Advantages and disadvantages of different types of wood adhesives

| Glue type | Advantages | disadvantages |

| PVA | + affordable price

+ environmental friendliness + versatility + ease of use |

- insufficient strength

- afraid of moisture - collapses at high temperatures (+ 60 ° С) |

| Polyurethane | + high resistance to dynamic loads

+ inert attitude to temperature changes + moisture resistance + UV resistant |

- high price

- Strong smell |

| Based on organic resins | + bond strength

+ versatility + resistance to water and aggressive compounds + reasonable price |

- skin protection is required

- high consumption - it is required to mix the components precisely |

The best polyurethane adhesives for wood

If the adhesive composition requires increased reliability, long-term resistance to mechanical stress, resistance to moisture and negative climatic conditions, then it is advisable to use a polyurethane composition. When comparing 7 products, it was found which is better. The list contains 3 of them.

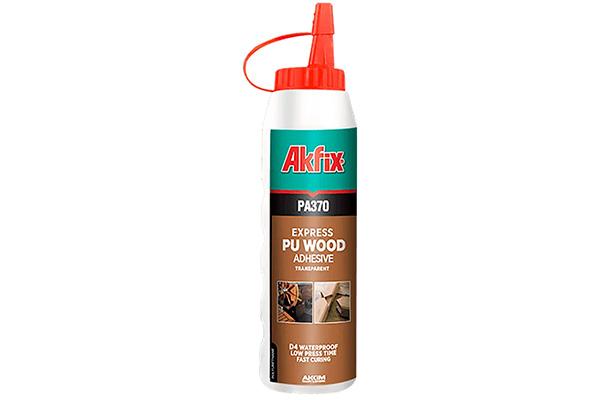

Akfix PA370 D4

Akfix PA370 is a ready-to-use 1-component polyurethane product that can reliably connect wood-based objects with metal, concrete, plastic in the shortest possible time. Effective for repair work in wooden floating equipment, due to its imperviousness to moisture and external factors. It must be remembered that when solidified, the product will slightly increase in size, increasing the quality of the joint.

Polyurethane glue for wood has proved to be excellent in joinery, in the manufacture of furniture frames, doors, joining multilayer elements in complex structures. To get the maximum strong connection, the temperature indicators of the external environment cannot be less than +5 degrees, and the elements to be glued are somewhat moistened. Dry fragments of the product can be easily removed with acetone. The maximum temperature indicators at which the seam will not lose its qualities are in the range of -40 + 100 degrees.

Advantages

- Convenient use;

- Low viscosity;

- Reliable gripping;

- Fast drying;

- Immunity to moisture;

- Heat resistance.

disadvantages

Flammability.

Based on the feedback, the tool will allow you to create reliable connections. Users note that the temperature range makes it possible to glue any material that is of wood origin.

Titebond Polyurethane Wood Glue 2300

The best wood glue made of polyurethane for wood, which is a breakthrough in the field of adhesive technology. The composition in question from a trademark from the United States occupies one of the leading places in this segment. The developer was able to strike a balance between the speed of hardening (45 minutes) and the time to maintain its qualities (20 minutes).

The product adheres firmly to all wood-based materials, from regular wood to wood shavings. The area of use is not limited to this: metal, plastic, stone and other materials are firmly glued. Differs in moisture resistance, however, in conditions of excessive humidity or under water, the resulting nodes cannot be left. The glue is not afraid of the cold, however, before use, it must be thoroughly warmed up to +12 degrees.

Advantages

- Fast setting;

- Versatility of operation;

- High bond strength;

- Resistance to moisture;

- Environmental friendliness of the material.

disadvantages

It is used only at +10 degrees.

Users note that the product is suitable for humid rooms, specific, does not dissolve in water.Not used for products that come into contact with food. Foams well, which is why it fills the space between the parts. Adheres wood to brick firmly.

