How to do brickwork

Masonry work should be carried out at an ambient temperature of + 5 ... 30 degrees. Other weather conditions must also be taken into account. Rains and winds affect the speed at which the binder solution dries. If the weather is not very favorable, it is better to postpone the installation work for another time.

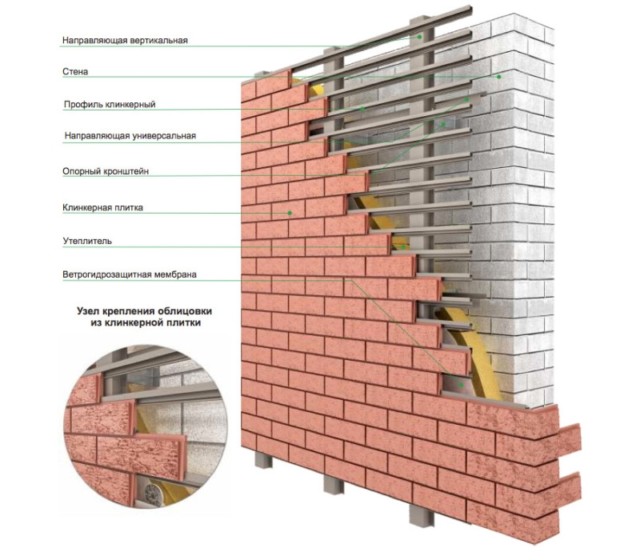

Facade cladding scheme with clinker bricks.

Before laying the front part of the facade on the wall, fix the waterproofing material. Thus, a barrier is created between the wall and the cladding layer for the formation of condensation.

When laying bricks, care must be taken to ensure that the workplace is designed in accordance with the rules. Step by step it will look like this:

- the base is being set up, the main elements of the future structure are being installed, insulation;

- drawings are carefully analyzed;

- masonry work begins with the fact that slats are installed along the entire length of the facade to mark the side edges - they are distributed vertically, then anchored.

It is necessary to prepare in advance the containers in which the masonry mixture will be prepared.

To get a good masonry mortar, you do not need to add lime to it - it is better to make it based on cement. But it is much more convenient to use ready-made mixtures from well-known manufacturers.

Clinker bricks are made from clay and baked in a specific way in special forms.

The jointing will be done 3-4 days after the laying, and a different mortar should be used for it. The mixture is made up in 1 of the following ways:

- white based on Portland cement - it is mixed with sand 1: 4;

- gray - its color intensity depends on the amount of cement.

Do not use a concrete mixer when preparing the grouting solution. Prepare a plastic container with the desired capacity. This is at least 25 liters.

Varieties, scope

There are three types of clinker bricks:

- Solid - before using this type of clinker brick, it is necessary to take into account the load that will be on the foundation, since this finishing element has sufficient weight, which creates additional problems, especially when it comes to the walls and foundation of an old house.

- Hollow - this variety is characterized by vertical voids in the "body" of the product. Such voids, of course, greatly reduce the weight of the clinker and dramatically increase sound and heat insulation.

- Clinker tiles. If clinker tiles are used for the facade, the appearance of the house will not differ in any way from the facade made of clinker bricks.

The difference is that clinker tiles weigh much less, and their price is democratic and affordable for everyone. Clinker tiles can be used for cladding old houses without fear of overloading the foundation.

In addition to the usual rectangular shape, clinker bricks are made in different shapes:

- Beveled.

- Rounded.

- Truncated.

- Combined.

