Substrate preparation and instructions for use

In order for the tiles to stick reliably to the surface, you need to provide them with optimal load-bearing capacity.

It is important to remove all fragile areas, sand them, completely remove traces of paint and plaster. Then the irregularities must be leveled with plaster, let it dry completely before gluing the tiles (usually the process takes 3 days)

The floors are leveled with a suitable floor mortar.

Also, all contaminants that potentially reduce the adhesion of the composition should be removed from the base:

- dust;

- dirt;

- fat;

- bitumen;

- butter.

If a cement screed is applied on the floor, wait at least 28 days until a moisture content of 4% is reached. Only then is the priming and laying of the tiles done. Wood bases are primed with special agents 1-2 times. Do the same with various plates, drywall. OSB plates, paint coatings are treated with coarse sandpaper and dedusted.

A notched trowel or square-notched trowel is used to apply the adhesive. Glue the glue with a trowel, put it on the base, level it with a spatula. Press the tile as hard as possible, repeat the work further, not forgetting about the tile joints. Butt-laying of tiles is not allowed. When installing large-format objects, stone, and facade work, glue is applied to the surface of each tile and to the base. The thickness of the glue line is from 3 mm, it depends on the complexity of the work and the size of the tile.

The traces of glue on the face of the tile are removed immediately with a wet cloth. After they have solidified, you will have to do mechanical cleaning. Grouting is carried out after the time recommended by the manufacturer. Do not allow the solution to come into contact with the skin, eyes

For this, it is important to follow preventive measures, wear gloves, protective clothing and glasses. Compliance with all the tips guarantees excellent results when working with tiles and other types of finishing materials

Peculiarities

Ceresit adhesives for laying tiles differ in their field of application, which can be recognized by the marking on the package:

- CM - mixtures with which the tiles are fixed;

- SV - materials for fragmentary repair of cladding;

- ST - assembly mixtures, with the help of which they arrange external thermal insulation on the facades.

Ceresit CM 11 glue is a material with a cement binder as a base, the addition of mineral fillers and modifying additives that enhance the technological properties of the final product. Porcelain stoneware or ceramics are fixed on it when carrying out internal or external types of finishing of premises at objects of housing and civil purposes and the industrial sector. It can be combined with any typical non-deformable mineral substrates: cement-sand screed, concrete, plaster leveling coatings based on cement or lime. Recommended for rooms experiencing constant or short-term regular exposure to the aquatic environment.

CM 11 plus is used for cladding with ceramics or natural stone with a maximum size of 400x400 and a water absorption value of 3 percent. According to SP 29.13330.2011. Floors ", it is also allowed to plant tiles (porcelain stoneware, stone, clinker) with a water absorption capacity of less than 3% for floor cladding without electric heating. In these cases, the composition is used exclusively when carrying out interior finishing work in household and administrative premises, that is, where operation does not imply high mechanical loads.

Product characteristics

The tile adhesive must have certain qualities and characteristics.Compositions from the German brand Ceresit have all the necessary functions.

CM11 product has the following properties:

- an environmentally friendly product, safe to use due to its special composition, while under the influence of high temperatures, the glue does not emit harmful volatile elements;

- excellent indicator of frost resistance;

- the mortar is resistant to slipping, retaining its shape and strength from year to year;

- high adhesion to the surface;

- the composition demonstrates excellent moisture-repellent properties, which are required for adhesives used in bathrooms and other similar locations;

- the product is suitable for work both outside and inside buildings;

- Ceresit CM 11 can be used for installing large tiles, the size of which reaches 50x50 centimeters.

The technical parameters of the product make it in demand in the conditions of repair.

- The product is diluted in water before use. For 25 kilograms, you will need 6 liters of liquid (an approximate ratio of 1: 4).

- The ready-made solution can be used for 1.5-2 hours. After which it dries, and the mixture cannot be applied.

- Air humidity indicator - 80%.

- The minimum temperature indicator for using the mixture is 5 degrees Celsius, the maximum is 30 degrees Celsius above zero.

- The "open" working time of the layer is 25 minutes.

- The maximum slippage of the tiles is no more than 0.5 millimeters.

- Consumption per 1m2 - from 1.7 to 4.2 kilograms.

- Complete drying takes 24 to 36 hours.

- The shelf life of the product in a whole package is one year.

Preparatory work

Facing works are performed on substrates with a high load-bearing capacity, treated in accordance with sanitary standards, which means cleaning them from contaminants that reduce the adhesion properties of the adhesive mixture (efflorescence, grease, bitumen), removing fragile crumbling areas and dedusting.

