Dried flowers in epoxy resin

To make the earrings beautiful, you need to purchase high-quality epoxy resin, forget-me-nots, heather, flowering forest herbs. You will also need to make a hook.

The instructions for making such a decoration are as follows:

- We prepare the epoxy resin strictly according to the instructions, leave it for 2 - 3 hours so that it becomes viscous.

- We take a sheet of paper and draw stencils on it with a pencil or pen. They can be of any geometric shape or irregular.

- Preparing a horizontal surface. It should be perfectly flat and clean. It is worth covering it with oilcloth.

- We put stencils on the oilcloth and cover them with ordinary paper files. The resin is poured onto the file, spread over the stencil with a thin stick or toothpick. The resin layer should be 2 - 3 cm. On top we lay out the dome in the form of a lid.

- The workpieces are hardened for two days. After that, the file is removed, and the product is given the desired shape using a nail file.

- We make another batch of epoxy. A point viscous mass is laid out on the finished base and dried flowers are placed there. The whole is covered with a lid and left to dry. To add bulk, apply another layer of resin.

- Use a nail file to make the final shape. You can also use sandpaper for these purposes.

- We take a needle and make a hole. We insert there fasteners for earrings. The decoration can be worn.

How to tint epoxy at home

DIY repair material resin

Varieties of dyes

Of course, it is more convenient to use special pigments designed for coloring this material, they are sold at retail outlets where goods for needlework are sold, for painting, usually resin dyes are acrylic. Tinting is divided into the following types:

- One specific color, it is easy to find popular colors (white, brown, red, blue, black, turquoise, green, and others);

- Fluorescent, special elements included in the composition allow colored objects to glow. Color and colorless options are presented;

- Shade-matte, from which the product acquires a matte finish, making it more elegant;

- Metallic, gives the product an iridescent finish;

- With sequins, it will give a nice shine to things.

The amount of paint applied allows you to give the product a different look. So, using one dye, but introducing a different amount, they get completely different objects. If you tint the object with a drop of the product, then the painting will turn out to be translucent. By increasing the amount, you will get a brighter effect. If there is a desire to completely remove transparency, and get a rich color, then pre-paint the surface with white paint.

The amount of paint applied allows you to give the product a different look.

In addition to ready-made solutions, natural and improvised components can be used for painting epoxy. For this purpose, the following are suitable:

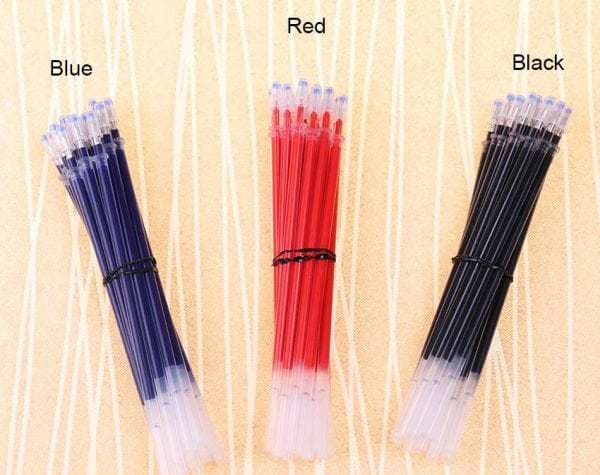

- Gel pen ink;

- Regular pen ink will also work;

- Ordinary oil and stained glass paints used for painting. Stain, nitro paint, alkyd paint (they are added before the hardener);

- Ink used to dye polymer clay;

- Printer toner, activated carbon, they will replace the black pigment;

- Talcum powder, chalk (it needs to be crushed), tooth powder;

- Brilliant green solution;

- Cosmetic shadows are also suitable, but stirring must be carried out carefully;

- Colored powder.

In addition to ready-made solutions, natural and improvised components can be used for painting epoxy.

Specifications

The production of dyes and pigments is a complex technological process. As a result, paints have some technical characteristics. Craftsmen, as a rule, rarely delve into the intricacies of production, however, some parameters should be considered when buying that or another brand color scheme.

The list of characteristics cannot be called universal, since each manufacturer specifies its own list of parameters. You can list what exactly the buyer will find on the packaging or in the instructions.

- Material. Dyes do not have a strictly defined chemical formula. In fact, it can be a wide variety of substances. The main thing is that they do not react with the main composition of the epoxy resin. For example, there are dyes based on propylene. Pigment powders are made from mica, and some ready-made additives are already made in the form of component "A" epoxy resin.