The best paints for wood

PUR glue Kleiberit 501.0, D4

One of the best universal adhesives is considered to be products from the German brand Kleiberit 501.0. The basis of the product is polyurethane, which makes the material resistant to moisture and resistance to temperature extremes. The 1-component composition is easy to use, it is permissible to use it to connect 2 elements made of wood, as well as other combinations, for example, polyvinyl chloride, miniplates, ceramics, concrete, etc.

The operation of the formed nodes is possible indoors and outdoors, in the rain or scorching heat. Excellent adhesion quality is confirmed by international standards. The compound is completely cured after 24 hours.

Dignity

- Ease of operation;

- Short hardening time;

- Elasticity;

- Versatility of application;

- Resistance to aggressive environments;

- Resistant to temperature changes.

disadvantages

- Long-term drying;

- Corrosive aroma.

In the reviews of domestic buyers, mainly positive characteristics are noted. This composition is convenient to use, it will not drain, the seam will turn out to be reliable. However, it is difficult to wash your hands after work; in the process of gluing, it is necessary to ventilate the room.

Views

Based on the purpose and ingredients used to make wood glue, there is a wide range of products on sale. The most popular type of composition is PVA, it is familiar to everyone since childhood. This substance allows you to glue paper, wood and wood-containing materials. Its main requirement is the moisture absorption capacity of the raw material. The eco-friendly composition is a white liquid, thick in consistency, which, when solidified, becomes colorless. The main characteristics of the product include the fact that the glue dries quickly, is sold ready-to-use, the composition can be easily removed from the base if necessary, it can be diluted with water. On sale you can find various types of products that differ in their area of application.

Epoxy adhesive refers to a two-component product, the composition solidifies without the participation of air in the reaction. This product can be used not only for gluing wood, the material is often used to work with other types of raw materials. During the preparation of the composition, it is worth strictly observing the proportions, since errors in dosage will lead to the production of a foaming mass that is unsuitable for gluing. The solidification period of the substance varies depending on the brand of product.

Not so long ago, Glue BF belonged to the group of the strongest and most durable products for working with wooden bases. The scope of application of the composition includes gluing wood, iron, PVC, polyurethane foam and other raw materials. There are several types of this composition, but moisture-resistant BF-2 or BF-4 is best suited for fixing wood. The products are distinguished by a rather specific material processing technology, which boils down to applying a layer, drying and then compressing the elements with each other - this technique is needed for the strength of the splicing line.

Joiner's glue composition is considered furniture, since it is in demand in this particular area of production, in addition, the products are used for repairing musical instruments. The reason why such a product has not gained wide popularity is the complexity of the work, because it is sold in dry form, which requires a number of works to prepare it for use.

It includes several varieties - sturgeon, skin, bone glue. These are environmentally friendly products that are made from organic substances. Products are sold in granules, and glue is also produced in the form of grains.Fish glue is mainly used as a professional composition for repairing musical instruments. The latter refers to gelatinous products. The main feature of such a glue for wood is the ability to soak the compound in water, as a result of which the elements will move away from each other.

The syndeticone compound is necessary for fixing the tree to the tree. This is a homemade product that contains sugar, hydrated lime and wood glue.

Polyurethane glue is a super-strong material that has high quality characteristics and belongs to expensive products. Among the indisputable advantages, it is worth highlighting the moisture and frost-resistant nature of the product, due to which the composition is recommended for working with wood both indoors and outdoors. Moisture and frost-resistant composition has the effect of filling the plane, providing protection of materials and their joints. The expanding composition is allowed to work in the temperature range from -30 to +100 degrees. Can be used for hardwood.

Casein wood glue has a completely natural composition. Such products are sold in the form of granules or you can prepare them yourself at home. The composition is used for MDF, chipboard, fiberboard, parquet, printing and painting. With the help of casein composition, elite furniture is made.

Among the disadvantages of the product, it is worth noting the hygroscopicity of the material, as well as the possibility of mold formation on its surface, but with proper storage, unpleasant situations with the composition do not arise.

Paste adhesives are used as assembly products for sealing small voids that prevent moisture penetration. They are heat-resistant and cold-tolerant. A heat-resistant product for gluing wood is rarely used, but for work with uneven substrates, the product will be an indispensable assistant.

