Advantages and disadvantages

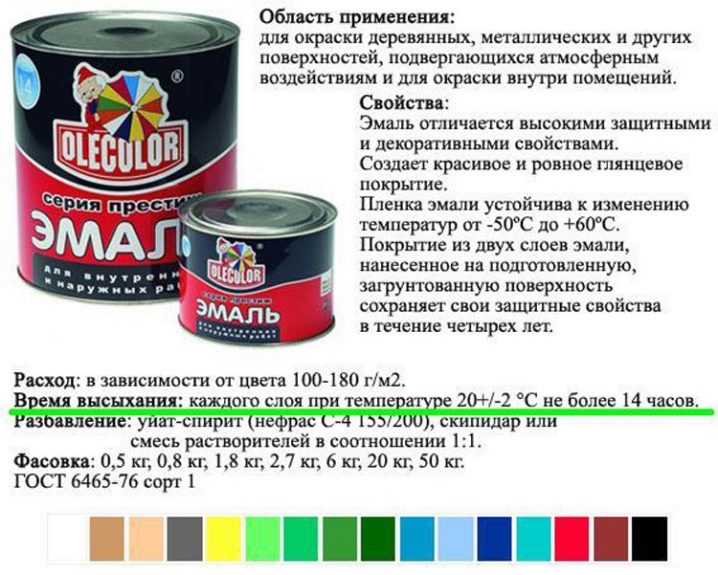

The indisputable advantages include the following properties of enamel paints:

- Wear resistance. Enamel paint, when used indoors, is able to maintain excellent appearance and technical characteristics for 15 years.

- Ease of use. Even a beginner can handle painting. To achieve the desired result, you must carefully read the instructions and follow them. Professional or special tools are also not needed; ordinary brushes can be used for application.

- Low cost. Within the framework of a market economy, each manufacturer sets its own price for its product, but the average price per kilogram of high-quality paint is 65-70 rubles.

- Rich color palette. Enamel paints are distinguished by their richness of shades. It all depends on which color is closer to you or more suitable for the existing interior. At your service is a bright, pastel, universal ball or any other range of shades, the main thing is to choose the right one.

- Fast drying. Unlike oil paints, which may take a very long period to dry, enamel paints dry very quickly, sometimes even one hour is enough for them.

Consider now those disadvantages that can influence your decision to purchase enamel paint:

High toxicity. If staining is done indoors, it is not recommended to stay in it for the next 24 hours.

Fragility. To a greater extent, this applies to those paints that are intended for outdoor use. Under aggressive or unfavorable atmospheric conditions, it will last about a year.

If you do not plan to update the treated surface every year, we advise you to pay attention to more practical options.

UV exposure. With regular exposure to the painted surface, the sun can shorten the life of this paint and varnish material.

As a result, it will tarnish and cracks will appear.

Principles of enamel compilation

It is useful to know a few principles related to the composition of enamels of the desired color and the perception of color in general.

It is important to know the following principles

drawing up enamels

When composing the enamel color, the addition of any dye other than white is equivalent to adding a colored film of the same color to the transparent viewing window, i.e., in this case, part of the color spectrum in the perceived light is cut out ("subtractive" - "subtractive", Russian, effect). When two additional dyes are added at the same time (red + cyan, magenta + green), all the tones of the spectrum are cut out and a color close to gray (black) should be obtained, but in fact, a brownish-dirty tone is obtained.

since the color of the dyes is not perfectly pure

White dyes work differently, they do not absorb, but reflect all the colors of the spectrum, then

there is the addition of a white dye, as it were, reduces the thickness of all colored films in the viewing window and the color turns out to be less saturated, more pastel.

Any given color can be reproduced with

using dyes of four original colors

(for example, magenta, yellow, cyan and black, as in

CMYK standard). And for translucent compositions (stains)

- it is enough to use three initial dyes.

In practice, the number of

source colors by one relative to their minimum number, but an even larger number of source colors only complicates the color matching.

