Other options

It is not always possible to understand acrylic or epoxy by the name. For example, friends advised using hammer paint or rust enamel for painting. Let's describe the most popular formulations, their constituent substances, and as a consequence the properties of paintwork materials.

Hammer paint

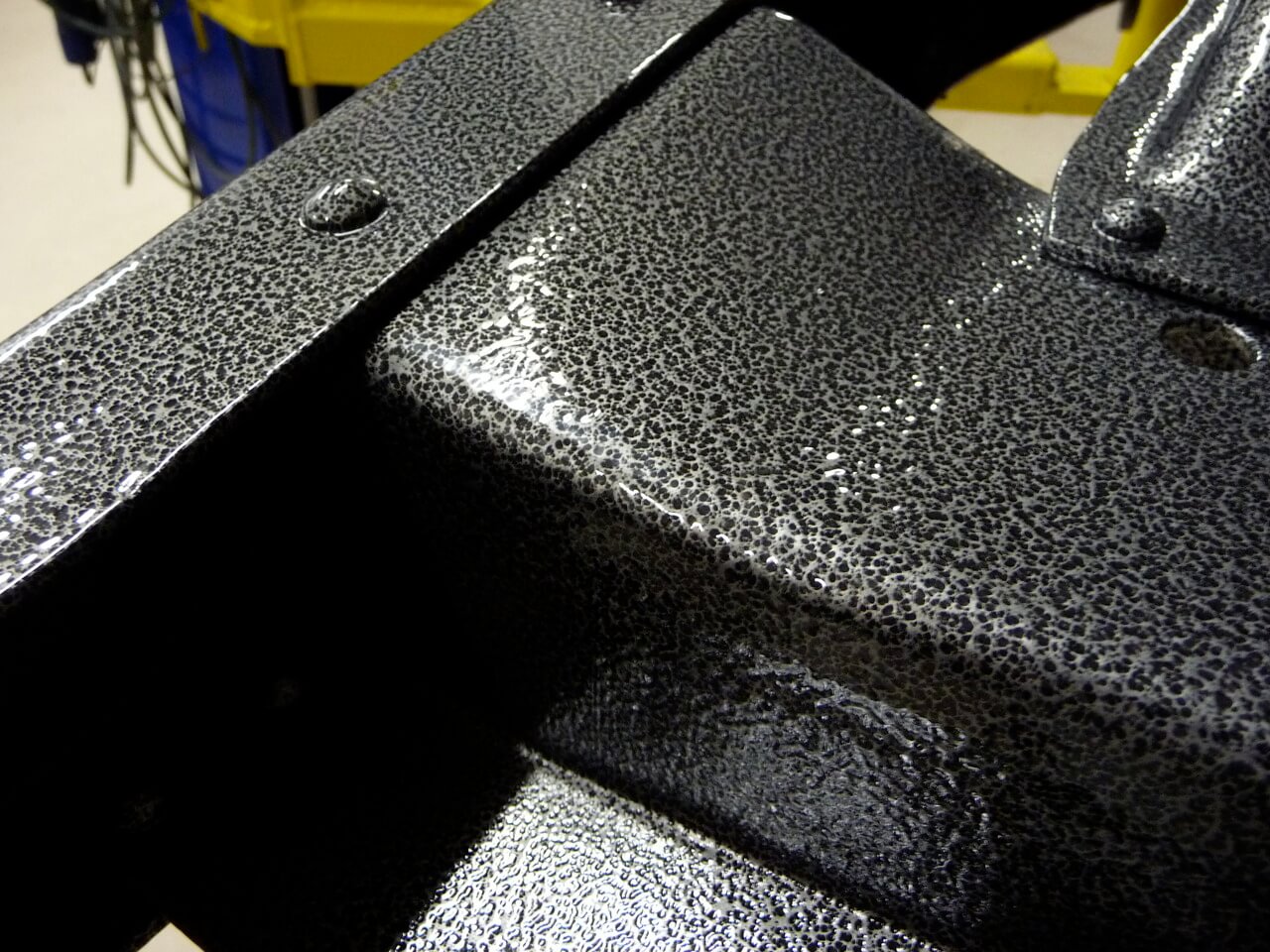

Another name for the paint is blacksmithing. The composition can have a different base, both alkyd and acrylic or epoxy. It is sold most often in cans, after application it forms a very characteristic coating, visually resembling a surface beaten with a hammer, hence the name.