To level the walls, it is advisable to use Ceresit CT-29 repair plaster mixture, and for floors - Ceresit CH leveling compound. Plastering work must be carried out 72 hours before tiling. Construction defects with a height difference of less than 0.5 cm can be corrected with a mixture of CM-9 24 hours before fixing the tile.

For the preparation of typical substrates, CM 11 is used. Sand-cement, lime-cement plastered surfaces and sand-cement screeds more than 28 days old and less than 4% moisture require treatment with CT17 soil, followed by drying for 4-5 hours. If the surface is dense, solid and clean, then you can do without a primer. In cases of preparation of atypical bases, a combination of CM11 with CC-83 is used. Plastered surfaces with a moisture content of less than 0.5%, wood-shaving, particle-cement, gypsum bases and bases made of light and cellular or young concrete, whose age does not exceed a month, and the moisture content is 4%, as well as sand-cement screeds with internal heating priming with CN94 / CT17 is recommended.

Claddings made of stone tiles or stone imitations, surfaces treated with high-adhesion water-dispersion paintwork materials, floating screeds made of cast asphalt need to be treated with CN-94 primer. Drying time is at least 2-3 hours.

Recommendations when working with Ceresit 17 glue:

Work should be carried out in dry conditions, at an air and base temperature from +5 to + 30 ° C and a relative air humidity not exceeding 80%.

Notes:

The product contains cement and, when interacting with water, gives an alkaline reaction, therefore, when working with it, it is necessary to protect the eyes and skin. If the mixture gets in your eyes, rinse them with water and seek medical attention.

All stated quality indicators and recommendations are valid for an ambient temperature of + 20 ° C and a relative humidity of 60%. In other conditions, the technical characteristics of the material may differ from those indicated.On substrates with low absorbency, the drying and curing time of the adhesive, as well as the time it takes to be ready for grouting and loading the tiles, can be significantly increased.

In addition to the technical description, when working with the material, one should be guided by the relevant building codes and regulations of the Russian Federation. The manufacturer is not responsible for non-compliance with the technology when working with the material, as well as for its use for purposes and conditions not provided for in this technical description. If in doubt about the possibility of a specific application of the material, you should test it yourself or consult the manufacturer. The technical description, as well as unconfirmed recommendations in writing, cannot serve as a basis for the unconditional liability of the manufacturer. With the appearance of this technical description, all previous ones become invalid.

Storage conditions:

In dry conditions, on pallets, in original undamaged packaging - no more than 12 months from the date of production.

Package:

You can buy Ceresit CM 17 glue from one 25 kg bag. The price is for one bag. Discounts are given for the volume.

Instructions for use

Before using Ceresit tile adhesive, you must carefully prepare the base. This is necessary in order to fully utilize the high adhesive properties of the mortar. It is recommended to remove the old base as much as possible, clean and level the surface.

The vertical surfaces should first be marked and set at the level of the first tiled row. This will prevent the cladding from slipping during the first 6 hours of installation.

- After mixing the solution, start working immediately. Apply with a flat spatula 200–300 gr. solution on the prepared plane.

- Use a notched trowel to create a ribbed structure. The depth of the grooves is adjustable depending on the size of the tile. The smaller the tile, the less unevenness.

- Apply the veneer within 10-15 minutes. So that the solution does not have time to grab. Tap a little with a rubber mallet in order to evenly sink the tiles and release excess air.

- The contact volume of the tile with the mortar should be 60–80%.

- Lay adjacent areas in parallel, leaving a distance of 1–5 mm. To ensure even installation, use cross-shaped dividers between the tiles.

- Remove excess glue immediately with a rubber spatula and warm water.

- Leave to fully adhere for 20–36 hours.

- After drying, fill the joints with grout.

Instructions for the use of glue Ceresit CM 11

Ceresite 11, in order to obtain the best indicator of reliability and strength of the material-to-surface connection, requires the correct work

It is important that the surface is well prepared. The stages of laying tiles with Ceresit glue will be described below.

To get the best indicator of the reliability and strength of the connection of the material to the surface, it requires the correct work.

To get the best indicator of the reliability and strength of the connection of the material to the surface, it requires the correct work.

How to breed

The rules for diluting the composition are simple, adhering to the principle of work, a homogeneous solution is obtained. If you add an elasticizer to the mixture, the fixing time will increase to 3 days. Dilute the glue according to the instructions:

- The required amount of the mixture is poured into a prepared container.

