Species overview

Each type of glue has its own area of application and distinctive properties determined by the composition.

Polyurethane glue is a liquid transparent product, but sometimes it has a light yellow tint. Based on the degree of viscosity, its purpose also changes.

One-component composition quickly cures in the open air due to natural moisture, although there is no hardener in its composition. Such glue is the optimal binder for the production of all kinds of rubber products: mats, carpets, roll material, paving stones and tiles.

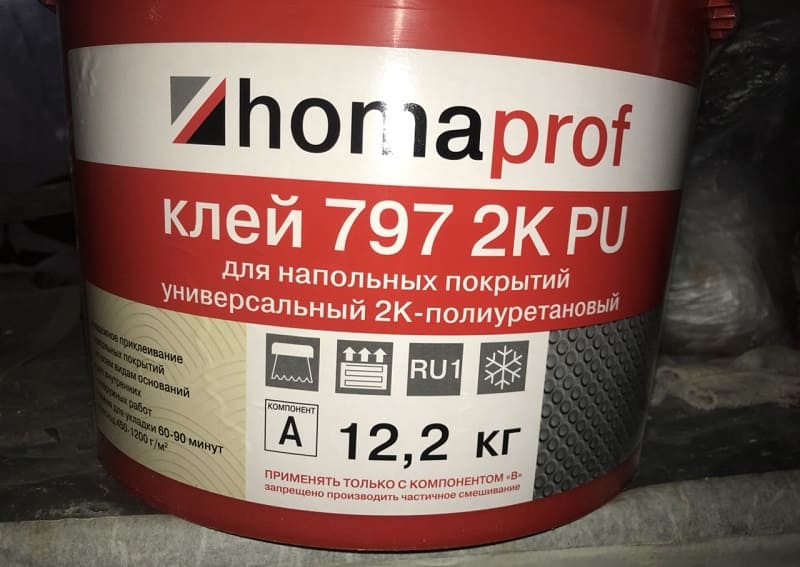

If a two-component composition of polyurethane glue is selected, then it will have to be prepared in advance - mix directly the glue and the hardener supplied with it. Only after mixing them does solidification occur, and the speed of this process depends on the taken proportions of the two components.

Advantages of polyurethane compounds used for rubber:

- ecological cleanliness, safety for humans and the environment;

- high amortization qualities;

- resistance to abrasion and external negative influences;

- good water resistance;

- the possibility of coloring rubber products by introducing pigments into the composition.

There is still a small drawback for these types - you need to use glue after opening the package quickly, the useful properties of the material are preserved for 30 minutes.

Rubber-bitumen mastics are distinguished by special characteristics. First of all, it is a low melting point, which reduces their elasticity and strength. In addition, the bitumen included in their composition excludes rubber staining.

However, in many respects, such glue has advantages over polyurethane:

- the possibility of using mastic on inclined and vertical surfaces due to its good viscosity;

- protection of any base from moisture, which means the exclusion of the development of fungus and mold stains;

- it is preferable to lay rubber on metal surfaces using a bitumen composition with anti-corrosion properties;

- if it is necessary to make a coating on concrete, asphalt, then you should also choose a mastic, since it gives better adhesion to these materials than polyurethane mixtures.

The disadvantages of the glue are vulnerability to low temperatures and high consumption due to high viscosity. Thus, different types of adhesive base should be selected based on the goals and operating conditions.

Polyurethane adhesive one-component and two-component - application

This long-lasting compound is used for bonding various surfaces. It is indispensable for working with porous materials, withstands the effects of moisture and aggressive environments. Due to its advantages, it has found application in various fields, it is used for various purposes:

This long-lasting compound is used for bonding various surfaces. It is indispensable for working with porous materials, withstands the effects of moisture and aggressive environments. Due to its advantages, it has found application in various fields, it is used for various purposes:

- In the shoe industry. It provides high-quality adhesion of the sole and leather surfaces. It goes well with synthetic leather, rubber, polyurethane and other artificial materials.

- For fixing ceramic tiles, expensive mosaics. Manufacturers recommend glue because of its reliability, thanks to the composition, the elements are prevented from falling off.

- For cladding wooden, metal surfaces, facades with any materials. For example, marble, natural stone. It is advisable to use the composition in places subject to vibrations.

- For wall cladding in rooms with high humidity. These are showers, kitchens, saunas, balconies.

- For the manufacture of sandwich panels.