Criterias of choice

The choice of a suitable adhesive must be carried out in a complex manner.

To achieve the greatest efficiency, it is important to take into account the conditions under which the operation will take place, the features of the surface to be treated, the ambient temperature and humidity, the external effect on the product and other nuances.

Appointment

When purchasing glue for wood products, it is important that it has a high setting speed and viscosity, which will make it easier to work on a vertical surface. Such adhesive solutions are based on polymer compositions that provide increased adhesion.

When choosing a suitable glue option, it is necessary to clearly indicate the purpose of the application. Depending on the application, immediate grasping or the creation of a strong seam that has good strength may be required.

Features of the tree

When buying, it is worth finding out the characteristics of the processed wood in order to understand how hard the wood species is and what type it belongs to. Depending on the structure of the material, the appropriate form of glue, its physical characteristics and the method of application are selected.

Temperature and humidity

Not all types of adhesive solutions are able to fulfill their purpose when exposed to high or too low humidity and ambient temperatures. The deviation of the indicators from the standard values provokes a change in the viscosity of the adhesive. An increase in the relative humidity of the atmosphere lowers the viscosity of the adhesive, as a result of which the hardening process and the increase in bond strength are slowed down.

Product load

For products that are in a static position and do not undergo stress, the indicator of the load that the joint formed by the glue can withstand does not really matter. If the products are located at a height or are exposed to external influences, you should first determine the level of load and select the appropriate type of glue.

Environmental friendliness

On an industrial scale, adhesive solutions are often used that do not have a high environmental friendliness.

When performing work in a domestic environment, you should pay attention to the composition of the substance and its safety for health and the environment. As a rule, most manufacturers mark the environmental friendliness of products with the appropriate green marking.

Water resistance

In order to determine the level of water resistance of the joint formed when using a particular type of adhesive, the corresponding standard developed in Europe is applied. Certification of substances for load groups D1-D4 is carried out taking into account the results of laboratory tests of glued products.

D1

Glue with a category of water resistance D1 is used for processing products in rooms with a temperature not exceeding 50 degrees (only a temporary increase is allowed). The mortar is suitable for application to wood with a moisture content of up to 15%.

D2

Substances of category D2 are intended for internal use with short-term exposure to liquid or condensation. At the same time, due to external influences, the moisture content of the wood should not exceed 18%.

D3

D3 water resistance means outdoor use. Short exposure to liquid is allowed. Adhesives in this category are highly adaptable to fluctuations in moisture levels.

D4

Category D4 is suitable for various indoor and outdoor applications. The glue joints are resistant to negative environmental influences.

The best resin based joinery adhesives

Composition of various resins has many beneficial properties. It will not change the shade of the processed wood, has excellent adhesion, high strength and electrical insulating qualities. However, when working with adhesive, proper ventilation of the room and the use of personal protective equipment are required. When comparing 7 products, it was found which is better. The list contains 3 of them.

Moment Joiner

Composition based on epoxy resin, an excellent product from domestic manufacturers. With the help of the composition, it is permissible to combine various wood species, plywood, MDF, fiberboard, chipboard, plastic with paper inclusions. The surfaces to be glued must be pressed for a quarter of an hour with a clamp or a vice. The full drying time of the elements before use will be 1 day. The tool does not change the shade of the processed material, which will increase the scope of its use. The tool can be used at positive temperature readings from +5 to +30 degrees.

Experts and amateur craftsmen note the following characteristics of Moment Joiner: short drying period, reliability, availability, transparency at the end of solidification. The disadvantages include sensitivity to moisture and low temperature indicators.

Dignity

- Transparency at the end of drying;

- Convenient use;

- Fast drying;

- High initial adhesion.

disadvantages

Poor moisture resistance.

It is made on the basis of epoxy resin, therefore it is not toxic to the user. Economical consumption is noted, effective for all types of wood.

