GWP glue bestsellers: choose the one you need!

Perlgips Gypsum polymer. This adhesive composition can be safely called an ideal material for laying internal partitions of various types from gypsum-groove plates in warm dry rooms. The main advantage of this glue is its super strong hold. The only limitation is that the material cannot be used in the cold.

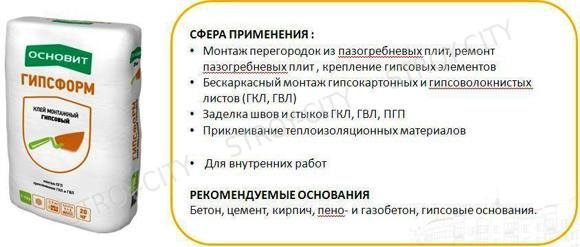

Basis Gipsform T-115. The adhesive for PGP, gypsum plasterboard and gypsum board, recommended for internal use, is distinguished by good plasticity and high adhesion. Application in a thin layer allows you to save a decent amount of money on installation.

Volma Montage. Popular GWP adhesive, enriched with mineral additives and intended for installation at an air temperature of +5 ºC. The use of such an adhesive guarantees easy application and excellent adhesion!

Volma Montage Frost - glue for GWP is frost-resistant, which easily withstands sub-zero temperatures down to -15 ºC thanks to special anti-frost additives.

Adhesive for tongue-and-groove plates and sheets of gypsum board and gypsum board SR 26

МРЗ Adhesive for tongue-and-groove plates and sheets of gypsum plasterboard and gypsum plasterboard SR 26 is intended for installation of partitions made of tongue-and-groove plates, repair of tongue-and-groove plates, fixing gypsum elements, for frameless installation of gypsum plasterboard and gypsum fiber sheets (gypsum plasterboard, gypsum fiber board).

It is used for sealing seams and joints of gypsum board, gypsum plasterboard, gypsum plasterboard in winter at air and base temperatures up to -10˚С. It is applied on concrete, brick, foam and aerated concrete, gypsum and cement plasters.

Substrate preparation:

The substrate must be dry and sound, free from dust, dirt, oil stains, and various delamination. It is recommended that significant surface irregularities be leveled with the appropriate SR 26.

To enhance the adhesion of the material to the substrate, treat the surface with the appropriate PRO primer. The substrate is ready for application only after the primer has completely dried. Avoid dusting the primed surfaces.

Mortar preparation:

To prepare the solution, the contents of the bag with constant stirring

pour into a container with clean water at the rate of 1

kg of dry mixture for 0.5-0.55 liters of clean water (for 1 bag of 20 kg - 10.0-11.0 liters of water) and mix until a homogeneous mass is formed.

It is necessary to mix the mixture in an amount that can be produced within 20-25 minutes.

Mixing is carried out using small-scale mechanization (professional mixer or electric drill with attachment) or manually. The solution must be kept for 1-2 minutes, then mixed again.

After that, the solution is ready for use. The solution can be used within 25 minutes after mixing with water.

When the viscosity of the solution in the container increases (within the pot life), it must be thoroughly mixed without adding water. To prepare the solution, use only clean containers, tools and water.

Work order:

When installing partitions from gypsum tongue-and-groove plates (GWP) mortar is applied in the horizontal and vertical grooves of the slabs to be laid.

Each plate to be mounted is pressed with force from above by the ridge of the next plate so that

so that excess adhesive flows out of the side seams.

The excess glue protruding in this case is removed with a spatula from the joint surface of the plates and returned to the container with glue. After drying, the detected irregularities are removed by grinding.

Installation of gypsum plasterboard (gypsum plasterboard) and gypsum fiber (gypsum fiber board) sheets on pre-leveled bases, the solution is necessary

apply with a notched trowel in continuous stripes around the perimeter of the sheet and in the center.

When installing gypsum plasterboard (GVL) on a base with irregularities of less than 20 mm, the solution is applied with a trowel pointwise

along the perimeter of the sheet at a distance of 25-30 cm and along the middle of the sheet in one or two rows at a distance of 35-40 cm.

On a base with irregularities of more than 20 mm, it is necessary to install beacons using

strips of plasterboard sheets about 10 cm wide.