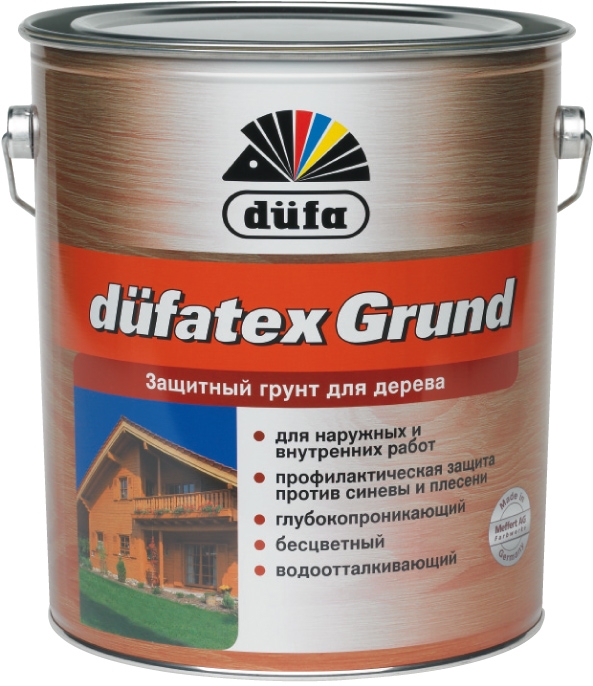

How to primer?

Hardware stores offer different types of primers, and sometimes it is very difficult for the DIYer to make the right choice. How to prime the surface before painting? To select the right primer mix, consider:

- Place of priming.For living rooms, you need to choose non-toxic compounds, but for outdoor work, toxicity does not play a big role, here you must give preference to mixtures that allow wood to obtain additional protective qualities.

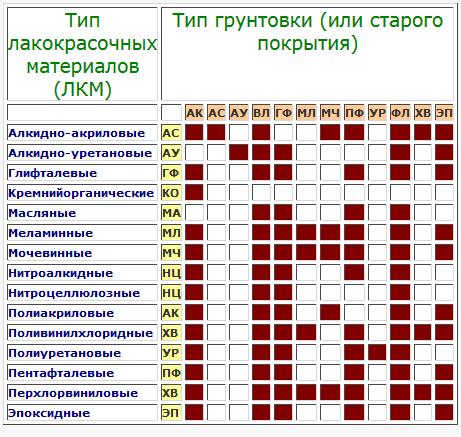

- The nature of the topcoat. The composition of the primer should be close to the dye, which is planned to be used for decorative finishing. If you use compositions of different structure, then a "chemical conflict" may arise, the surface color will be of poor quality, the paint will begin to bubble and flake off.

Having decided on the choice, it is worth considering the most commonly used primers.

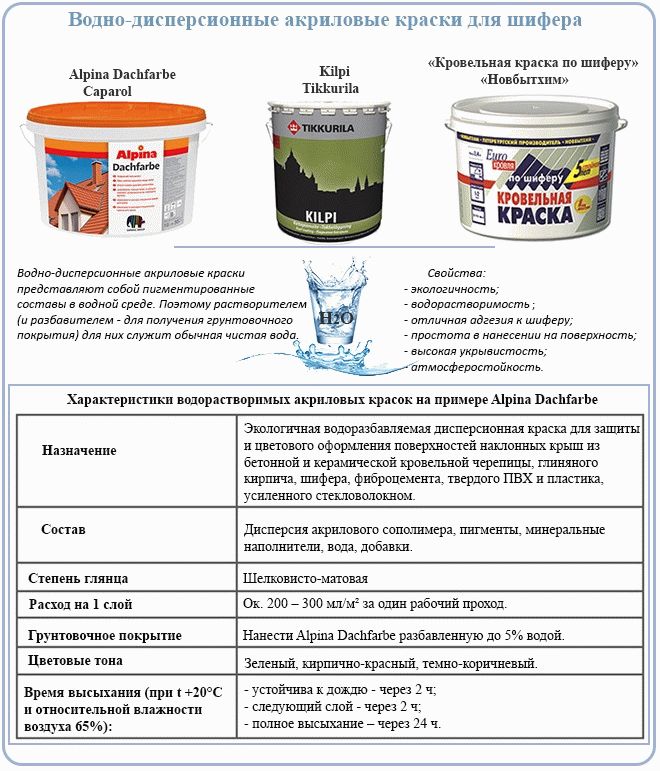

Acrylic

The water-based acrylic primer is non-toxic, penetrates deep into the wood structure, dries quickly and is very durable. Very often, various mixtures are added to this type of soil, which increase their protective properties.

