Determination of color and its application

The color scheme can be used as one color, or combine several pigments at once to obtain a more complex and unique shade. It contains various pigments and additional elements that give greater saturation and color stability, also water and resins are present in the composition. Kohler is added to the paint

to achieve a special color other than a simple color.

The concentration of this color in the tinting agent is higher than that of the desired shade, therefore, at the moment of mixing with paint, the main shade becomes more diluted and begins to be better suited for painting.

The composition may include inorganic and organic substances that affect the quality index of the dyeing material, its brightness and the retention time of the resulting color after dyeing.

Color matching methods

The coloring pigment is needed for mixing with white enamels, plaster, decorative putty. It is used for adding to water-dispersion compositions, alkyd coloring elements.

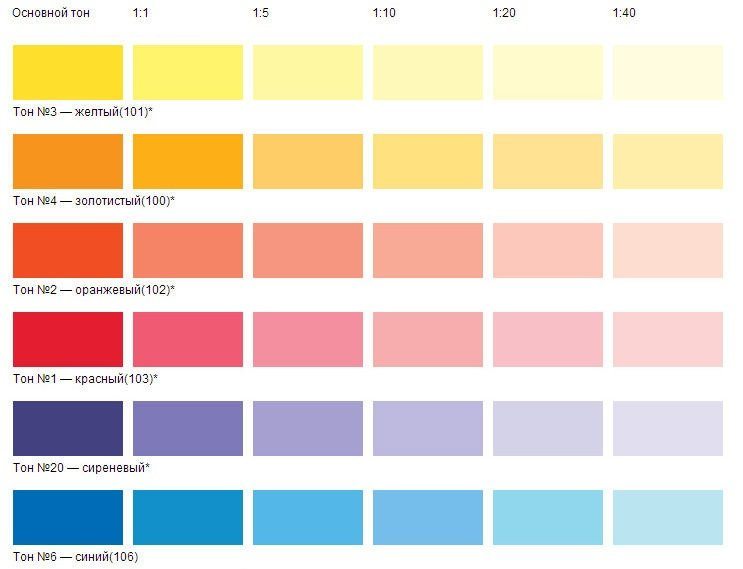

To achieve the desired color, two tables are applied at once:

- RAL - it is designed for 210 tones;

- NCS - Designed for 1950 shades.

These scale charts help you find the right shade quickly and easily.

Manufacturers can use their own methods of color grading, but you need to be sure to know in advance what color you need. The shade is selected by comparing the shade with the general color of the walls

It is necessary to pay attention to the fact that with repeated self-mixing of the tone composition, it is unrealistic to achieve the same effect.

This is due to the impossibility of determining the amount of paint in the container up to a whole gram. Due to the strong saturation of the tinting mixture, the color of the resulting tone can be strongly changed even with a slight deviation from the resulting color.

With manual kneading

it is best to calculate the volume of the coloring matter so that one mixing is completely enough for the entire surface of the part to be painted. In this case, it is imperative to increase the amount of coloring pigment consumption by twenty percent, so that it is exactly enough for painting.

During work, you can use dispensers to add the desired tone to the paint, and to obtain a better finish, you can use drills to thoroughly mix the dye.

The consistencies of colors of paints and varnishes can be divided into the following types:

The coloring paste is divided into two types - facade and universal. The characterization of each colorant will be determined according to the presence of organic and inorganic pigments in the composition.

What you need to know to mix paints correctly.

Not all white paint is suitable for coloring, not all of them can end up with the dark shades you need. You need to look at the binder and the pigment that are in a certain type of paint - they determine whether it can be used for a specified purpose. The pigment and the binder are directly related to each other, and in order for the material that you should end up with the original idea, it is necessary that there is no more pigment than the binder can capture.

When choosing a coloring material, pay attention to how much binders are in the paint. It should be borne in mind that when the paint is tinted, their pigments increase, and this substance may not be enough

Manufacturers are also aware of this - releasing paints with various amounts of this substance.

If you decide to tint the paint by hand, then in a specialized store you need to purchase a color scheme for the paint (select colors to embody the idea of the final finish). And definitely needed - white paint with a suitable composition. At home, it is quite difficult to mix paint colors, but if there is a firm intention to get a unique, complex tone that you cannot find in any store or create on a tinting machine, then this will not stop.

You can get tint colors containing several components of the palette at once. For those who plan to paint a room with two different colors, it is also recommended to use manual tinting. Different shades are precisely matched. If you need to adjust the look of the walls for some significant element of the interior, they also use a similar mixing of paints.

What is paint color

The word "color" is translated from the Latin "color" as a color or tone. In the chemical industry, color is a special highly concentrated pigment composition, with which you can get almost any shade of paint. Moreover, not only water-based, but also facade, oil, acrylic products can act as a basis. Depending on the concentration of such a pigment composition in the paint, you can achieve both rich and bright colors, and muted, pastel shades.

What is it needed for

The use of color schemes helps property owners to translate almost any design ideas into reality. The process of mixing and diluting a paint and varnish material with a pigment is called tinting. Its use is suitable not only for finishing work inside the object, but also outside it. With the help of a special pigment solution, you can get unique shades, for example, you can give the paint a copper, pearlescent, bronze, golden hue.

Kohler can be used on concrete, brick, plastered walls. Compositions with its use can also be processed on other surfaces: plasterboard, wood, fiberboard, chipboard. The use of tinting is necessary in the following cases:

- the initial layer has small defects;

- you need to choose a shade in accordance with the color scheme of the interior;

- it is required to decorate the interior using several shades of one or more colors;

- you need to correct errors that have arisen when calculating the volume of paint or the absence of a color previously used.

Views

- With organic pigments. Products of this type are distinguished by a more saturated range of colors, but the paints and varnishes obtained on its basis lose their brightness and saturation over time due to exposure to sunlight. For this reason, formulations with organic pigments are not considered the best choice for facade paints.

- With inorganic pigments. Such products are more resistant to aggressive external factors, including burnout. True, such a color scheme for paint cannot boast of a wide range of shades.

