest. Both production methods comply with GOST 5631-79. Also, recently, a ready-made thick material has appeared in stores - silver paste PD. It costs more, but it is much more convenient to use it for painting surfaces - you just need to dilute it. There is already diluted BT-177 paint on sale, it is completely ready for application.

Applying acrylic paint to oil

It is not recommended to apply acrylic on old oil paint, as in this case good adhesion of the materials cannot be expected. It is much preferable if acrylic is used as the bottom layer, and an oil solution is applied on top.

However, if desired, you can still treat the old oil layer with acrylic. However, in this case, you need to thoroughly prepare the surface.

The preparatory work is as follows:

- Sand the surface with a layer of old paint. For sanding, we need a fine-grained sandpaper.

- We remove dirt and dust from the processed material, and then degrease the surface.

- We are waiting for the surface to dry.

- Apply 2-3 layers of acrylic solution.

However, preparatory work alone does not yet guarantee a successful application of acrylic to an oil base. To achieve the desired result, the acrylic composition must be quite thick, that is, diluted with water in a proportion not exceeding 1 to 1.

Sometimes the oil composition eats into the surface so firmly that it is not possible to remove it. In such cases, paints with specially enhanced adhesive qualities, for example, "Master-121", will help. Such paints are able to adhere even to moderately oily surfaces.

Unfortunately, water-based paint is not always good, and if you are already disappointed in all its charms, you can return to a well-tested oil paint.

Please note that even in advertisements, it is written: "water-based paint is in no way inferior to enamels", is not inferior, and therefore no better than oil enamels. And in practice, when you paint old windows, doors or other buildings with nails, water-based paint, after a year the nails will rust and rust will indicate their location.

This is due to the fact that the water-based paint "breathes", which means it passes moisture to the iron and it rusts.

So it turns out that when painting surfaces without iron elements with water-based paint, it is good. But if there are old windows or doors with old non-galvanized iron elements, it is better to use proven oil enamel. But the question arises, is it possible to paint with water-based paint, oil? And forget the stories that water-based paint is erased with water. Forget it with a damp cloth, you won't wipe off high-quality water-based paint. So the answer is simple - you can, because the composition of the water-based paint is similar to the composition of the putty, on wood, so clean it a little with sandpaper, remove the excess and you can paint, but it is better to soak first with a deep penetration primer, which improves adhesion (adhesion of new paint) and strengthens the surface . Author of PBT

Acrylic paints were introduced to the market half a century ago. It is safe to say that this is a real breakthrough in the construction and repair industry. Today this type of coating is preferred by most consumers.

The composition of this material is simple.Consists of three elements: resin (binder), water and coloring pigments. Those who are not yet familiar with this coating are interested in whether it is possible to paint a tree with it? The answer is undoubtedly yes. Moreover, this option has many advantages over similar formulations. How to paint wood with acrylic paint and how to choose the right product?

Bronze powder

FFT Bronze Powders and MICs mixed with liquid or gaseous oxygen burn intensively, but do not explode.

Mixes FFT Bronze Powders and MICs with a calcined and hydrophobic airgel in liquid oxygen do not explode at any powder content. A mixture of powder with a hydrophobic airgel burns intensively in oxygen gas at any powder content.

As bronze powder the commercial powder used for the preparation of the bronze paint is used.

Airgel mixture with bronze powder FFT It is used in the manufacture of tanks for liquefied gases and, in comparison with pure airgel and perlite, makes it possible to reduce by 3 - 4 times the amount of heat flux through a layer of insulation of the same thickness.

The additive gives a similar effect bronze powder to white soot BS-280 and aerosil A-380. In this case, the mixture with white carbon black has a slightly lower coefficient of thermal conductivity than the mixture with airgel, and the mixture with aerosil has a slightly higher coefficient. Considering the significantly lower cost of aerosil, it is advisable to use it instead of airgel in most products isolated with a mixture with BPI powder.

When insulated with a mixture of airgel and bronze powder the amount of losses decreases to 0 45 kg / h in nitrogen and to 0 to 40 kg / h in oxygen, or to 0 72% per day. The decrease in losses during the filling of the shielded powder is relatively small due to the large inflow of heat through the thermal bridges. According to the data of calculations and tests, the heat inflow through supports, suspensions and pipes is 19 5 W, which corresponds to 0 33 kg / h of oxygen, or approximately 50% of the total losses during airgel insulation. The heat flow through the insulation in the case of shielded powder is 4 0 W, which corresponds to a loss of 0 07 kg / h, or 0 13% per day. Consequently, the use of screened vacuum powder insulation can have a significant effect while improving the design of the tank in order to reduce the flow of heat through the hangers, supports and pipes.