The purchase of acrylic primers with protective additives allows you to combine the stages of priming and impregnation, which does not in any way affect the quality of the preparation of the base for painting. Can be used for facade and interior work.

Alkyd

This primer is ideal where there is high humidity. It provides reliable protection against swelling, rot and mildew. It is low-toxic, but dries for a very long time (the drying process takes about 18 hours at normal humidity and a temperature of 18-20 degrees Celsius).

On the street, such primers can be used only in clear weather or under a canopy. Alkyd primers are well suited for preparing wood floors and walls in baths, baths or saunas for painting.

Epoxy

Primer mixtures based on epoxy resins, after application, form a durable moisture-proof layer on the board. Toxic, dry quickly. It is a little difficult for novice craftsmen to work with them due to the fact that the primer is released in the form of two components that are mixed before use.

Epoxy primers are an excellent option for outdoor use, especially in regions with a high rainfall.

Shellac

This type of primer is used extremely rarely, only if raw wood was used for construction. Shellac soil-mixtures, due to the methyl alcohol contained in them and insect milky juice, contribute to the rapid drying of the wood structure, replacing the water in the pores with methyl alcohol. This replacement helps to avoid drying deformations.

After the selected primer has been applied and dried, the base is additionally sanded and cleaned of fine dust. This completes the preparation for painting, and you can apply a decorative layer of paint.

A competent choice of protective equipment and compliance with all the necessary steps before painting will not only ensure the durability of the repair, but also reliably protect the tree from environmental influences.

Varieties of anti-corrosion protection

For the treatment of small areas or for the prevention of corrosion, a primer-enamel for rust is used. This paint combines three properties: enamel, primer and rust converter. But anti-corrosion paints are just a general name for drugs that differ in their composition. Depending on the anti-corrosion components that make up their composition, they are divided into the following groups.

Insulating

After drying, such a primer-enamel for metal forms a strong film that blocks access to the base of water and oxygen. These dyes, as a rule, are made on the basis of red lead and additionally have heat-resistant qualities.

These characteristics allow them to be used for outdoor work and for painting surfaces in water. Fast drying: this coating provides reliable anti-corrosion protection already after 2-3 hours.

Passivating

This primer paint is used to slow down the development of corrosion. The anticorrosive substances included in its composition with their chemical formula significantly slow down the course of oxidative processes. Suitable for use in humid locations.

Converter

Contains phosphoric acid. The acid, after a chemical reaction with iron oxide (corrosion), forms a strong and inert to oxidative processes iron phosphate. The use of converters allows not only to protect the structure from destruction, but also to partially restore the damaged metal base.

Phosphating, two-component

The composition includes phosphoric acid and passivating additives. Has a low consumption when applied to the surface, has high adhesion. Coating with such paints is possible even for galvanized metals, which are practically impossible to treat with other anti-corrosion agents.

Tread

Anti-corrosion enamel with the smallest metal particles dissolved in it forms a durable metallized coating after drying. Application of paints with protectors is recommended in high humidity conditions.

Quick-drying primer-paint not only possesses high anti-corrosion qualities, but is also economical: its consumption per 1 square meter is small.

Protectors are often used to paint boats or metal piers in the water.

Inhibitory

It contains a unique formula. Such a primer-enamel for rust gives the oxidized structure after interaction with it the properties of a primer. Inhibitory paints are fast drying and have high adhesive properties.

Their disadvantages include a large, in comparison with other primer paints, material consumption caused by abundant saturation of the rust structure. But, despite this small drawback, inhibitor paints are most in demand for providing anti-corrosion protection and decorative painting of metal products.

The colorant selected in accordance with the technical characteristics will stop corrosion only if:

- The rusting area is small.

- Rust has a strong bond with the metal base.

The use of three-in-one paint in case of large damage to the product or on a loose fragile area of rusting does not give a positive anti-corrosion effect. For such violations of the metal structure, major restoration work is required.

Types of primers by type of surface

As a rule, universal primers are used for all types of surfaces. A good result can be obtained by using specialized primers that are suitable for the surfaces to be treated.