Tinting rules

You can color the paint manually or by computer. Thanks to the first option, you can save a significant amount of money and perform the procedure directly at the repair site. There is also a drawback: it is almost impossible to reproduce exactly the same tone again. The second type of tinting is controlled by a special program. The operator only needs to choose the color of the color scheme, and the program itself will determine the proportions, after which it will give out the finished composition.

Having decided to dilute the pigment yourself, consider the technique:

- Decide on the required amount of color scheme. It is better to buy more initially than look for identical products later.

- It is recommended to select a color for painting surfaces with the manufacture of a probe. To do this, fill a small container with 100 mg of white paint and add a few drops of pigment to it.Get the desired shade by mixing.

- Check how the resulting composition looks on the wall or other surface to be painted. The color of the finished solution does not always match the shade of the paint and varnish applied to the wall. The result should be considered under the prevailing lighting in the room (artificial or natural), after the composition has dried.

- If you know how many drops you had to add to get the desired color, then by recalculating the consumption of the composition per liter of paint, you can dilute and get the required amount of color.

- You need to add the pigment composition to the paint and varnish material in a thin stream. At the same time, do not forget to mix everything thoroughly to get a concentrated composition with a uniform color.

Machine room

Machine mixing of paint-and-lacquer material is controlled by a computer using a standard form of recipes set in the program. An identical color can be obtained again if necessary.

The pluses of computer tinting are assigned:

- accuracy and speed of the process;

- re-obtaining the desired shade;

- the correct selection of paint when creating a dark shade;

- a wide range of resulting tones.

Minuses:

- impossibility of tinting directly on the construction site itself;

- the impossibility of creating complex shades;

- quite high cost.

For more information on tinting paint, see the next video.

Work order

Manual and computer tinting have a number of distinctive features. And if with the latter it is not necessary to go into details, tk. The service will do everything for you, then the rules and procedure for manual tinting are still worth working out if you don't want to spoil the material and waste valuable time.

DIY paint tinting

For manual tinting:

Prepare large, clean mixing containers.