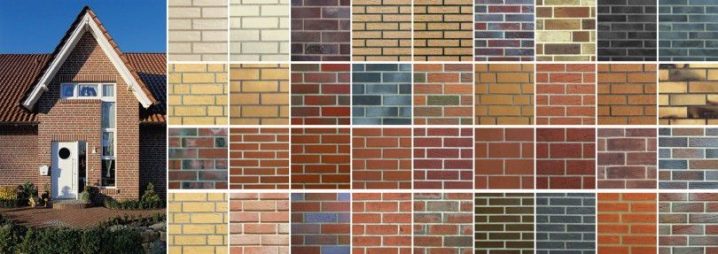

The facades of houses made of clinker bricks or slabs, in addition to the advantages of a technical and operational nature, acquire an aesthetic appearance that attracts the attention of passers-by. Especially if you use contrasting colors and curly shapes for facing the corners of the house, window and door openings

This coating is used not only for cladding the facades of houses and buildings. Low-rise homestead buildings are erected from it. Using increased fire resistance, clinker bricks are used to build fire resistant walls.

It is used for cladding interiors. Due to the strength of clinker tiles, they are used to make playgrounds, paths in the garden, and even equip driveways for a car.

Durability and safety

Clinker facing bricks do not require special care and efforts to preserve their aesthetic appearance. Dirt does not penetrate into its surface and is easily washed off with water, this is ensured by the extremely low porosity of the material. This property also prevents mosses from growing on the walls. Over time, the color of the brick does not fade, since mineral dyes are added directly to the clay at the stage of forming the blanks. This facing material retains its original appearance throughout its entire service life.

In terms of strength, clinker facing bricks are twice as high as ordinary ones. It has a high level of compression resistance and resistance to mechanical damage. Architects use it to erect foundations and plinths of buildings that bear the weight of the structure and must withstand heavy loads.

General information, pros and cons

What is clinker brick? The Dutch were the first to use the technology of processing clay with high temperatures two hundred years ago, when there was not enough stone to build houses. They created a man-made version of the rectangular shape and gave the name, which comes from the German word "klinker", which means "brick". The main component for the production of this type of wall cladding is shale clay, which is mined in Germany. There are no impurities in it, it has a homogeneous composition, refractory and elastic. Silty clay is also used.

The technology is as follows: clay is fired at very high temperatures from 1100 to 1300 degrees Celsius, which leads to sintering of the raw material and acquiring high strength. This is how a new cladding material was invented, which is still used today for both wall masonry and facade cladding.

The appearance of a private or country house, summer house, etc. is the face of the home owner

The first impression of him is created before you get into the interior, therefore the owners of the houses pay great attention to the exterior decoration of the facade.

Clinker brick facades have recently become popular in Russia. This type of wall decoration is relatively expensive and not everyone is able to use it for wall masonry or cladding. The high cost is explained by the fact that there are very few manufacturers of this type of product in Russia, therefore the main suppliers are foreign factories.

Thanks to the applied technology, this type of finish has higher technical and operational performance:

- An environmentally friendly product - only natural raw materials are used for its production: refractory clays and dyes.

- Durability - resistant to mechanical stress and heavy loads.

- Durability not less than 100 years.

- Resistant to temperature extremes, withstands severe frosts.

- Does not lend itself to the aggressive influence of the external environment.

- High density and therefore minimal moisture absorption.

- Does not fade in the sun.

- Not susceptible to decay, mold, etc.

- Fire resistant - often used for buildings for a specific purpose: fire walls.