Titebond moisture resistant joinery

1-component adhesive for gluing wood materials. Possesses a high class of water resistance, it is effectively used for outdoor work: assembling furniture in the garden, birdhouses, mailboxes. The composition is distinguished by strong initial adhesion, fast hardening, creates a reliable seam, and is well processed. The downside will be susceptibility to moisture and negative temperature parameters.

Dignity

- Connection reliability;

- Versatility of operation;

- Fast setting;

- Exposure period in clamps;

- Cutting tools do not deteriorate during the processing of the joint.

disadvantages

- Weak water resistance;

- Large spending.

Users note a strong adhesion of the adhesive in a short period.The disadvantage is the rapid expenditure of funds.

Uhu Plus Endfest 300

Two-component universal glue for wood has good adhesion performance. It is made of epoxy resin, which will allow materials of different origins to be glued to the processed wood object. An exception will be glass items. The composition hardens for 1.5 hours, the compounds are completely ready for use within 12-24 hours. The seam will acquire shock resistance, wear resistance and moisture resistance.

To make a working solution, you need to mix 2 ingredients, following the instructions of the developer. Then the components are thoroughly mixed until a homogeneous consistency is formed. The finished composition is applied with a brush or a spatula. Among the advantages of the glue from the German brand, the emphasis is on high strength, resistance to mechanical influences, moisture. Differs in reliable initial adhesion, high adhesion.

Dignity

- Reliability;

- Immunity to moisture;

- Strong hitch;

- Connection with wood of any objects;

- Does not conduct current.

disadvantages

- Proportions must be observed;

- It is necessary to prepare a working solution.

Based on the reviews, the adhesive composition has increased strength, immunity to mechanical influences, moisture.

How to choose the best wood glue for wood

The choice of a suitable adhesive material must take into account a number of requirements. Let's list the most important criteria.

1. Purpose

All funds are divided into universal and highly specialized. The latter cope with their task as efficiently as possible. However, buying them is not always justified. So, if you need to repair, for example, a small photo frame, it is impractical to buy an expensive super-strong and waterproof product. PVA or its analog is suitable

It is important to understand the features of the product and its operation. A quick-set mixture may be required for a vertical joint.

A part under load requires a particularly strong connection, etc.

2. Features of wood

The characteristics of the material, the features of its processing, depend on the type of wood. The adhesive mass must match them exactly. It is a little more difficult if different types of wood are combined. Each has its own characteristics. In this case, choose especially carefully.

Which wood glue is better to buy

When choosing wood glue, buyers are often confused by the variety of offers. Our rating is compiled with the aim of helping users understand which wood glue will best cope with specific tasks.

Before making an important decision, we recommend that you consider the following factors:

- The type of wood, taking into account the penetration (adhesion) ability.

- What materials will you work with, what to glue with what, in what combinations.

- What loads will the glue seam subsequently experience?

- Operating conditions, this includes temperature conditions, drops, humidity level.

The choice of the best wood glue should also be based on the recommendations of experienced craftsmen, builders, positive and negative feedback from users.

Akfix PA370 D4

Akfix PA370 is a ready-to-use 1-component polyurethane product that can reliably connect wood-based objects with metal, concrete, plastic in the shortest possible time. Effective for repair work in wooden floating equipment, due to its imperviousness to moisture and external factors. It must be remembered that when solidified, the product will slightly increase in size, increasing the quality of the joint.

Polyurethane glue for wood has proved to be excellent in joinery, in the manufacture of furniture frames, doors, joining multilayer elements in complex structures. To get the maximum strong connection, the temperature indicators of the external environment cannot be less than +5 degrees, and the elements to be glued are somewhat moistened. Dry fragments of the product can be easily removed with acetone.The maximum temperature indicators at which the seam will not lose its qualities are in the range of -40 + 100 degrees.

Advantages:

- Convenient use;

- Low viscosity;

- Reliable gripping;

- Fast drying;

- Immunity to moisture;

- Heat resistance.

Disadvantages:

Flammability.

Based on the feedback, the tool will allow you to create reliable connections. Users note that the temperature range makes it possible to glue any material that is of wood origin.