The greatest application of powdered metallic pigments is aluminum and bronze powder.

IMASH, when added to airgel 50% Bronze Powder FFT the thermal conductivity coefficient at 90 K decreases from 0 0013 kcal. This is due to the mutual reflection of thermal infrared rays by metal particles of the powder in the insulating space; as a result, the flow of heat to the liquid as a result of radiation is significantly reduced.

Materials filled with a mixture have a higher load capacity. bronze powder and copper formate or salicylate. These compositions are used to coat worn out brake hydraulic cylinders of automobiles, as well as the inner surface of oil well tubing, operated with sucker rod pumps.

In tanks for liquefied gases, a mixture of airgel with bronze powder in the amount of 100 kg per 1 m3 of insulated space. The addition of metal powders to vacuum-powder insulation reduces heat flux through the insulation by 3 - 4 times.

Types of odorless paints

The coloring of various objects in a living room is complicated by an unpleasant odor and the release of toxic substances from the coloring base. New technologies have made it possible to cope with this problem. Currently, there are a variety of quick-drying paints that are odorless and contain a small amount of harmful impurities. There are types of paints and varnishes by composition:

- acrylic;

- latex;

- oil;

- water-dispersive.

Alkyd paints have a slight odor, but contain a harmful organic solvent, which makes them unsuitable for interior decoration of the house. All coloring formulations have their own advantages and disadvantages and are intended for strictly defined surfaces.

Acrylic based

Acrylates are widely used in interior decoration materials. Due to their moisture resistance, they are one of the best odorless wood paints. Fast drying compound suitable for finishing concrete, wood floors and windows. Acrylics are also used for artistic surface decoration. Their advantages include the following:

- odorless non-toxic composition;

- no harm to health;

- combustion resistance;

- versatility of use;

- ease of application (with a brush or textured roller);

- high adhesive performance;

- large palette of colors;

- various textures;

- the coating is resistant to cracking;

- short drying time;

- uniform distribution over the area of application;

- protection against rapid wear;

- low susceptibility to solar radiation, humidity, temperature changes.

Acrylic coloring mixtures have a rather high price, which can be attributed to their disadvantages. This disadvantage is offset by outstanding performance.

Standard acrylic paint in white. To obtain the desired tone, the appropriate color is added to the composition, the mixing proportions are indicated by the manufacturer. Some stores may offer computer based color matching. Thus, you can get the desired color without independently searching among the products presented.

Acrylic-based paints and varnishes may contain antiseptic additives that protect the painted surface from mold and mildew. This option is necessary for wood coatings used in rooms with high humidity. The substances in the composition can also protect the surface from contamination and water penetration, so that cleaning can be done less often.

Enamel with latex

There are no harmful substances among the components of latex paint, it is non-toxic and odorless. The composition is suitable for various surfaces:

- bricks;

- plaster;

- various types of ceilings;

- papered walls.

Enamel with latex is resistant to wear and tear, has good strength, is not subject to swelling and drying out. This option is great for baths and kitchens due to its moisture resistance. Initial hardening of the paint occurs 20-30 minutes after application. It will take one hour to dry completely.

Oil paints and varnishes

Oil paints are obtained by mixing drying oil with pigmenting substances. Such compositions can be diluted with linseed oil to achieve a more fluid consistency. Odorless oil paints for metal are especially popular, there are also varieties for concrete, wood and plaster.

Oil-based paints and varnishes can be colorless or colored, used for facades and interior work. They can be used to apply patterns, inscriptions or drawings. Affordable price makes this type popular among buyers. The only drawback is the long drying time.

Water-dispersive compositions

Water-thinnable paints are the safest. They are standard white and are used for painting floors and walls in children's rooms, schools and hospitals. Paints and varnishes dry quickly and look good on surfaces, and are also not affected by moisture.

You can give a different color to water-dispersion paint using color schemes. It is not harmful to the skin and can be easily washed off with water without any solvents. Such paint cannot be used to paint heating systems, metal and wood products.

Pros and cons of serebryanka

People have been using silver for more than a century, and during this time no one had time to get bored with the paint.On the contrary, it is being used more and more often for various needs. What is the secret of such popularity? It's all about the huge number of advantages that it has:

- Serebryanka does not exfoliate, it is a fairly strong and at the same time thin material. But at the same time, if you need it, you can easily get rid of the paint.

- The paint turns into a protective layer for the surfaces to which it is applied. It creates a thin, but even, smooth layer, fully reflecting the texture of the surface.

- It is used on various materials - from wood to concrete and metal.

- Long service life, so, in water, the paint does not deteriorate for 3 years, nominally - about 7 years, but in reality even longer.

- Not afraid of high temperatures.

- Immune to corrosion.

- Non-toxic.

- Dries quickly.

- Coloration in a pleasant silver color.

- With its help, you can achieve different shades of metal using pigments.

Of course, in addition to the pluses, this paint has its minuses, the main of which is its explosiveness. At what temperature can a metal fence be painted outside? Therefore, such a powder should be stored in a dry place and in a tightly sealed container, away from possible sources of fire, direct sunlight.

Do not keep the paint next to food, as the smell of silver is quickly absorbed.

It should also be noted that the paint is incompatible with oil and alkyd paints. In addition, silver should not be applied on top of NBH and nitro-enamel paints, since in combination with such a coating the paint will not last long on the surface, it will quickly go away and, possibly, swell with bubbles.

Serebryanka powder. Why is she so good

Its popularity is based on two main qualities. This is, first of all, its properties of a protective nature, as well as the decorativeness that it provides to any surfaces when painting. It is used to cover metal (it can be pipes, bridges, etc.), it holds well even on wood. Silver powder is an aluminum powder. When we dilute it, then varnishes and various pigments are also added to the composition. In fact, the composition of the silver is not particularly complicated, but it has its significant advantages:

- The layer, when applied, turns out to be uniform, thin and very smooth. In addition, it adheres well to the surface when properly prepared.

- Silverfish serves for a long time. If it is airspace, then about 7 years, and in water - up to 3 years.

- Serebryanka gives any surface a very attractive look.

- Good corrosion resistance.

But, she also has her own, rather serious drawback that you definitely need to know. The powder itself is very fire and explosive.

The presence of an open fire nearby is NOT ACCEPTABLE! Observing these conditions, you, first of all, ensure your own safety!

How to dissolve? Drying oil or varnish?

For dilution of silver powder, both of these components are suitable. But, if you do this you will be drying oil, then it should only be synthetic. There are some differences when mixing, but they only concern proportions. So, the powder marked PAP-1 is diluted with BT-577 varnish, while the ratio should be 2: 5 (that is, in other words, powder - 2 parts, and varnish - 5). So the silver that you get in the end will be able to withstand even +400 degrees Celsius during operation.

How to dilute correctly?

How this can be done, we have already decided, now we will decide on the intricacies of the process of making silver.

- Let's start again with the PAP-1 mixture. It is being bred gradually. At the same time, the varnish is used in small quantities, and these very small volumes are thoroughly mixed. It works well, for example, with a mixer.

- PAP-2 powder is diluted with any type of varnish. Here the proportions are slightly different - 1: 4, or, it can be 1: 3 (that is, the powder is 1 part, and the varnish is already 3 or 4).When you combine these components, the mixture will turn out to be quite thick, it is better not to use it right away.

- The choice of painting tool is the factor that determines the required consistency of the finished silver. And for this you can use an ordinary brush, or paint with a roller or spray. Working with these tools, you can dilute it with a solvent, turpentine or white spirit is also suitable. Under the spray gun, you need to prepare a more liquid consistency. In this case, the solvent and powder mix equally, that is, 1: 1. For painting with a brush or, for example, a roller, they do it already 1: 0.5, that is, they put less powder.

- If you dilute silver oil with linseed oil (remember that it is exclusively synthetic!), Then here the proportions are maintained by analogy with varnish.

All these methods of diluting silver powder end up giving approximately the following consumption: you can easily paint one square meter with 100 grams of ready-made paint.

How to paint with silver paint correctly?

If you want the paint to hold well, then you need to apply at least three layers. At the same time, be sure to wait until each of the previous layers is completely dry, and only then apply the next one.

You need to work with silverware only in personal protective equipment. At the same time, the space should not be closed, which means that windows and doors must be opened.