Concrete floor primers

For priming concrete floors, it is necessary to use impregnating, deep-penetrating and adhesion compounds. The following primers will help to prepare the concrete floor for further finishing:

- acrylic - penetrating and adhesive;

- polyurethane - adhesive, dedusting, filling pores, protecting from chemical influences;

- epoxy - moisture-proof, resistant to mechanical and chemical influences;

- alkyd - deeply penetrating, abrasion resistant;

- polyvinyl acetate - used as a base for paint and PVA glue;

Wood primer

Primers for wood surfaces are deeply penetrating and strengthening. Applied before coating with paint or varnish. Penetrating into wood and strengthening it, they create a thin vapor-permeable film on the surface, which prevents destruction. Primers are used for wood:

- acrylic - deep penetrating and bonding fibers;

- alkyd - filling and protective composition;

- shellac - serves for processing raw coniferous wood, neutralizes the release of resin to the surface;

- oil (linseed oil) - impregnates wood, is used before painting or filling the base;

- glyphthalic - used for further processing with epoxy solutions;

Features of choosing a primer for a wooden floor

The main tasks of the wood primer are to close the porous structure and strengthen the fibers, which corresponds to a deep penetrating primer. The primer for the floor must be waterproof, antiseptic, protecting against mildew and mildew. The primer must have high adhesion in order to secure the topcoat as reliably as possible.

When choosing a composition, it is necessary to pay attention to its transparency. This will emphasize the texture of the wood and remove restrictions on the use of finishing materials.

Non-transparent compounds are used in the case of subsequent painting of the floor surface.

To protect the surface from fire, it is necessary to use primers with fire retardants.

Biocides with antiseptics will protect wood from insect pests, mildew and mildew.

Underfloor heating primer

To treat the surface of a warm floor, which is poured with a cement (concrete) screed, concrete primers are used.

The underfloor heating screed must be vapor permeable, not stained, and have good adhesion.

The optimal primer is an acrylic primer.

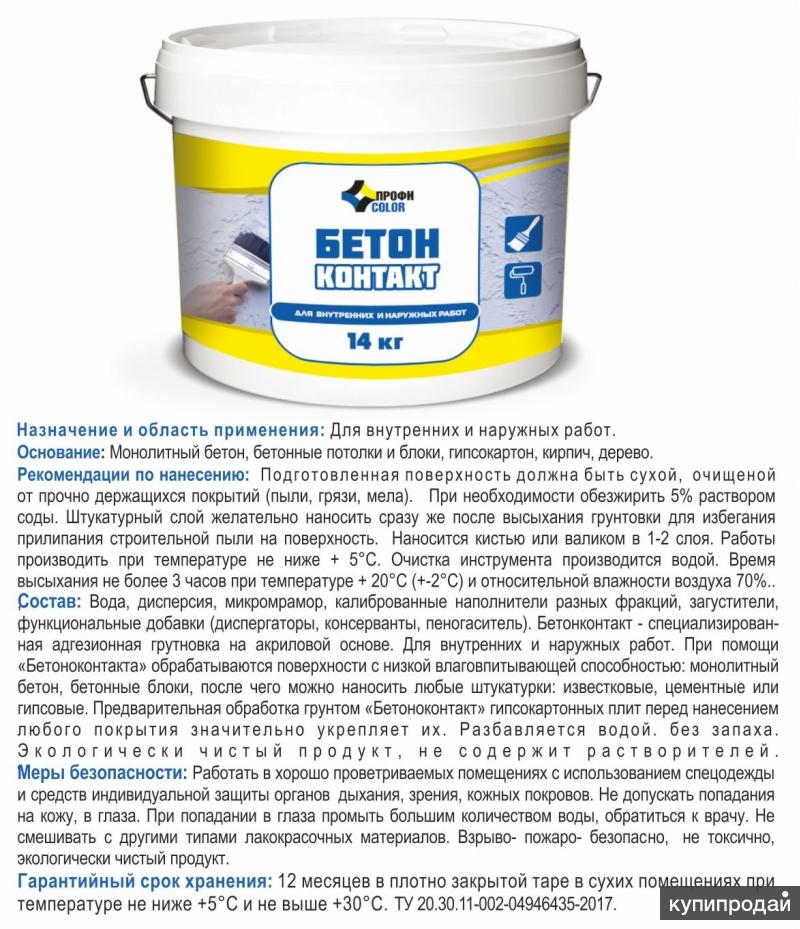

Under the tiles

Preparation of the base for laying tiles involves dedusting and reducing the water-absorbing properties of the floor.

For laying tiles on a concrete or cement base, it is necessary to treat the surface with primer, which will strengthen the surface, protect the base from moisture and ensure maximum anchoring of the tile to the floor. In this case, you need to use deep penetration soil.

The best composition would be an acrylic-based primer.

Laminate floor primer

If concrete acts as the base of the floor under the laminate, then priming of the surface is mandatory. The primer of the floor for laying the laminate must remove dust, ensure the waterproofing of the surface, carry out an antiseptic treatment against the appearance of mold and mildew.

For priming the floor under the laminate, polyurethane and acrylic primers are suitable.

Chipboard floor primer

A chipboard floor requires protection from moisture, mold and mildew. For priming the surface of a chipboard floor, primers for processing wood products are suitable. The exception is shellac primer, which is used for surfaces made of softwood.

If in the future the floor will be painted, then it is necessary to use soil compositions that are consistent with the paint. For alkyd-based paints, an alkyd primer is used. For acrylic paints - acrylic.

For polymer floors

Priming the surface before the installation of self-leveling floors has the goal of reducing water absorption, increasing adhesion and creating conditions for uniform distribution of the liquid composition of the self-leveling floor.

For the installation of polymer floors, epoxy primer is suitable.

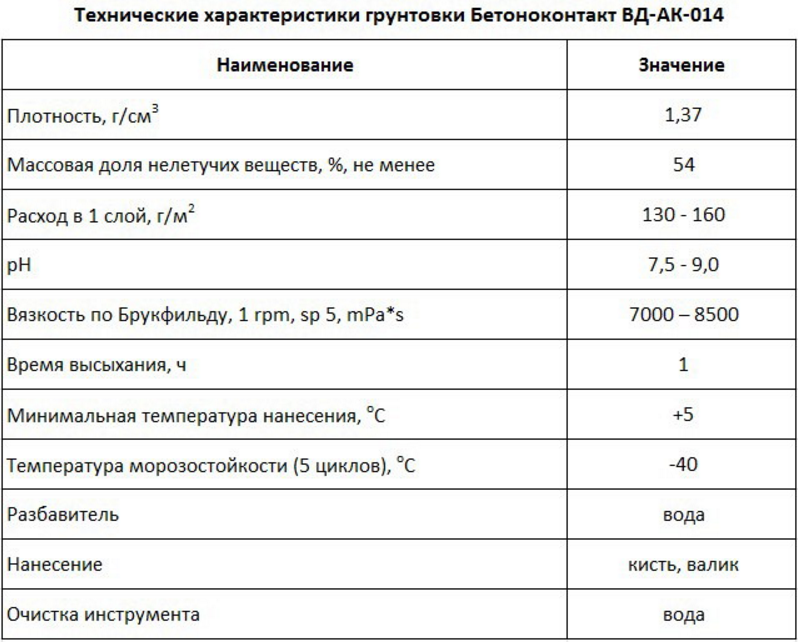

Primer consumption for putty and plaster

It is necessary to prime the walls before puttingty. This layer can significantly reduce material consumption, as it will not be absorbed into the plaster. The primer will prevent moisture penetration, which will extend the life of the finish and prevent premature cracking. The presence of antifungal ingredients will help prevent mold. In addition, applying putty requires a certain skill, the primer will even out the surface, which will facilitate the process of creating an ideal layer. A layer applied to the putty will create a perfectly flat surface for painting, wallpapering.

The calculation of material consumption depends on several factors:

- Base type

- Primer type

- Method, quality of application

In most cases, when working indoors on plaster and putty, an acrylic matt primer is used.It dries quickly, does not contain harmful components. On average, it is consumed about 200 ml per 1 m2. The environmentally friendly Optimist primer is now very popular. The consumption rate of this product is from 120 to 250 ml / m2. A special mixture is used to create decorative plaster. It is consumed in the amount of 200 ml per 1 square meter of surface.

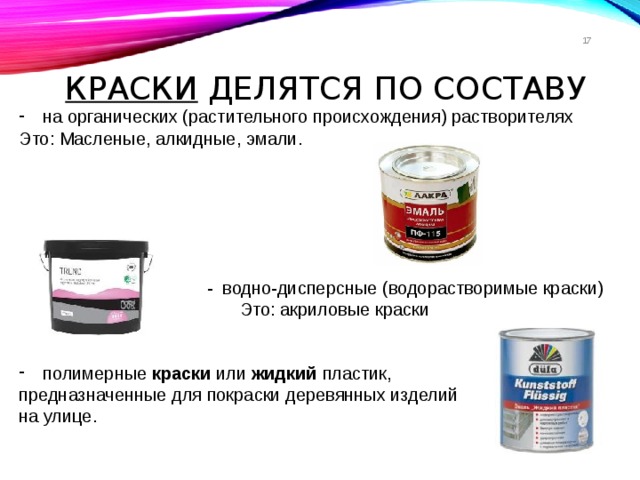

Marking

Even before going to the store, you can decide what kind of paint you need. To do this, you should understand that the letters and numbers on the label have their own meaning. We have already figured out the letter marking. Let's try to understand what the first digit after it means.

Let's take paint - PF-115 enamel. We will judge only by the first digit, that is, by "1". It is she who means the field of application. Even if you did not find in the description for what surfaces and works this or that paint can is intended, you can easily find your way by looking at this figure:

- 1 - intended for outdoor use or, in other words, weatherproof;

- 2 - for interior work (officially - limited weatherproof);

- 3 - conservation;

- 4 - waterproof (suitable for rooms with high humidity);

- 5 - special enamels and paints (have individual characteristics of use and a narrow range of applications);

- 6 - oil and petrol resistant;

- 7 - resistant to chemical attack;

- 8 - heat-resistant;

- 9 - electrically insulating or electrically conductive.

Purpose and description

The aforementioned primer is used for painting cast iron and steel products, as well as structures, on the surface of which the remains of rust or scale are tightly retained. The thickness of corrosion products can reach 70 microns. During operation, the painted surfaces can be exposed to the atmosphere, aggressive vapors and gases, as well as salts and chemicals, with the only note that their temperature should not exceed 60 ° C.

Primer-enamel XB-0278 can act as an independent or as a multi-layer coating together with weather-resistant varnishes or enamels. This mixture is used to paint the bases, the cleaning of which at the stage of preparation may be difficult for certain reasons. These include fences, garages, or trellises.

The composition is used in car repairs for priming the surfaces of fenders and other parts that do not require decorative finishing.

Division of primers by functionality

Before choosing how to prime a tree before painting, it is necessary to understand not only the different compositions and types of these mixtures. You should be aware that they have different purposes.

Antiseptic

Wood primer can be used for antiseptic purposes. In this case, it is used where there is an increased risk of attack by insects or molds. In addition, antiseptic compounds are able to repel moisture, as well as resist fire more effectively.

After treatment with antiseptic primers, a layer of paint is applied on top of them. The adhesion is so strong that insects cannot penetrate between the layers and cause direct damage to the wood fibers.

It is used where there is an increased risk of attack by insects or molds.

It is used where there is an increased risk of attack by insects or molds.

Anti-corrosion

Anti-corrosive primers are used more often on metal, where the likelihood of rusting is maximally high. But, if wooden boards are nailed with metal nails or pressed against with screws, then with high humidity and unfavorable weather conditions, there is a high probability that rust will start to appear in this place quickly enough. This leads to a violation of the structure of the tree, and also causes outwardly unattractive phenomena. therefore, in order to prevent such an effect, they use anti-corrosion primer and wood where necessary.

They use anti-corrosion primer and wood where necessary.

They use anti-corrosion primer and wood where necessary.

Flame retardant

This option for wood is able to effectively resist the occurrence of a material fire. The following can be distinguished as protective properties:

- Resistance to short-term exposure to fire;

- Elimination of the pyrolysis effect;

- Prevention of ignition by prolonged exposure to high temperatures.

Thus, fire-retardant impregnations for wood are able to provide deep and superficial fire protection of structural materials used in residential construction.

This option for wood is able to effectively resist the occurrence of a material fire.

This option for wood is able to effectively resist the occurrence of a material fire.

Hydrophobizing

It is also called water-repellent. The outer coating of wood with such compositions provides:

- Formation of a film that does not allow moisture to penetrate under it;

- Resistance of the material to destruction under the influence of liquid.