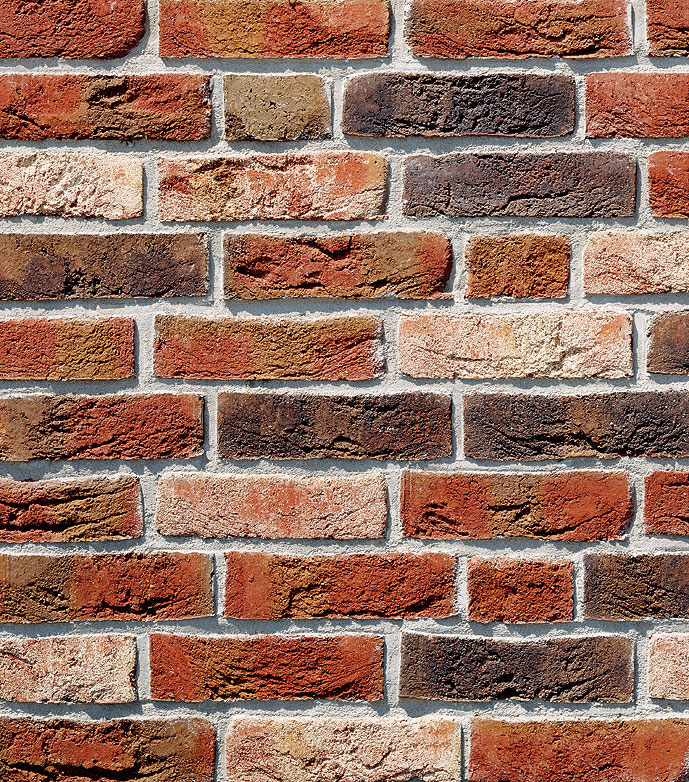

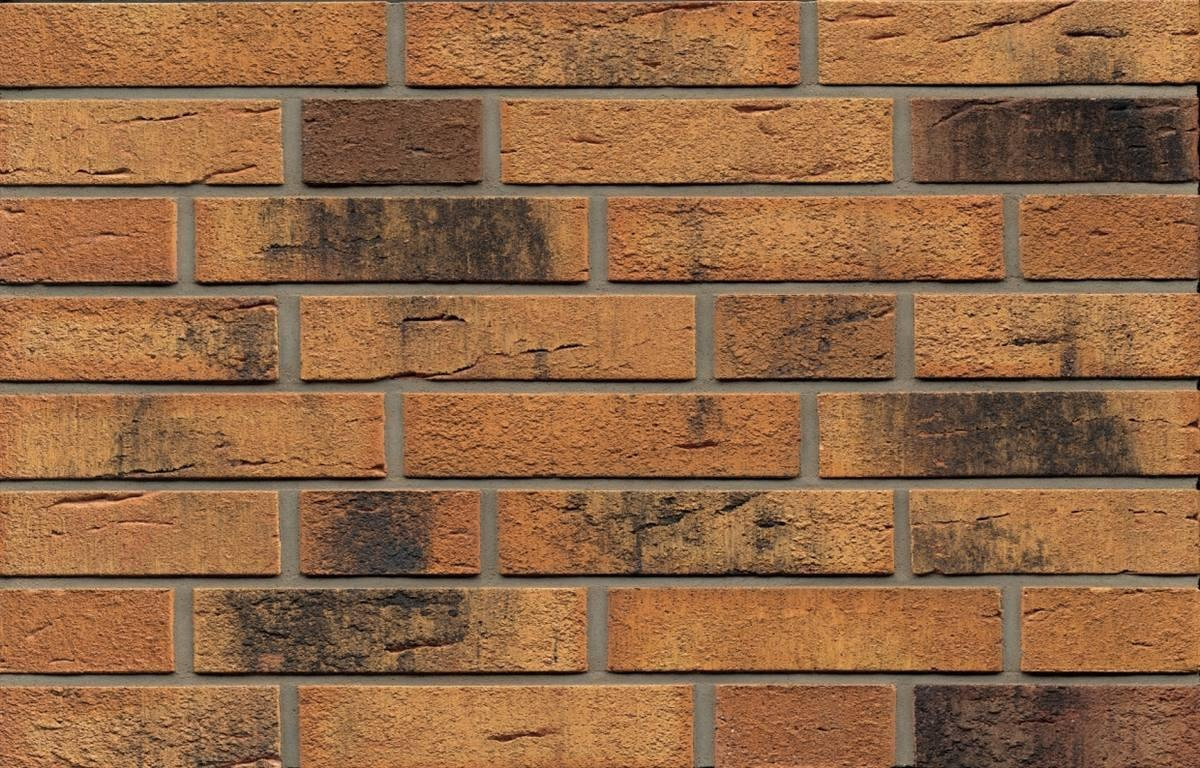

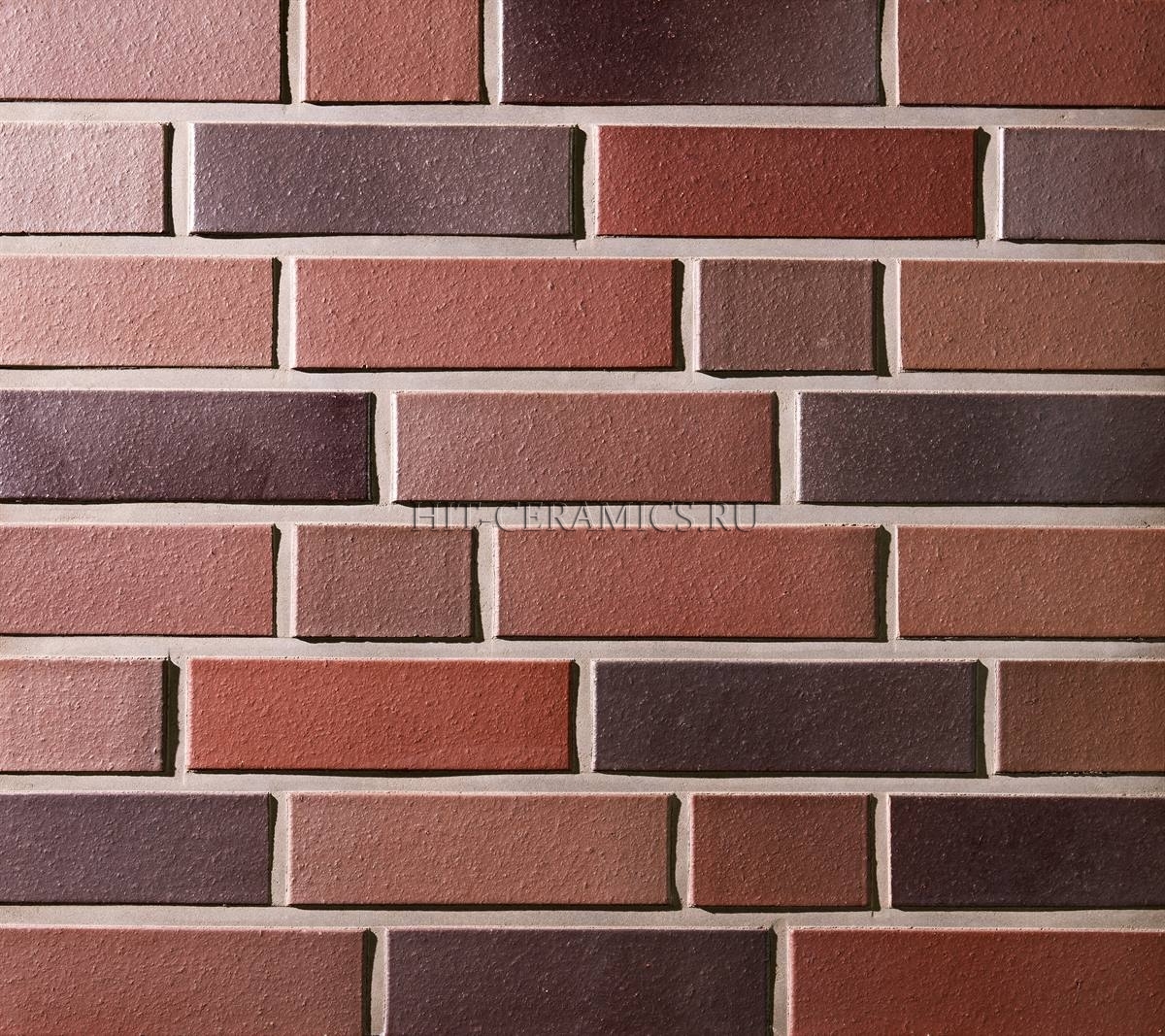

- A wide range of textures and colors.

- Easy to maintain, does not need frequent repairs.