- Pour water with a temperature of 15 to 20 degrees, the required amount is indicated on the package.

- If required, add an elasticizer.

- All components are mixed together, you can use a construction mixer, or a drill with a nozzle.

- Having received a homogeneous mass, it is left for five to seven minutes.

- After the required time has elapsed, the glue mass is mixed again.

- If the mass is too thick, it is permissible to add water, but you need to calculate no more than 5 mm. per kilogram.

Having received a homogeneous mass, it is left for five to seven minutes.

Having received a homogeneous mass, it is left for five to seven minutes.

Preparation of the base

Wall and floor requirements include evenness and reliability. During the preparatory work, they begin with cleaning the surface from all types of dirt, and the old finishing material should also be removed.The surface is degreased, leveled, applied plaster mixture, it is better to use the products of the same company, manufacturers create solutions that are ideally suited to each other. If the density and strength of the substrate are good, then a primer can be dispensed with. In other cases, surface priming is required.

The surface is degreased, leveled, applied plaster mixture.

The surface is degreased, leveled, applied plaster mixture.

Work execution process

On the vertical part, you need to make a markup, also install a bar marking the 1st level of tile laying. In this way, material slipping can be avoided. Next, perform the following actions:

- You need to start applying the ready-made solution immediately, working with a flat spatula, apply glue to the surface.

- Pass through the mixture with a notched trowel, the depth of the ribbing is determined based on the size of the material.

- There are 10-15 minutes before the solution hardens, so you should have time to apply the tile to the surface during this time, tap the tile with a rubber hammer.

- The covering area of the tile material with a solution should be 60-80%.

- The entire wall is also trimmed, a distance of 1-5 mm is left between the tiles, it is convenient to use cross-shaped dividers to maintain the evenness of the laying.

- When excess glue protrudes on the front side, they are immediately removed with a rubber spatula and wiped with a damp cloth.

- The glue should dry for 20-36 hours, after which it will be possible to gently walk on the floor tiles.

You need to start applying the ready-made solution immediately, working with a flat spatula, apply glue to the surface.

Drying time

How long the CM 11 glue will dry is influenced by humidity and temperature indicators. The norm is taken as indicators of +20 degrees and 60% humidity. In low temperatures plus high humidity, it will take longer to dry. Hardening of the solution in the container begins in 3-4 hours, setting takes place in 15-25 minutes. Dries completely and gets final strength in 7-11 days.

How long the CM 11 glue will dry is influenced by humidity and temperature indicators.

How long the CM 11 glue will dry is influenced by humidity and temperature indicators.

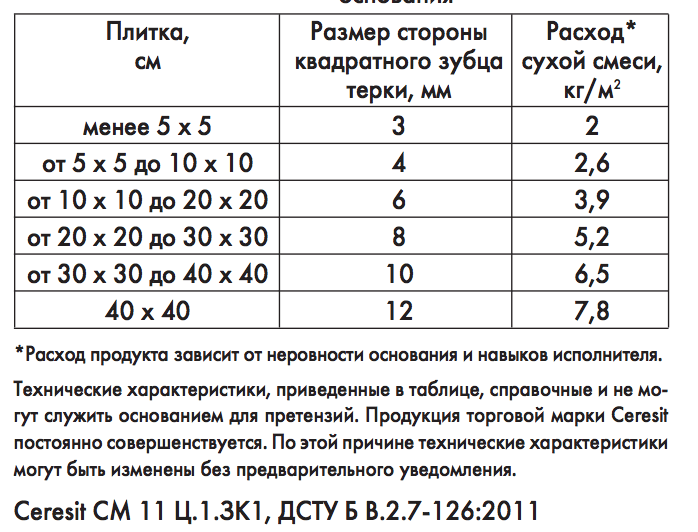

Recommendations for use

- A notched trowel or a notched trowel is suitable for applying cement tile adhesive, in which a smooth side is used as a working side. The shape of the teeth should be square. When choosing the height of the tooth, they are guided by the tile format, as shown in the above table.

- If the consistency of the working solution and the height of the teeth are selected correctly, then after the tiles are pressed to the base, the surface of the walls to be faced should be covered with an adhesive mixture by at least 65%, and floors - by 80% or more.

- When using Ceresit CM 11, the tiles do not need to be soaked beforehand.

- Butt-laying is not allowed. The width of the seams is chosen based on the tile format and specific operating conditions. Due to the high fixing ability of the glue, there is no need to use ditches, which provide evenness and the same width of the tile gap.