- Type of. Everything is very simple here: paint is presented in the form of liquid, paste or powder. The buyer must determine for himself which consistency is more convenient for him to work with. The fact is that professional artists “play” with shades. Naturally, this is achieved by dispensing paint. But if, for example, the addition of powder does not affect the curing process in any way, then when the liquid component is added, the proportion will be violated and additional adjustment will be required.

- Colour. In principle, the customer can visually assess the shade, however, after mixing the dye with the resin, the result may change. Many skeptics argue that the hue will change, but not the color itself. But it is enough to recall a number of cases when black paint was bought, but in reality it turned out to be dark blue or brown. Modern manufacturers provide a huge selection of colors, and each of them can be combined with a phosphor.

- Weight / Volume / Dimensions. All these parameters indicate the amount of dye in the package. Before going to the store, the buyer must calculate how much material will be required to implement his plan. Then he buys resin, hardener and colorant in such quantities as to minimize costs.

- The effect. The manufacturer often indicates additional color properties. Examples include whitening, pearl, ultraviolet glow, dark glow, and finally no effect.

How to make jewelry resin

To prepare jewelry resin, two components are needed - the epoxy resin itself and the hardener, without which it will not work to use the epoxy for its intended purpose. To create a "working" composition and decorations you will need:

- gloves to protect the skin of the hands, respirator;

- mixing tools;

- molds for pouring resin (there are special silicone molds for needlework and creativity);

- decorative elements - colored additives, glitters, various accessories.

Operating procedure

Work with jewelry epoxy should be in a ventilated area, without sources of open fire, in personal protective equipment - in a respirator and gloves.

Read the instructions. In order for the resin to have the desired consistency, you need to accurately measure the portions of the components. If the proportions are violated, then the resin can turn out to be brittle, sticky, chemically unstable.

Prepare the molds. If you use special silicone ones, then you do not need to prepare them: finished products made of hardened jewelry resin can be easily removed from silicone molds. Molds made of other materials should be lubricated with liquid of colorless helium candles or petroleum jelly.

Mix the measured portions until smooth. It is necessary to stir for a relatively long time - 10 minutes, until the moment when the raw material becomes homogeneous and more viscous. If bubbles form, remove them. If you want to add color to the resin, add dyes at this stage.

The resin is molded and left to cure

It is important to protect it from dust, since the surface of the solidifying mass is sticky and any speck can easily spoil it. The molds must stand exactly on perfectly horizontal surfaces, otherwise the composition will harden unevenly.

If using a cold curing epoxy, leave the molds for a day, covering from dust

If you are working with a hot mix, bake the prepared mass according to the manufacturer's instructions. Typically, a hot-curing composition requires 20-25 minutes of baking at a temperature of 110-130 ° C.

When the mass is completely solidified, the product is ready. At this stage, it can be sanded, trimmed, polished and otherwise processed.

At what stage should the product be shaped?

From the moment of mixing the components to hardening, the jewelry resin goes through several stages.

- At first it is liquid, at this time it is convenient to pour it into relief forms: the liquid composition will fill all the patterned parts.

- Then it becomes viscous and convenient for pouring into non-embossed forms.

- Further, the composition becomes viscous, like honey, at this stage the resin can be used for gluing.

- The epoxy becomes even thicker, its surface is sticky and unsuitable for processing.

- The stickiness disappears and the resin becomes elastic and pliable. The mass is easily formed, its consistency is similar to rubber. At this stage, it is convenient to mold it, but additional fixation is needed, otherwise the mass will take its original shape.

- The epoxy continues to harden and eventually hardens completely. The finished product is durable, almost unbreakable.

Distinctive features

This material contains resin (epoxy) and a specialized hardener. Additional components are pigment, plasticizer and siliceous filler.

Also, the features of epoxy grout are:

- waterproofness;

- stable even shade;

- resistance to dirt and dust, resistance to alkali or acid;

- long period of operation (more than 50 years);

- use in facing with ceramic, marble, porcelain stoneware and stone tiles;

- can be used for car wash, garage, swimming pool, workshop, laboratory;

- becomes an alternative to tile adhesive.

The need for application

The epoxy itself is crystal clear. This allows you to give it the most original colors, create a spectacular shine and achieve color transitions.