Despite such positive qualities, such a cladding has disadvantages:

- Large weight (1.5 times heavier than the ceramic analogue) - this disadvantage is due to the high density obtained during firing. Clinker tiles do not have such a disadvantage.

- Moisture is not removed from the main walls - it is also due to the high density. It is eliminated in the process of wall cladding by creating air circulation.

- High price. But clinker tile cladding will cost much less.

- The need to use hard mortars for masonry and facade cladding.

How clinker bricks are made

To obtain a clinker brick for the facade, resistant to natural influences, it is necessary to strictly follow the technical process.

Applicable materials

As for the components, you will need the following:

- Clays of refractory grades with a large amount of kaolin - the content of aluminum oxide should be 17-23%, in this case the clay bars are not deformed during firing.

- The composition should include iron oxide of 2 or 3 valence - it is this component that determines the final shade of the building material after heat treatment. The clinker has a fairly wide range of shades from dark purple to red with a cherry tint. The amount of iron oxide can be up to 8%. If this component exceeds the indicated dosage, then during heat treatment a dense film forms on the surface of the clay, which prevents the necessary chemical processes from proceeding, in particular, the oxidation of carbon and the further release of carbon dioxide - so that the surface of the bricks warps.

- Calcium - the amount of this substance should not go beyond 7-8%, otherwise the building materials will turn out to be porous, deformed, the service life of such a material is reduced.

- Magnesium oxide - ideally 3-4%, when this indicator is exceeded, the final product either loses a lot in volume or is strongly deformed.

Extrusion molding method

Having a production workshop available, you can make high-quality products from heat-resistant clay:

- All components are mixed until homogeneous - the resulting plastic mass is sent to the production line to the extruder conveyor.

- The mixture under pressure exits the extruder, passing through a molding hole of the corresponding section. As a result, a rectangular volumetric strip with figured voids inside gets to the conveyor.

- Moving along the processing line, the strip goes through the cutting stage - individual bricks are obtained, which are sent for drying.

- As soon as the humidity reaches 2-3%, the workpieces are sent to the oven.

- For firing, a tunnel kiln 200 m long is used - during their transportation through the hot tunnel, the workpieces are fired at temperatures above 1000 degrees Celsius.

Extrusion method

The advantages of building materials obtained in this way are precise dimensions and stable quality. This is how most European companies make clinker. But the specified equipment is quite expensive and implies significant energy costs, which negatively affects the cost of the finished product.

Semi-dry pressing

Energy costs for semi-dry pressing are significantly lower, however, the quality of building materials is also lower. The technical process is as follows:

- The clay powder mixture is moistened and poured into prepared forms.

- This is followed by the pressing stage.

- The workpieces are sent to the drying chamber for 1-2 days, the temperature regime is 80-85 degrees Celsius.

- The prepared blanks are sent to the oven.

Semi-dry pressing method

Burning

Firing is the final stage of both technological processes. Most often, a tunnel oven is used for this, into which the blanks are fed on special pallets. The clay firing process is continuous. Passing sections in a furnace with different temperature conditions, the clinker goes through a series of heat treatment cycles - due to this, the clay mass is sintered into a monolith. The strength of the bricks is close to that of steel.

Firing process

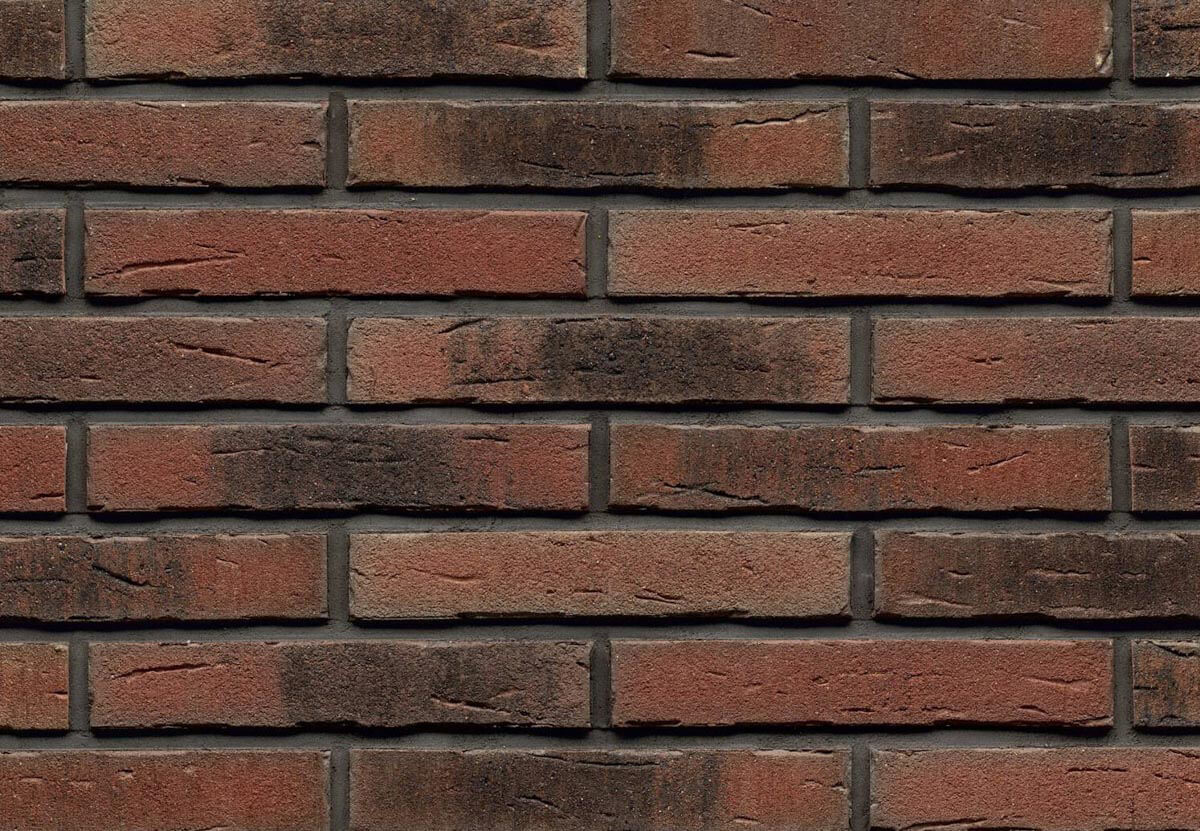

No. 7. Clinker brick texture

The classic and simplest option is a smooth matte finish. In this case, nothing special has to be done in the production process.To diversify the appearance of a brick, to give it a relief or gloss, the following technologies are used:

- the standard method involves applying a certain pattern to the molded, but not yet fired mass. After the process of processing the product in the oven, the pattern is preserved, and as a result, a brick with the necessary relief is obtained. Such manipulations do not affect strength;

- Shotcrete is a popular decorative treatment for clinker bricks. Before firing, mineral chips are applied to one or several faces. Under the influence of high temperatures, it melts and bakes with clinker, forming interesting color transitions and a unique pattern;

- engobing involves the application of a thin layer of ceramics, called engobe, to the formed dried brick. It is a mixture of clay and metal oxides. In the furnace, the engobe is melted, baked with clinker and allows you to obtain a product with an interesting shade, and the color depends on the composition of the engobe. If engobe is applied only to a part of the brick surface, then you can get a material with a smooth color transition. This is how artificially aged bricks are produced;

- glazing allows you to get a brick with a glossy slippery surface. The production technology resembles that described above, only the ceramic layer in this case is replaced with a glaze layer. We emphasize once again that glazed clinker bricks do not absorb moisture at all, and they are less polluted.

Any type of clinker brick is suitable for facing the facade - it all depends on personal preferences and tastes. For paving paths, it is better to take a product with a noticeable relief - they will be less slippery.

Selection Tips

When choosing clinker tiles, initially calculate the required amount of material. To do this, you can use a special program or calculate the area of the site that you plan to do with this material. Please note that the planned thickness of the tile joints will affect the consumption of materials. This rule especially applies to cases when a large surface area is finished with clinker tiles.

Try to purchase tiles with a margin. This is necessary so that you can cut it off at the joints of adjacent walls or replace elements in cases of damage. Therefore, approximately 10% more clinker should be purchased for finishing.

If you purchase clinker for facades, it is important to pay attention to its characteristics. Facade models cost from 4,000 rubles per sq. m, so you should calculate the cost of such coverage

When buying, try to choose between popular foreign brands that represent already proven quality models. Many of them offer a long warranty period. Although domestic clinker tiles are cheaper, their quality is generally lower.

m, so you should calculate the cost of such coverage. When buying, try to choose between popular foreign brands that represent already proven high-quality models. Many of them offer a long warranty period. Although domestic clinker tiles are cheaper, their quality is generally lower.

When choosing clinker tiles, keep in mind that interesting models with a relief texture are much more expensive, but they are not so practical. In addition, the maintenance of such a clinker will require additional costs for its processing by a master. Although outwardly such a coating looks presentable, it must be maintained in good condition.

When choosing clinker, pay attention to its color. It should be in harmony with all the elements of the building when it comes to exterior decoration.

Moreover, this applies not only to the design and color scheme of the building, but also to its architectural features. That is why, when choosing, it is better to ask a designer or architect for advice.

Try to select the clinker in such a way that it matches the design of the roof and does not look too bright. Contrasting options look tasteless.

When purchasing clinker, you also need to buy an adhesive mixture for attaching these elements and a grout with which you will process the joints. As for the glue, in this case, a durable frost-resistant coating designed specifically for this finishing material is more suitable. It is best to select clinker adhesives that can withstand more than 50 freeze and thaw cycles. Thus, you will provide a more reliable fastening of finishing materials to the facade of the building.

Grout is also an important element, so you need to pay attention to its quality and color. It must be able to compensate for the thermal expansion of the tile.

As for its color, it should be in harmony with the tiles.

If you plan to do clinker cladding on your own, then it is better to take a closer look at the facade panels with clinker tiles. In this case, the most practical will be thermal panels, since they provide an additional layer of thermal insulation. In addition, laying them yourself is much easier than piece clinker.

No. 2. ADVANTAGES AND DISADVANTAGES OF CLINKER BRICK

Features of raw materials and production technology make it possible to obtain a brick with a unique structure, which has a lot of advantages:

- durability. The material retains its original qualities for 100 years or more;

- strength. If we compare different types of bricks in terms of compressive strength, then clinker bricks confidently take the lead. The parameter, of course, can fluctuate within certain limits, but it will never be lower than 250-300 kg / cm2, which corresponds to the strength grade M250-M300. By the way, in the construction business, bricks of these brands are used to lay the foundations of apartment buildings;

- low moisture absorption (4-6%) is explained by the almost complete absence of pores in the structure of the material, because the raw material in the process of pressing and sintering turns into a monolith. That is why clinker bricks are used for the construction of critical structures, especially those whose operation will take place in difficult conditions (an aggressive environment with a high level of humidity). Efflorescence does not appear on the material. By the way, clinker bricks covered with glaze do not absorb moisture at all; - frost resistance, which is due to the high density of the material and minimal moisture absorption. Even the simplest clinker brick can withstand 75-100 freeze / thaw cycles, and some types can easily tolerate up to 300 cycles. Excellent frost resistance made the material popular in areas with harsh climates. The most frost-resistant products are created for paving paths;

- resistance to temperature extremes;

- fire resistance. The presence of refractory components in the material and high firing temperatures provide clinker bricks with a record resistance to fire. Experiments have shown that the material can withstand temperatures up to 18000C, and structures after a fire do not deform or collapse;

- environmental friendliness. The product is based on natural raw materials, so there is no need to talk about harm to health and the emission of toxic substances. All major manufacturers of clinker bricks check raw materials and finished products for radioactivity, so you can be 100% sure of your own safety;

- great appearance. Clinker brick looks natural and noble. The shade depends on the characteristics of the composition of the raw material, so each brick is unique in its kind. Considering the variety of sizes and shapes, you can choose a material for every taste;

- versatility and wide scope. Clinker bricks are used in cladding, full-scale construction, stoves and sidewalks.

Among the main disadvantages of clinker bricks, it is worth noting:

- high price, because a material with such impressive performance, as you might guess, cannot be cheap. However, if you compare the cost of the material and its durability, then the purchase can be considered an investment in your maintenance-free future. Clinker brick costs twice as much as ceramic brick, but bypasses it at times in terms of durability and resistance to negative external factors. On the other hand, it is worth noting that it is precisely because of the high price that clinker bricks are rarely used as a building material - they prefer to use it for cladding;

- high coefficient of thermal conductivity as a result of the almost complete absence of air pores. For high strength and moisture resistance, you will have to pay with high-quality insulation;

- low soundproofing qualities, which again comes out of the absence of pores, therefore, enclosing structures made of this material will also need good sound insulation;

- clinker bricks should be laid by professionals. In addition, in this case it is necessary to use special solutions - the usual masonry composition will not work, since the material has a low moisture absorption.

We should also note the low vapor permeability. The minimum number of pores gives clinker bricks resistance to moisture, but at the same time prevents air from passing through the material. That is why, when using the material as a building or facing material, it is necessary to take care of high-quality ventilation.

Suture shaping technique

The beauty of clinker tile masonry is guaranteed not only by the material itself, but also by the correct execution of the seams, for which there are two ways.

The first is similar to laying ceramic tiles using special crosses. And after they are removed, a grout will be required for clinker tiles, when choosing which it should be borne in mind that it has not only decorative and aesthetic value, but also a purely protective one, namely:

- does not allow moisture to pass under the cladding, and, consequently, to the surface of the walls;

- serves as protection against the effects of other unfavorable factors, and also directly affects the thermal insulation capacity of the cladding;

- protects tiles and especially its corners from chips as a result of mechanical or natural stress.

Grouting must be done very carefully, trying not to touch the front surface of the masonry. It is imperative to properly prepare a solution that has a fairly loose structure, which is easiest to apply using special rubber spatulas.

Ventilated facades: types, installation technology. - here is more useful information.

The next step, when the grout grasps a little, is to level the joint with the help of jointing and remove excess (including from the clinker surface) with a brush.

An important point is the observance of the sequence of operations: the horizontal seams are processed first, and then the vertical ones.

You will be interested in this article - Facade plank of larch and pine.

But if, when facing with clinker tiles, it is necessary to achieve the effect of masonry under a brick, then the seams are formed using a metal rod, the thickness of which will be the width of the jointing.

As a rule, a rod with a thickness of 6 to 10 mm is used. In this case, the first row of tiles is laid on the profile, and before laying the next one, the rod is first installed (necessarily on glue), and then the masonry continues.

Grouting with this method may not be performed, since after the glue has set, you need to carefully remove the rod, which will form a perfect and protected seam, thanks to the glue mixture. But if you want to make a contrasting or colored seam, it is perfectly acceptable to use grout.

On average, the process of drying the masonry takes a week, but it is important, when working outdoors, to pay attention to the weather forecast, since the optimal conditions for this are the air temperature from 10 to 25 ° C, and the humidity is not higher than 65-70%. But, if unlucky, and rainy weather turned out, it is imperative that the masonry must be covered with plastic wrap in order to prevent erosion of the adhesive composition, and as a result, deterioration of the strength characteristics of the cladding

But, if unlucky, and rainy weather turned out, it is imperative that the masonry must be covered with plastic wrap in order to prevent erosion of the adhesive composition, and as a result, deterioration of the strength characteristics of the cladding.