Manufacturers

When choosing the really best paint for wood, pay attention to its packaging, components, expiration date. Good manufacturers release their products in sealed containers, convenient for long-term storage.

They also correctly label the product, indicating on the packaging all the information necessary for the consumer.

Among the already established manufacturers of wood painting products:

- Tikkurila is a Finnish brand that specializes in the production of all kinds of finishing materials. Although its products have a fairly high price in comparison with others, they are fully compensated for by quality. Painting wooden lining, ceilings, floors, furniture, windows and doors with materials from this manufacturer will give them an excellent appearance and protection from environmental influences;

- Alpina - the products are made in Germany, they are distinguished by an attractive price and good quality. The manufacturer produces materials for both exterior decoration of wooden buildings and interior work. The advantage is a wide color palette;

- Neomid is a domestic manufacturer that can easily compete with foreign firms. Neomid manufactures interior paint for wood with increased refractory properties;

- Belinka is a product with an average cost and high quality from Slovenia. Has a wide range of finishing materials for wood, including protection against fungus, moisture, sun, chemicals. This product is easy to work with as it has an optimal texture and does not flow on the surface.

Now you know that when choosing which paint to paint a wooden house inside or outside, you need to pay attention to the main characteristics and positive properties of the available assortment and purchase what is best for your case and budget. However, remember that good and correctly selected finishing materials will help keep the treated surface intact and neat for a long time and will allow you to make repairs much less often.

For lovers of natural compositions, we recommend that you familiarize yourself with such material as paint with wax for walls. Perhaps this is what you need. You may also be interested in learning how to paint the steps of a wooden staircase.

Rating of paints for wood for interior work

Tikkurila is a Finnish company that produces impeccable quality compounds for the treatment of interior and exterior coatings.

Tikkurila Empire base

Tikkurila Empire base is a paint that is suitable for painting wood and metal surfaces, as well as for finishing furniture. Alkyd based. Packaged in cans of 0.255 l, 0.9 l, 2.7 l and 9 l. The paint has many advantages, ideal for interior work... Has a semi-matte effect, there is a slight sheen. The price for a can of 0.9 liters is 700-800 rubles.

Tikkurila Empire base

Advantages:

- easy to use;

- does not flow;

- does not splash;

- the smell is weak, barely noticeable;

- little consumed;

- can acquire any color from the catalog;

- hides flaws;

- dries for 3 hours.

Tikkurila Miranol

- another quality paint for wood surfaces. The price for a 0.9 liter can is about 700 rubles.

Advantages:

- lies down easily;

- no smudges;

- dries up in 3-4 hours;

- a wide range of colors;

- dense, one layer is enough.

Tikkurila Miranol

Disadvantages:

has a mild odor.

About the features of the material - in the video:

TEKNOS

Is a Finnish company that cares not only about the quality of its products, but also about their environmental friendliness. The company's advanced technology allows it to excel in this matter.

TEKNOS biora balance water-based is practically odorless, perfect for painting even a children's room.

TEKNOS

Advantages:

- does not contain solvents;

- safe;

- practically odorless;

- matte beautiful finish;

- hides small irregularities;

- persistent.

Disadvantages:

high price.

ALPINA

Is a German brand with a 100-year history. Produces a huge number of different products for interior and exterior surfaces. The first cold water-soluble paint was invented.

Alpina Aqua Buntlack is an acrylic based paint that produces a beautiful gloss. Available in 0.7 l and 2.5 l cans.

ALPINA paint

Advantages:

- does not have an unpleasant odor;

- many saturated colors;

- easy application.

Disadvantages:

expensive - 2,000 rubles for 2.5 liters.

ADLER

Is an Austrian paint manufacturer with a good reputation in Europe.

ADLER Lignovit Color is an acrylic paint that provides long-term protection of wood surfaces. Prevents mold, mildew and blue from penetrating. Suitable for all wooden elements both indoors and outdoors.