For products used outdoors, this issue is especially relevant. The problem is that ultraviolet rays have a destructive effect on this material. A characteristic sign of a violation of bonds within the epoxy is its turbidity. The application of LCI allows you to postpone this process for a long time.

The coating must be regularly renewed, the frequency of treatment is calculated taking into account the time spent in the sun, the intensity of the action of sunlight and the characteristics of the enamel used.

In some situations, a more practical solution would be to give the necessary shade even at the stage of manufacturing the elements. This practice is effective if the materials are used inside the dwelling, when the negative effects of the sun's rays are completely neutralized.

Protective coating

Despite all its advantages, epoxy also has disadvantages. For example, if products made from this material are used outdoors, they must be covered with paint or varnish. The fact is that ultraviolet light is capable of having a destructive effect on the material. A clear sign of the destruction of bonds within the epoxy resin is its cloudiness. Painting can delay this process.

Coating should be renewed regularly to maximize product life.To understand how often a new coat should be applied, it is necessary to take into account the intensity of exposure to sunlight, the time spent under UV light and the type of paint used (its characteristics).

The choice of paint and varnish material

Having learned how to paint epoxy resin, it will not be difficult to choose the best option among the huge assortment of paintwork materials in the store. If the resin hardening process is not completed, chemical adhesion can occur, that is, the substances "mix" with each other after application, but this process has a downside. The fact is that sometimes the amines in the epoxy resin bind to the constituents of the paints, as a result of which the protective coating does not dry out. Sometimes the outside of the paint may be dry, but the inside does not dry out for a long time.

When choosing paintwork materials for painting epoxy resin, the following paints should be preferred:

- two-component polyurethane;

- two-component epoxy;

- alkyd enamels (oil paints).

One-component polyurethane and epoxy paints may not dry out and are therefore not suitable for overpainting. When choosing, it is worth considering the following:

- Epoxy paints are not UV resistant and should not be used outdoors.

- Polyurethane paints are difficult to apply. The fact is that they form a glossy surface, on which the slightest flaws are clearly visible. Although if you work hard and apply a high-quality coating, it will last a long time. Polyurethane paint is UV resistant, has good resistance to moisture and other external factors. Differs in excellent wear resistance. The disadvantages include the high price.

- Alkyd enamels are not picky to apply. You can use a roller, brush or spray. The coating easily hides small imperfections. Alkyd enamel is inexpensive, but it can dry for a very long time.

- If UV protection is required, colored paints should be chosen over transparent paints.

Dyeing technology

In general, epoxy should be painted like any smooth surface. You must first prepare the surface and then start painting. If the epoxy is completely dry, chemical adhesion of the coatings will not occur.

It is important to place emphasis on good mechanical adhesion. For this, the surface is roughened.

To do this, it is treated with fine sandpaper.

If there is an old coating on the epoxy, it must be completely removed. This can be done in two ways - mechanical or chemical. In the second case, washes or solvents are used.

It is important to know that not all types of solvents sold in stores are suitable for working with epoxy. If the composition contains methylene chloride, it is categorically impossible to use a solvent or remover.

The substance is capable of corroding epoxy resin.

To ensure good adhesion of the protective coating to the substrate, an epoxy primer is often used. It adheres well to epoxy resin, but at the same time serves as an excellent base for alkyd enamel or polyurethane paint. If you follow these simple rules, you can apply a high-quality and decorative coating on epoxy so that it can last for a long time.

The application of paintwork materials depends on the type, although the usual painting tools are used - brushes, rollers or a spray gun. The method of application is selected depending on the area and surface characteristics (smooth, embossed, etc.).

How to paint epoxy resin - step by step instructions

Before starting work, you need to acquire the following components:

- gloves;

- syringe;

- dyes;

- epoxy resin;

- silicone mold;

- wooden mixing sticks;

- plastic cup.

Necessary actions:

- We take a syringe and measure out the required amount of epoxy resin into a glass.The most convenient is a syringe for 5 cubes, but you can use it for 2 cubes, only you will have to type several times, and this is not very convenient.

- We add the catalyst in the required proportion.

- Mix the components well until a homogeneous transparent substance is formed.

- We put the container in a water bath to get rid of air bubbles.