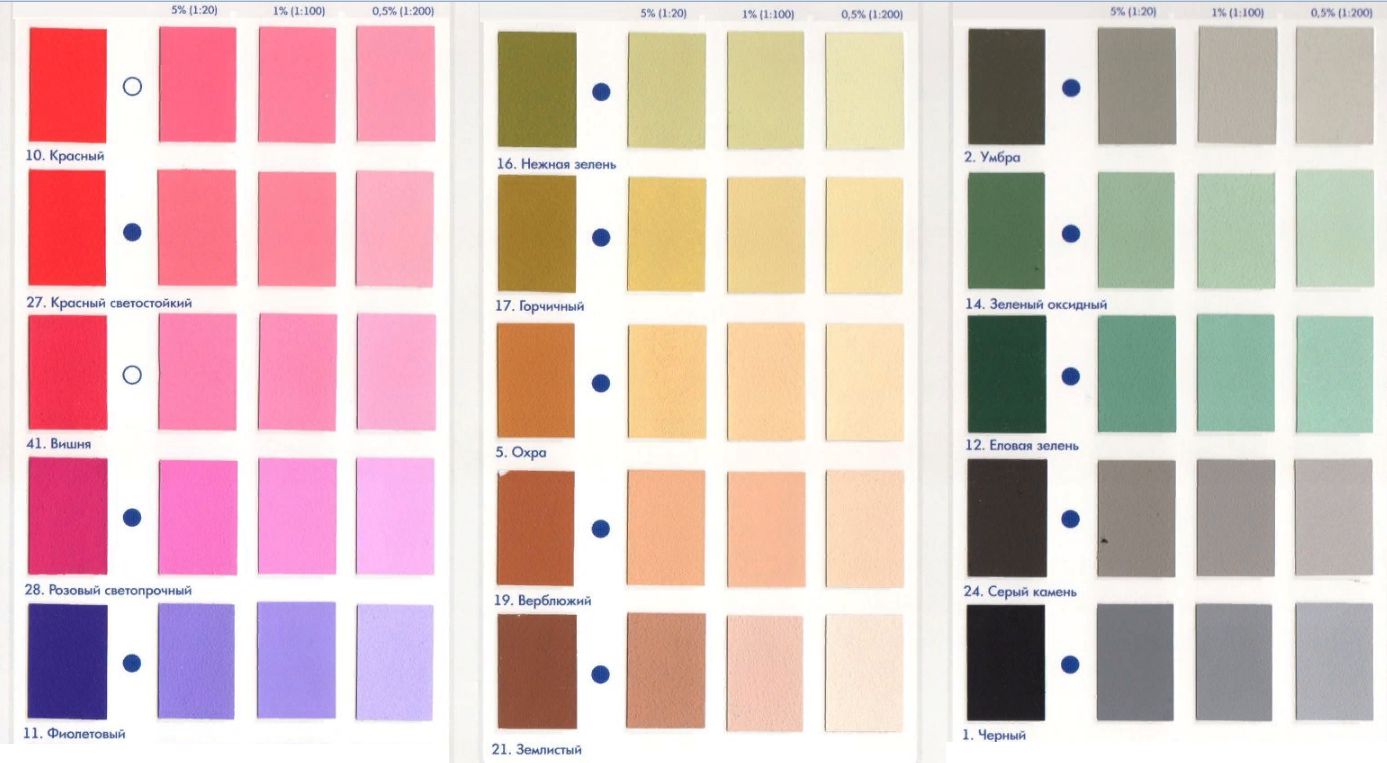

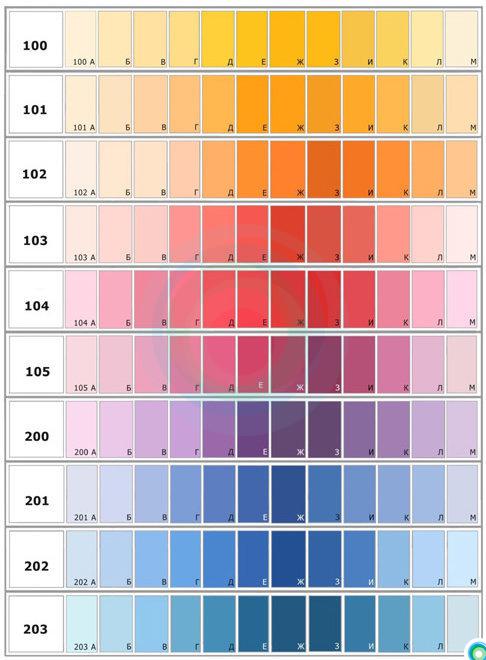

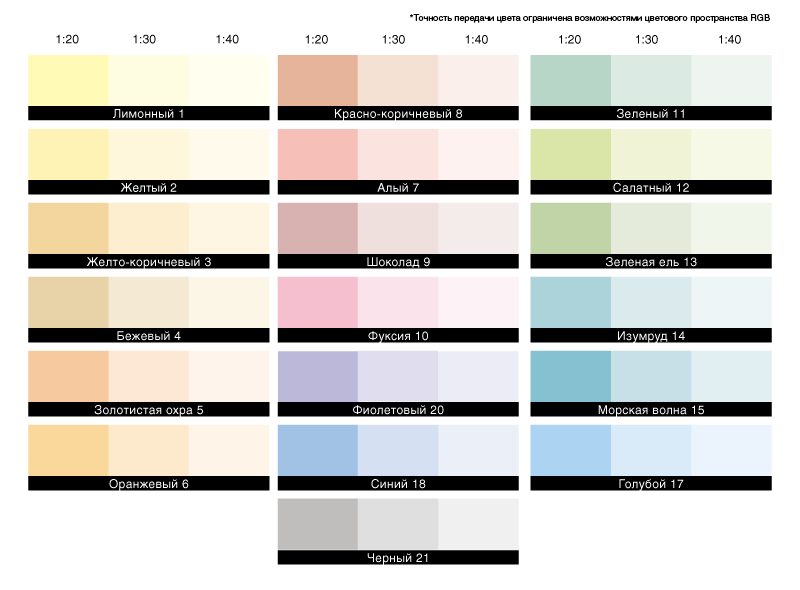

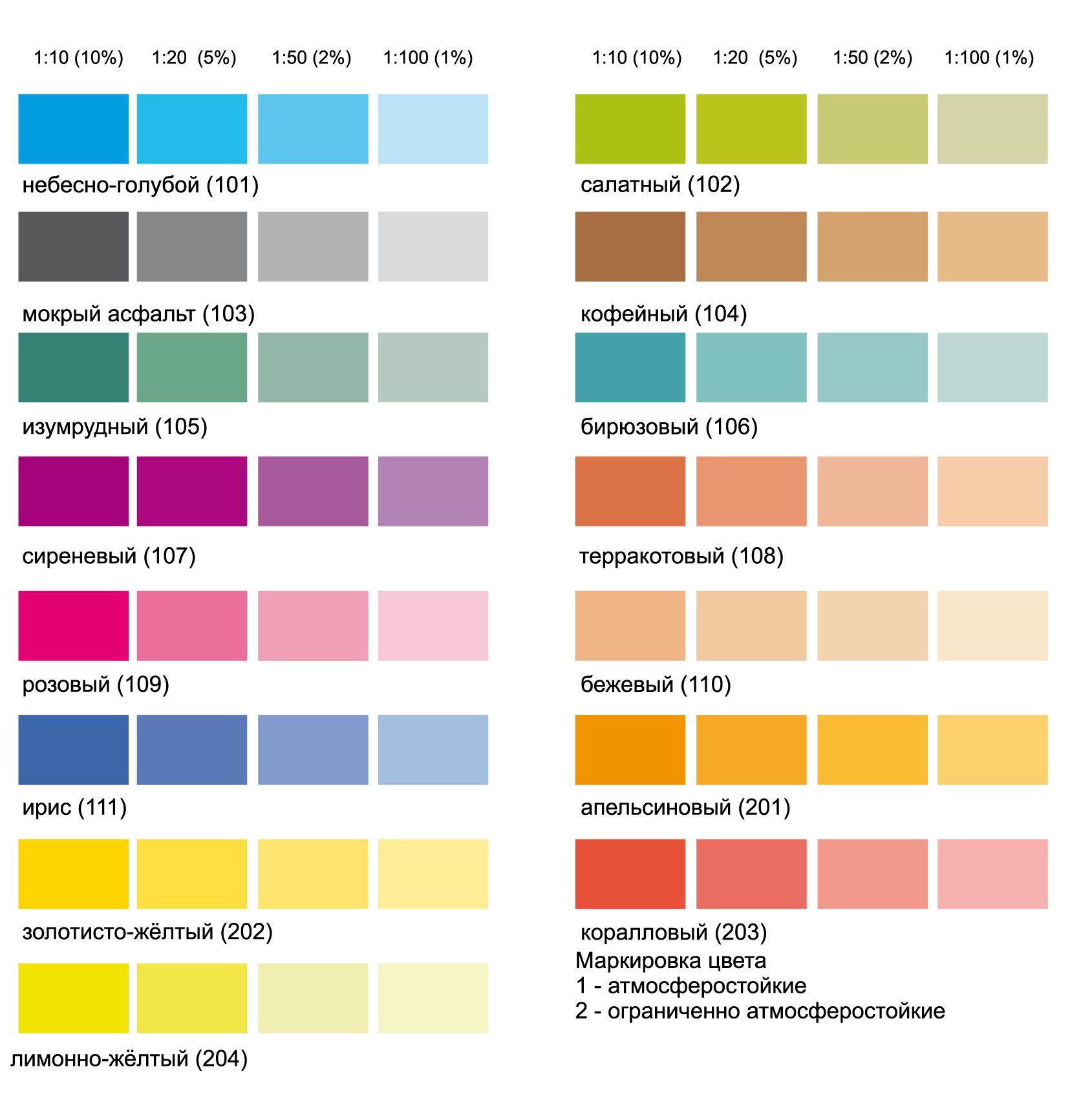

Calculate the required amount of color using a card or color chart (each manufacturer has its own). If desired, you can make your own individual color.