ADLER

Advantages:

- reliable coverage;

- does not crack after a long time;

- little consumed.

Disadvantages:

the price is almost 4000 for 4 liters.

ACE PAINT

Is a very large and popular American company that often offers innovative products to its customers.

ACE Contractor Pro Interior Wall Paint is an acrylic paint for interior work, suitable not only for wood, but also for drywall, wood, brick and other surfaces.

ACE PAINT

Advantages:

- economical;

- does not exfoliate;

- covers irregularities well.

Disadvantages:

sold in large quantities, more suitable for large-scale works.

SENEZH

Is a Russian company known for its products for the processing of wooden surfaces, in which it has achieved great success.

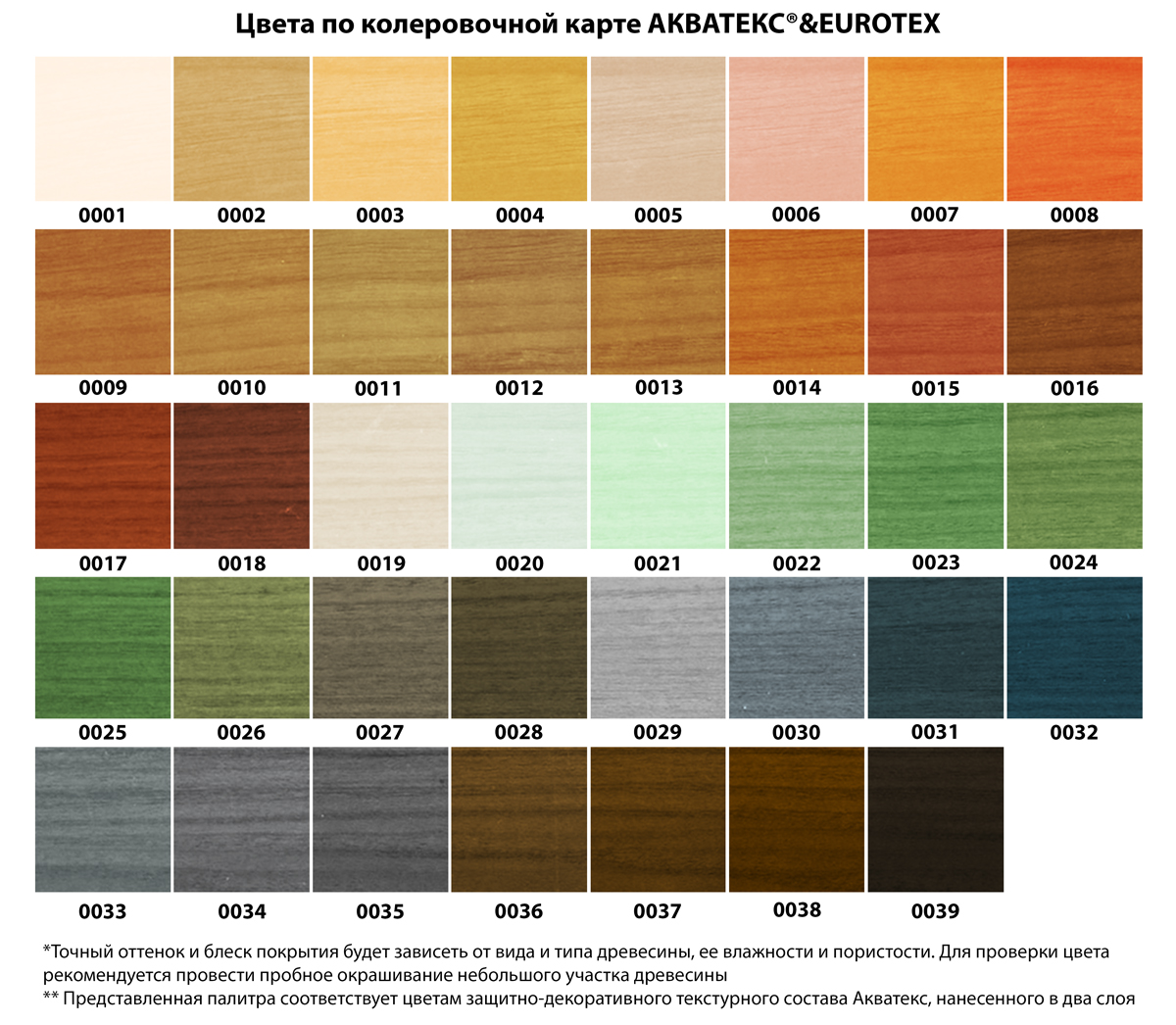

SENEZH AQUADECOR is an antiseptic with the main task of protecting the wooden surface. There is a fairly large palette of colors.

SENEZH

Advantages:

- protects the tree as much as possible from the effects of various negative factors;

- there is no unpleasant smell;

- many colors to choose from.

Disadvantages:

- it is not always possible to achieve the color that is indicated;

- more consumption than indicated by the manufacturer.

Popular paintwork materials

Let's dwell on the most common paints that can be used for wood processing.

Acrylic paints and enamels. Acrylic paints and enamels are water-borne and practically odorless, dry quickly, are environmentally friendly and durable. These materials are usually great for outdoor and indoor use. Modern covering materials have a wide range of colors, while the brightness of the coatings remains for a long time. Any method (brush, roller or spray gun) can be used to apply the compositions. Facade opaque paints perfectly withstand high and low temperatures, as well as direct ultraviolet rays, since they usually contain special additives (wax, oil, UV filters and lightfast pigments). The paint protects the wood surface from damage when exposed to moisture, without clogging its pores. It is forbidden to store water-borne materials at subzero temperatures.

Alkyd paints and enamels. They attract with an affordable cost and a variety of shades, and you can tint them yourself. Such materials are allowed to be used for both indoor and outdoor work, since they tolerate precipitation and other unfavorable external influences well. However, for indoor use, paints based on organic solvents are less preferable because of the pungent odor. It is possible to operate structures treated with this type of material even at temperatures above -30 ° C. Such a surface dries within 8-24 hours, but the paint hardly penetrates into the wood fibers. It is customary to use alkyd compounds for wooden street structures, entrance doors or window frames.

Oil paints. They perfectly protect the tree from water, but in terms of performance they are in many ways inferior to other analogues. In particular, they dry for a relatively long time for about 2 days, smell strong and often form smudges. You should also take into account their poor compatibility with other paints and varnishes and insufficient wear resistance. Inexpensive oil paints fade very quickly under the sun's rays. However, these materials also have advantages: low consumption and excellent elasticity.

Water-based paints based on polymers.The main advantages of these formulations are odorlessness and environmental safety. They are poorly suited for outdoor work, since they cannot tolerate high humidity and other unfavorable external factors. Due to this feature, it is not recommended to use them also in the kitchen, bathroom or sauna. However, some varieties, due to the presence of special polymers in the composition, acquire the necessary water resistance. But their cost is quite high compared to other paints of this type.

Polyurethane paints and varnishes. Often used for painting wooden floors and furniture. These compounds are not toxic, and the layer formed by them is resistant to mechanical stress and elasticity. Polyester paints. These materials are manufactured using polyester resins. They are expensive, therefore they are mainly used in restoration work on wood. They are also used for decorative processing of various products.

Nitrolacs. Used for decorative processing of wooden products and elements inside the premises. These compounds are distinguished by their flammability, susceptibility to ultraviolet rays, therefore they are not used for the street. Their main field of application is the finishing of wooden furniture and interior elements.

Selection of paints and varnishes

LKM are classified according to the following criteria:

- By composition (water and organic);

- By protective action (against organic and chemical substances, mechanical influences, changes in humidity and temperature);

- By the method of use (internal, external, combined);

- By type (impregnation, paints, stains, varnishes).

1. Paints. They can be used for processing new and old doors. There are no difficulties with the choice, but due to incompetence, people choose the wrong material. Paints and varnishes are transparent and opaque. The first formulations include certain pigments exhibiting a woody structure. But often opaque coatings are used, consisting of organic solvents (oil, alkyd and other types).

The most popular is alkyd enamel, the cost of which is affordable. This coating has high strength, a wide range of shades. But the enamel smells bad, its unpleasant smell remains for 2 days, so they work with it on the street, first removing the canvas from the hinges or freeing the room. An alternative solution is acrylic enamel, which also has many colors but no toxic odor. The dried paint has no particular strength, therefore, it is additionally treated with acrylic varnish to protect it from mechanical stress.

Rice. 2. Paint on wood

A more resistant coating for wood doors is nitro paint, which has optimal durability. The composition is toxic, sometimes leads to allergic manifestations, so you need to work with it in protective equipment. If an old surface is treated with nitro paint, preparation and grinding of the panel to a light shade is carried out in advance.

2. Varnishes. Refers to traditional coatings that give wood a shine and protect its surface. Usually varnish is used for covering doors in rooms with high humidity (baths and saunas).

There are many different varnishes:

- Acrylic. The material is resistant to negative influences, moisture and ultraviolet light. Distinguish between matte and glossy coating without toxic odor.

- Nitrocellulose. Varnish can be applied to wooden doors. The coating is not suitable for treating bathrooms and baths, as it has insufficient strength and cracks quickly.

- Water-based varnish. It has no unpleasant odor. Material properties may vary due to different additives.

- Polyurethane. The varnish has high strength and adhesion to wood, it is matte, semi-gloss and glossy.In addition to wood, polyurethane varnishes can be applied to parquet, veneer, countertops.

- Oil varnish. There is no strong smell. The composition contains a lot of fatty resins, so the old coating is removed from the door in advance. It is better to apply with a brush due to its thick consistency.

- Polyester. The composition has a pungent odor, is highly durable, but toxic, therefore it is suitable for processing street doors.

It is better to paint interior doors with acrylic or polyurethane coating, and resistant materials are suitable for external works or rooms with high humidity.

Rice. 3. Varnish on wood

3. Stains. The task of such compositions is to tint the tree and provide temporary protection against negative influences. But a constant renewal of the layer is required, which emphasizes the woody structure.

There are several options:

- With lacquer base (azure). The composition reduces the duration of work, but it is difficult to achieve aesthetics, therefore, a monochromatic surface can be obtained by spraying with a spray gun;

- With oils. Dilute with solvent before use;

- With water. It dries longer, but there is no toxic odor. The composition penetrates deeply, giving a richer shade and a clear pattern that looks beautiful;

- Alcohol-based. It dries quickly, but is more expensive and has a pungent odor.

Fig. 4. Wood door stain

To protect wood from fungus, moisture and dirt, oil wax is used, which penetrates deeply into the surface. The coating gives strength and shine.

DIY painting OSB plates inside the house

Before painting the OSB indoors, you need to understand the intricacies of the work, in the positive aspects of this solution. Coloring is an option that can be implemented quickly, while not spending much money. You can also say about the following advantages of painting:

- A variety of types of paints and varnishes and color options, which makes it easy to choose a shade suitable for the interior of the room;

- Ease of the process, you do not need to have special skills and knowledge, this is saving money on the services of professionals;

- Ease of repairing damage, in case of their occurrence, individual areas can be painted again;

- The possibility of repainting when the finish is boring, the coating can always be renewed by changing the color;

- Improvement of the protective properties of the surface, there are paints and varnishes that have a moisture-protective characteristic, which also create a protective layer against ultraviolet radiation;

- Surface cleanability, many types are washable.

Painting OSB boards indoors is a way to hide the textured coating characteristic of the material. Although some property owners prefer to highlight the texture by only changing the shade, then a varnish or stain is used.

Painting is also carried out on special types of wallpaper. Before painting the wallpaper and sticking it on the OSB, surface preparation is carried out.