Recognizable effect: hammer paint on metal gates

Recognizable effect: hammer paint on metal gates

The effect itself is achieved due to the addition of degreased aluminum powder to the base paint. In fact, all the properties of the paint depend on what composition was taken as the basis. And the hammer effect has its advantages:

- perfectly hides small surface defects;

- improves thermal performance;

- enhances resistance to water and temperature extremes.

Anti-corrosion compounds

Another common name is rust paint. One-component epoxy compounds that significantly reduce the cost of metal cleaning work. The composition of such paints includes anti-corrosion additives, which provide durable protection against rust and at the same time create a decorative coating. Paints can be glossy or matte, while this does not change their performance properties.

Advantages:

- It is possible to work with such compositions at a large temperature range from -20 to + 80 ° C, which makes it possible to paint communication systems associated with the water supply.

- Before application, the metal does not require special cleaning or priming, while the output is a durable coating that is resistant to moisture and dirt.

- Manufacturers claim a lifespan of about 8 years. In fact, the paint lasts longer, only slightly reducing its protective properties.

The compositions have disadvantages and the main one is the price. In addition, surfaces that are in direct contact with drinking water cannot be treated with this type of paintwork.

Anti-corrosion compounds form a dense film on the metal surface

Anti-corrosion compounds form a dense film on the metal surface

Rubber paint

Acrylic composition option. In appearance it resembles liquid rubber or mastic, but the technical characteristics of the finishing layer are different from rubber. It is quite simple to work with such a composition, it is not toxic, because it is water-dispersible. At the same time, there are certain additives in the paint that give the paint layer the following properties:

- elasticity,

- high strength,

- resistance to low and high temperatures (range -60 / + 50 ° С),

- not susceptible to high humidity.

The paint does not require any special surface preparation before application. It is an excellent waterproofing agent. Due to this property, it is very often used for painting metal roofing materials.

Rubber paint is an excellent material for metal roof processing

Rubber paint is an excellent material for metal roof processing

Pantolac Stancolac

The fourth place in the ranking is given to a Greek product made from alkyd resin and synthetic additives. The product is weather resistant. The paint can be spread over the metal with a roller or brush. When using a spray gun, a nozzle with a diameter of 4 mm is required. In order for the decorative layer to last up to 8 years, a thickness of up to 80-100 microns is recommended. At an outdoor temperature of + 20º, the surface will dry for 5 hours, after which you can start applying the second layer. Rust removal is not required before starting painting. Consumption of the substance is 9-10 m² per liter. Complete rejection of the decorative layer occurs after 96 hours.There is only a white version on sale, and the rest are obtained by tinting.

Our experts decided to add the paint to the rating due to its high resistance to water. Under static impact, for example, when painted metal is completely immersed in liquid, iron will remain unavailable to moisture for 24 hours. This is the best option for painting forged fences and gates with many complex elements that retain water.

Dignity

- suitable for steel, aluminum, copper and zinc;

- converts corrosion;

- high mechanical strength;

- supports surface bending up to 1 mm per meter without cracking;

- resistance to fading.

disadvantages

- work can be carried out at temperatures from +10 degrees;

- it is recommended to degrease the surface;

- you need very good ventilation of the room;

- no ready-made colors - only tinting.

Features of paint application

The first step is to choose a tool that will be used to paint. Traditionally, a brush, roller, spray gun, or spray cans are used. When choosing, you need to be guided by the type of surface, if the surface is flat, then a roller and a spray gun will do, if there are many complex transitions on it, then they resort to a brush. Small objects are painted with spray cans.

The first step is to choose a tool that will be used to paint.

The first step is to choose a tool that will be used to paint.

Brush

The brush should be chosen with natural bristles, the application on the surface is carried out in 2-3 layers, the processing is especially careful on the curly elements, corners. In this case, the thickness of one layer should not be more than 100 microns.