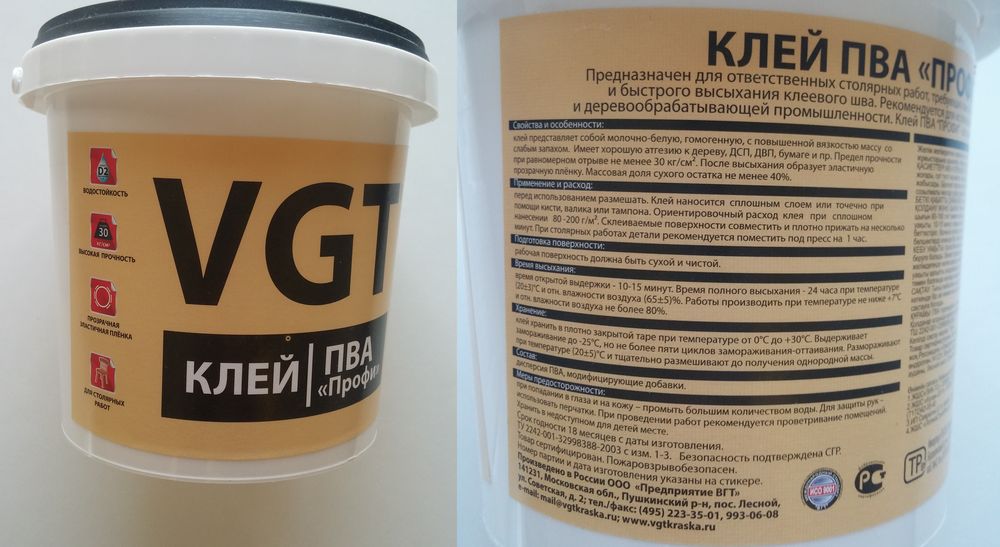

Polyvinyl acetate and heat resistant adhesive

PVA universal construction adhesive

PVA universal construction adhesive

PVA glue refers to those types that quickly glue surfaces from various materials, it takes about 20 minutes. The final hardening of wooden parts takes place after 24 hours. The solidification of such a composition occurs as moisture is absorbed into the surface and then evaporated. PVA glue does not contain harmful substances in its composition, therefore it is often used to repair various wooden products that are in household use. Another positive quality is the ability to retain its properties well in tightly closed packaging for a long time.

He also has a significant disadvantage - this is the lack of resistance to moisture. They are not recommended to glue parts and surfaces that are constantly in contact with water. For these purposes, there is a thick yellow PVA that is easy to sand.

When the question arises, which glue is better to buy for gluing wood subjected to different thermal influences, the answer is one: buy a heat-resistant one. These formulations:

- do not collapse even at very high temperatures;

- do not stick surfaces;

- do not break the wood structure.

It should be noted that these formulations are sold in special rods. In order to use them, you need to purchase a special, so-called glue gun. This option is the best and very convenient if you need to glue small objects. The product can be applied with a pistol in a very thin layer. A significant plus of these compositions is that it takes a very short time to solidify - a few seconds.

Bone glue

Application area. The best option for the restoration of old furniture, including antique ones.

Working properties. The adhesive material is designed for drying under high pressure. Bone glue provides a reversible gluing of wood to wood: the connection can be disassembled using water or alcohol.

Compatible with finishing compounds. The glue is tinted with aniline dye to match the final finish.

Open time: 30 minutes.

PUR glue Kleiberit 501.0, D4

One of the best universal adhesives is considered to be products from the German brand Kleiberit 501.0. The basis of the product is polyurethane, which makes the material resistant to moisture and resistance to temperature extremes. The 1-component composition is easy to use, it is permissible to use it to connect 2 elements made of wood, as well as other combinations, for example, polyvinyl chloride, miniplates, ceramics, concrete, etc.

The operation of the formed nodes is possible indoors and outdoors, in the rain or scorching heat. Excellent adhesion quality is confirmed by international standards. The compound is completely cured after 24 hours.