Painting OSB boards indoors is a way to hide the textured coating characteristic of the material.

Painting OSB boards indoors is a way to hide the textured coating characteristic of the material.

Why do you need to do this, features

When deciding how to paint OSB inside the house, one must not forget about the woody component of the material. This makes it possible to use a larger number of dyes produced for wood.

However, this material has a number of features that they pay attention to when choosing:

- Poor indicator of surface adhesion, not all paints can adhere well to such a surface, the presence of special bonding agents in the constituent elements does not allow paints to penetrate deep into the enamel;

- The textured structure of the material, the surface may seem even, but in fact there are roughness and unevenness on it. Therefore, preparatory work is mandatory, you cannot do without grinding, such a texture requires an increased paint consumption;

- The service life of the panels, the longer the panel is used without treatment, the more difficult the painting will be, the more difficult it will be for the coloring matter to adhere to it. In this regard, it is better not to postpone painting the panels inside the house for a long time.

All these features require special attention when choosing the paint to be used. Therefore, different options will be described below, their features and properties obtained as a result.

The longer the panel is used without treatment, the more difficult the painting will be.

The longer the panel is used without treatment, the more difficult the painting will be.

Successful examples and options

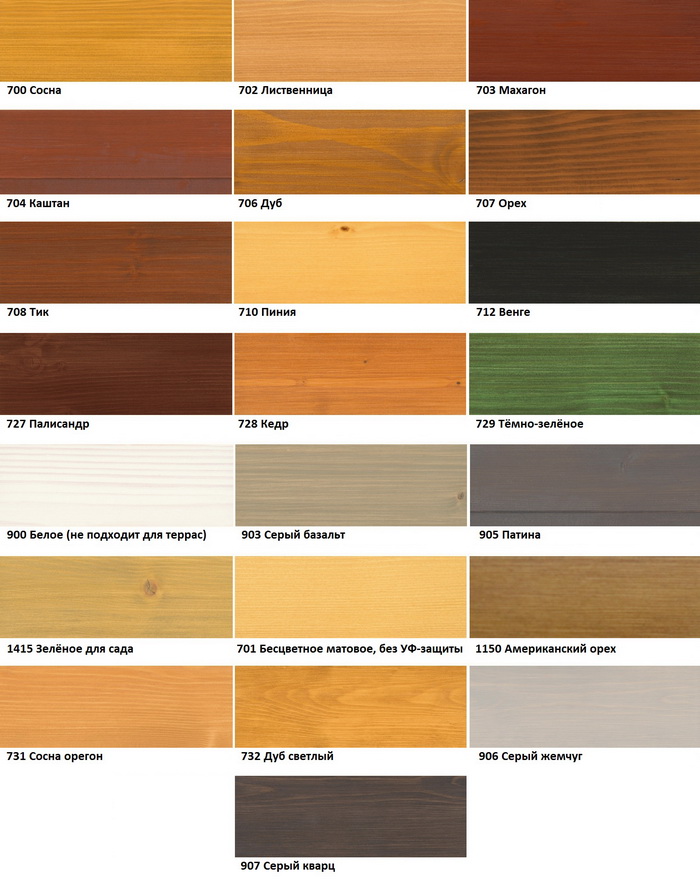

Consider several good options for coloring wood with different compositions.

For the terrace, you need to select the paint individually, taking into account all the features of a particular wood species as accurately as possible. There is no doubt that open areas of wood need to be painted darker so that street dirt and dust have less negative impact. Moreover, for an interior board, such a requirement is not always made, but only for design reasons.

Antique staining does not always mean using a patina effect, but darker and more saturated tones should be used in it. The picture clearly shows how they replace the original light wood background.

You can choose from reds, lilacs, yellows or greens - they all look equally attractive.

You will see the wood painting technology in the next video.

Colorful palette: what to choose?

In this video, they will tell you what types of paints are best for painting a wooden floor.

We watch and remember!