Any surface for silver plating should always be prepared. If it is metal, then there should be no remnants of old paint on it, as well as dust with dirt, or rust with greasy spots. The tree must be sanded.

If the surface is primed, then one single layer can be applied to it.

When applying silver on an unprepared surface (on which there is already something), do not apply it on nitro enamel, oil paints or NBH.

In this video, they will also tell you how you can dilute the silver. But, be sure to work in personal protective equipment!

How to dilute serebryanka with linseed oil for perfect surface coloring

Diluting silver oil with linseed oil is a more economical method, but also such a mixture does not have the protective properties that are inherent in the composition with varnish, for example, the same heat resistance.

This process includes several stages of work:

- Preparatory stage. The tools necessary for work are being prepared. You need a container in which the mixing process will take place. A tool for applying paint to the surface is also prepared (brush, spray gun, roller). And of course the drying oil itself is prepared. For safety, wear rubber gloves so as not to

- harm the skin and not stain them.

The mixing process itself. First, powder should be poured into the container, followed by drying oil, acting gradually, in parallel, stirring the mixture with slow movements. It is more convenient to use a mixer for stirring, and a more uniform mixture will be obtained with them. The manual method will take approximately 15-20 minutes.

Dilution of silver oil with linseed oil is a more economical way, but also such a mixture does not have protective properties.

If the solution is too thick, add the solvent, in a ratio of 1 to 5, this ratio ensures that the paint will not spread during the painting process.

If the solution is too thick, add a solvent.

Proportions for PAP-1 and PAP-2

The proportions for these types of silverfish are different. So, which ratios are correct, depending on the type of silver, will be described below:

- PAP-1 is diluted with drying oil in a ratio of 2 parts of powder to 5 parts of drying oil, if necessary, add a solvent, solvent;

- PAP-2 can be diluted with any kind of components, proportions can be used, either 1: 3 or 1: 4 (the first number means the amount of powder added).These proportions will give a very thick mixture, which is almost impossible to paint the surfaces, so they should be dissolved with turpentine, other types of solvents. Solvents are added in an amount based on the type of instrument to be painted. And this is 1: 0.5 for the roller and brush, and 1: 1 for the spray gun.

They act slowly, thoroughly mixing the solution so that it is applied in an even, beautiful layer. If the proportions are observed correctly, then the paint will turn out to be uniform and will have all its positive qualities.

They act slowly, thoroughly mixing the solution so that it is applied in an even, beautiful layer.

Galvanized metal painting technology

The process of carrying out painting work itself includes several stages, in order to get an excellent result, you should take time to study the methods of painting. And act exactly on the recommendations.

The first stage is surface preparation, which also includes preparing the material for better adhesion to the coloring agent. In order for the paint to show adhesion to the galvanized coating, there must be small "roughness" on the surface. If the surface is flat and such "roughness" is almost not observed, they are obtained using abrasive agents.

Even if the material has stood on the street for a year, and has already become covered with the necessary peeling coating, it is necessary to first degrease and get rid of contamination.

The previously painted product is cleaned from the previous layer. A solvent can be used for cleaning, and a metal brush can help to clean the paint.

Even if the material has stood on the street for a year, and has already become covered with the necessary peeling coating, it is necessary to first degrease and get rid of contamination.

Even if the material has stood on the street for a year, and has already become covered with the necessary peeling coating, it is necessary to first degrease and get rid of contamination.

Further purification from contamination is carried out. First, the paint is thoroughly mixed and poured into a convenient container. Work with any tool suitable for painting is allowed. For painting small parts, you can buy special paints in spray cans.

Before applying the 2nd layer, wait until the first one is completely dry. It is better to paint products in two layers. Applying three coats will give the best barrier effect, and the color will be bright and beautiful.

Before applying the 2nd layer, wait until the first one is completely dry.

Before painting galvanized iron, you should also take care of safety. Provide good ventilation in the room, provided that internal work is carried out. If you have to paint a large area, then wear a respirator and protective clothing, gloves.

If you have to paint a large area, then wear a respirator and protective clothing, gloves.

If you have to paint a large area, then wear a respirator and protective clothing, gloves.

Galvanized iron will become even more durable if you take care of additional protection with paint

Do-it-yourself painting is a simple process, only it is important not to forget about safety measures

It is also important to pay attention to the choice of the dye itself, this stage is the most important when working with painting galvanized iron. In order for the result of painting work to be beautiful, reliable and durable