In cases of stone cladding or facade work, a combined installation is recommended, which implies additional application of an adhesive mixture to the mounting base of the tile. When forming an adhesive layer (thickness up to 1 mm) with a thin spatula, the consumption rate will increase by 500 g / m2.

The joints are filled with the appropriate grouting mixtures under the CE marking after 24 hours from the end of the facing work.

To remove fresh residues of the mortar mixture, water is used, while dried stains and drips of the solution can be removed exclusively with the help of mechanical cleaning.

Due to the content of cement in the composition of the product, when it comes into contact with liquid, an alkaline reaction occurs

For this reason, when working with CM 11, it is important to use gloves to protect the skin and avoid contact with the eyes.

Views

For the installation of screeds on bases with internal heating and work with deformable bases in the Ceresit - Henkel line of adhesives there are highly elastic mixtures CM-11 and CM-17 with low-modulus CC83 filler.By adding this elastomer, the final product acquires the ability to withstand shock and alternating loads. In addition, the presence of an elasticizer in the composition prevents the formation of microcracks in the binder base.

Highly elastic SM-11 can:

- to carry out external facing of floors and walls with any existing types of tiles;

- arrange screeds on bases with underfloor heating;

- to make cladding of plinths, parapets, external flights of stairs, private areas, terraces and verandas, flat roofs with an angle of inclination up to 15 degrees, outdoor and indoor pools;

- to veneer deformable foundations made of fiberboard / chipboard / OSB boards and gypsum plasterboards, gypsum, anhydrite, lightweight and cellular concrete bases or recently poured under the age of less than 4 weeks;

- work with ceramics, including glazed ones outside and inside;

- perform tiling work on surfaces with durable paint, gypsum or anhydrite coatings that have good adhesion.

For cladding with marble, light-colored clinker, glass mosaic modules, it is recommended to use CM 115 white. Large-format floor tiles are laid using CM12.

Glue specifications

Ceresit glue is a cement composition with the addition of fillers and synthetic modifiers, which qualitatively increase the characteristics of the finished material. It is a free-flowing mixture in packages of 5 and 25 kg. for dilution with water.

- The amount of water for diluting the working consistency per 25 kg. 6-7 liters. 5 kg. - 1-1.3 liters.

- Possibility to add CC 83 modifier to increase the flexibility of the mixture after drying.

- The mobility of the solution (the ability to spread under its own weight) is low.

- The base temperature for normal operation with a solution is from +5 to + 30˚С.

- The setting time is 15 minutes.

- The position of the elements on the solution can be corrected for 20–25 minutes.

- The time before grouting the inter-joint space on the walls is from 8 hours, on the floors from 16 hours.

- Withstands temperature fluctuations from -50 to + 70˚С.

- Withstands at least 100 freezing cycles.

- Slip resistant. Deformation indices do not exceed 0.5 mm.

All values operate under average temperature and humidity conditions. Temperature: + 20˚С. Relative humidity: 60% - Specifications may vary under other conditions. So at low humidity and elevated temperatures, the mobility of the solution decreases and the setting time is shortened.

Technique of work and qualifications of the master

In order for the finish to be durable and beautiful, the work must be done correctly and it must start with the correct choice of building mixtures.

If you yourself cannot determine what is best suited for those and other works, then you can always turn to the services of a qualified specialist. He will not only tell you which glue is better to use, but also tell you about the technique for performing the work.

It is as follows:

- First you need to prepare the base. If it has strong deviations, then level with a leveling compound or similar material to the optimum level.

- Thoroughly saturate the entire surface with a deep penetration primer.

- Carry out the markings on the floor or wall surface and start to work, spreading with an even layer of the selected thickness, for example, 4, 6, 8 and 10 mm, depending on the size of the tile and the parameters of the notched trowel.

Laying tiles is a difficult and time-consuming task, so it is better to entrust the work to an experienced specialist with high qualifications. But if it is critical, then try your hand, guided by the instructions of the masters.

Execution of works:

To prepare the mixture, take a measured amount of clean water with a temperature of +15 to + 20 ° C or CC 83 elasticizer diluted with water (see the table for the proportion).

The dry mixture is gradually added to the liquid with stirring, achieving a homogeneous mass without lumps.

Stirring is carried out with a mixer or a drill with a nozzle at a rotation speed of 400-800 rpm.

Then maintain a technological pause for about 5 minutes to ripen the mixture and mix again.