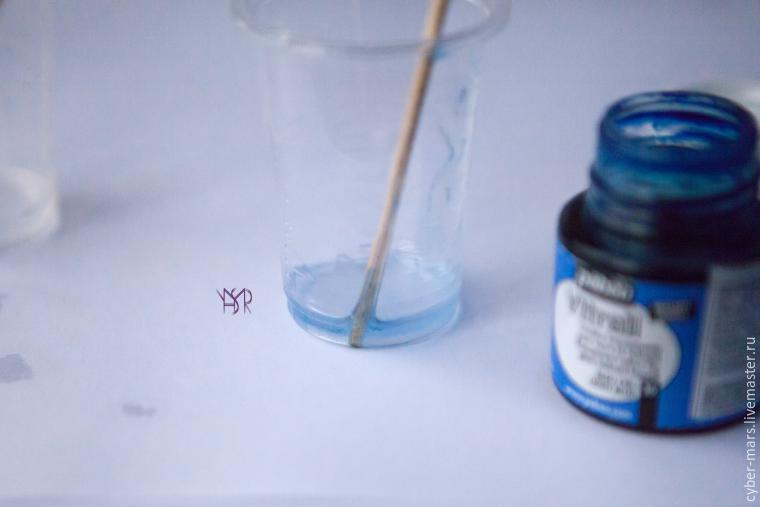

- When the bubbles are gone, you need to take the stained glass paint and add a couple or three drops to the glass.

- Mix everything well. It is worth noting that a dense color will not be achieved during the mixing process. The mass will remain translucent. But don't use a lot of paint. Maximum 5 drops.

- The paint mixes well with epoxy resin, so this procedure will not take much effort and time.

- Instead of stained glass paint, you can add oil paint to the composition. But its volume should be minimal, literally at the tip of the match. This paint gives a strong color, so do not overdo it. The saturated color directly depends on the amount of oil dye.

- The main thing is that mixing is thorough, in order to avoid clots. Generally, paints mix very well with resin.

- The effect of oil paint is more significant than that of stained glass, but still the substance remains translucent.

- After the resin is poured into a mold prepared in advance.

- The mold is placed in a dry place and covered with a kind of dome to prevent dust from entering.

- The epoxy resin hardens within two days.

Left - resin with stained glass paint, right - with oil

Specialized paints

If you do not want to spoil the material, do not use homemade paints, give preference to professional ones. With them you will achieve what you want.

result, get the color you want. Pigments can be purchased at specialty stores that sell art supplies. Epoxy dyes are:

-

monochromatic. You can buy almost any shade: blue, yellow, black, red, white and green;

-

fluorescent. The special components included in the composition make the product glow in the dark after dyeing. Such pigments can be colored or colorless;

-

matte. Will make the finished product matte, with them you can create unique decorations;

-

pearlescent. The dyed decoration will shimmer;

-

dyes with glitters.

Using different amounts of dye, you can create completely different shades. You can tint the resin with a small amount of paint; in the end, the finished product will turn out to be translucent. You can make the color more saturated by adding a lot of pigment.

How to tint the product, what dyes to choose for epoxy?

While working with the material, many people ask themselves this question. The best option is to buy the product from the same brand as the resin you have chosen to work with. The pastes of the Poly Max Dream and MG-Epox-Color companies have proven themselves well. They are available in packs of 5-10 grams.

The consumption of such dyes is minimal - to obtain a translucent product, add only 0.01-0.05% of the total mass to it for epoxy resin. A more saturated shade is achieved by adding pigment up to 5% of the total mass.

Staining technique rules

For a successful tinting, strictly follow the manufacturer's recommendations. By following the following rules for working with dyes, you will achieve the desired result:

-

the percentage of oil, alkyd dyes for epoxy resin in the total mass must be at least 10;

-

other components are added to the material no more than 7%;

-

epoxy materials do not tolerate water well; do not use water-based dyes;

-

work with this substance is carried out at a temperature not lower than 22-23 degrees. This temperature is the most optimal for curing the resin.

The manufacturer adds solvents to some resins, so the room should be well ventilated during work.

— When tinting resin, strictly follow safety precautions. Use disposable utensils to guide material and wear rubber gloves on your hands. You can protect the respiratory tract with a respirator. If substance comes into contact with skin, wash with plenty of soap.

To stain epoxy, you will need a disposable spoon, a plastic cup, medical syringes, pouring molds, and dyes. At the first stage of work, a hardener must be added to the epoxy. Usually this substance comes with a resin. The material is kneaded in small proportions, large volumes are very hot, and this threatens to completely deteriorate the resin. After that, the finished substance is poured into special containers, their quantity is determined by how many shades you need.