In this case, it is especially important to fix the proportions of the color scheme and the base in order to reproduce a similar tone if necessary.

Place a white base in a bucket and add one or more color components (it is better to take 20% less than the norm and gradually add color). First mix the composition by hand, then take a drill with a zigzag mixer and stir the paint until smooth.

Remember or write down the exact ratio of the ingredients used

It is better to immediately prepare enough material for the entire scope of work. Since it will be impossible to get an identical composition.

Apply paint to part of the surface. Keep in mind that fresh paint looks darker than dry paint. And the color of the coating on a large area is lighter than on a small one. There is also a difference in color perception under natural and electric light.

If you are satisfied with the test result, proceed with painting the rest of the surface.

Video: how to color paint yourself

Computer tinting

With automatic mixing:

- The paint color is selected from the catalog and its number is entered into the calibration machine program.

- The program calculates the component composition of the coating. One or more colors are automatically added to the base paint.

- The material is thoroughly mixed until smooth.

In this way, you can create more than 10 thousand shades. Colors can be added to all types of paints, varnishes, impregnations, enamels, etc. Their properties do not change when colored components are added.

Tinting methods

What is tinting for paint is already clear. But you can do it in different ways. The choice depends on material capabilities and preferences.

Tinting by means of a computer

Computer tinting of paint in tinting machines is considered the most accurate.

Advantages:

- quickness of tone creation;

- maximum accuracy;

- the ability to choose a color scheme for fans of almost all brands;

- simultaneous toning of several cans of paints at once;

- savings for large areas of work;

- automatic selection of base paints for dark tones;

- preservation of recipes and the ability to get new colors in the future.

The disadvantages include only one factor - the impossibility of making tinting directly at the facility.

Manual tinting

Do-it-yourself paint tinting involves manual mixing of components and an independent selection of pigment.

Process features:

Manual mixing is used when you want to create a unique color, consisting of several colors.

It is also used if you need to create a smooth transition of shades in one room.

It is very important to do a trial mixing and apply the resulting color to the surface until completely dry. This is the only way to get a perfectly accurate shade.

This should be done under the same lighting conditions under which the paint will be used.

Remember, artificial lighting can greatly change the shade of yellow and blue paint. The same is true to varying degrees for the rest of the colors. So be prepared for this. In short, cold tones look darker, and warm tones look lighter.

If the walls are painted over a large area, then, unlike a small painted area, the color will also be perceived slightly differently.

The main advantage of manual tinting is the ability to create color directly at the workplace.

The disadvantage is that you have to immediately mix the entire amount of paint required to paint the intended area. Because in the future it will be impossible to create exactly the same shade. In this respect, computer tinting wins.

What equipment is used?

Specialized equipment for tinting is used both with the computer method and with the manual:

- A dispenser is required to deliver the exact amount of pigment to the total mass.

- Mixer in the form of a mixer or shaker. When tinting at home, you can use an electric drill with a special attachment. Thanks to the mixer, it is possible to obtain the most homogeneous mass. Remember that pigment can form filaments and clumps.

- The spectrophotometer is designed to read information even from a small colored sample. Thanks to this device, the computer program selects the color scheme.

Characteristics of PF 115 paint.

The appearance of this paint is matte or glossy. White is the primary color. In addition to the main color, enamel is also produced with other colors (gray, blue, yellow and cream are the most common options).

In general, this paint has a high-profile status - the best domestic development among alkyd paints and varnishes. One of the main technical advantages of enamel is the ability to maintain its quality in all climatic zones.

Enamel paint PF 115 is able to withstand any atmospheric influences, is friendly with strong winds, rain, and also easily tolerates sudden temperature changes from -50 to +60 degrees. Due to its structure, this paint forms an excellent waterproof layer. This allows you to wash the surface with paint with any detergent.

Compositions

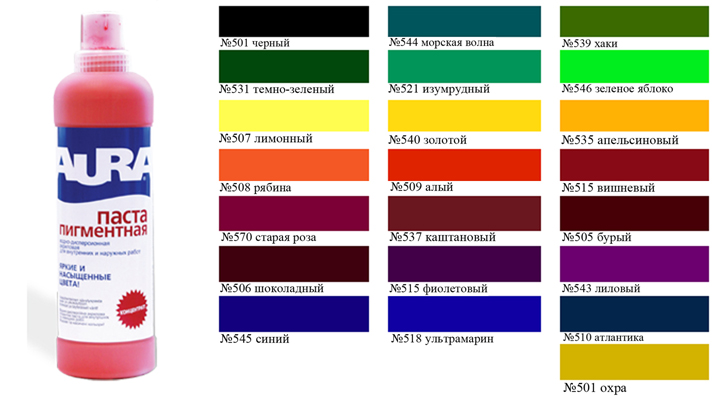

There are several types of tint.

- Paint (this composition must fully correspond to the used paint and varnish material).

- Paste (assumes ease of use, allowing you to adjust the shade when mixing).

- Dry composition (the most affordable, the only drawback is the limited color range).

To create, dilute and get the correct tone for uniform coloring of the plane, you need to take tinting paint. This type of paint is created by mixing basic basic shades with a coloring element - color scheme.

There are 6 basic colors:

- blue;

- green;

- black;

- Red;

- yellow;

- White.

Where are they used?

Most often, colors are used when you need to choose a certain shade, taking into account the entire design of the room, as well as when decorating the interior, when you may need some special color of acrylic paint. But to get it, you just need to add the necessary pigment to the acrylic mixture.

Also, colors may be needed if the shade of paint you need is not on the counter.

Thanks to the correctly chosen colors, you can not only revive the design of the room, but also make cosmetic repairs in a fairly short time.