The adhesive is applied to the substrate with a smooth trowel and the comb structure is profiled with a notched trowel.

The size of the teeth is chosen depending on the size of the tiles (see table).

If the cladding will be exposed to moisture and frost, as well as in the case of translucent tiles, it is recommended to additionally apply a continuous thin layer of adhesive to the mounting surface of glass or clinker tiles ("combined fixing method").

Do not soak the tiles! The tile is laid on white ceresite glue on white cement and pressed no later than 20 (15) minutes after its application, while the glue sticks to the hands.

The position of the tiles can be adjusted within 25 minutes after laying.

The area of adhesive contact after pressing the tiles should be at least 65% on walls and 80% on floors.

Tiles must not be installed end-to-end! The width of the joints is set depending on the size of the tiles and the operating conditions.

It is recommended to fill the facing joints with Ceresit CE 40 grout no earlier than 24 hours after laying the tiles.

Fresh glue residues can be easily washed off with water, dried ones can only be removed mechanically.

Recommendations:

Work should be carried out in dry conditions, at an air and base temperature from +5 to + 30 ° C and a relative air humidity not exceeding 80%.

Notes:

The product contains white cement and gives an alkaline reaction when interacting with water, therefore, when working with it, you must protect your eyes and skin. If the mixture gets in your eyes, rinse them with water and seek medical attention.

All stated quality indicators and recommendations are valid for an ambient temperature of + 20 ° C and a relative humidity of 60%. In other conditions, the technical characteristics of the material may differ from those indicated. On substrates with low absorbency, the drying and curing time of the adhesive, as well as the time it takes to get ready for grouting and loading the veneer, can be significantly increased.

In addition to the technical description, when working with the material, one should be guided by the relevant building codes and regulations of the Russian Federation. The manufacturer is not responsible for non-compliance with the technology when working with the material, as well as for its use for purposes and conditions not provided for in this technical description. If in doubt about the possibility of a specific application of the material, you should test it yourself or consult the manufacturer. The technical description, as well as unconfirmed recommendations in writing, cannot serve as a basis for the unconditional liability of the manufacturer. With the appearance of this technical description, all previous ones become invalid.

Storage conditions:

In dry conditions, on pallets, in original undamaged packaging - no more than 12 months from the date of production.

Package:

You can buy ceresite white glue for marble and mosaic CM 115 both wholesale and retail in 25 kg paper bags. The retail price is indicated above, request wholesale discounts by phone.

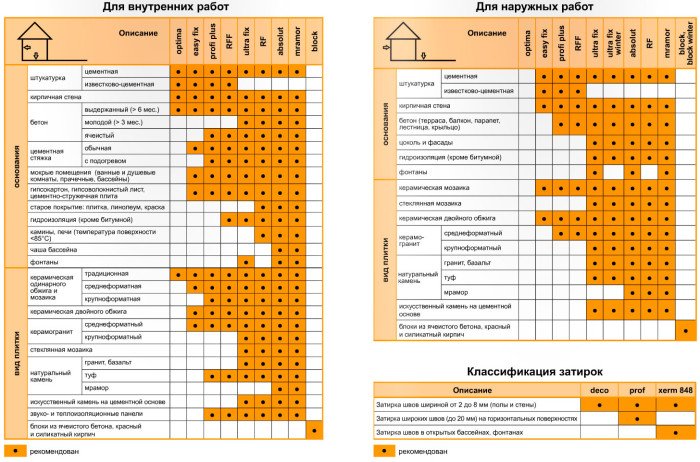

Scope and variety of adhesives

Dry building mixes "Ceresit" are produced by Henkel and are used for external and internal work, for walls and floors, various types of bases. The range of tile adhesives is huge; there are universal and specialized products on sale. All compositions of "Ceresit" differ in the field of application, and for the convenience of determining the purpose they have the following marking:

- SM - building mixtures for fixing ceramic tiles;

- SV - adhesives for fragmentary repair of the lined surface;

- ST - mixtures for the installation of external (facade) thermal insulation.

The purpose of the funds is different, the user can always find the right solution. Standard adhesives of the CM brand have high adhesion to brick, concrete, are used for laying tiles, tiles, mosaics, porcelain stoneware indoors and outdoors (for example, "Ceresit CM 110"). Some adhesives, due to their moisture resistance, can be used in the bathroom, other wet rooms. Elastic adhesives will help to fix the finishing material on surfaces prone to vibration and shrinkage. There are also special adhesives of the CM series for:

- large-format floor tiles;

- mosaics and marble (white adhesives);

- clinker;

- facade tiles.

The CT line includes ready-to-use products and dry mixes for outdoor use. The most popular with builders are the following compositions:

- CT 84 polyurethane adhesive for expanded polystyrene (used for the installation of external thermal insulation of facades);

- CT 190 plaster and adhesive mixture (CT190 is used for the installation of mineral wool boards and the base plaster layer for facade thermal insulation);

- CT 85 plaster mix for expanded polystyrene boards (for indoor and outdoor use).

In the CB 10-100 series, acrylic and other assembly adhesives in cylinders are produced, with which they work inside and outside the premises. All of the indicated Ceresit adhesives can only be attached to tiles and thermal insulation materials, and for laying other coatings, you should select specialized compounds (for example, UK 400 for PVC and linoleum). Each glue has a certificate of conformity confirming its high quality.

Consumption rates

Ceresite

| Name | Max. tile side length, cm | Comb teeth size, mm | Consumption, kg per sq. m |

|---|---|---|---|

| Ceresit CM 9 (for ceramic tiles) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 20 | 8 | 3,2 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 11 Plus (for tiles and porcelain stoneware) | 5 | 3 | 1,7 |

| 10 | 4 | 2 | |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 12 (for porcelain stoneware and large tiles) | 30 | 10 | 4,2 |

| 60 | 12 | 6 | |

| Ceresit CM 14 Extra | 15 | 6 | 2,7 |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| 45 | 12 | 6 | |

| Ceresit CM 16 (elastic) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 17 (super elastic) | 10 | 4 | 1,5 |

| 15 | 6 | 2,1 | |

| 25 | 8 | 2,7 | |

| 30 | 10 | 3,2 | |

| 40 | 12 | 4,1 | |

| Ceresit CM 115 (marble and mosaic) | 10 | 4 | 2,5 |

| 15 | 6 | 3,4 | |

| 25 | 8 | 3,9 | |

| 30 | 10 | 4,4 | |

| Ceresit CM 117 (flexible adhesive for facade tiles, stone and porcelain stoneware cladding) | 10 | 4 | 1,8 |

| 15 | 6 | 2,5 | |

| 25 | 8 | 3,2 | |

| 30 | 10 | 3,6 | |

| 40 | 12 | 4,7 |

When using the elasticizer Ceresit CC 83, it is diluted with water 2 to 1 and used to mix the mixture.

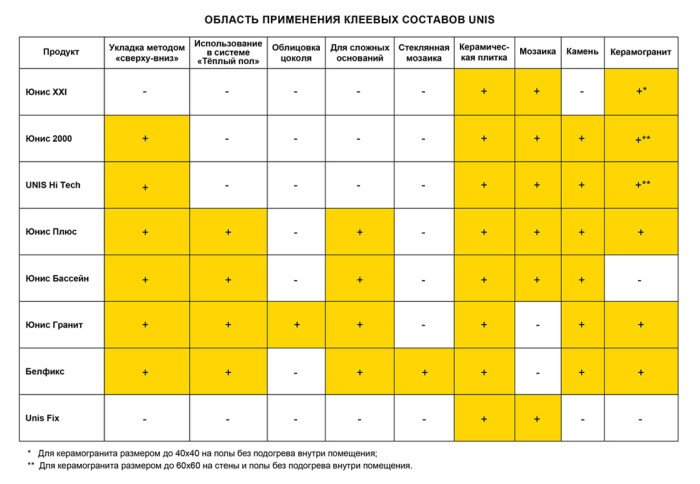

Eunice

Eunice tile adhesive selection table

| Name | How much tile glue is needed per 1m2 when using a 6 * 6 mm comb | Recommended layer thickness, mm |

|---|---|---|

| Eunice Plus | 3,5 | 3-15 |

| Eunice 2000 | ||

| UNIS XXI | ||

| Unis HiTech | ||

| Eunice Granite | 3-10 | |

| Eunice Belfix | ||

| Unis Fix | 3,5-5 | 3-15 |

| Eunice Pool | 3,1 | 3-6 |

Hercules

| Name | Average consumption with a layer thickness of 1 mm, kg / sq. m | Max. layer thickness, mm |

|---|---|---|

| Universal GM-35 | 1,53 | 20 |

| Superpolymer GM-45 | 1,53 | |

| For porcelain stoneware GM-55 | 1,53 | 20 |

| Elastic GM-195 | 1,43 | |

| For underfloor heating GM-125 | 1,49 | |

| Heat resistant GM-215 | 1,81 | 20 |

| Strong GM-115 | 1,53 | 20 |

| For GM-165 mosaic | 1,33 | |

| Aqua-stop GM-145 | 1,49 | |

| Base GM-25 | 1,53 | 10 |

Vetonite

Adhesive selection table Vetonit

| Name | Average consumption with a layer thickness of 1 mm, kg / sq. m | Max. layer thickness, mm |

|---|---|---|

| Optima | 1,29 | 10 |

| Easy fix | 1,29 | 15 |

| Granit fix | 1,29 | 15 |

| Profi plus | 1,35 | 15 |

| Ultra fix | 1,29 | 15 |

| Ultra fix winter | *3-3,5 | 15 |

| Mramor | 1,29 | 15 |

| Absolut | *3-3,5 | 30 |

| weber.vetonit RF | *3-3,5 | 15 |

| weber.vetonit RFF | *3-3,5 | 15 |

* Consumption is indicated in kg / sq. m when working with a spatula with teeth 6 * 6 mm.

Kreps

| Name | Glue consumption, kg / m2 | Approximate cladding area using packaging 25 kg, m2 |

|---|---|---|

| A plus | 2-4 | 8 |

| Aqua | ||

| Base | ||

| Standard | ||

| Super | ||

| Kreps Prostoklei | ||

| Reinforced | 2-3 | |

| Express | ||

| White Reinforced |

Plitonite

| Name | Length of the longest side of the tile, mm | Comb teeth height, mm | Dry mix consumption, kg / m2 | The area of the laid tiles when using 15 kg of glue, m2 |

|---|---|---|---|---|

| Plitonite A | 4 | 1,8 | 14 | |

| 109-200 | 6 | 2,7 | 9 | |

| 201-250 | 8 | 3,6 | 7 | |

| 251-300 | 10 | 4,5 | 6 | |

| Plitonite B | 4 | 1,7 | 15 | |

| 109-200 | 6 | 2,6 | 10 | |

| 201-250 | 8 | 3,4 | 7 | |

| 251-300 | 10 | 4,3 | 6 | |

| > 301 | 12 | 5,1 | 5 | |

| Plitonite B profi | 4 | 1,7 | 15 | |

| 109-200 | 6 | 2,6 | 10 | |

| 201-250 | 8 | 3,4 | 7 | |

| 251-300 | 10 | 4,3 | 6 | |

| > 301 | 12 | 5,1 | 5 | |

| Plitonite C light | 51-108 | 4 | 1 | 15 |

| 109-200 | 6 | 1,5 | 10 | |

| 201-250 | 8 | 2,1 | 7,1 | |

| 251-300 | 10 | 2,6 | 5,8 | |

| > 301 | 12 | 3,1 | 4,8 | |

| Plitonite Bb | 51-108 | 4 | 1,8 | 14 |

| 109-200 | 6 | 2,6 | 9 | |

| 201-250 | 8 | 3,5 | 7 | |

| 251-300 | 10 | 4,4 | 6 | |

| > 301 | 12 | 5,3 | 5 | |

| Plitonite B super floor | 109-200 | 6 | 2,9 | 9 |

| 201-250 | 8 | 3,9 | 6 | |

| 251-300 | 10 | 4,9 | 5 | |

| > 301 | 12 | 5,9 | 4 | |

| >401 | 15 | 7,3 | 3 | |

| Plitonite SuperFireplace ThermoGlue (W) | — | — | 1,4-4,5 | 25 kg per 9 m2 with 6 mm notches |

| Plitonite -AquaBarrier HydroGlue | 3 | 1,3 | *19 | |

| 51-108 | 4 | 1,7 | *14 | |

| 109-200 | 6 | 2,6 | *9 | |

| 201-250 | 8 | 3,5 | *7 | |

* The area of the laid tiles when using a bag of 25 kg.

Suite

The Belarusian manufacturer Typhoon does not indicate the exact consumption for the Lux and Lux Plus tile adhesive. The approximate consumption of kg per square meter is from 2 to 4.

| Name | Approximate consumption, kg / m2 |

|---|---|

| Standard | 3-5 |

| A plus | |

| Suite | |

| Premium | |

| Quick |

| Name | Consumption, kg / m2 |

|---|---|

| Knauf Fliesen | 2,2-2,9 |

| Flizen Plus | 1,7-3,7 |

| Flex | 2,2-2,9 |

| Marble | 2,3-2,9 |

EC

| Name | Consumption of dry mix when working with a spatula with teeth 6 * 6 mm, kg / m2 |

|---|---|

| EK 1000 WIDE | 3,4 |

| EK 2000 KERAMIK | 3,3 |

| ЕК 2000 KERAMIK ECO | 3,3 |

| EK 3000 UNIVERSAL | 2,8 |

| ЕК 3000 UNIVERSAL ECO | 2,8 |

| EK 4000 TITAN | 2,7 |

| ЕК FAST FIX | 2,7 |

| EK 5000 AQUA | 2,7 |

| EK 6000 MOZAIK | 2,8 |

| EK 8000 KAMIN | 2,7-2,8 |

Bolars

| Name | Average consumption when using a 6 mm comb, kg / m2 | Max. layer thickness, mm | Cladding area with one bag 25 kg, m2 |

|---|---|---|---|

| Base | 3-3,5 | 10 | 8 |

| Standard | 3-3,5 | 10 | 8 |

| Elastite | 3-3,5 | 6 | 8 |

| A plus | 2,7-3,2 | 6 | 8 |

| Granite | 2,7-3,2 | 6 | 8 |

| Aqua plus, for pools | 2,5-3 | 6 | 9 |

| Elite | 2,5-2,8 | 6 | 10 |

| Express | 3 | 6 | 8 |

What does the expense depend on?

When cladding walls with ceramic, porcelain stoneware, marble or other types of tiles, one of the selection criteria is consumption. This is a variable value that different craftsmen will have their own, which depends on many factors.

For example, it is worth considering professionalism as a fundamental point. If the master is experienced, then his losses will be minimized, but if the work is performed by a beginner, then when buying a building material, a margin of at least 5% should be taken into account for losses.As for the consumption, it varies within certain limits depending on the properties and type of materials.

For example, dry Ceresit CM 9, provided that the thickness of the adhesive layer is no more than 2 mm, and the size of the tiles is less than 10 cm, then at least 2 kg / m2 will be required.

| Name of glue | Max. tile side length, cm | Comb teeth size, mm | Consumption, kg per sq. m |

|---|---|---|---|

| Ceresit CM 9 (for ceramic tiles) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 20 | 8 | 3,2 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 11 Plus (for tiles and porcelain stoneware) | 5 | 3 | 1,7 |

| 10 | 4 | 2 | |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 12 (for porcelain stoneware and large tiles) | 30 | 10 | 4,2 |

| 60 | 12 | 6 | |

| Ceresit CM 14 Extra | 15 | 6 | 2,7 |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| 45 | 12 | 6 | |

| Ceresit CM 16 (elastic) | 10 | 4 | 2 |

| 15 | 6 | 2,7 | |

| 25 | 8 | 3,6 | |

| 30 | 10 | 4,2 | |

| Ceresit CM 17 (super elastic) | 10 | 4 | 1,5 |

| 15 | 6 | 2,1 | |

| 25 | 8 | 2,7 | |

| 30 | 10 | 3,2 | |

| 40 | 12 | 4,1 | |

| Ceresit CM 115 (marble and mosaic) | 10 | 4 | 2,5 |

| 15 | 6 | 3,4 | |

| 25 | 8 | 3,9 | |

| 30 | 10 | 4,4 | |

| Ceresit CM 117 (flexible adhesive for facade tiles, stone and porcelain stoneware cladding) | 10 | 4 | 1,8 |

| 15 | 6 | 2,5 | |

| 25 | 8 | 3,2 | |

| 30 | 10 | 3,6 | |

| 40 | 12 | 4,7 |

We also recommend looking at - Knauf tile glue: varieties, application

How to calculate consumption per 1 m2

To calculate the Ceresit CM11 tile adhesive consumption per 1 m2, you just need to multiply the average consumption indicated by the manufacturer in the instructions by the thickness of the applied layer. It is equal to 1.3 kg / m2. For example, a 4 mm layer is made on a 30x30 tile. As a result, he receives the required amount of glue. Thus, the consumption is influenced by: the size of the tiles, the skill of the paver, the level of preparation of the base.

The consumption is influenced by: the size of the tiles, the skill of the installer, the level of preparation of the base.

Ceresit glue stands out among its analogues for its excellent adhesion property to different materials, adhesion strength. Working with glue is easy. You can carry out the facing work yourself, without resorting to the services of professionals, which will significantly save your budget. It is important to carry out high-quality surface preparation.