When painting floors made of wood, choosing the right paint is crucial.

The modern industry of finishing and building materials offers a fairly wide range of various paints and varnishes for the design of floors of different types.

However, when choosing a paint specifically for a plank floor, you should consider:

- the type of wood to be painted;

- functional features of the operated premises (conditions, terms of use, humidity, etc.);

- the possibility of preliminary and repeated treatment of the floor covering;

- compatibility of paint / varnish with the previous flooring.

Before buying the material you like, you need to find out its individual properties and characteristics.

Today, all types of varnishes and paints are conventionally divided into transparent (their containing substances are capable of exhibiting the natural structure of wood) and colored opaque ones that have organic solvents (acrylic, alkyds, oil).

So what are the most popular paints for painting floor coverings?

It should be noted that only special profile dyeing materials are used for wooden floors.

Let's take a look at some of the types of wood floor paints.

Dispersion acrylic paint

For several years in a row, it occupies a leading position among other paints and varnishes.

The versatility of acrylic paints is proven by their versatility in the treatment of external and internal surfaces.

The set of multiple advantages of these paints includes:

- vapor tightness and protection of the floor surface from atmospheric moisture;

- color fastness;

- wide color palette;

- strength (service life up to 10 years);

- ease of handling.

Oil base

This is the most common type of paint material, which was extremely popular a few years ago, primarily because of its budget.

This type of product has deep saturated colors, sufficient resistance to temperature fluctuations and a homogeneous structure, which made it so popular.

However, it dries for a long time and over time it can radically change its appearance.

Cracks and peeling may appear on the surface.

Wear-resistant paint

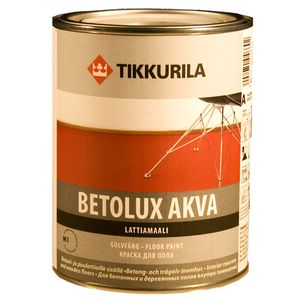

Tikkurila - wood floor paint.

It should, by definition, be the best option for wood floors.

However, she, like others, has its advantages and disadvantages.

Its advantages:

- wear resistance;

- hygroscopicity;

- ease of application;

- resistance to flaking and fading;

- fast drying.

A striking representative of such paints on the market of paints and varnishes today is the water-dispersion acrylate paint "Tikkurila", which is suitable exclusively for washable surfaces, having good elasticity, durability, and protection against mold and mildew.

Easy to apply "Tikkurila" dries quickly, keeping its original appearance for a long time.

In addition, this paint option is quite economical.

The only drawback that can greatly influence the choice is the presence of a very strong specific odor during staining, which disappears only after a few days or weeks.

By the way, this product is prone to flammability.

Rubber compound

A real breakthrough in the construction industry was the appearance of this type of paint.

Despite her "youth", she also managed to gain wide popularity.

And this is fully justified.

After all, the versatility of paint is proven by its extraordinary properties and a wide range of applications.

These paints are water-based, completely environmentally friendly and safe for human health.

The main advantages of rubber paints:

- superelasticity;

- high strength;

- atmospheric stability;

- lack of smell;

- water resistance;

- cleanliness and environmental friendliness;

- low consumption;

- affordable price.

Today's paint market offers a very wide range of products for painting wooden floor surfaces.

But taking into account the specifics of the purpose of the floor, it is better to make a choice in favor of natural environmentally friendly products, such as dispersion acrylic or rubber paints.

Types of paints, classification

The door material plays an important role in the choice of coating. As a rule, they are made of metal - entrance, and from wood - interior. The difference is significant - for iron models, an anti-corrosion component is always added. The classification of paints is as follows:

- Covering and glazing. The former have pigment - it is difficult to choose the color of the doors due to the variety, the latter are distinguished by the complete or partial absence of shades.

- Interior and facade. The first are intended only for interior work, the second, for exterior.

- Protective. In addition to the usual functions, they prevent the negative impact of the environment on the door material - metal or wood.

Colors of paints

Each composition to one degree or another contains the components of others. For example, facade glaze is used on the surface of both wooden entrance and interior doors, has a protective antibacterial composition, has any shade - the color of a nut, for example.

Types of paints for steel doors

Compositions are divided into basic types that serve as bases for coating options. In detail:

- Nitroenamel or nitro paint. Cheap coverage. It is used only for entrance doors and in the absence of people in the dwelling for several days. It's all about volatile, harmful components and a pungent odor. There are more disadvantages than advantages: heterogeneity, susceptibility to aggressive influences - moisture and shock. Quick-drying enamel - one layer per day.

- Acrylic. It is created on a water basis, and therefore this paint for interior doors is odorless. They are successfully used in painting doors made of any material. It has a soft consistency, but at the same time it is one of the strongest, since it has high adhesion - adhesion to the surface. Application in several layers will allow the metal sheet to look dignified.

- Hammer paint. The name was given due to the result of surface treatment - forging or hammering. The trade name is Hamrayt.In addition to metal, it is used on other surfaces. Possesses frost resistance, resistance to mechanical shock, and moisture. Used on surfaces with imperfections - uneven welds, poor machining or cutting.

- Powder paint. The decorative appearance of the door leaf is impeccable. It is used in the manufacture of metal doors, applied in 1–2 layers and the owners will not have to worry about the condition of the surface in the future - durability is guaranteed. The disadvantage of the composition is the high price, which ceases to be a disadvantage, due to its resistance to any kind of impact.

Types of paints for steel doors

The first three options are also successfully used on wooden surfaces, if the paints are marked as interior. There is no need for an expensive fourth type to cover interior doors.

Types of paints for wooden interior doors

Models are solid massive canvases or MDF. Both those and others need painting if the appearance is already unattractive. But in the massif this fact occurs much less often than in chipboard, therefore it is emphasized by all kinds of compositions that do not have a color scheme - varnishes, glaze glazes. More details:

Water-based. Colored or white enamel, inexpensive, environmentally friendly. It is applied to the surface, under the future layer of varnish, since the composition does not have strength and with great activity - opening and closing - it will exfoliate. If the humidity in the apartment or house is high, then this defect cannot be avoided.

This is important for wood structures and rooms where the humidity is constant - kitchens, baths, bathrooms. Glazing

This is a paint for doors under a tree or completely transparent. Gives the canvases a finished decorative look, emphasizing the natural beauty of the material. Unlike varnish, the composition is not transparent, which is why it received the characteristics of a glaze. The components allow you to smoothly make the transition to shades, linger on the natural pattern. Perfect on all surfaces - dull, smooth or textured. Lucky. Inside the apartment, only water-based formulations are used - nitrolacquer will not work.

Painted wooden doors

The main stages of preparing a wooden structure for painting

The technology of painting a wooden house outside includes several stages. If you want the paint to lay down smoothly and beautifully, so that the coating turns out to be of high quality and durable, you must strictly adhere to the technology and consistently carry out all the preparatory work.

- First, the logs are sanded with a grinder with a coarse abrasive having a grain size of P 60-80. Small cracks, notches and other defects that remain on the wood after sawing are removed from the surface.

- Then the surface is polished. For this work, a fine-grained nozzle P 120 or ordinary sandpaper is suitable, with the help of which the wood is brought to smoothness. As a result, the surface becomes even and completely ready for further processing. After sanding, the wood absorbs impregnations and paints and varnishes better.

- With the help of a building hair dryer, the walls of the house are cleaned of wood dust formed during the sanding process.

- If there are resin stains on the wood, remove them with a solvent.

- In the presence of small cracks and knots that were not eliminated during grinding, these places are putty with a special putty on wood.

- All metal parts (screws, nail heads) are coated with a special metal primer.

- Further, the surface is treated with an antiseptic primer on a water or oil basis to protect the wood from the adverse effects of atmospheric and biological factors. After the primer has completely dried, start painting the house.