The brush should be chosen with natural bristles; application on the surface is carried out in 2-3 layers.

The brush should be chosen with natural bristles; application on the surface is carried out in 2-3 layers.

Roller

A roller is best suited with a short nap made of wool or fur. Working with a roller allows you to quickly paint even surfaces, parts with corners, irregularities are better processed with a brush. The first coat should be applied using a solvent of the same brand for the paint.

A roller is best suited with a short nap made of wool or fur.

A roller is best suited with a short nap made of wool or fur.

Spray gun

When choosing a spray gun, you need to have the skills to apply coloring compositions using it. The paint is diluted to obtain the desired viscosity, the surface must be smooth and clean.

Hammerite paint for metal the instructions describe the proportion of the addition of Brush Cleaner & Thinners, it is equal to 2/1. Dilution will provide the required viscosity.

When choosing a spray gun, you need to have the skills to apply coloring compositions using it.

Spray can

Before spraying, thoroughly shake the aerosol, apply from a distance of 15-20 centimeters, you need to make 3-4 layers, from the thinnest to the densest. The 2nd layer can be applied after 2-3 minutes, 3 and 4 after 15-20 minutes.

Before spraying, the aerosol is thoroughly shaken, the application is carried out from a distance of 15-20 centimeters.

Before spraying, the aerosol is thoroughly shaken, the application is carried out from a distance of 15-20 centimeters.

How to apply?

The manufacturer gives a guarantee for the coating for more than eight years, subject to the metal processing technology.

Here are some tips to consider when applying this product to surfaces:

- First you need to prepare the selected surface. To do this, it is necessary to clean the metal from various contaminants, degrease it.

- After opening the can, the composition must be mixed well. After mixing, it is worth leaving the paint for a few minutes so that the air trapped in the jar comes out.

- The temperature of the surface to be treated and the environment should be at least +5 degrees and not more than +30 degrees. Air humidity should not exceed 70%.

- For painting welded surfaces such as benches, fences and the like, use a brush. For large areas of painting, it is better to give preference to a roller or spray gun.

- It is better to choose a brush of high quality with natural or mixed bristles.This is because Hammerite products contain organic dyes that can dissolve synthetic bristles.

- It is necessary to apply 2-3 layers of dye to the surface, with intervals of at least 30 minutes.

- For vertical surfaces, the layers should be as thin as possible, but there should be at least three.

- When applying paint with a brush, it is not required to dilute the composition. When using a roller, the product must be diluted with a special solvent and Hammerite cleaner in a solvent-to-paint ratio of 1: 10. When using a spray gun, this ratio should be 1: 7.

- Since thinning changes the thickness of the coating, it is worth increasing the number of layers to at least three or four.

How Hammerayt paint is applied to a metal surface

Prior to application, surface treatment with a primer is optional. But if you want, you can do it. The effect of adhesion of paint to metal will only intensify. To do this, apply Hammerite No. 1 Anti-Rust.

If there are areas of well-adhered old paint on the surface, do the following. Apply Hameright to it in a test spot. Let dry for 30 minutes and inspect. If the coating is intact and even, then the composition of the previous paint allows you to apply a new one to it.