Advantages:

- Ease of operation;

- Short hardening time;

- Elasticity;

- Versatility of application;

- Resistance to aggressive environments;

- Resistant to temperature changes.

Disadvantages:

- Long-term drying;

- Corrosive aroma.

In the reviews of domestic buyers, mainly positive characteristics are noted. This composition is convenient to use, it will not drain, the seam will turn out to be reliable. However, it is difficult to wash your hands after work; in the process of gluing, it is necessary to ventilate the room.

Composition of various resins has many beneficial properties.It will not change the shade of the processed wood, has excellent adhesion, high strength and electrical insulating qualities. However, when working with adhesive, proper ventilation of the room and the use of personal protective equipment are required. When comparing 7 products, it was found which is better. The list contains 3 of them.

One- and two-component PVA adhesives

Speaking about which PVA glue is better for wood, it is worth noting that there are two types of these compositions - one-component and two-component. The first option is versatile and suitable for working with wood indoors. The second type assumes the additional presence of a hardener in the composition, has a high level of moisture resistance and is recommended for use outdoors.

Any composition, for example, PVA glue Moment Joiner, in the case of rare use tends to delaminate. In addition, over time, a precipitate forms in the mass. Therefore, before each use, the mass must be shaken well.

The use of glue in combination with finishing compounds is a dangerous business. Traces of dried sticky mass show through under a layer of varnish or stain.

The open time is the same for both types of glue. And it is equal to 3-5 minutes.

Where are applied

Adhesives based on polyvinyl acetate are used in joinery work.

Their main areas of use are:

- production and repair of various furniture;

- interior decoration of premises (as a rule, floor surface).

One of the frequently asked questions by people sounds like this: is it possible to add PVA glue to the whitewash for trees? The answer is unequivocal - yes, you can! A joinery is perfect for this purpose. It will improve the protective characteristics of the whitewash mixture, as a result of which it will become resistant to different temperature conditions and precipitation.

Advantages of joinery PVA

PVA joiner's glue has gained well-deserved popularity due to its impressive list of its advantages.

From the reviews, several important ones can be distinguished:

- fairly economical consumption;

- the most elastic seam that is not subject to temperature extremes and bends;

- the ability to work with high humidity;

- environmental friendliness of the material due to the absence of toxins in the composition.

Based on this, it is one of the most popular for working with furniture and wood, in general among all types.

Disadvantages of carpentry PVA

Like any product, joinery PVA, along with positive aspects, also has negative ones. This product has only one significant drawback, which is weak moisture resistance. This only applies to pure glue. Since it contains a liquid, when exposed to water on the dried mass, it can begin to exfoliate.

But PVA manufacturers have long found a way out of the situation and began to add additional components to their products that enhance the resistance of the composition to moisture. So, now on store shelves you can find adhesives with inscriptions on the packaging "D2", "D3" or "D4" - it is on them that you should be guided when buying an adhesive mass.