Before proceeding with the selection of acrylic enamel and the required color scheme, be sure to make all the calculations of the materials.

Paint tinting can be done in two ways:

- Manually;

- Using a computer.

Since everyone works by hand at home, acrylic paints with a color scheme need to be diluted about 10% more than you need. This is done because it can be very difficult, if not impossible, to reproduce the same color.

Coloring paint is best done in one container so that the acrylic mixture with a tint is homogeneous. Otherwise, diluting paint with color scheme in different containers, you risk getting completely different shades.

Also, do not forget about the following important points before tint paint:

Acrylic mixtures, which are intended for interior decoration, are often whiter than all others.

This is an undoubted advantage, since when tinting such paints, the future shade will turn out to be cleaner and more saturated, and also there will not be any stains and impurities in it;

Try to acquire acrylic paints and enamels exclusively for the intended purpose, since their compositions may differ, and this is especially important, since the color will also slightly affect the composition. If in the future you use the paint for other purposes, then it will not serve you for the prescribed period;

Matte colors of color schemes will look more restrained compared to glossy options, which can shimmer and play with shades in a peculiar way.

Despite the fact that both acrylic paints and colors are safe for humans, work with them exclusively with gloves.

In addition, it is important to know that high-quality color products do not have characteristic and unpleasant odors. It will not be difficult to dilute the paint with a color scheme, but the necessary shade must be thought out in advance

Tips for tinting acrylic paint - in the next video.

A wide range of facade paints can be found on the market. Foreign and domestic manufacturers present facade paint for various types of surfaces, different colors and textures.

Some formulations are created specifically for the color scheme. Tinting is required to achieve the desired shade of the dye composition with certain characteristics. To get a unique color that cannot be found in finished form, you need to mix several shades of color and paint at once.