Today the following types of water-repellent primers are presented on the market:

- By designation, they are distinguished - strengthening and adhesive;

- In terms of composition, there are - acrylic, silicone, aluminum, epoxy. It is epoxies that are effective when it is necessary to create a colorless or white coating. Their chemical composition makes the natural color of the wood brighter and the white paint lighter.

The outer coating of wood with such compositions ensures the resistance of the material to destruction under the influence of liquid.

The outer coating of wood with such compositions ensures the resistance of the material to destruction under the influence of liquid.

Universal

The universal impregnation provides a reliable layer that is capable of:

- Effectively protect wood indoors and outdoors;

- Align the top layer, contributing to a more convenient and economical staining;

- Suitable both for applying a subsequent color layer and for applying a transparent varnish, revealing the structure of the tree.

The universal impregnation provides a reliable layer that is able to effectively protect the wood indoors and outdoors.

What to look for when choosing?

A few tips:

Appearance. Even the highest quality paint can become unusable if the storage was carried out in violation of the norms or the bank itself is damaged. Before buying, carefully inspect the container; it should not have dents, scratches or other damage. This is not about aesthetic beauty, but about the fact that as a result of air ingress, the paint could dry out.

Shelf life. It can be easily found on the label or on the jar itself.

Always pay attention to this. The more time before the expiration date, the better

After all, force majeure circumstances are not excluded, in which you will have to postpone the planned painting.

Consumption. It is also indicated on the paint can. If you purchase enamel in several colors, then the consumption must be calculated for each one. For example, dark blue can cover 14-17 square meters of area, while red only 5-10. The white paint of this group is capable of covering an area of 7-10 square meters.

GOST inscription. The digital code may vary, but its very presence is as much a prerequisite as the expiration date or labeling.

Each finishing material has its own pros and cons. Knowing about all the nuances and subtleties, it is quite possible to find the ideal option for yourself. For the types and rules for choosing paints for the ceiling, floor and walls, see the following video.

How to paint

Before proceeding with the application of anticorrosive enamel, the base must be prepared for work in order for the painting to give the maximum protective effect. To do this, you need to do the following:

- Brush off corrosive damage by removing loose pieces of rust. Cleaning can be carried out using a sander with the appropriate attachment, except for the area affected by rusting. It is recommended to additionally grind the adjacent surfaces.

- Rinse thoroughly the entire area prepared for painting and dry thoroughly. Depending on the size of the item, you can wash it under running water, with a rag, or using a portable car wash. The use of a car wash, as practice has shown, gives a better cleaning of the surface due to the fact that water with detergent is supplied under pressure.

- Treat with a degreaser. White spirit, gasoline or other quick-drying solutions can be used as a degreaser. If it is not possible to carry out a complete degreasing of the structure, then the solution must at least treat the rusty places. If you do not use a degreaser, the adhesion of the primer-paint to the substrate will deteriorate significantly.

Only such preparation will help to say "stop" rusting. After the degreasing solution has dried, dye can be applied. For a long-term result, experienced craftsmen advise:

- Apply a primer-enamel in at least 2 layers, and re-painting should be carried out only after the previous layer has completely dried.

- Apply the second layer after the previous one has dried, but no more than 5 hours later. If more than 5 hours have passed, then it is worthwhile to find out in the instructions the time of complete polymerization of the composition (usually 25-30 days) and only after this period, re-coat. Neglecting this recommendation will lead to a decrease in the protective qualities of the primer paint and to the fragility of the decorative finish.

If you choose the right enamel-primer with corrosion protection, depending on the nature of rust and the operating conditions of the product, as well as follow all the stages of applying the dye, you can get reliable and long-term protection of the metal structure from the development of corrosion changes.

Peculiarities

A deep penetration primer has a number of features that distinguish it from a protective primer. Thus, it provides the smoothest and most even application of the finishing layer. Even the thinnest paint and varnish composition, including water-dispersion paint, as well as wallpaper and other materials, fits well on it.

This composition reduces the level of absorption of finishing materials. By filling all the pores on the surface-base, it significantly reduces the consumption of building and finishing mixtures. Thanks to him, paints and varnishes, as well as adhesives, will not be wasted. They will remain on the surface in the same amount as they were originally applied.

A feature of these compositions is their versatility. They are suitable for many surfaces. Manufacturers even present models that are called so - universal deep penetration primers. They can be used to treat any surface.