Colors for epoxy resin are introduced into the finished substance; they can be matte, fluorescent or with the addition of sparkles. Stir with a spoon until a homogeneous mass is obtained. After that, leave the mixture alone for 15 minutes so that air bubbles come out of it. When the substance is ready, pour it into the mold and leave it to solidify. Epoxy colorants should be mixed in a clear jar so you can control the amount of pigment.

Many people have a question, what can replace the dye for epoxy resin? Any home remedies that do not contain water are suitable for this: gel pen ink, stained glass paints, brilliant green, printer ink, talc, etc. But, only professional colors for epoxy resins can achieve a unique result, create an original product or decoration.

Safety rules when working with epoxy resin

In their work, designers use a specialized epoxy - jewelry (or decorative). Unlike structural resin used in industry, this resin is non-toxic. But it becomes completely safe only after the end of the polymerization process. During operation, the resinous substance emits harmful vapors.

Be sure to use personal protective equipment when working with epoxies: gloves, a respirator mask and goggles. Keep work clothes with long sleeves. In case of contact with the skin, the substance should be immediately removed with a cotton pad soaked in alcohol, and then this place should be rinsed with plenty of soapy water.

Separate requirements are also imposed on the premises in which the work is carried out. The room must have access to good ventilation. And when mixing, coloring and pouring resin, adhere to the set temperature regime of + 22-25⁰С. Only if all the recommendations are followed, the coloring of the resinous substance will turn out perfectly.

Main characteristics

When choosing permanent paints for external resin coating, preference should be given to two-component epoxy and two-component polyurethane compounds. The use of alkyd enamels (oil paints) is also allowed.

When choosing, you should also take into account the following factors

- Alkyd and epoxy paints are characterized by extremely low resistance to ultraviolet radiation, so they should not be used for outdoor work, as well as for painting surfaces that are planned to be used outdoors.

- Higher quality polyurethane paints. However, they are laborious to apply - the coating forms a glossy coating, any, even the slightest flaws will be noticeable on it. Nevertheless, polyurethane enamel is wear-resistant, resistant to UV radiation, and retains its performance characteristics under the influence of moisture and other external factors. Of the shortcomings, only the high cost can be distinguished.

- Alkyd enamels are cheap, they are picky to apply, they can be painted with epoxy with a brush, as well as with a roller or spray. This coating easily hides minor defects, but the enamel dries for a long time.

Before starting work, be sure to do a little test. To do this, paint must be applied to a small fragment in an inconspicuous place and see what the result is. To make sure that the coating is dry not only outside, but also inside, you can try to pry it off with your fingernail.

When making items used indoors, it is better to give preference to special dyes. They are added to the resin prior to starting work.

Coloring can be monochromatic, with glitter, mother-of-pearl or luminescent. If you introduce a drop of dye into epoxy resin, you get a beautiful translucent sheen. For a more intense color scheme, you must first paint the resin white, and only then re-tint with colored paint.

What dyes are used for

Color for epoxy is a special tool that helps to obtain the desired shades. The epoxy itself is usually distinguished by its transparency. But when they decide to use it as a jewelry resin, then most often it requires touching up. After all, its use for jewelry or other types of products involves bright colors.

In the creative process, the resin can be partially painted, then the effect of transitions into different colors is created, overflows are created. There are many options for using dyes for resin, they are limited only by imagination.

It became clear why this material should be painted, but it is not yet clear how to paint the epoxy. This will be discussed in detail in the next chapter.

In the creative process, the resin can be partially painted, then the effect of transitions into different colors is created, overflows are created.

What is epoxy resin

It looks like a transparent liquid, which contains resin and hardener. Once these two components are mixed, the composition gradually hardens and forms a transparent plastic.

Epoxy resin cannot be classified as environmentally friendly, but modern technologies can minimize the risk of negative effects on human health. For this, the maximum cleaning method is applied. Despite the almost complete absence of odor, in comparison with construction analogues, jewelry epoxy resin still has negative properties.

Epoxy resin tables

Precautions when working with this substance must be observed in any case. The construction of crafts should take place in a well-ventilated area.

Do not forget about gloves and try to prevent this substance from getting on the cornea of the eyes. This can lead to serious negative consequences.

Resin tinting rules and techniques

When painting epoxy resin with special compounds, it is necessary to be guided by a number of rules. First of all, strictly follow the recommendations of the color manufacturer. In addition to them, or if you are using a homemade composition, be guided by the following information:

- Oil-based or alkyd-based dyes (for example, corresponding paints) should make up no more than 10% of the total mass of the color composition produced. Colors with a different composition are added in an amount of not more than 7%.