Tinting technology

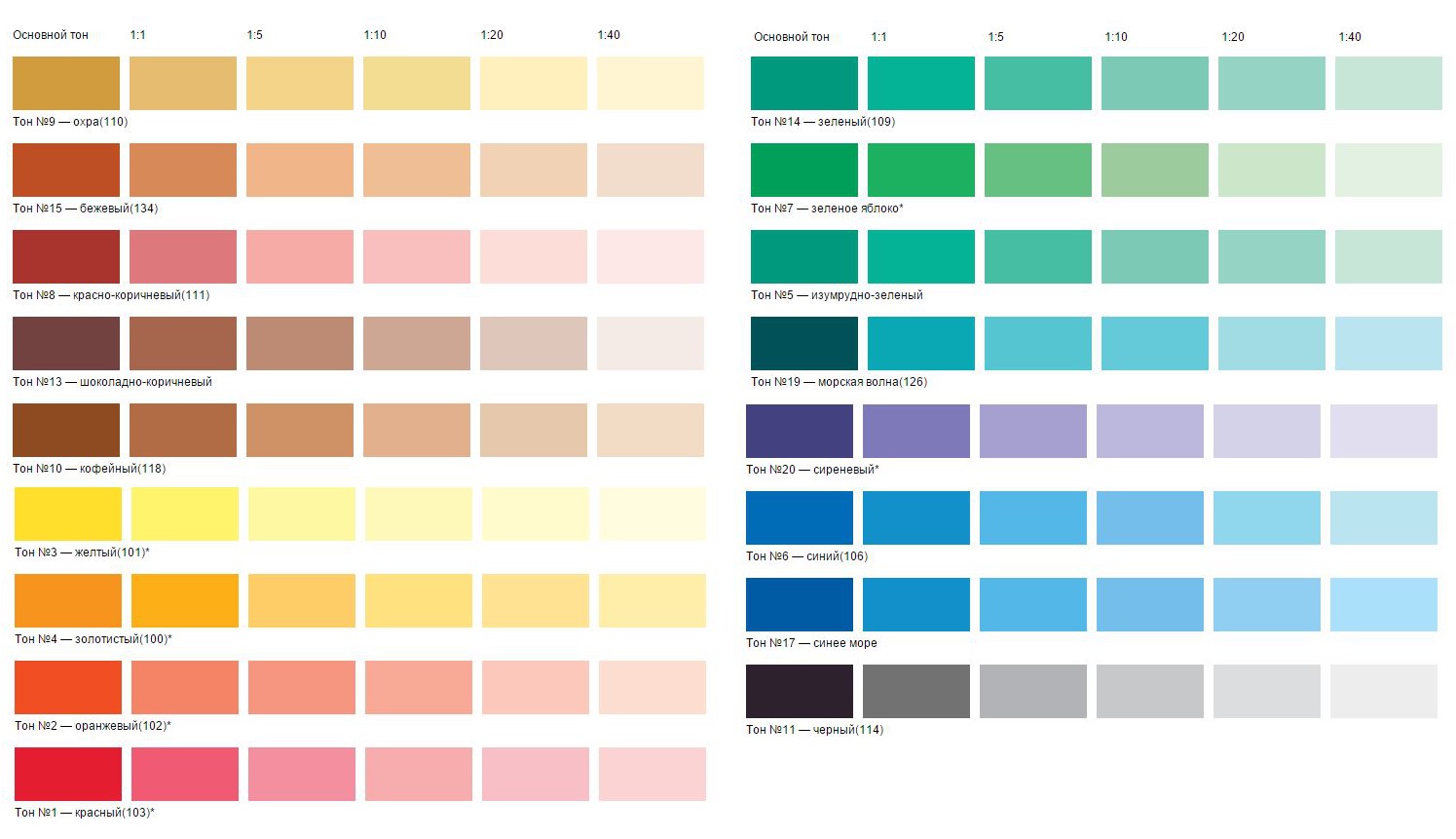

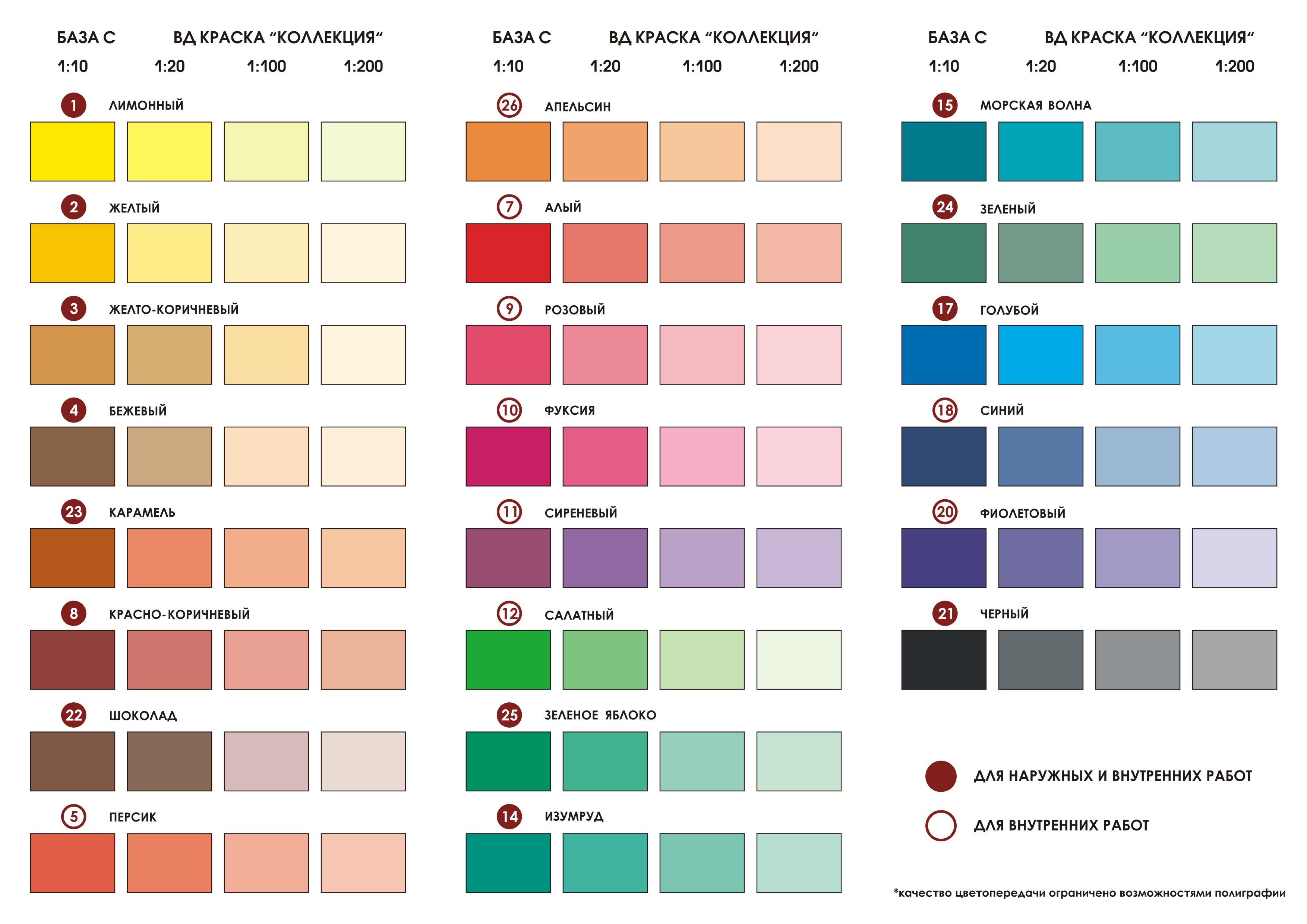

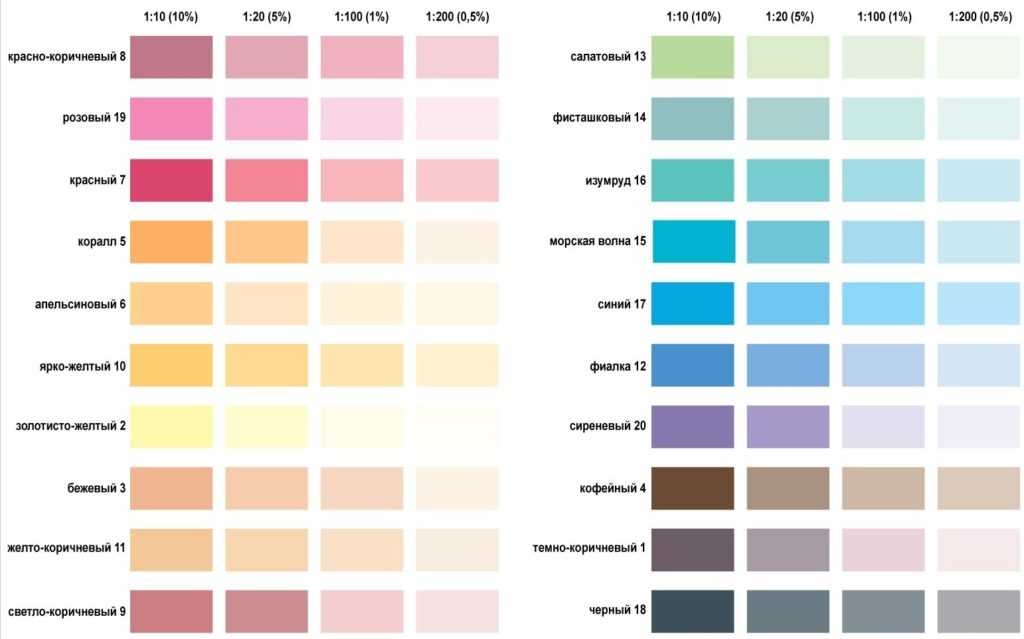

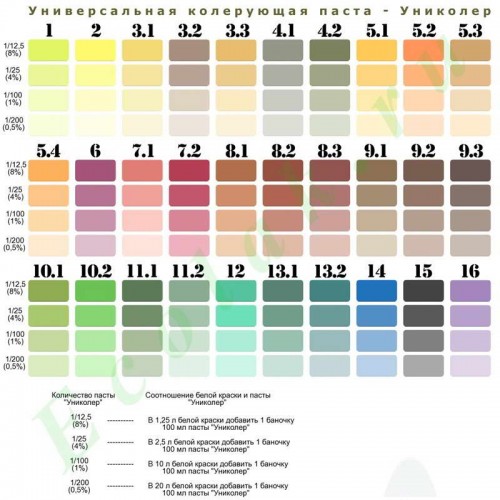

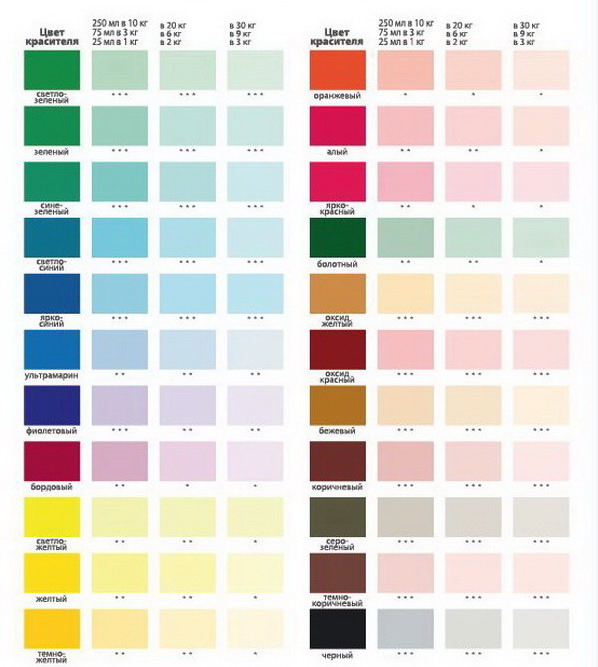

Before tinting the paint, you need to calculate the color consumption, choose the tone and prepare the necessary tools. Of course, if you do it at home. To facilitate the work, specialists have created a special tinting table, thanks to which you will know how to properly dilute the pigment, in what ratio. But you need to understand that it is rather arbitrary, and the proportion may differ depending on the paints and components used.

Color calculation rules

To correctly calculate the ratio, it is necessary to subtract a fifth of the pigment quantity. As an example, consider the color that is as close as possible to the sea wave. To obtain such a shade, you need to add blue and green colors to the white paint.For example, 200 ml of paint consumes 10 drops of blue pigment and only 4 drops of green. To calculate the consumption per 5 kg of paint, you accordingly increase the amount of pigment by multiplying. As a result, we get: 250 drops of blue and 100 drops of green.

Mixing components - step by step instructions

- Prepare some small containers. Remember, they must be perfectly clean.

- Pour in the tinted ingredients and be sure to record the data on the amount of ingredients.

- Apply a small amount of the resulting paint to the surface to be painted later.

- Let dry.

- Apply another coat if necessary.

- Color assessment is carried out only in daylight and after complete drying.

- After you achieve the desired shade, you can start tinting the entire mass of paint.

- For a large area of staining, you will need many containers or one, but large. If you use 3-4 small containers, then pour the paint into it in exactly the same amount.

- Wash containers, dry thoroughly and dry. Even dust must not be allowed.

- Stir the laid out paint with a wooden stick and start gradually adding color. Stir with a piece of wood first, then use an electric drill with a mixer attachment. This will give uniformity.

- Then you can paint the surface.

Overview of the most popular colors

Today, the construction market is simply overflowing with various coloring pigments of any type and manufacturer. The most popular and demanded among foreign and domestic pigments are the following:

- Tikkurila Symphony is used for tinting Tikkurila paint. Possesses the widest range of shades (2256), up to 10 only whites. It is used for interior decoration works. But for the interior, the company of the same name produces the pigment "Tikkurila Facade". There are also options for adding color to antiseptics and varnishes.

- Natural Color System (NCS) is manufactured according to Swedish and Norwegian standards. In this system, there are 6 basic (base) colors and many shades. Thus, it turns out that the basic shades are qualified by letter designations, and the percentage of the main color in the color scheme is digital.

- "Tex" is produced specifically for water-dispersion dyes. It is of high quality, despite the fact that it is a domestic product. It is made from imported active pigments on German equipment.

- Aqua-Color is produced in St. Petersburg. Differs in versatility, high quality and a wide range of shades. It is used for all paints and finishing works.

- The Olka manufacturing company produces the Unicoler paint. Designed for many types of LCS.

- The Moscow factory "Rogneda" produces coloring pigments "Dali". Also of high quality, used for enamels, whitewash, water-based paints. Suitable for all surfaces.

Read about how to tint acrylic paint in a special material on our website.

How long does tinted paint last and how to store it correctly?

How long tinted paintwork materials are stored depends on two parameters: the can is open or closed and what is the shelf life of the paint and varnish material. Sometimes during repair work, unforeseen circumstances arise, and painting has to be postponed. It should be borne in mind that the pigment settles within a day, so the composition will have to be thoroughly stirred before staining.

Closed jars can be stored for several months or even years. The shelf life of each paintwork material is indicated on the packaging. In this case, you must observe safety measures:

- make sure that the jar is carefully closed and the composition does not leak;

- the material should be in a dark, dry place away from direct sunlight;

- do not store paintwork materials near sources of open fire.

Tinting paints is an excellent solution that will help to give the necessary shade to the facade of a building or interior items. It is not difficult to tint paintwork materials if you act strictly according to the instructions.

How to color paint with your own hands

Tinting of paints differs depending on the type of paint and varnish material. When working with pigments, the type of paint should be taken into account: working with an acrylic composition will differ from tinting with water-based, latex or alkyd paintwork. What is the easiest paint to tint at home?