- In the production of metal-plastic windows. Using glue, the corner parts of the structure are assembled.

- When carrying out repairs or finishing works. The glue perfectly holds bricks, glass, wood, concrete, slate, ceramics together, and the composition will perfectly cope with a combination of different materials.

- For the production of garden furniture.

- For gluing artificial turf.

- For the arrangement of playgrounds, tennis courts by gluing crumb rubber products.

- For the protection and insulation of metal pipes.

- Bonded surfaces withstand rough use.

Bonding technologies

Experts use the following methods in their work:

- Cold. It is based on the application of a thin layer of glue in two stages. The first layer is applied evenly and kept for 15 minutes, then another one, it is left for 5 minutes. After that, the working parts are pressed tightly. The surfaces to be glued are pre-cleaned and degreased.

- Hot. Glue is applied to the prepared elements and kept for up to 30 minutes. Then the surfaces are heated to a temperature of 70-90 degrees, pressed against each other by means of a press.

- Wet. It consists in the preliminary treatment of surfaces with water. This is necessary for the best adhesion - as a result of a chemical reaction, a hard polyurethane film is formed.

The curing time of the adhesive depends on the ambient temperature. After complete drying, the composition perfectly retains the elements. It reacts to changes in humidity levels. That is why, when gluing elements of a wooden floor or parquet, capable of movement, it will stretch after them. In addition to elasticity, the composition has another excellent quality - it protects the seams from the negative effects of moisture.

What is the difference between a two-component polyurethane adhesive and a one-component adhesive?

There are different types of glue, but all of them are characterized by the same property. It consists in the fact that when interacting with the atmosphere, the compositions increase in volume. This allows them to be used for bonding porous structures. One-component formulations - ready to use at any time, two-component formulations - must be prepared before use. As a rule, the pot life of the finished composition does not exceed 3 hours. Before cooking, you should consider how much you can use up during this time.

What is crumb rubber tile adhesive?

Polyurethane-based adhesive is a colorless or transparent-white liquid that is used as a binder when laying polyurethane, rubber or rubber tiles on any surface - asphalt, concrete, wood, paving stones, etc. The advantages of this type of binder include the following properties:

- lack of color, which does not affect the quality of the finished tile surface, even if part of the glue comes out during laying;

- high adhesion to any type of surface;

- lack of emission of harmful substances;

- no shrinkage as it hardens;

- fast process of mixing and laying, as well as hardening - on average, until complete commissioning of tiles glued with polyurethane glue takes 24 hours.

Adhesive for concrete and rubber tiles during mixing and operation does not stick to hands and does not stain the surface, if necessary, it can be easily washed off with plain water and does not require the use of special solvents based on acetone. However, there are nuances in using this type of binder:

- the temperature of the air and the floor surface should be in the range of 10-25 ° C above zero;

- the relative humidity should not be higher than 70%; it is not recommended to use it on a damp surface after rain;

- you need to prepare the glue immediately before laying the tiles, because it hardens quickly, which makes its further use impossible.

The viscous binder polyurethane rubber tile adhesive is available in one-component and two-component applications, which are used in a variety of applications when laying tiles or rubber rolls. The two-component adhesive is so called because it consists of two main components - glue and hardener, which are sold separately and come into effect at different times during the installation of the rubber tile. Such an adhesive for laying rubber tiles has high filling characteristics and the ability to adhere to the surface of the subfloor and rubber chips.

Features of working with adhesives

Adhesives can be used as a component of the base of rubber tiles, or for gluing crumb rubber to a base, for example, concrete

To obtain high-quality results, it is important to observe certain conditions of humidity and air temperature, under which the glue will harden qualitatively and will retain its properties for a long time.

The air temperature during operation should not exceed 30 degrees and not be less than 5 degrees. Moreover, the base temperature must also be warmed up to the required parameters. If the substrate is cold, the adhesive will harden unevenly. If temperature is too high, the polymerization process will start too early.

Before starting work in an open area, the forecast of the breed should be studied. It is not recommended that it rains during the day. To get a better attachment to the base, you should treat it with a primer.

Apply liquid glue with a brush or roller, if the composition is viscous, it is worth using a notched trowel.

If a two-component adhesive is used, it is important to observe the proportions of the adhesive indicated by the manufacturer when mixing it.

Using hot molding glue

The method of hot gluing and molding rubber coatings has a number of features. The working surfaces are pre-cleaned of possible contamination, after which glue is applied and kept for about half an hour. After that, the layers to be glued are heated to 70-90 degrees. The heated products are pressed tightly against each other using a powerful press.

The method of hot gluing and molding rubber coatings has a number of features. The working surfaces are pre-cleaned of possible contamination, after which glue is applied and kept for about half an hour. After that, the layers to be glued are heated to 70-90 degrees. The heated products are pressed tightly against each other using a powerful press.

Features of the cold pressing method

Cold forming technology differs from the previous method in that it does not require heating the blanks. Works are performed at ambient temperature. The glue is applied to the glued surfaces in two layers with an interval of 15 minutes. 5 minutes after the application of the second layer, the workpieces are glued together. To achieve the necessary adhesion, the surfaces are pre-degreased.

Rubber tile

Such tiles are resistant to frost and high temperatures, friction, deformation, moisture and ultraviolet light. It can be laid on any surface that does not require special preparation - asphalt, concrete, stone, paving stones. The excellent anti-slip properties of the rubber tiles make them useful in places where a high level of security is required (nursing homes, hospitals, schools and kindergartens).

Polyurethane glue is added to the base of the tile even during its manufacture at the factory, which makes its installation with such a binder very reliable and durable. The tiles are installed in a floating way using a special adhesive based on polyurethane. This polyurethane adhesive, which is absolutely harmless to the environment and humans, has good adhesion properties due to deep penetration into the porous structure of rubber tiles.

Polyurethane adhesive for cold forming

Polyurethane-based adhesives are widely used in construction and production of building materials. Such mixtures are part of rubber coatings, which are used to equip adjoining territories, sports grounds, etc.Also, polyurethane glue can be used when laying parquet floors and other types of flooring materials. The adhesive composition provides excellent adhesion, gives the finished products the necessary strength and elasticity, and increases their service life. The properties of the material are retained for decades, even with intensive use of rubber coatings.

Polyurethane-based adhesives are widely used in construction and production of building materials. Such mixtures are part of rubber coatings, which are used to equip adjoining territories, sports grounds, etc.Also, polyurethane glue can be used when laying parquet floors and other types of flooring materials. The adhesive composition provides excellent adhesion, gives the finished products the necessary strength and elasticity, and increases their service life. The properties of the material are retained for decades, even with intensive use of rubber coatings.

Useful tips for residents of the city of Chelyabinsk and other cities of the country

The following recommendations, shared by experienced specialists, will help to avoid undesirable consequences:

- It is better to store the tube in an upright position, upside down, for this you can build a special stand.

- Before closing the container with glue, you need to remove the remaining air from it. To do this, gently press on the walls of the tube. Close the cap tightly.

- If glue accidentally gets on your clothes, it can be removed after drying. To do this, we crush the dried mass and extract each particle.

- When purchasing glue, we choose the volume of the composition that can be consumed within the next few months.

-

Excess glue formed along the seams

we remove only after complete drying.

These simple tips will help you get the job done quickly and efficiently!

One-component polyurethane adhesive for crumb rubber

Given the type of binder, the adhesive is polyurethane and bituminous. The intended use depends on several factors: the type of substrate, the curing conditions and the technical characteristics of the floor covering. Polyurethane adhesive has a number of advantages, namely:

- environmental Safety;

- moisture resistance;

- abrasion of the coating;

- resistance to mechanical damage;

- providing elasticity;

- long service life.

One-component adhesive can be used for laying material not only indoors, but also in open areas. Due to the absence of solvents, the coating does not deteriorate under the influence of moisture, ultraviolet and sun rays and temperature extremes.

How does adhesive work?

The PVC tile adhesive sold in the construction markets is most often a two-component adhesive. It is mixed with a special substance in certain proportions, after which rubber segments are placed on it. When the adhesive cures completely, it forms a remarkably strong bond between the rubber segments. Consequently, the coating becomes durable and is not afraid of any mechanical stress.

The reliability of the entire coating, which is intended for long-term operation, depends on the quality of the glue. Some companies produce completely harmless polyurethane adhesives that are allowed to be used even at home. When the composition is completely cured, it is safe even for young children. Tiles glued with good glue cannot be torn off the floor.

Features of polyurethane glue

The polyurethane composition differs from other adhesives:

- Composition. The glue is almost completely, up to 95%, composed of solid synthesized resins and is a synthetic substance.

- Curing process. When glue interacts with water vapor, a chemical reaction occurs with the formation of bubbles of carbon dioxide. In this way, it resembles polyurethane foam. The glue is applied in a thin layer, the composition interacts with air and expands, flowing out beyond the application site. And so it hardens. The surplus, which turned out to be all the seams, after hardening, is removed with a knife.

- Versatility of application. They can be glued to metal, wood, stone, plastic, and other non-porous materials. Glue firmly sticks together homogeneous and dissimilar materials, and it can be used to glue shoes, fix mirrors to wall surfaces, and use it to repair furniture.

High technical characteristics.

Advantages of polyurethane adhesive

Advantages of polyurethane adhesive

Resistant to moisture.The property of water resistance allows the use of polyurethane compounds for gluing objects and materials used in conditions of high humidity or in contact with water. In this case, the moisture-resistant seam becomes a sealant.

Resistance to subzero temperatures and heating, temperature extremes.

Chemical neutrality when interacting with gasoline, oils, aggressive compounds. It is not recommended to use polyurethane glue for gluing elements made of silicone, polyethylene, polypropylene. But not because of chemical reactions, but because of the poor quality of adhesion.

Ease of use. The composition is convenient to use - it is easy to apply to the surface and distribute. A sufficiently long time before hardening (about 20 minutes) allows you to correctly position and fix the parts without haste

"Important" For the appearance of reliable adhesion between the parts, you need to wait 1 hour. It is recommended to fully use the object or the glued material in a day.

No harm to glued materials

It does not saturate porous surfaces with moisture, and there is no risk of deformation of products. The glue can be used even when laying parquet flooring without fear of swelling of the wooden blanks.

How to use?

With the help of polymer glue, you can independently lay a rubber coating on a site of any size and type: wood, concrete or asphalt.

To do this, you need to prepare tools: a spatula, notched and painting, a building level, a roller, a sponge or brush for applying, a rubber hammer, chalk, a broom or a vacuum cleaner.

Any method of installing rubber plates involves a preparatory stage. The surface under the tiles is pre-cleaned and leveled, irregularities and defects are eliminated, small debris is removed with a vacuum cleaner.

The workflow algorithm looks like this:

- the base must be primed with a mixture of polyurethane glue and turpentine in equal proportions;

- separate the perimeter of the site with a rope;

- apply glue and level it with a spatula;

- it is better to lay no more than 4 tiles at a time;

- you need to start work from the center of the site, gradually moving to the edges;

- installation consists of laying out the plates with their pressing, avoiding significant gaps;

- there should be no air under the coating, the glued material must be tapped with a hammer to exclude "waves";

- at the end, a border is installed along the edges of the treated area;

- if excess adhesive remains on the rubber, it should be removed immediately.

When installing tiles, the approximate consumption of glue is about 300 g per 1 sq. m. It should also be borne in mind that the humidity of the air during installation should not increase more than 70%, and the temperature of the air and materials should be within 10-20 degrees. A double layer of polyurethane glue will have to be applied if the installation takes place next to open natural and artificial reservoirs.

About polyurethane glue "Gambit M", see below.

Sale of adhesive mixtures for floor tiles in Chelyabinsk

The company "MATECO" offers a wide range of adhesive mixtures for laying PVC floor tiles. We sell only high-quality certified products manufactured in accordance with the current GOST and ISO standards. Adhesives are supplied in various packages, so that each customer can purchase the required amount of material based on their own needs.

The company "MATECO" offers a wide range of adhesive mixtures for laying PVC floor tiles. We sell only high-quality certified products manufactured in accordance with the current GOST and ISO standards. Adhesives are supplied in various packages, so that each customer can purchase the required amount of material based on their own needs.

When ordering adhesive for PVC tile coverings from our company, you can count on the following advantages:

- Reasonable prices. We buy adhesive mixtures directly from manufacturers, therefore we sell products with minimal margins.

- Free consultations. Employees of the company will help you choose the glue and calculate the required amount of material.

- Permanent availability. Warehouses hold large stocks of goods ready for shipment.

- Fast shipping.The goods will be promptly delivered by our own transport service or through a partner logistics company.

If you are interested in additional information, please contact our managers by calling the specified number. We will accept the order and answer your questions.

Company"MATECO"offers a wideselection of goods

- Artificial grass

- PVC tile

- Polyurethane adhesive

- Rubber covers

- Rubber tile

- Rubber mats

Our experts are always ready to answer your questions.!

Advantages of polyurethane adhesive

Advantages of polyurethane adhesive