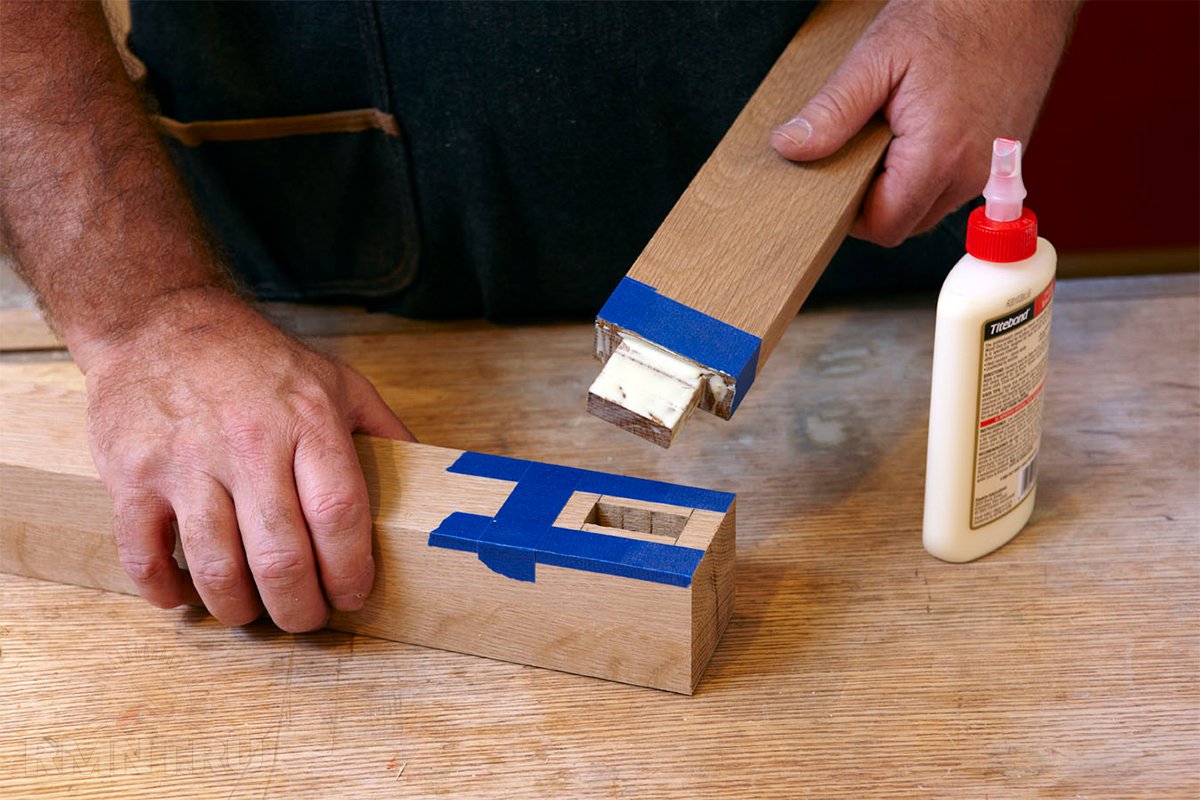

How wood is glued

This process can be carried out both with the help of one glue, and with additional fasteners (self-tapping screws, pins and dowels). The gluing technology depends on the type of connecting elements.

Watch the video:

What is the essence of gluing

The parts are preliminarily cleaned and processed to expose the pores. When the adhesive is applied, it penetrates deep into the wood.

When wood is glued together, when it dries, the solution is converted into many thin threads, which reliably connect the parts together. If the seam is strong, the joint is stronger than the pieces of wood themselves.

It is recommended to choose parts that are similar in texture and color, exclude damaged and cracked ones, as well as with protruding pods.Unlike solid wood, glued wood is less likely to deform and crack.

There are different technologies for gluing wood:

- on a smooth puffer. Method of joining smooth parts;

- on a microthorn. A similar technology for gluing wood is carried out by increasing the penetration of the solution to a thickness of up to 5 mm;

- a jagged surface is formed on the parts;

- on a spike of a toothed type. Increases penetration up to 10mm when creating a serrated tenon;

- on the thorn-groove (or in other words the sprue-comb). Fusion by connecting the groove elements.

Bonding process

When wood is glued, the adhesive is most often applied to both blanks in an even layer. Its thickness largely depends on the type of glue and consistency, as well as the type of surface (the thinner - the less glue is required).

When joining two parts, the solution should come out in the form of a uniform roller. All streaks must be removed immediately after the first stage of hardening. It is better to do this with a scraper or spatula. If excess glue hardens, it will ruin the whole picture and prevent further surface treatment.

You will learn more from the video:

After applying the composition, wooden elements must be kept for a certain amount of time. So the glue will penetrate deeper, all the moisture will evaporate and the adhesion substances will concentrate. During this period, do not keep the seam in a draft and expose the surface to the penetration of dust particles.

Some formulations are applied hot to instantly bond the elements. In this situation, holding is not required.