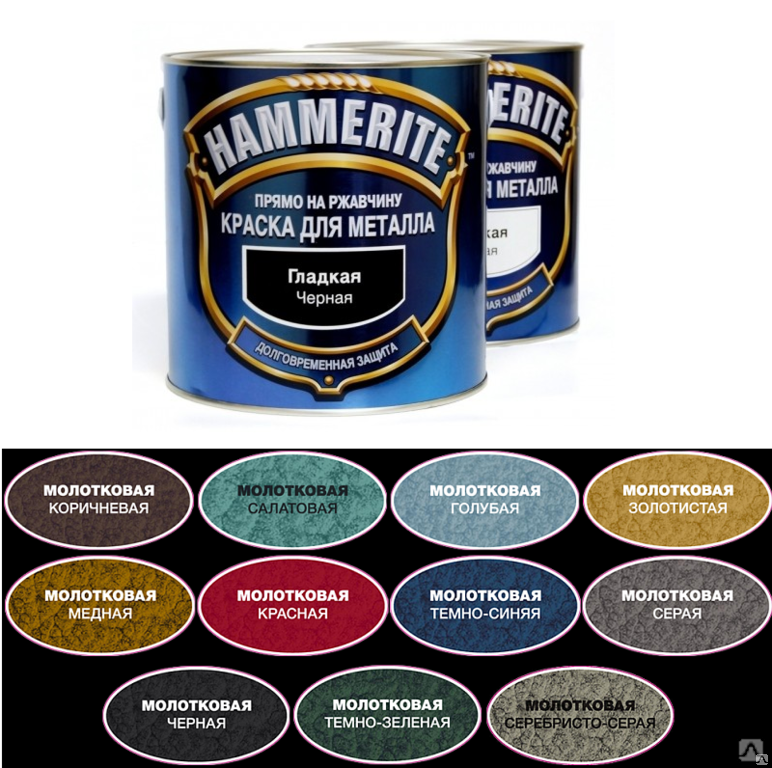

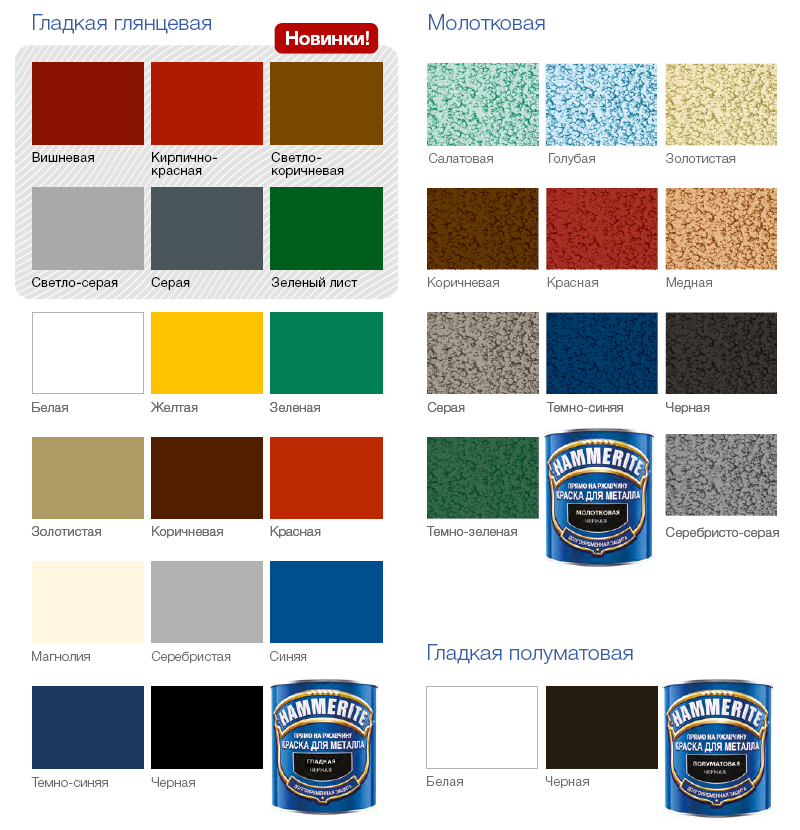

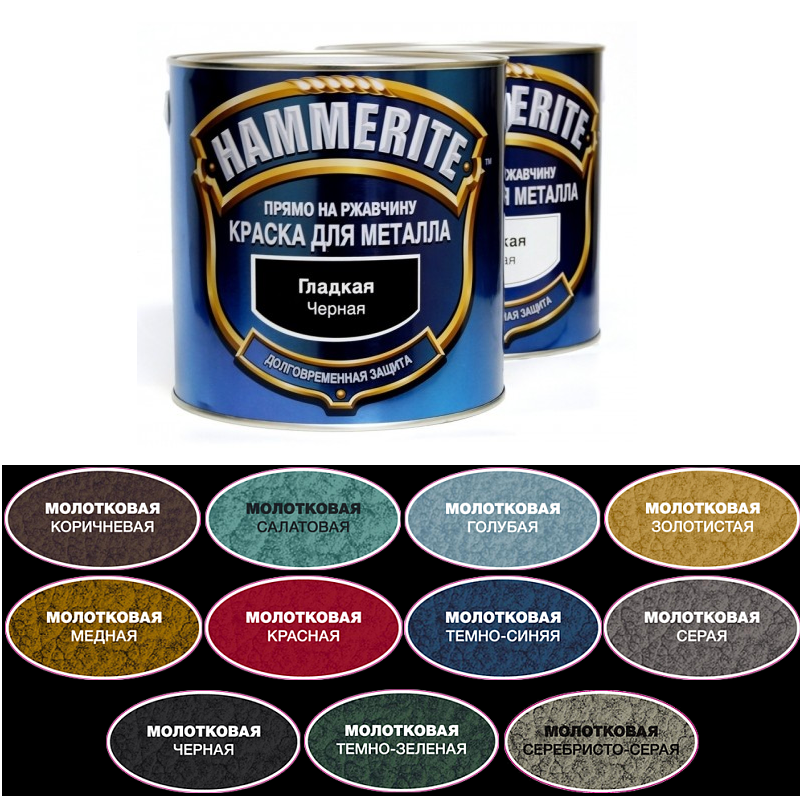

Hammerite coating colors

Hammerite coating colors

The composition is applied to the surface in the following main ways:

- paintbrush or roller;

- using paint spray in a special canister;

- using air spray (compressor with spray gun).

Consider the features of the application of each of the methods.

The first is with the use of a brush, when Hameright paint is applied on medium-sized surfaces and on objects with complex elements and shapes.

- Assess the viscosity of the paint before use. Generally no additional thinning is required. If it has thickened, it must be thinned. To do this, add 1 part Hammerite Brush Cleaner & Thinners to 9 parts of paint and mix thoroughly.

- Use good quality brushes made from natural bristles. This will ensure an even coating from the first pass. Do not use brushes, the fluff of which remains on the surface during the painting process.

- Dip your brush into Hammerite paint no more than half the size of your work surface. This will make it possible to use paint sparingly and without smudges.

Brushing Hammerite Paint

Brushing Hammerite Paint

Move the brush preferably in one direction, overlapping each subsequent stroke by half with the previous one. This will ensure the uniformity of paint application. Be sure to carefully apply Hammerite to areas of the product to be painted, where access is inconvenient and difficult. This is your special focus area

It is imperative that the composition gets there in the required quantity. Otherwise, these untreated parts of the surface will become hotbeds of developing rust.

Painting is done in at least 2 and no more than 3 layers. Coating in one layer will not provide the desired effect. Applying more than 3 coats will result in unnecessary consumption of paint material. Painting vertical metal surfaces requires special attention. This is due to the fact that, being at such an angle, the applied paint can drain and form smudges. Continuously monitor the condition of previously applied layers. If necessary, without letting them dry out, immediately correct this area of the surface with a brush. Before applying the next layer, it is necessary to withstand a time of at least 3 hours for the previous one to dry. You shouldn't be in a hurry. This will destroy the previously applied coating.

Part painted with Hammerite paint

Part painted with Hammerite paint

The second is using a roller. The basic requirements for the preparation of the paint composition remain the same as when using a paint brush.

The peculiarities include the method of dipping the roller into a special container for applying paint to its working surface. Do this evenly over the entire fleecy area. Performing such an operation will ensure the application of the Hameright compound evenly and without gaps.

Painting with a roller

Painting with a roller

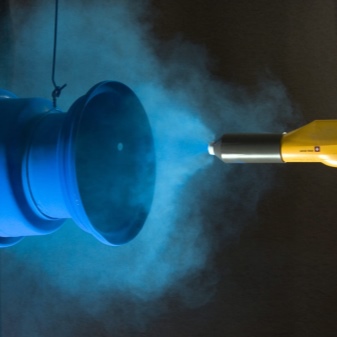

The third is by air spraying. The paint composition is applied from an aerosol can or a compressor with a spray gun.

Large areas are painted with a compressor and spray gun. In this case, it is imperative to meet the requirements for the viscosity of the paint. It is necessary to prepare the composition in a ratio of 2 parts paint and 1 part Hammerite Brush Cleaner & Thinners. If this ratio is violated, the spraying process will be difficult or impossible. The thick compound will not spray normally from the spray gun nozzle. Excessively thinned will cause smudges or an unacceptably thin coating.

Paint application by air spray

Paint application by air spray

The paint is applied in 3-4 layers with intervals between applications in 30 minutes.

Hammerayt paint for rust is a good solution for metal painting. It will provide time and labor savings in surface preparation, coating durability during operation.

How to remove corrosion effortlessly

Both manual and mechanical cleaning can be used to remove loose pieces of rust.

For mechanical cleaning:

use special metal brushes for grinders or drills; select the appropriate size of the brush, depending on the area and configuration of the object that you intend to paint with Hammerayt paint; treat the surface with a mechanical brush; inspect the treated surface for possible residues of non-peeling rust

Pay special attention to places that are difficult to reach for a mechanical brush: joints, bends, corner joints. Re-process them if necessary.

If after that peeled rust remains on them, then remove it manually.

Removing rust from metal mechanically

Removing rust from metal mechanically

For manual cleaning:

- use metal brushes for cleaning metal products;

- remove loose rust from the surface;

- then perform stripping in the same sequence as for machining.

Manual rust removal

Manual rust removal

Main characteristics and features of the coating

The results and characteristics of the paint composition may differ from manufacturer to manufacturer, but for the most part hammer paints have similar characteristics:

- For the binder, an alkyd resin is used in the composition.

- The density of the substance is 1 kg / l.

- Indicators of the remainder of the coating on the surface - 47%.

- Drying time parameters - at least two hours.

- If you need to apply several layers, then each subsequent one is applied 5 hours after the previous one.

- Shelf life in a container is 2 years, subject to all storage rules.

- Gloss level indicators - 66.

- Withstands the influence of temperature up to + 80 ° С.

- For one coat, use a liter of hammer paint per 10 m2.

Among the main advantages of the paints in question, there are several of the most attractive:

- it is not required to clean the entire surface from rust before use;

- the coating tolerates vibration and many atmospheric phenomena;

- paint helps to protect metal from rust;

- re-painting of the metal structure may not be required for 10 years;

- the paint does not contain toxic elements that adversely affect human health;

- the coating does not have a strong and pungent unpleasant odor, which contributes to the use of the substance even in poorly ventilated rooms;

- the coating has a wide variety of shades, which makes a very rich choice;

- paint does not fade for a long time;

- dirt and dust do not adhere to such a coating.

The only drawback is that old paint is very difficult to remove from the painted surface. In some cases, even a strong solvent does not help.

Application area

Hammer effect coating is a widely used material for painting a wide variety of metal surfaces. It looks especially gorgeous on forged products. In addition, paint with a hammer effect is used:

- For painting machinery, as well as various equipment.

- Metal pipes.

- Coloring of the main units in structures of different types.

- Glass surfaces.

- Fences and fences made of appropriate material.

On the street, this coating is very often used specifically for painting fences and other metal structures. They will be able to stand for a huge amount of time and not change their appearance.

Surface preparation

In order for the surface to last as long as possible with a new coating, it must be properly prepared. First of all, the surface is preliminarily wiped with acetone. It is easy to use a thin sheet of plain paper to test readiness. If you run it over the surface and there are no traces left, the product is ready for painting.

In order to better prepare the surface for painting, it is advisable to process it with an iron brush. After such stripping, the adhesion of the surfaces is improved.

The next step is to treat the surface to be painted with a primer. She will create a special film on which the paint will adhere to an even and durable layer.

Metal paint Hammerayt

For metal objects, protection against damage and rust is especially important. Hammerayt paint is able to solve these problems, as it is specially designed for the treatment of all metal substrates.

Hammerayt paint is intended for the treatment of all metal substrates.

Hammerayt paint is intended for the treatment of all metal substrates.

Features and specifications

It is equally suitable for the treatment of both interior and exterior surfaces. In addition, it has a number of additional advantageous features:

- The spectacular look of the product is achieved through a wide color palette. A separate category is hammerite paint, after drying of which the surface looks like chasing;

- Excellent adhesion even in slightly rusty areas. The paint can last at least 8 years;

- The compositions can be applied in a wide temperature range from -20 and 85 degrees;

- The product can be used for plastic, including sewer, drainage and so on;

- Resistant to sunlight. The original color remains for five years even under constant exposure to ultraviolet radiation.