These compositions differ in some of their characteristics depending on the species. However, there are a number of properties that are characteristic of all types of deep penetration primers.

So, they mainly include water. She is a thinner. In the composition of these materials, a chemical diluent is practically not used. The maximum amount of non-volatile substances in deep penetration soil is no more than 20%.

The density of the deep penetration primer is similar to that of water and is 1 kg per 1 cubic meter. dm. That is why the peculiarity of this composition is that during the repair process it is possible to calculate its consumption. As a rule, for finishing 1 sq. m is spent from 100 to 200 g of this material, depending on the quality of the base. The absorbency of the substrate can greatly increase consumption, even though you will be using the same primer for different surfaces.

A special feature of the deep penetration primer is its short drying time. But, as a rule, the specific period of time for which it dries out depends on what percentage of the total mass is water.

Even the most well-impregnated surfaces dry in less than 3 hours. Particularly porous surfaces can dry in an hour. The compositions dry most quickly at an air temperature of +20 degrees and a humidity of 70%.

But this composition can also be used in rooms with high air humidity. From this, its properties will not deteriorate at all, only the drying time will increase.

An important feature of using deeply penetrating primers is that they are used for certain finishing materials. As a rule, this is cement plaster or walls for painting, brick, lime whitewash before wallpapering, monolithic concrete, concrete screed, aerated concrete, OSB, chipboard

Deep penetrating soil can greatly affect the absorption rate of the material, regardless of its appearance. When finishing work, it is often used for concrete, aerated concrete and aerated concrete.

Deep penetration primer does not adhere well to the surface if there are dirty or oily stains on it. Therefore, the wall must always be prepared in advance. If you find stains after you have covered the wall with this compound, you must remove the contaminated area along with the primer. Otherwise, the properties of the material in this area will be greatly deteriorated. The absorption capacity is always lower in areas with oil stains. Therefore, the desired effect will not be, the primer simply will not be absorbed into them.

This primer is excellent for utility and industrial premises. In homes and apartments, it is often used to renovate kitchens and bathrooms. In these areas, it deeply penetrates walls, floors and ceilings and allows you to fight against mold and mildew. Thus, a durable and reliable layer is formed on the surface, which significantly reduces the level of water absorption. Thanks to this, the surfaces are not destroyed by moisture, and the possibility of the development of harmful microorganisms is also reduced.

Peculiarities

Primer-enamels of this type are universal mixtures. They help to update the look of metal products. It is not necessary to prime the substrate before applying paint. The enamel itself can act as a primer.

The primary task of paint is to stop the spread of rust on processed products and prevent the formation of new foci of corrosion. In addition, enamel has a decorative function. It can be made in various colors and is used as a topcoat.

Most often, this composition is used to cover products located on the street. It can be both furniture elements and iron gates, garage boxes and other structures. Primer enamels help prevent the material from being affected by negative climatic conditions. They are resistant to cold weather, heat and high humidity. However, this does not negate the possibility of using the mixture indoors for processing interior elements.

The use of mixtures in the process of car repairs has become widespread. This is most important when processing its internal components, which are often in contact with liquids such as oil and gasoline, and are also exposed to high temperatures. After covering the elements with enamel for one or several times, they become inert to the effects of an aggressive environment.

In addition, 3 in 1 primer enamels are widely used in industry. This was also facilitated by their resistance to aggressive conditions.

The use of primer enamel is possible not only when working with metal surfaces. In addition to cast iron, aluminum and steel, they are perfect for brick, concrete and wood substrates.

The versatility of the mixture is achieved thanks to its ingredients. First of all, it is based on alkyd-urethane varnish. It includes alkyd resins and urethane additives. Performs a linking function.

The presence of anti-corrosion materials helps to solve two problems at once.The first is to neutralize rust that has already hit the product. The second is to prevent new foci of corrosion. This is due to the formation of a phosphate film on the surface.

In addition, the composition contains enamel. It is with its help that the finishing layer of the painted element is formed. Due to the plasticizer and similar impurities, the working properties of the mixture are significantly improved. The content of the solvent in the base helps to maintain the viscosity of the composition.

The base of the primer and the additives contained in it are constantly being improved. This is due to competition between manufacturers. The color spectrum of the compositions is wide enough, which makes it easier for the consumer to choose.