- Do not use water-based dyes, as the resin loses its polymer properties even when exposed to moisture vapor

- Mixing is carried out at a temperature of 22-23 degrees. Under such conditions, the process of coloring and hardening of the composition goes well.

If you are going to paint the resin for the first time with a specific type of dye or a new color, it is recommended to make a trial batch in a small amount to evaluate the result.This will help minimize errors.

For tinting epoxy resin it is necessary to prepare:

- Disposable dishes: spoons or wooden sticks, a transparent cup, a medical syringe for 5 ml or more

- Form for pouring

- Rubber gloves and a respirator for personal safety. It is also recommended to work in a well-ventilated area, as some solvents and paints can be toxic to the body.

What to prepare for resin staining

What to prepare for resin staining

The staining process itself boils down to the following steps:

- We measure the required amount of epoxy resin with a syringe and pour it into a glass

- Add the reagent in the appropriate proportion and mix. The ratio of resin to reagent is specified in the manufacturer's instructions.

- A glass with the composition is placed in a water bath to free it from air bubbles

- The selected colorant is added to the prepared resin in small portions. If it is a liquid composition, then with drops from a pipette, if it is pasty and viscous, then on the tip of a wooden stick, a small amount of powder from a spoon.

- Pour into pre-prepared forms or blanks. It is worth noting that there are many options for making target products using not only molds. For example, jewelry made from dried flowers is very interesting:

- The product is covered with a protective dome against moisture and dust and left to harden for 2 days.

Video: tinting epoxy resin

Thus, there are many options for how to paint with epoxy. The use of ready-made dyes is the most convenient and fastest way of dyeing. On the other hand, using improvised dyes is an economical and creative process. Choose what inspires you and make the most unique and unsurpassed products from this polymer.

How to choose the right proportions

It should be noted that there is a pigment and tinting paste. They create different coloration. Tinting, only changes color, and the pigment paste has the property of hiding power. You need to take this into account when choosing a tool. Dyes in powder form should be of the finest grinding. When working with them, they must be applied before the hardener.

But all there are several rules that will help in working with improvised coloring options:

- Oil, nitro paints, alkyd paints and varnishes can be added to the resin no more than 10%, otherwise they will make a kind of rubber out of the mixture;

- Other coloring elements can be added in an amount of no more than five to seven percent by weight of the epoxy;

- Do not allow water to get into the resin, it will deteriorate from it.

The proportion of dyes added to the mixture is indicated by the manufacturers on the packaging, so it is preferable to choose special products.

The proportion of dyes added to the mixture is indicated by the manufacturers on the packaging, so it is preferable to choose special products.

Tinting with improvised means

You can paint the epoxy resin in another way. Pigment substances are not always on hand, sometimes the desired color is not in the store. Home remedies come to the rescue

It is important that they do not contain water

You can paint the epoxy with the following means:

gel pen ink in any color - you just need to squeeze a little ink into the resin, the shade will be bright, saturated;

simple pen ink;

ordinary oil or stained glass paints for painting, as well as nitro paint, alkyd paint, stain (it is important to inject the hardener after such means);

inks for painting polymer clay;

ink for the printer, activated carbon (will give a deep black color);

talcum powder, powder, crushed chalk, kaolin, tooth powder (will provide a white color);

pharmacy brilliant green.

Preparation of epoxy glue.

How to prepare epoxy? - To prepare epoxy glue, you first need to find a suitable container in which the glue will be mixed. The container must be stable and not shallow.A plastic PET water bottle cut in the usual way for preparing a mixture in it is not very convenient. The bottom of such a bottle usually has five indentations, which do not allow high-quality stirring of the entire mixture with a small amount of it. It is more convenient to use the neck of a plastic water bottle with a tightly screwed cap. You should also first take care of where this unstable neck will subsequently be placed when stirring the epoxy. Because stirring the epoxy, holding the vessel in your hands, is fraught with spoiled carpets, clothes, etc. In short, before stirring the epoxy, it is necessary to thoroughly prepare, and not to do it "off the beaten track", anyhow and in whatever.

Next, the epoxy mixture must be thoroughly mixed (5-10 minutes) until a homogeneous, consistent mass is formed.

Pour the mass into the cavity and leave it to dry completely.