Hammerite metal paint is almost universal. It performs paint and varnish functions, can serve as a primer, and also transforms rust. To grasp the surface, the mixture takes half an hour. It takes about three hours for a perfect grip. Full disclosure of all advantageous properties can be assessed after 6 days.

The paint performs paint and varnish functions, can serve as a primer, and also transforms rust.

The paint performs paint and varnish functions, can serve as a primer, and also transforms rust.

What is included in the material

Hammerayt enamel dries quickly. No additional mechanical treatment of the surface is required before use. The material acquired its unique properties due to its composition:

- Advanced alkyd resin;

- Coloring elements;

- Anti-corrosion agents;

- Wax and solvent;

- Additives, fillers.

The resin creates a denser structure. The presence of a solvent helps the material dry faster. The material acquired its water-repellent properties not only due to the presence of silicones, but also due to a unique component - glass particles.

The presence of a solvent helps the material dry faster.

There are three varieties of Hammerite paint:

- Matte;

- With gloss;

- Hammer.

The composition of the first two types is practically the same. It is hammer paint that is of interest, in a mixture of which aluminum flakes are contained.They create the effect of embossing on the surface with small dents and other relief patterns. Due to silicone fillers, the pattern is stable and does not change its original shape.

Aluminum flakes create an embossed effect on surfaces with small dents and other embossed patterns.

Aluminum flakes create an embossed effect on surfaces with small dents and other embossed patterns.

Scope of application of hammer paint

Hammer paint, with enhanced anti-corrosion properties, is designed specifically for painting metal structures. It can be applied to rusted areas without first cleaning and priming.

Resistance to environmental influences made it suitable for painting wooden surfaces, which is something that exterior designers are using. The scope of this type of paintwork materials is not limited only to this. It can be found in the painting of industrial equipment, agricultural machinery, and office furniture.

In addition, it serves as additional protection for downpipes, and is also a unique decorative element for painting tiles, plastic and glass.

Resistance to environmental influences made it suitable for painting wood surfaces.

Resistance to environmental influences made it suitable for painting wood surfaces.

Applications

The use of hammer paint is possible in most areas:

- for the processing of various metals. Suitable for coating equipment and metal products made of steel, copper, iron, aluminum, etc .;

- in construction it is used for painting most metal structures;

- application is often carried out on doors, safes and certain types of furniture for industrial use;

- in the automotive industry it is used to cover the body and disks;

- intended for application to forged products;

- used to create an interesting effect in the interior, the substance gives the feeling of antiquity;

- in the advertising direction it is used to cover glass and plastic.

Color palette

A wide selection of palettes is another positive point in the paints of this manufacturer. There are podcasts for each type of enamel.

Glossy textures are available in cherry, red, brick red, light gray, light brown, gray, gold, blue and white. You can also choose the color of leaf green, magnolia, dark blue, just blue and yellow.

Hammerayt matt enamel colors: white, black.

Hammer enamel: dark blue, dark green, silver, gray, blue, golden, brown, red, light green, black, as well as a shade of copper. At the same time, the manufacturer replenishes each line of the color palette with enviable regularity.

A wide selection of palettes is another positive point in the paints of this manufacturer.

A wide selection of palettes is another positive point in the paints of this manufacturer.

Peculiarities

Hammerite paints are specially formulated for various metal surfaces. They have several advantages. So, the products meet the highest quality requirements that apply to the products of the chemical industry. The composition of the paints has a 3 in 1. This means that in addition to the coloring pigment, there are substances that protect the metal from corrosion, as well as a primer, so there is no need to treat the surface with additional primer solutions.

The coating that forms this material is quick-drying. To "grab". the applied layer takes only 30 minutes. The coating gets its initial strength after 3 hours, full acquisition of properties is achieved in 6 days. The coating can be applied with a brush and roller or with a spray gun. A fairly wide range of colors makes it possible to use paint in almost any design. In addition, it does not have a pungent odor.

Complete cleaning of the metal surface

Rust is removed to the required limits. We proceed to the final cleaning of the metal surface before painting. If the product is completely new, then the main task is to degrease it. For this:

- Remove any possible dirt deposits from the metal.

- Using an emery cloth, lightly rub it over the surface.This will enhance the adhesion effect of the Hamerayt compound and ensure its good adhesion (adhesion).

- Degrease and clean the surface with Hammerite Brush Cleaner & Thinners. To do this, apply it in a thin layer to the surface and rub with a clean brush.

- Keep the surface in this state for 5-7 minutes.

- To remove the resulting composition, use water and detergent.

- Rinse the surface to be treated with clean water and dry.

Means for degreasing metal surfaces

Means for degreasing metal surfaces

Types and features of hammer paint

Now the industry produces different types of hammer paint, so you can buy:

1. alkyd-styrene enamel, withstand temperatures up to 130 degrees in both directions from zero, dissolving only in xylene and suitable for any type of work, for example - ML-165;

2. epoxy enamel for external work "2 in 1", intended mainly for construction vehicles and street metal objects - lamps, gates and so on, it is applied to rust and perfectly masks chips, is resistant to all weather conditions, dissolves with solvents No. 648 and No. 667, example - EP-1323 ME;

3. nitro enamel intended for "home" use, that is, suitable for pieces of furniture and fragments of interior interiors, with a pronounced decorative effect and lower technical properties in heat resistance, resistance to precipitation and other external influences, is dissolved by common solvents for enamels, for example - NC -221;

4. hammer paint hammerite - English enamel, with very high technical and decorative properties, as well as full versatility in use and the absence of a strong specific odor.

In addition, the paint is divided into ordinary in cans and sprayed aerosols in cans.

Hammer paint has various forms of release, which allows the consumer to choose the most convenient method of application

How to paint hammer paint correctly?

Painting with hammer paint does not require any special skills, tricks or tricks. Although the "blacksmithing" and undemanding, but some preparatory work is worth doing:

- if on the surface there is a layer of crumbling, swollen, crumbling old paint - oil, bitumen-containing or powder, then it must be cleaned off;

- new products must be degreased, completely cleaned of grease using any technical means, for example, white spirit, solvent and acetone;

- the surface must be freed from loose, falling rust and falling off layers of paint;

- for wooden surfaces or products, a primer is needed, water-based acrylic is ideal, this is necessary in order to obtain a decorative effect, without primer, the paint is simply absorbed into the wood;

- glass, plastic and other materials must be degreased and clean.

The technology and method of painting itself depends on which tool you plan to use:

The brush must be chosen carefully, checking before buying for convenience and for "shedding", that is, buy with stubble that does not come out. This tool is irreplaceable for complex surfaces, with details or hard-to-reach places.

The painting itself should be carried out as follows - two layers on horizontally located surfaces and three on verticals. This will provide maximum decorative effect.

Ideal for large and flat surfaces such as walls or countertops. It is necessary to purchase one made of velor or fur with a short medium-hard pile, the paint corrodes the foam rollers.

The paint is applied in two or three layers. Depending on where the work is going - horizontally or vertically.

3. Aerosol can

Good for painting defects, decorating complex artsy surfaces or individual elements, as well as when performing artistic images on cars.

It is applied in 3-4 layers from a distance of 15 to 25 cm. Anything that cannot be stained must be securely covered. The first layer dries from 2 to 5 minutes, the next from 20 to 30 minutes.

4.Pneumatic spray gun

Good for working on large areas with decorative elements, both protruding or convex, and sunken. Due to the fact that the spray gun will not be able to paint exactly any surface, a good additional reinforcing decorative effect is created. Coloring is carried out in 2-4 layers, be sure to thoroughly dry each of them.

Airless and pneumatic spray guns are not the best choice for this paint as the enamel is very heavy. The use of this tool will require dilution and a change in its density, which will inevitably lead to a loss of technical and decorative qualities.

The average material consumption, if hammer paint lays down on rust and other difficult surfaces, is from 100 to 150 grams per square meter.