The glued wood is pressed using special compression equipment to achieve a stronger adhesion. At home, you can use a vise and metal frames with a clip. The pressure range should be maintained within 0.2-1.2 MPa. This is enough for home making.

If the technology is followed correctly, the result is reliable and durable. Unlike metal fasteners of parts, gluing does not spoil the appearance.

There are a lot of adhesives on the market

Varieties of joinery adhesives

These are classic compositions.

- Glutinic. The raw materials for them are fibers that are found in cartilage, ligaments, tendons, bones and even the skin.

- Mezdrovye. These adhesives are made from animal skins.

- Bone. In terms of the reliability of the joints of wooden parts, they are somewhat inferior to analogues.

- Casein. The most common joinery adhesives in everyday life. The basis is cow's milk (skim). In the composition of at least 8 different components (phenol, turpentine, liquid glass and a number of others), therefore, such joinery adhesives are considered universal.

- Fish. They are classified by grade depending on the raw materials used. For the higher, for example, the swim bladder is taken. Other waste from fish processing is used for the production of lower grades - scales, heads, intestines. It is these compositions that are used in carpentry. In addition, they are much cheaper.

Application

To ensure a high level of strength of the connecting seam, you should competently approach the preparation of the elements for fixation. The wood must be well sanded, sawdust removed, and dust or existing dirt must be removed. If you plan to work with wood and porcelain, or with glass, acrylic surface or plastic, the material must be degreased. Acetone works well for this.

A two-component polymer product involves several application options - in the first case, the compositions are mixed, forming a homogeneous composition, in the second option, each ingredient is applied to one of the materials, after which they are fixed with each other.

Varieties of wood glue are applied in two layers, allowing the previous one to harden a little. For flat elements, you can apply one layer, evenly spreading it along the location of the fibers on the material.For a more effective connection, the elements must be placed under a press or pressed against each other in some other way.

Quick-drying compounds do not need additional pressure

However, attention should be paid to the leakage of the substance at the junction - all excess must be promptly removed from the bases

Manufacturers rating

For wood, ready-made adhesives on a synthetic basis are more in demand. Among the brands that have proven themselves on the market for such products on a positive side, it is worth highlighting several manufacturers.

Titebond - formulations that are produced by an American company. The specialization of the products is the manufacture of furniture from wood and wood-containing materials, work with floor coverings, including tiles, finishing of various structures with wooden elements. The formulations include artificial and natural ingredients, do not contain solvents and resins, which ensures a high level of adhesion of the bases to each other. In the review of the products of this manufacturer, the product "Titebond ii premium" should be highlighted, which is recommended for fixing paper products, wooden elements, in demand for the manufacture of doors and window blocks, chairs and other furniture. The products are allowed to be used for work outdoors and indoors. With the help of such adhesives, they decorate facades with wooden fittings.

"Moment" is a product of a German concern, widely used in the industrial and domestic spheres, the composition is relatively cheap, therefore it is convenient for minor and major repairs. Quite often, these products are used to repair kitchen utensils - waterproof glue glues mugs, cutting boards, etc.

"Titan" is a multipurpose compound that glues wood, glass, plastic and paper with high quality. It is sold in different containers - from 60 g to 1 liter. Among the assortment, one can single out glue-mastic, which is used for repair and finishing work with wood.

PVA furniture Kleiberit 303.0

It is not difficult to find a composition with the best technical characteristics and resistance to liquid, because PVA Kleyberite glue is sold in every specialized store. It has long held an honorable place in the ranking, and the quality of the product has been tested by time and experienced craftsmen, who praise this brand in everything.

The adhesive has universal properties. It allows you to combine different types of wood, as well as finished wood-shaving products, veneer. The main highlight of the composition is the ability to reliably bond hard and exotic wood.

It is important that after applying the mass to the surfaces to be joined, the parts are firmly squeezed together for 10 minutes at a temperature of more than 10 degrees Celsius. And when the glue dries up and the wooden elements become almost impossible to separate, the composition will acquire a whitish color, and the level of its frost resistance will reach 30 degrees below zero.