Glue the strips with SR-26 PRO gypsum glue. Adjust the installation of beacons to eliminate drops using a level or plumb line. After the glue has completely dried, a sheet of gypsum board (GVL) is glued to the beacons. The mortar is applied with a notched trowel to the sheet in stripes around the perimeter and in the center.

Recommendations when performing work:

Lay rows of sheets with offset vertical seams. It is necessary to leave a seam 2 mm wide between the sheets, between

sheet and floor - 10 mm, between sheet and ceiling - 5 mm. Close up the seams between the sheets.

Plaster leveling putty SR 26 It is recommended to prepare the surface for painting with finishing putty SR-18 PRO. Observe the recommendations when performing work in the winter.

| Name | Indicators |

| Composition | high quality gypsum, mineral fillers, modifying additives |

| Colour | White |

| Application temperature | -10 ... + 30˚С |

| Water consumption for 25 kg of dry mix | 10.0 - 11.0 liters |

| Consumption of dry mix for the installation of GWP per 1m² | 1.5-2 kg |

| Consumption of dry mix per 1m² of surface when gluing gypsum plasterboard and gypsum plasterboard on a flat surface | 3-5 kg |

| Consumption of dry mix per 1m² of surface when gluing gypsum board and gypsum plasterboard on an uneven base (up to 20 mm) | 4-6 kg |

| Recommended adhesive layer thickness | 2-30 mm |

| Drying time of the layer | 24 hours |

| Adhesion to the substrate | ≥ 0.5 MPa |

| Pot life of the solution | at least 20 minutes |

| Shelf life | within 6 months from the date of manufacture |

Additional Information:

When starting repairs, we always want to choose the best and highest quality materials for our home, so that later we can enjoy the coziness and comfort.

Therefore, by choosing knauf perlfix glue, we take care of the reliable fastening of drywall sheets or insulation, and we are sure that they will last for many years.

Knauf perlfix is a dry mix (assembly mix) made with certain polymer additives.

Knauf perlfix glue is chosen by professionals, as it

- easy to work

- Has excellent sound and heat insulation qualities

- Made from environmentally friendly materials

Knauf perlfix is used only when working inside a building. This glue is not suitable for outdoor use.

Knauf perlfix 30kg is designed for gluing drywall sheets, as well as gypsum panels and other materials on various types of surfaces. It is worth noting that perlfix knauf glue is also suitable for working with uneven or already plastered surfaces. The only requirement is to observe the thermal regime, and not to work at temperatures below five degrees Celsius with a plus sign.

Knauf perlfix (the price of the product is indicated in the price list) is not picky, but before work it is still worth cleaning the work surface from various fats, dust, sand, paint and other elements. This will provide better grip for the knauf perlfix 30 kg.

Knauf perlfix (the price is presented on the store's website) is quite easy to prepare for use. knauf perlfix 30 kg is mixed in fifteen liters of water. After the mixture is completely dissolved, it is necessary to let it infuse for two minutes, and then stir for five minutes. Next, Perlfix Knauf glue is infused for no more than five minutes and re-mixed. That's it - the glue is ready to use!

Popular types of adhesives for working with gypsum material

In the building materials market in modern times, there is a huge assortment of various types of adhesives for slabs. If you don't know what kind of glue is right for your design, you can easily get confused in this variety. At the moment, there are several brands that have already managed to properly recommend themselves.

tongue-and-groove plates

Volma-montage

The photo shows that Volma-montage can be attributed to the first type of mounting glue. The composition of this type of glue is made of a gypsum binder, which combines well with a variety of mineral-based additives. The use of this glue allows you to achieve high-quality adhesion, retain moisture, and also make the installation of plates easy due to the simplicity of the preparation process.

We invite you to watch a video that highlights the subtleties of installing gypsum boards.

The use of such glue allows for frameless installation of tongue-and-groove plates in a vertical position. In addition, it is possible to strengthen gypsum components, as well as sheets of thermal insulation.

"KNAUF Fugenfüller"

Knauf Fugenfüller glue deserves a special place. The glue is a dry putty mixture, which is performed on plaster. It is used for sealing joints, as well as for filling surfaces. Such a product is considered not only economical in its cost, but also allows you to simultaneously use the material as an adhesive and putty. If you need to complete the construction in a short time, you should use Knauf Fugenfüller glue.

"Weber.cel gips"

Next, we should mention the Weber.cel gips glue. It is a white powder. In the process of its manufacture, gypsum, friction sand and various polymer additives were used. This mixture must be mixed with water during cooking. It is a durable type of adhesive designed to work with drywall, tongue-and-groove boards, and other types of soundproofing materials. It is applied with a spatula. Within a short period of time after application, the surface is capable of withstanding severe stress.

"IVSIL PLAST"

The presented glue is considered to be no less popular type. This type is made on a binder with polymer additives. This composition is very effective in working with gypsum fiber sheets.

"BOLARS Gipsokontakt"

Do not forget about this glue. Made on the basis of gypsum-sand with the addition of the required amount of polymer additives. The use of this material allows you to achieve high-quality installation of tongue-and-groove plates. Its scope includes indoor work.

When buying glue for installation work, you should rely not only on the qualities of the above manufacturers, but also on cost. Experts recommend purchasing glue only in large hardware stores in order to eliminate the likelihood of buying counterfeit products. Before proceeding with the use of glue, you should carefully read the instructions.

Glue VOLMA-Ceramic

Another mixture from the same manufacturer is made on the basis of Portland cement, fractional sand and various modifying additives. Dry tile adhesive VOLMA-Ceramic is more often used for finishing works. It is characterized by ease of use, high peel strength, plasticity.

Technical characteristics and scope

The tool is suitable not only for interior, but also for exterior facing work using different materials:

- Medium to small ceramic tiles. Will keep in dry and damp areas. Facing walls, floors.

- Medium and small size porcelain stoneware. In this case, Volma Ceramic is only suitable for laying on the floor.

- Clinker tiles.

The bases can be brick, PGP, gas and foam concrete, gypsum plasterboard, GVL. The main thing is that they are strong and dry. The adhesive can be applied to screeds, cement-based plaster, lime. For better adhesion, the surface is primed.

Characteristics of VOLMA tile adhesive:

- grey colour;

- hardens in a day;

- suitable 3 hours after dilution;

- begins to lose its adhesiveness after 10 minutes (open time);

- retains properties at a layer of 2–5 mm;

- the position of the tiles can be adjusted within 10 minutes after laying;

- air temperature, base - from +5 to + 30 ° C;

- 0.18–0.22 liters of water is spent for each kilogram of the mixture;

- adhesion to concrete - at least 0.5 MPa;

- frost resistance - F 35, withstands at least 35 freezing and thawing cycles.

Consumption depends on the surface, tools, layer thickness, approximately 1.3–4.5 kg for each m2 of base.

On sale there is a similar tile adhesive of the same company - VOLMA-Ceramic +. It is a little more convenient and reliable:

- open time is twice as long;

- you can correct the position up to 15 minutes;

- adhesion to concrete is more reliable - from 0.6 MPa.

Volma-Ceramic + is better stored. Loses little in quality after freezing, thawing, heat aging. The adhesion to concrete is reduced to 0.5 MPa. When stored in damp conditions, adhesion to this substrate is not lost.

Storage conditions and solution preparation

It is better to store Volma Ceramic glue in its original packaging. The warranty period is 12 months at normal humidity.

Prepare the solution like this:

- Pour the dry mixture into clean water with a temperature of +10 to + 20 ° C.

- Mix well. A construction mixer or drill with the right attachment will do.

- Wait 5-7 minutes and stir again.

When preparing the solution, the proportions indicated on the package are observed. If there is too much water, the tile adhesive loses its quality.

Useful video on the topic:

Operating procedure

When laying tiles, there are several steps:

- Apply the solution to the base surface. Apply a toothed trowel.

- Spread the adhesive evenly.

- Profile the surface with the trowel tines.

- Laying tiles.

- Strongly pressed with an offset.

- The seams are rubbed after 24 hours using a special grout.

Execution of works

Installation of tongue-and-groove plates

First, it is necessary to mark the premises for laying the first row of slabs. The first row of tongue-and-groove plates is mounted on a pre-leveled base. Apply the assembly adhesive into the existing grooves of the masonry elements. After that, the slabs should be pressed against each other according to the “groove-comb” scheme, and the protruding excess mortar should be removed with a spatula. The assembly of the rows of slabs is carried out with an offset of the vertical joints by at least 10 cm. The elements of the masonry must be laid within 15 minutes after the application of the mortar. The position of the masonry elements can be corrected with a rubber mallet within 10 minutes after installation. The horizontal control of the masonry is carried out using a level. To increase the strength and rigidity of the structure, every second row of slabs is attached to the walls using special metal corners.

Installation of gypsum plasterboard and gypsum fiber sheets

- For unevenness of the substrate up to 5 mm, apply the assembly adhesive with a notched trowel evenly over the entire sheet area. After that, the sheet should be pressed to the base and adjusted to the level.

- For unevenness of the base up to 20 mm, apply the assembly adhesive in portions along the perimeter of the sheet with a minimum interval, as well as in the center in one row along the sheet with an interval of 30 - 40 cm. After that, the sheet should be pressed to the base and adjusted to the level.

- If the unevenness of the base is more than 20 mm, the surface must be pre-leveled with drywall strips 10 cm wide, glued horizontally and vertically to the base. Plasterboard strips must be positioned at the level of the upper and lower edges of the sheet to be glued then, as well as every 60 cm of the width of the sheet. Then apply the adhesive solution using a notched trowel to the mounting plane of the sheet. Then the sheet must be pressed to the base and adjusted to the level.

Laying rows of gypsum board and gypsum plasterboard is carried out with an offset of the vertical seams. During installation work, a 5-7 mm gap must be left between the sheets. In the future, these seams are filled with special putty compounds. Technological gaps with a width of 10 mm should be left between the floor and the sheets to be glued, which are necessary to remove moisture from the solution.

General recommendations

Further work is recommended to be performed no earlier than 2 days after gluing gypsum plasterboard or gypsum fiber sheets.

All the above recommendations for use are correct at a temperature of + 21 ° C and a relative humidity of 60%. In other conditions, the setting and drying times of the material may vary.

ATTENTION!!!

Gloves must be worn to protect hands during work. Keep out of the reach of children. In case of contact with eyes and skin, rinse thoroughly with water.

Along with the above instructions for the use of the material, when carrying out work, one should be guided by the corresponding SP (SNiP) and instructions. The technical description does not replace the professional knowledge and skills of the contractor. If you doubt the possibility of using the material, you should test it yourself or contact the manufacturer for advice.

Laying tiles on GWP

Let me remind you that ceramic tiles are laid on flat walls with a deviation from the vertical level of no more than 2-3 mm per meter of length. The unevenness of the wall surface in the light should also not exceed 2-3 mm.

Correctly laid GWP partition allows you to get the necessary evenness without any problems. Moreover, if significant flaws were made during the installation of the GWP, the partition can be leveled with a gypsum plaster mixture. (For details, see the article Is it necessary to plaster tongue-and-groove slabs).

Waterproofing

The basis of the GWP board is gypsum and the surface of the GWP partition belongs to gypsum bases with high hygroscopicity. This means that the gypsum surface absorbs water well and gradually degrades in a humid environment.

In the classic version, the gypsum surface is protected from moisture with a two-layer deep penetration primer, followed by treatment with a coating polymer primer. For example, weber.tec 822.

However, the use of moisture-resistant boards GWP allows you not to waterproof the walls. Although the places of direct contact of the walls with water (shower, bath) are recommended in any case, they should be treated with a layer of waterproofing.

In addition, waterproofing with the use of a special waterproofing tape is mandatory at the junction of the walls from the PPG to the bathroom floor. This is especially true in apartments, where the walls were built instead of the destroyed plumbing booth. The destruction of the cabin, a priori, removed the waterproofing layer on the bathroom floor, it needs to be restored.

The choice of adhesive for laying tiles on GWP

In theory, any universal C1T class tile adhesive is suitable for laying tiles on gypsum, pre-primed surfaces. For example, Unis adhesives.

In practice, read the information on the packaging of the adhesive. The adhesive must be suitable for plaster substrates. For reinsurance, you can choose an adhesive that is designed for difficult substrates. For the paranoid, I recommend grade C2E glue. For example, LITOFLEX K80 glue.

By the way, the class of tile adhesive is deciphered as follows (EN 12004 standards):

- The letter C stands for cement glue;

- Number 2 - improved technical characteristics;

- Letter E - increased time of open application on the wall.

Grout selection

The main purpose of grouting joints between tiles is not decoration, but protection of the layer under the tiles from water and moisture.

When all of the above rules are followed, namely the use of moisture-resistant plates, abundant primer, waterproofing and the use of moisture-resistant glue, the choice of the type of grout does not matter. Any good quality grout will work, including mineral-filled cementitious grout like Ceresit or Atlas.

When in doubt, use an expensive two-component epoxy grout (Litokol Litochrom or Sopro Topas).

Usage

Average consumption of glue-foam for silicate and gypsum boards: for products up to 130 mm wide - 1 strip, for larger-sized 2 strips for each joint. When working, you should follow some recommendations.

- The surface is carefully prepared, cleaned of dust.

- The can is shaken for 30 seconds, placed in a glue gun.

- 1 row of blocks is placed on a classic mortar.

- Foam is applied from the 2nd row. The balloon is held upside down, the nozzle of the gun during application should be 1 cm from the surface of the GWP. The optimum jet thickness is 20-25 mm.

- When applied horizontally, the strips are not made longer than 2 m.

- The leveling of the slabs is carried out within 2 minutes, the position adjustment is possible no more than 5 mm. With a greater curvature, installation is recommended to be repeated, as well as when the elements are torn off at the joints.

- After a break of more than 15 minutes, the gun nozzle is cleaned.

Installation is recommended in heated rooms or in warm dry weather.

Brand overview

Among the manufacturers producing adhesives for tongue-and-groove plates, there are both well-known Russian brands and large foreign companies. In the classic version, the formulations are supplied in bags, it is better to store them in a dry place, avoiding direct contact with a humid environment. Package sizes may vary. For novice craftsmen, 5 kg bags can be recommended - for preparing a single portion of the solution.

Volma

Gypsum dry glue for installation of Russian-made GWP. It differs in a democratic price and availability - it is quite easy to find it on sale. The mixture is produced in the usual and frost-resistant version, withstands a drop in atmospheric temperatures down to -15 degrees, even when laying. Suitable for horizontal and vertical slabs.

Knauf

A German company known for the high quality of its building mixtures. Knauf Fugenfuller is considered a putty compound, but can be used for laying thin partitions and non-stressed structures. Has good adhesion.

Knauf Perlfix is another adhesive from a German brand. It is focused specifically on working with building gypsum boards. Differs in high bond strength, good adhesion to the material.

Bolars

The company produces a special glue "Gipsokontakt" for GWP. The mixture has a cement-sand base, polymer additives. Produced in bags of 20 kg, economical in consumption. The adhesive is intended for indoor use outside of a humid environment.

IVSIL

The company produces compositions in the Cel gips series, designed specifically for the installation of GWP and drywall. The product is quite popular, has a gypsum-sand base, good adhesion rates, and quickly hardens. Cracking prevents the addition of polymer additives to the composition.

Foam glue

Among the brands producing foam adhesives there are leaders. First of all, this is ILLBRUCK, which produces PU 700 compound on a polyurethane basis. Foam holds together not only gypsum and silicate boards, but is also used when joining and fixing bricks and natural stone. Hardening occurs in 10 minutes, after which the glue line remains reliable protection against any external threats, including acids, solvents, contact with a wet environment. 1 cylinder replaces a 25 kg bag of dry glue; with a seam thickness of 25 mm, it provides coverage up to 40 linear meters.

Also noteworthy is Titan with its Professional EURO foam adhesive, which is optimal for working with silicate GWPs. The Russian brand Kudo produces a composition with similar characteristics to Kudo Proff. Among the universal foam adhesives, the Estonian PENOSIL with its product StoneFix 827 is also of interest. The joint acquires strength in 30 minutes, it is possible to work with both gypsum and silicate boards.

Usage

The surfaces on which the assembly adhesive is used must be dry, clean and free of dust. For better adhesion, the surface should be primed and allowed to dry.

The GWP plates themselves do not require additional processing and wetting with water.

The glue is diluted in a clean container according to the instructions on the package. The dry mixture is poured into the water, not vice versa.

When installing partitions, glue is applied with a spatula to the adjoining grooves (end sides) of the plates. When installed on the plate, pressure is applied so that the adhesive is squeezed out of the joint.Excess glue is removed. The thickness of the joints between the tiles is more than 2 mm.