Working with acrylic composition

How to color the acrylic composition correctly? Before you start working with a whole jar, you need to create a probe and look at the resulting color. A white base is poured into a tray and a drop of pigment is dropped from a pipette. If you want a richer color, then add another drop. All values are recorded in detail in order to then recreate the shade on the entire volume of LMB.

The amount of colorant in acrylic paints should not exceed 8%. The number of drops in the jar is proportional to the amount in the sample. After adding the pigment to the white base, the composition is thoroughly mixed. Do not use improvised means and mix the tinted paint by hand, otherwise the color will be uneven. For mixing, use a drill with special attachments or a construction mixer.

A mandatory parameter that is taken into account when working with acrylic enamels is the degree of whiteness. The higher the value, the richer the tone.

Oil paints

What color is suitable for oil paint? Liquid or paste pigments are added to oil paints, powders will not work. If a powder is purchased, it must first be diluted in drying oil, but it is so difficult to achieve the desired shade. The percentage of colorant content should not exceed 1.5%.

Not every colorant is suitable for oil paint, so when buying, you should read the instructions on the package. Manufacturers producing colors for oil paints: Tikkurila, Teks, Olki.

Water-based paintwork materials

When tinting water-based paints, the amount of pigment should not exceed 20% of the white base. This is the largest percentage of colorant that can be added to paints and varnishes.

Powder color is well suited for water-based paints and varnishes. Unlike other paints, it dissolves evenly in them. Liquid dye is also suitable.

To achieve a rich tone, the color is added gradually, drop by drop and constantly stirred. It is convenient to use the syringe with the needle removed. You need to add pigment at least 2 hours before painting, otherwise it will settle to the bottom. It should be borne in mind that on a painted surface, the color will look much brighter than in a container.

Rubber (latex) paint

For tinting rubber (latex) paints, the same substances are suitable as for water-based paints and varnishes. Rubber paints are very thick, liquid colorants are suitable for coloring them. In order for the tone to be uniform, the latex paintwork should be thoroughly mixed, it is advisable to do this not by hand, but using professional equipment, for example, a construction mixer.

The tinted rubber paint dries and becomes one shade darker than when applied. It is necessary to paint the entire surface with tinted latex paint at once. If you break the painting into stages, then the joints of the painted areas will be visible.

Alkyd composition

Paste colors are best for alkyd formulations, but water-based liquid pigments are also used. The colorant can be taken the same as for the water-based paintwork materials.

How much color to add to the base? The percentage of the coloring pigment should not exceed 7% of the total paint volume.

Mixing paint

So, for you, you need to make a probe first. To do this, you need to have a container of a small volume at hand.These can be containers for baby food, yogurt packaging, or measuring plastic cups - the main thing is to keep them clean.

So:

As a dispenser, you can use honey pipettes, but syringes are better, since they have divisions. By the way, tinting pastes are often sold already in syringes. It is also convenient to use the color scheme, packaged in soft tubes with a narrow nose. Also prepare a sheet of paper and a pen to write down the ratios of paint and color.

Everything you need for painting

For work, several brushes of various sizes, rollers, a bath for paint and primer, masking tape, spotless napkins are also useful. When using water-based paints, brushes can be washed under running water. In other cases, you need to take care of the solvent.

If there are no graduated marks on your container, apply them yourself, accurately determining the volume of water to the strip.

Then, pour paint into a jar, and add color there, starting with a couple of drops. Stir, look - if the shade is very pale, add one drop at a time, not forgetting to count and write down their number.

In order not to be mistaken

As soon as you get a tone that visually suits you, you need to evaluate it on a test board.

Better, if it is not a wall or ceiling, use drywall, if the base surface is plastered, or plywood, if the wood sheathing is to be painted. Cut the sheets into 40 cm squares, and test the resulting colors at first with strokes.

Wood paneling also needs to be painted

-

If you realize that the color scheme is not enough, add no more than one drop at a time.

When, in your opinion, the desired tone intensity has been achieved, color the test sheet completely. Even if it seems to you that what you need has now turned out, do not rush to tint the entire volume of paint and start the main work.

-

Since it is unrealistic to appreciate the raw coating at its true worth, leave the reference for a few hours until the paint is completely dry, and see what happened first with daylight, and then with electric light.

Maybe you will realize that the color came out brighter than it seemed at first, and come to a decision to reduce its saturation.

Beautiful shade of paint creates harmony

When you tint the full volume of paint, reduce the estimated amount of color by 20 percent. Only when the 1st layer of coating is applied to the walls, it will become clear how correctly you have approached the appropriate shade. If necessary, a small amount of color can be added to the paint before applying the second coat.

It will not be superfluous to recall that the base surface must be perfectly prepared for painting: leveled, putty (see.

How to correctly putty the walls for painting - a detailed description of the process), sanded and impregnated with a soil composition.

Even the most luxurious shade is not able to hide the imperfections of the surface, and a careless attitude to the preparation technology can generally lead to a sad result.

Stages of staining

Wall painting is divided into several stages:

- Wall surface preparation: leveling, elimination of defects with putty. Then the entire surface is sanded with sandpaper and covered with 1-2 coats of primer. Read about how to perfectly putty and paint the walls evenly here.

- The stage of color preparation and paint mixing. It is discussed in detail above.

-

Wall painting stage. For work, a roller with a fur coat is used. Its optimal size is 15-18 mm. You will need a bath and a small brush. Each time the paint is poured into the tray, it is necessary to thoroughly stir the bulk of the paint in the bucket. The pigment gradually settles to the bottom. In the absence of regular stirring at the end of the work, the shade will turn out darker than at the beginning.

Painting begins from the corner of the room: the corner itself is painted with a brush, and the surface is processed with a roller at a distance of 5-10 cm to both sides of the corner. All stripes are applied vertically, with an overlap. If painting is done over wallpaper, then the joint of the wallpaper and the joint of the colourant must not match.

- Drying stage. It takes about 5 hours. More specific recommendations are indicated on the packaging. Subsequent layers are applied only after the previous one has completely dried.

We offer you to watch a video about the stages of wall painting: