The choice of insulation

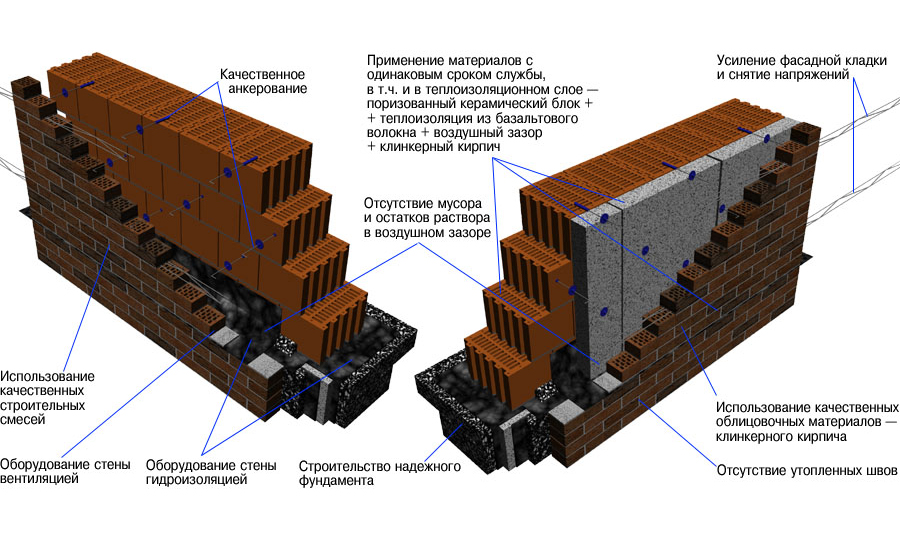

As a heat-insulating material, a wide range of heaters can be used that meet the recommendations of SNiP.

Firstly, the thermal conductivity of the material should be such as to ensure the protection of the internal premises at the maximum negative values characteristic of the given region.

Secondly, the insulation must have sufficient vapor permeability. Otherwise, moisture will accumulate inside it, which will lead to a loss of its thermal insulation qualities.

And thirdly, the internal insulation must be fire resistant. Due to its incombustibility, it will not only not support combustion, but also create a fire retardant layer inside the masonry.

Mineral wool

Mineral slab

Mineral slab

Numerous family of mineral fiber-based insulation materials have excellent heat-saving characteristics. They are made by whipping molten minerals in a centrifuge: glass, basalt, slag, etc. A low level of heat transfer in this case is achieved due to the high porosity of the material - air gaps do not allow cold to penetrate through the mineral wool.

Mineral insulation is absolutely non-flammable, but it is very afraid of dampness. When wet, it almost completely loses its heat-saving properties, therefore, when laying it, it is necessary to take care of an effective waterproofing device.

Expanded polystyrene

Expanded polystyrene is another thermal insulation material often used in three-layer masonry.

Expanded polystyrene sheets

Expanded polystyrene sheets

It is produced by saturating liquid polystyrene with air, which, after solidification, takes the form of porous round granules. For filling wells in the wall, it can be used in sheet form or as bulk material. It is much less afraid of dampness than mineral wool, but unlike it is flammable, so walls insulated with expanded polystyrene should be protected from open fire. Even if the fire does not damage the brickwork, it will cause the styrofoam inside to burn out and melt. To replace the insulation, you will have to carry out time-consuming and expensive work to dismantle the facing part of the wall.

Bulk insulation

In private construction, sometimes three-layer masonry is made with backfilling of internal wells with various mineral fillers: slag, expanded clay, etc. This technique is somewhat cheaper and simpler than laying min-boards or expanded polystyrene sheets, but its effectiveness is much lower. This is due to the lower thermal protection of slag and expanded clay.

Slag is very hygroscopic - it tends to absorb and retain moisture, which can cause an increase in its thermal conductivity and premature destruction of adjacent brick layers.

SNiP requirements

All building stones that are used in the construction of structures must be selected in accordance with the standards for various types of building materials, which also determines SNiP. Brick that is used for outdoor masonry must have a rectangular shape and clear edges. Each building stone is visually inspected by a master before laying.

And it is also important to properly prepare the solution, which should have a mobility of no more than 7 cm.To ensure such parameters, it may be necessary to add various components to the cement mixture, including plasticizers, lime and chemical additives

These components are introduced depending on the requirements of the manufacturer.

In winter, it is recommended to keep the temperature of the solution not lower than +25 degrees. If conditions do not allow adhering to such a temperature, then it is necessary to add plasticizers to the solution.

Also SNiP determines that it is prohibited to use building stones that do not have appropriate certificates, especially when erecting residential buildings.

A bit of theory

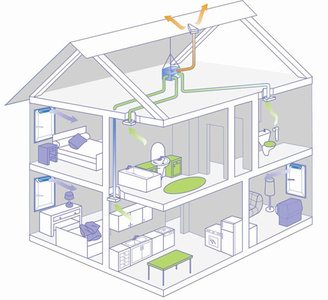

At the beginning of our story, we will consider the most important theoretical aspects that you need to know. Without this knowledge, the procedure for creating a ventilation system will not be crowned with success.

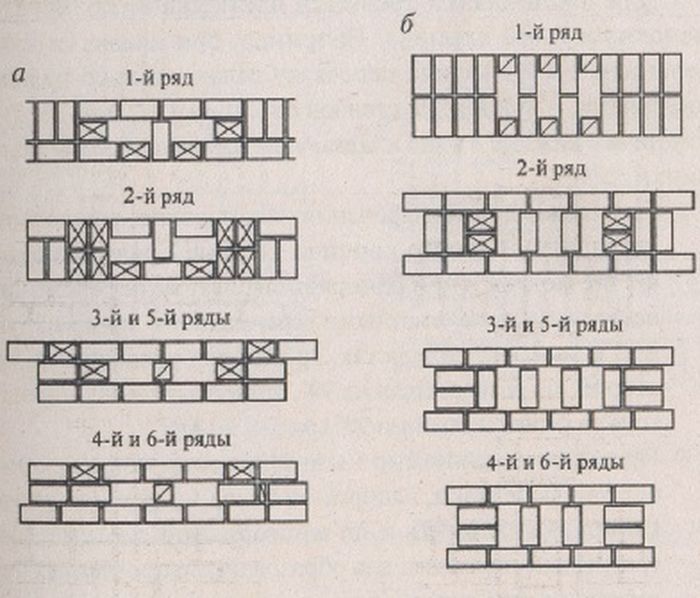

The order of the masonry channel for a wall of one and a half bricks

Methods for organizing the ventilation system

Today, two methods of ensuring air circulation in rooms are actively used: natural and mechanical.

Natural

It involves the implementation of air exchange due to the pressure difference inside the building and outside it. When using this technique, fresh air will enter the room through organized openings in the ceilings.

In this case, the laying of brick ventilation ducts should be carried out even at the stage of building a house. In order to increase the efficiency of such a system, it is recommended to install a deflector in the channels.

It is a special aerodynamic device that creates an area of reduced pressure. With an increase in the amplitude of this indicator, the thrust increases.

Mechanical

Such a project is much more difficult to implement with your own hands, but it gives a higher efficiency to the system. It consists in the use of various fans or ejectors. They are installed directly into ventilation shafts.

It is worth noting the advantages of this method:

- The thrust is increased several times compared to the natural system.

- Allows you to install special filters that will clean the air from dust.

- It is possible to create climate control in the house by installing split systems.

- It does not depend in any way on weather conditions, therefore, it is able to create favorable conditions even in regions with a harsh climate.

Combined ventilation system

However, among all these advantages, one serious drawback slips - the impressive price. In particular, the costs will be for the purchase of special equipment and for electricity (also learn how to organize a brick chimney with your own hands).

Primary requirements

The first step is to familiarize yourself with the list of basic requirements in order to know what to strive for. These instructions are contained in SNiP 2.04.05-86. which affects the aspect of ventilation and air conditioning.

In this photo you can see the mine, which is designed for two rooms at once. This solution is very reasonable, since it reduces the number of operations.

- A brick ventilation shaft should be built only if there is a design scheme for the building and in compliance with all rules and regulations.

- To remove air from heated rooms, it is necessary to create a ventilation system with natural impulse. The combustion products from the furnaces must be removed by means of the flue duct.

- It is necessary to place brick ventilation ducts taking into account fire safety rules. In particular, they should not be located in the immediate vicinity of stoves or fireplaces. If this rule is not taken into account, in the event of a fire, they will become ignition catalysts.

- Ventilation grilles must be such that their cells are always open. It is desirable that they do not have vertical protrusions.

The lattice can be decorated and then the hole will acquire a presentable appearance.

- The dimensions of the ventilation ducts made of bricks for the chimney must be such that the required cross-section is ensured.

You need to choose it based on the thermal power of the furnace:

- 14x14 cm - with a power of no more than 3.5 kW.

- 14x20 cm - with a power of 3.5-5.2 kW.

- 14x27 cm - with a power of more than 5.2 kW.

Factors on which thrust depends

In the cold season, the temperature difference between the outside and the premises will be significant. In such a situation, the amount of exhaust air is significantly increased. Simply put, the warmer it is outside, the less thrust is required.

Thrust is the speed at which air currents travel.The amount of air removed from the room directly depends on it. Also, this indicator is influenced by the cross-sectional area of the ventilation duct. The larger it is, the stronger the craving.

As a result, it can be noted that for the cold regions of our country, a more efficient ventilation system is required.

Tip: The lower the temperature, the faster condensation forms. Therefore, mines ventilation ducts in cold regions need to be coated with antiseptics.

How much does it cost to build a masonry

Used bricks can be used for the ventilation duct

Used bricks can be used for the ventilation duct

Despite the popularity of monolithic and frame housing construction, brickwork from piece materials is still in demand during construction. Experienced craftsmen with certain skills and knowledge can do the work qualitatively. If it is planned to invite specialists to perform this type of work, then an estimate must be drawn up. It is influenced by:

- number of storeys of the building;

- area of premises;

- geometric complexity of channels;

- dressing with already existing masonry;

- the need to finish sedimentary seams;

- type of material and its price, etc.

At the same time, the speed of work does not depend on such characteristics of the brick as strength grade, frost resistance, color preferences. Therefore, these parameters do not affect pricing.

Refined calculations take into account the real costs of working time for each type of work performed (man-hours). After the timing of each construction operation, its exact duration is determined. Having these data, as well as the size of the average wage for a specific region, you can calculate the hourly rate using the formula:

P = C / V,

where:

Р - tariff (rub.);

С - salary (average) (rubles / day);

V - duration of work per day (hour).

Example

The team performs the laying, working 12 hours a day. With an indicator C = 900 rubles / day, the cost of work for 1 hour will be: 900/12 = 75 rubles per hour.

It is also taken into account that the tariff for laying, for example, a hollow one-and-a-half brick will be much lower. This is justified by the higher speed of work execution.

The number of piece units in a unit of masonry volume in this case will also be less. All this explains why the prices for this type of service in different regions, at different objects are different.

A properly executed ventilation system in the house will help maintain optimal microclimate parameters, promote clean air in it, and prevent the formation of pollution in the ducts and heat loss.

Technique of work

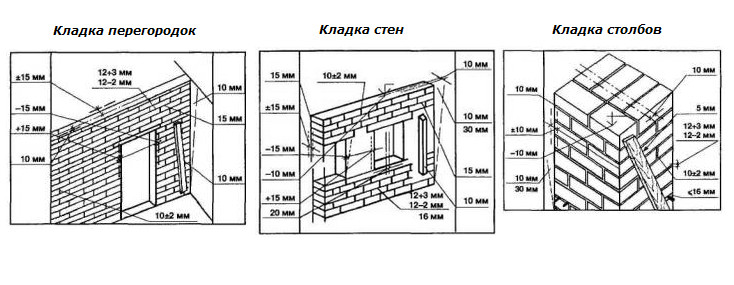

An important point in the construction of a brick wall is the laying technique. There are two main ways of doing this. The choice depends on the quality of the building material, the plasticity of the cement mortar and the weather, which affects the time of its hardening.

Press

This method is suitable when the cement is not plastic, and the reference cone goes into the solution by about 9 cm. The solution is laid out with an indent from the front side by about one and a half centimeters.

- There is a trowel in the right hand, a brick in the left.

- The solution is applied with a trowel to the bed - row below.

- Part of the concrete is scooped up with the edge of the trowel to the vertical edge of the adjacent stone.

- A stone block is placed with the left hand.

- The element is pressed, tapped to shrink. The remains of the solution are removed with a trowel.

Inspiring

Thus, the elements are laid on elastic cement when the cone sinks 14 cm.

- The mortar is spread evenly over the entire surface of the masonry.

- Each new element moves to the previously laid in such a way that when moving, an influx of cement is obtained on its face. That is, the solution ended up on a spoon or a stick - depending on the styling.

- At the same time, both vertical and horizontal seams are filled at the same time.

- The surplus is removed with a trowel.

Pexels

Unsplash

Rules for the construction of brick ventilation ducts

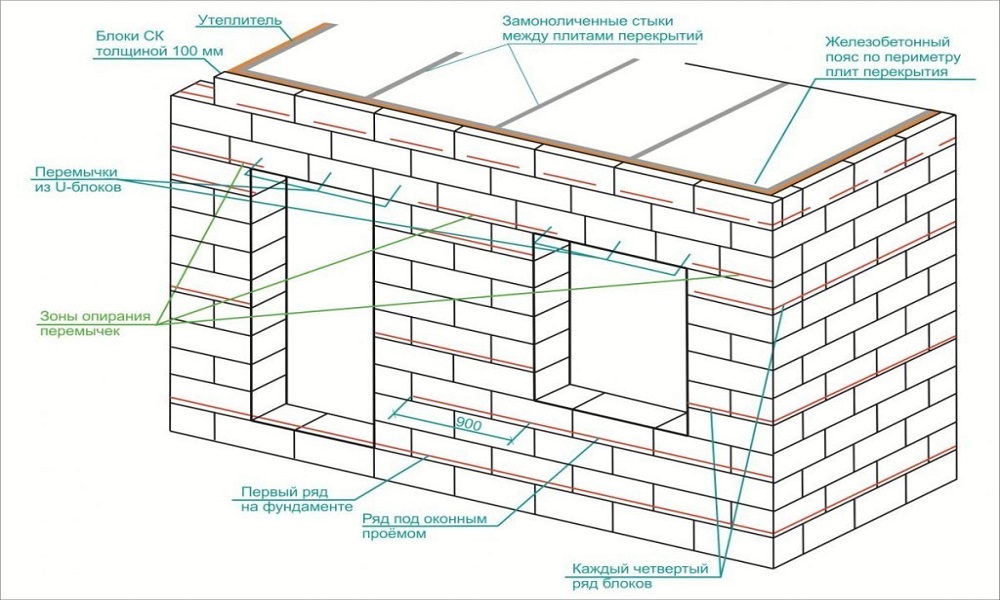

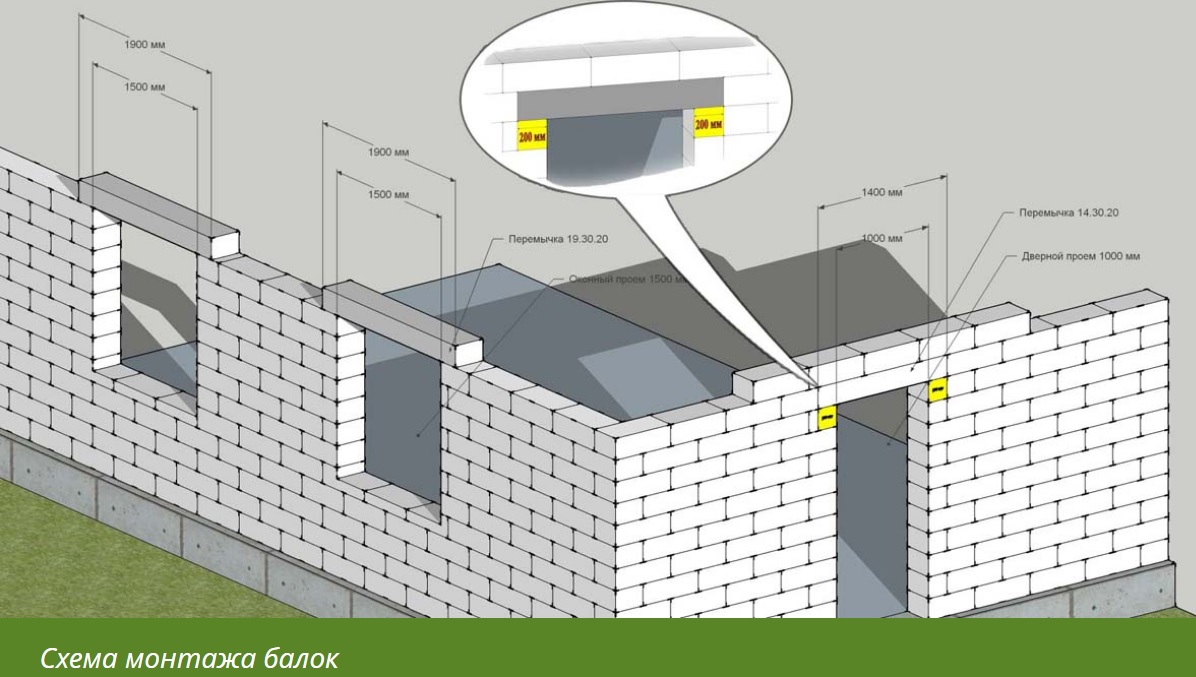

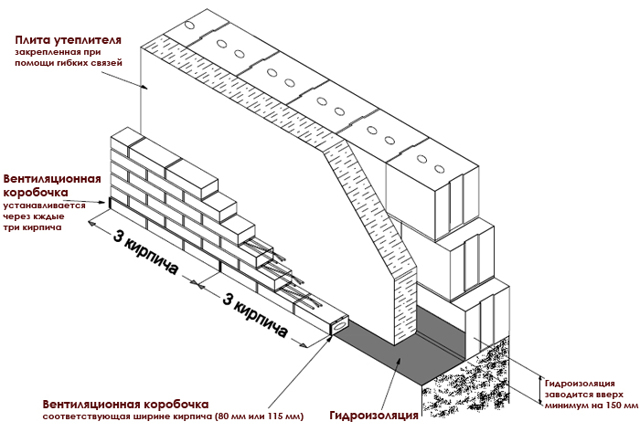

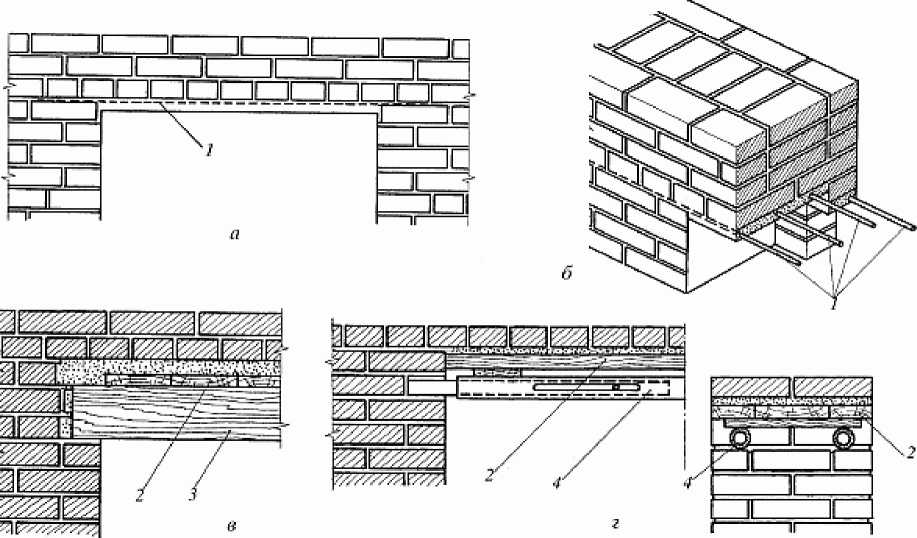

In order to facilitate the completion of the task, at the preparatory stage of work, a template is made with the help of which the brick is laid. First of all, the optimal dimensions of the shaft are determined. They are different for the chimney and kitchen hood. In the first case, they are guided by the following data:

Determination of the height of the exhaust shafts.

- for heating devices with a power of up to 3.5 kW, the optimal channel section is 14 × 14 cm;

- for devices with a capacity of 3.5 to 5.2 kW - 14 × 20 cm;

- if the heat source has a power of more than 5.2 kW, the ventilation duct should have a cross section of 14 × 27 cm.

To make a template, you need a board 2.5 m long, 2.5 cm thick and 14 cm wide. Markings are applied to it, corresponding to the design location of the ventilation ducts in the wall. This template will help you not deviate from the vertical guidance of the masonry and build even straight shafts and chimney openings. During the laying of the walls, regular verification with a template is carried out.

Instead, so-called buoys can be used. They are wooden boxes, the dimensions of which correspond to the section of the shaft being built. The height of the buoy should be equal to the height of 7-8 rows of brickwork. During the construction of the hood or chimney, a displacer is installed, and the masonry is led around it. This allows you to keep the exact dimensions of the shaft and its compliance with the vertical.

The section of the pipe can be square or rectangular. The channels in the wall are located side by side, the distance between them is one brick. During masonry, a single-row dressing of the wall with ventilation shafts is carried out. The main canal can have several outlets to rooms on different floors. The child must be no more than 1 m away from the main one.

In order to avoid clogging the holes during construction work, the cavities of the mines are covered with rags, crumpled paper and other materials suitable for this purpose.

Determination of the readiness of the mortar for laying bricks.

If buoys are used during the construction of the walls, their installation will by itself prevent clogging.

During masonry, special attention is paid to the quality of the seams. Cement-sand or clay mortar must be smoothed so that the surface is as even and smooth as possible

In this case, there will be no deposits of soot and grease on the inner walls of the mine. The brick channel must be sized so that no cutting of these building stones is required.

To complete the work, a drawing will be required, the use of which will not allow vertical deviations horizontally. For one-and-a-half and double masonry, there are their own, verified by practice, methods of masonry. They are recommended for ventilation systems in low-rise buildings.

Overview of common mistakes

Self-arrangement of the ventilation system in brick buildings is often accompanied by the appearance of repetitive errors. Firstly, in rooms without windows, a channel is not provided, in this case the air humidity rises, mold and fungi form on the walls. To solve this problem, it is enough to equip an air duct with a capacity of 15 m³ / h.

The outer wall is equipped with a hole, believing that it will be enough for a full air exchange. A fan must be installed in it, and the surrounding brick must be protected with a hydrophobic compound so that moisture does not accumulate in the "window" zone.

To improve air circulation in the house, interior doors can be equipped with ventilation grilles.

To improve air circulation in the house, interior doors can be equipped with ventilation grilles.

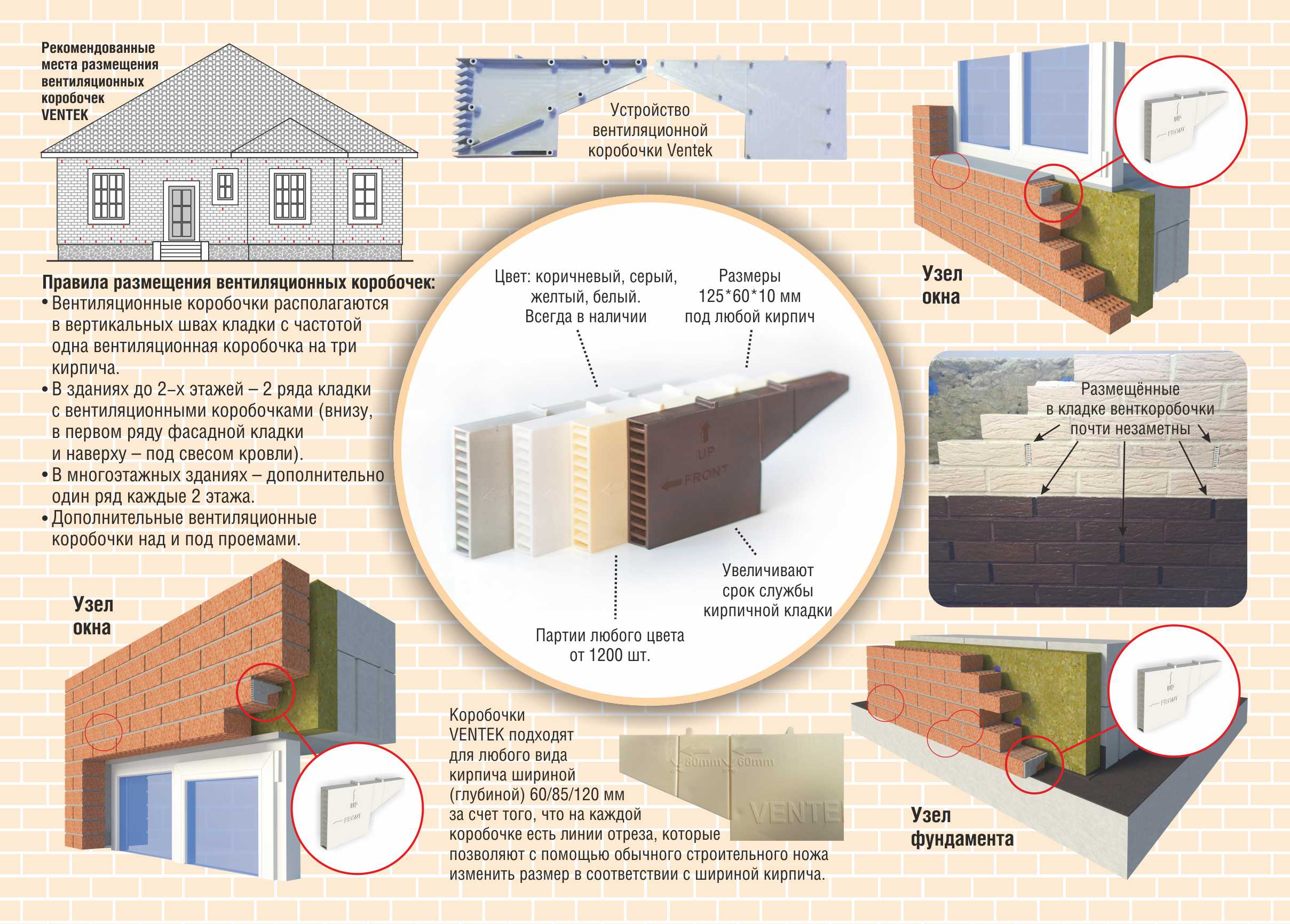

If the internal doors are not equipped with ventilation holes (a gap at the lower edge of the leaf is enough), the effective flow cycling will be disrupted. masses. Their total area can vary within 80-150 cm².

If plastic double-glazed windows are installed in a brick dwelling, hermetically enclosing the internal microclimate, coupled with an artisanal air duct system, they can lead to the effect of blocking the premises. To ensure the full operation of the ducts, you can equip the windows with special ventilators that promote additional air circulation.

Hood connection

In the kitchen, the action of only ventilation arranged in the wall may be “lacking”, especially if cooking is often done and the kitchen is small. The hood helps out, which removes unpleasant air from the kitchen

It is important to correctly connect it to the ventilation duct. The distance to the ventilation shaft is desirable to be minimal

Otherwise, the extraction effect will be reduced. And long air ducts look ugly.

To connect, you need special air ducts and adapters. The elements are connected tightly. A number of rules are important for safety and efficient operation. When connecting the exhaust pipe, it should not completely block the ventilation duct: when it is not working, the main ventilation is active, from the draft of air. To do this, do not forget to place the grate above the inlet of the exhaust tube.

So that the hood does not fail, it is necessary that the air has no obstacles

This is why it is important that the length of the duct is shorter. And it's better to forget about the turns.

The smoothness of the pipe will also contribute to the quality traction. Therefore, corrugated pipelines, which are preferred because of their flexibility, still retain the air flow. If you can't do it, you need to smooth out the turns. Dangerous: if a gas heating column is used in the kitchen, the hood cannot be taken out into its smoke channel

Brickwork ventilation duct technology

Exhaust ventilation ducts in a brick house are able to remove heat along with the exhaust air, therefore it is recommended to foresee a rather effective detail when designing in advance - a bend in the form of a brick ladder. In this case, there will be an obstacle for the premature outflow of heated air masses.

Brick: what it should be, notes on masonry

For the construction of brick walls in residential buildings, it is customary to use a solid stone. If there is a need to use hollow facing analogs during masonry, all the recesses in them must be filled with a working solution or clay. Silicate brick is not suitable for the formation of high-quality air ducts, this material tends to collapse under the detrimental effects of temperature extremes.

Often, when creating a ventilation duct, there is a need for bricks with non-standard parameters, for example, when bandaging seams, when forming zones of contact of walls. Mechanical processing of the material is carried out using the following tools:

- grinders;

- a pick hammer or trowel;

- specific cutting mechanisms.

To save money, it is better to handle the battle in this way, that is, a brick with chips, missing corners.

When drawing up an estimate for the material, several conditions are taken into account:

number of storeys of the building;

geometric characteristics of channels, configuration;

with regard to sedimentary joints, the importance of finishing;

area of premises;

the need for dressing with the exploited masonry;

cost and type of brick.

Experts note that the final cost of the work is not influenced by such factors as the brand of the material, its color, the degree of resistance to freezing.

For the construction of ventilation ducts, you should use an ordinary solid ceramic brick

For the construction of ventilation ducts, you should use an ordinary solid ceramic brick

Features of the preparation of the solution

For the installation of ventilation ducts, the same solution is used as for the construction of internal brick walls. The batch will have optimal strength if the proportions are carefully observed during the assembly of the components:

- you need to take 3 parts of building sand, certainly cleaned;

- 1 part of cement grade M500.

The dry components are combined in advance, water is poured into them in dosed portions, stirring the mixture continuously.It is necessary to achieve such a characteristic consistency of the batch so that when the container is tilted, the solution does not pour out.

The mortar for brickwork should be quite thick

The mortar for brickwork should be quite thick

Masonry order

All work is reduced to the following stages:

Careful drawing up of a drawing of the future design.

Striping - This uses the folding template described above.

Layout of the first row in strict accordance with the level, in the process a wooden box or buoys are used

It is important to keep all corners and surfaces straight.

If the laying is carried out in high temperature conditions, in order to protect the brick from excessive dryness, it is necessary to periodically moisten it with water - then it is possible to improve the adhesion of the mortar and material.

All is laid out in accordance with the drawing up to 4 rows.

Buoys are mounted on bricks - they are laid out, adhering to the level, directly into the channel. These elements protect the duct from debris that invariably accompanies installation work, and help to maintain the strict geometric shape of the hole.

The buoys are moved every 7-8 rows.

If during the design the chances were revealed that combustion products would enter the room and nearby ventilation systems along with air, it is better to use the masonry made according to the "end-to-end" scheme.

During work, it is important to carefully observe the same thickness of the joints. When laying, it is necessary to maintain the shape of the corners and carefully observe the same thickness of the seams

When laying, it is necessary to maintain the shape of the corners and carefully observe the same thickness of the seams

When laying, it is necessary to maintain the shape of the corners and carefully observe the same thickness of the seams

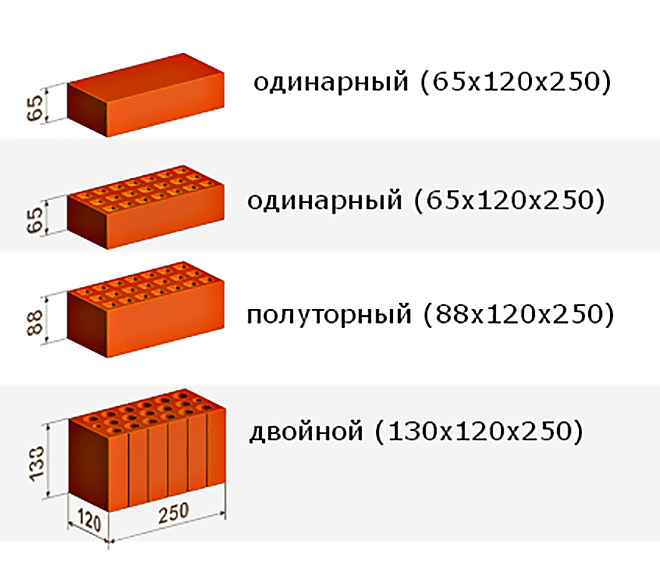

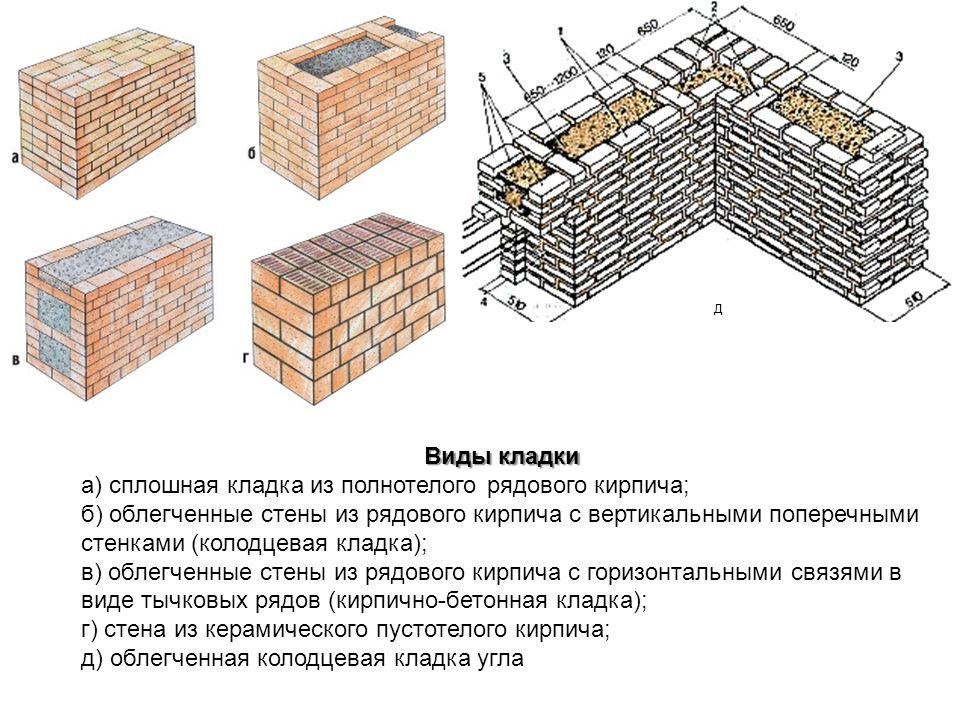

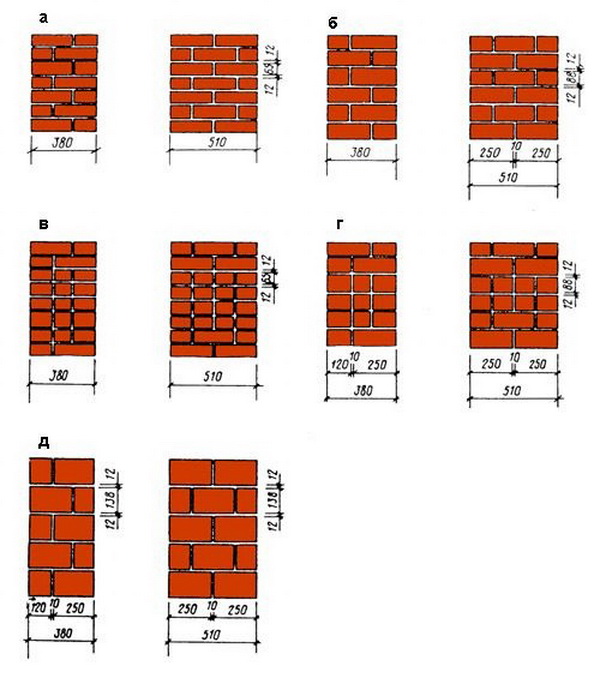

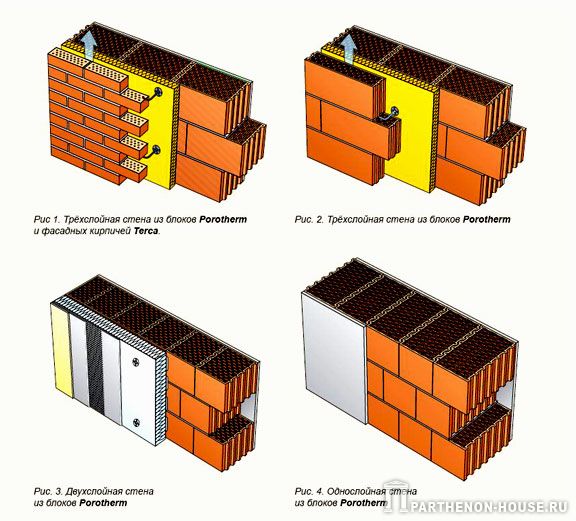

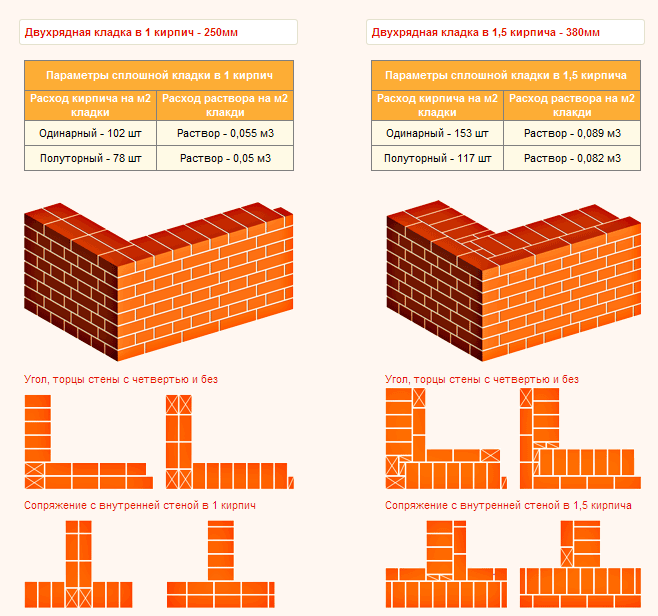

Types of brickwork for walls

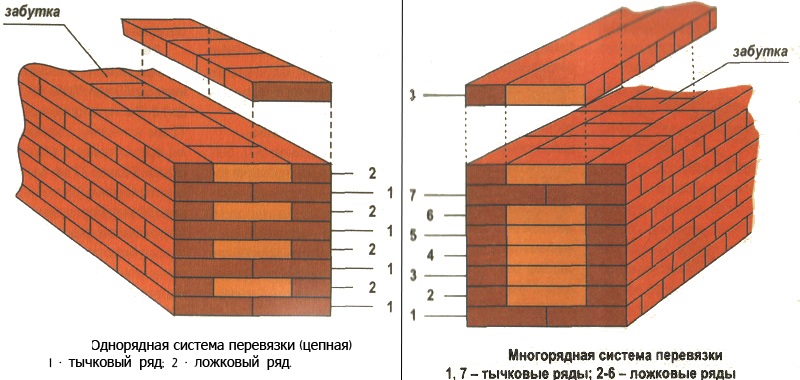

Another professional term used by bricklayers is bandaging. This is the layout of the material, the order of their laying. Thanks to her, all the elements are connected into a single whole, a monolithic mass with an equally distributed load. The dressing is carried out by displacing the stone by half or a quarter.

- If the elements are poked outward, such a row is called a butt row. Then only the smallest facet of the stone is visible.

- Spoon - a row in which all elements are turned with a long edge - a spoon.

There are three main options for suture dressing. Consider each type of brickwork with a photo and a name.

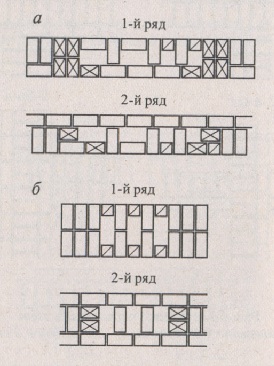

Single row

It is also called chain. The point is in the sequential alternation of rows of poke and spoon. Such a dressing is used for the construction of rough buildings, when facing is planned in the future. Suitable for both external and internal load-bearing walls. And also such decorative styling is most often found in interior design.

- The first and last level must be poked.

- Longitudinal seams are shifted by half a brick, transverse - by a quarter.

- The vertical seams should not line up with the upper and lower seams, the stones overlap them.

Such a dressing is considered difficult to work with, but at the same time it is the most reliable.

Multi-row

This is a way to build external and internal walls. The scheme is as follows: six rows are laid with sticks (for a single brick), they are tied up with a spoon row. If the stone is modular, there will be five rows of sticks.

- The first and last row must be made butted.

- The spoons are tied with a shift of half a brick, regardless of the thickness of the stack.

- The jabs of the seventh row overlap the spoons of the previous one by a quarter.

A multi-row dressing system is cheaper than a chain dressing, and the installation itself is also easier. But its strength is considered lower. In addition, it cannot be used in all works.

Three-row

Usually, fences, piers, pillars and other more decorative structures, in which the load is not provided, are laid out in this way. With this scheme, one stick level alternates with three spoon levels.

There are a number of more complex types of brickwork, they are used for facing work. These include, for example, Bavarian - the alternation of stones of different colors, chaotic - this is the alternation of the spoon and butt sides in a chaotic manner, or Gothic - the same alternation, but ordered.Without experience, such masonry cannot be done on our own; it requires technical excellence and skill.

Instagram @kirpgorod

Instagram @kirpgorod

Instagram @brick_building_

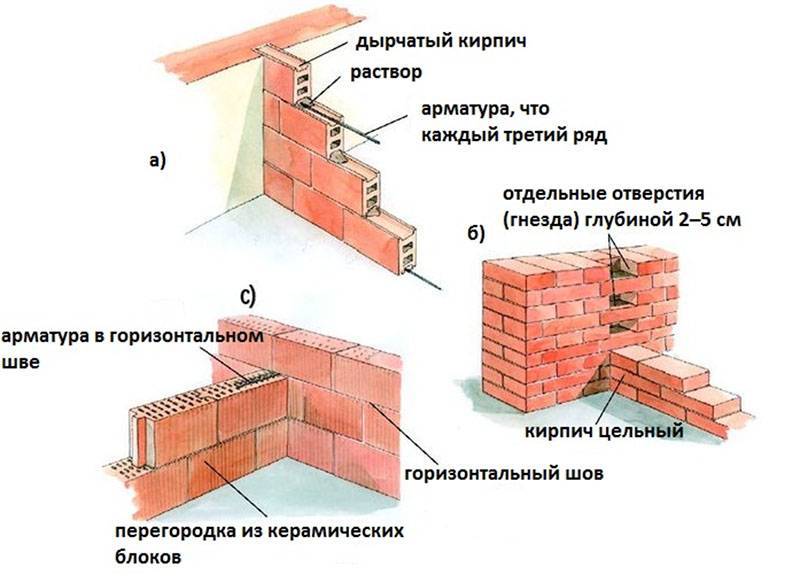

Reinforced

Separately, it is worth mentioning the reinforced layout. This technique involves reinforcement with reinforcement. It is placed in a solution between levels. In this case, the reinforcement itself can be performed both horizontally and vertically (using a mesh or individual rods).

- As a result, the amount of reinforcement should be at least one tenth of the total installation volume.

- The nets are laid at least every three levels - for ceramic products, four - for thickened ones, and five - for ordinary ones.

- The mesh diameter is at least 3 mm.

Instagram @brick_building_

Instagram @brick_building_

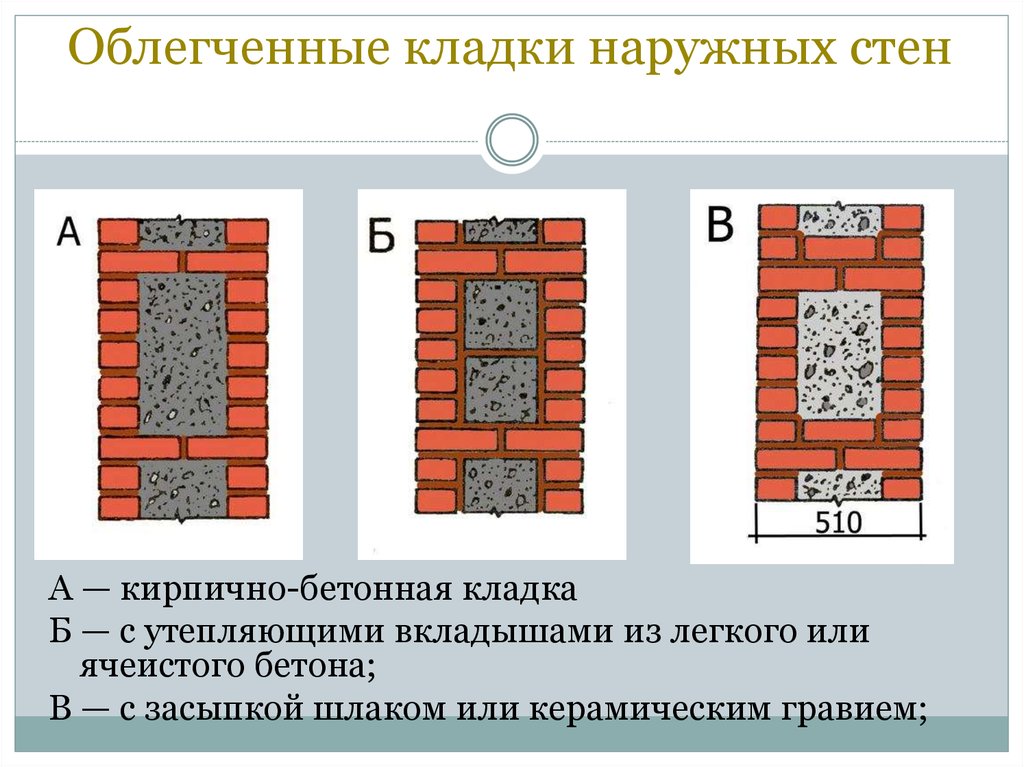

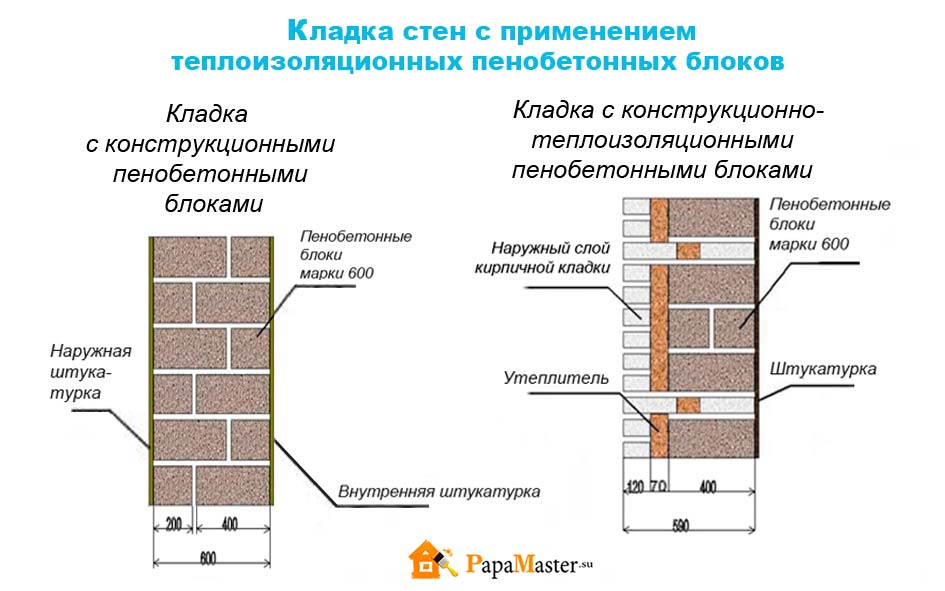

Lightweight

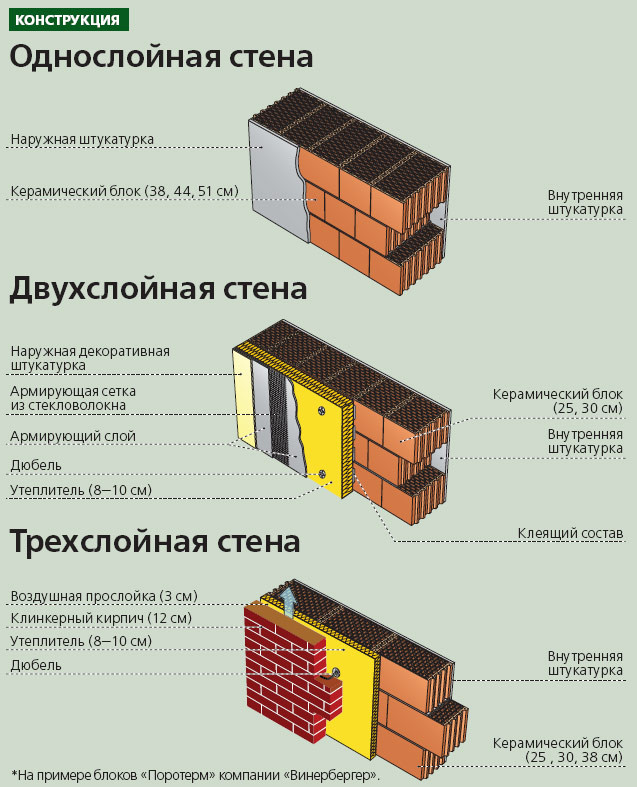

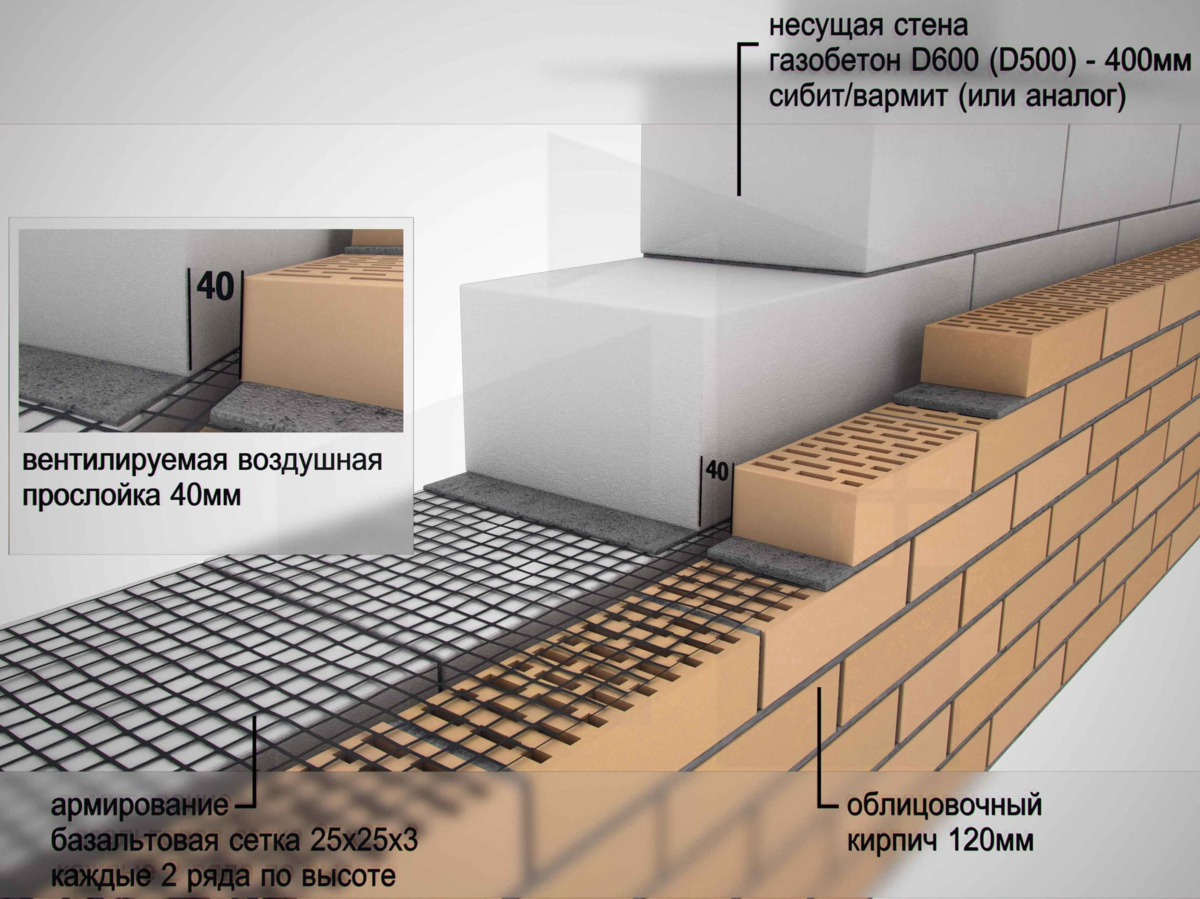

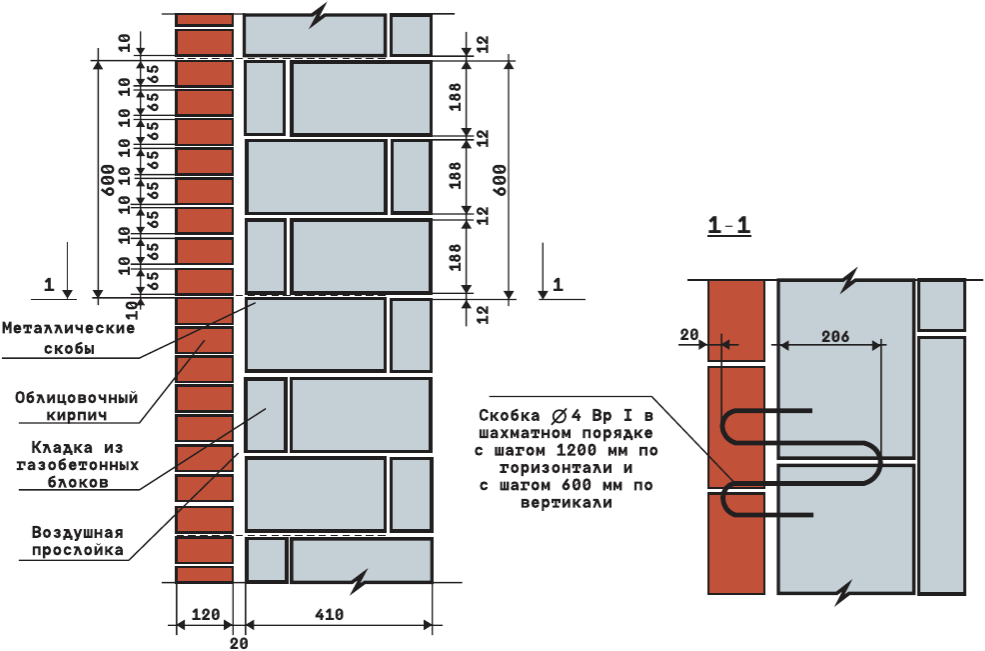

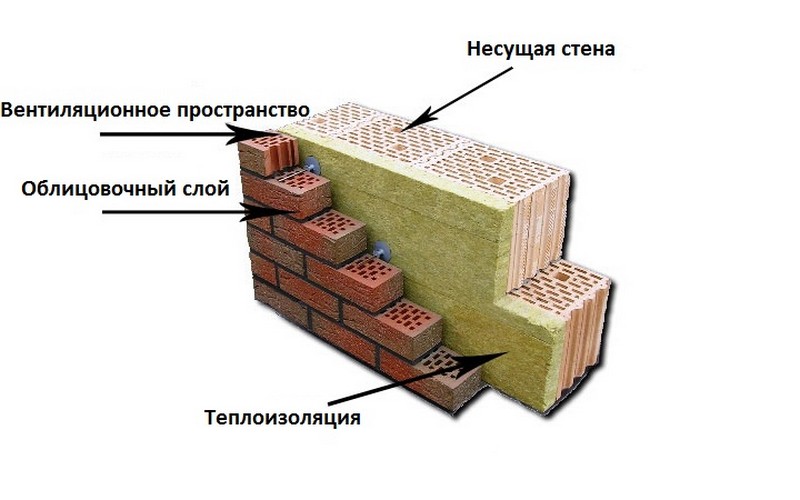

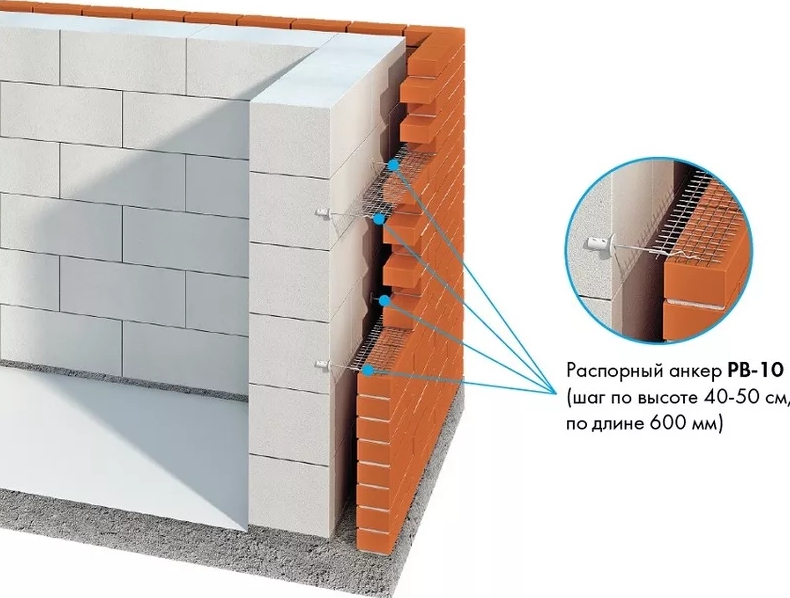

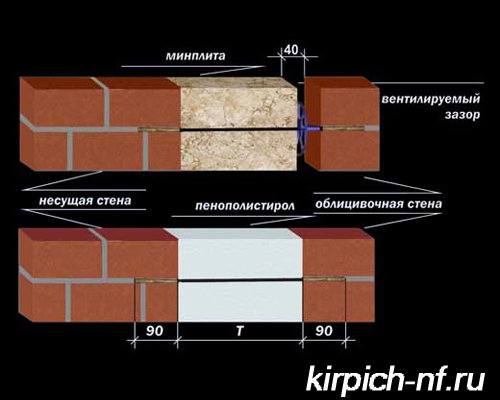

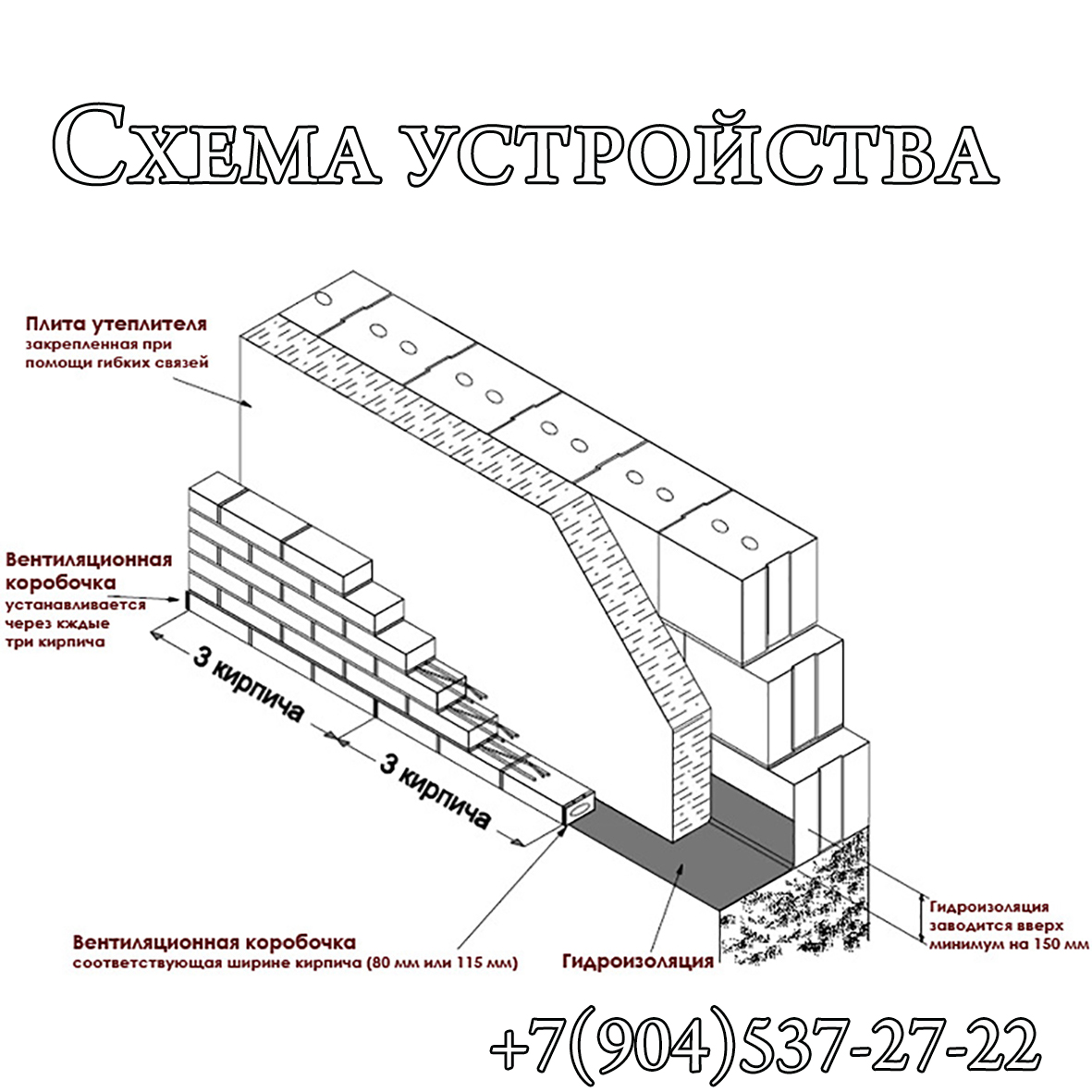

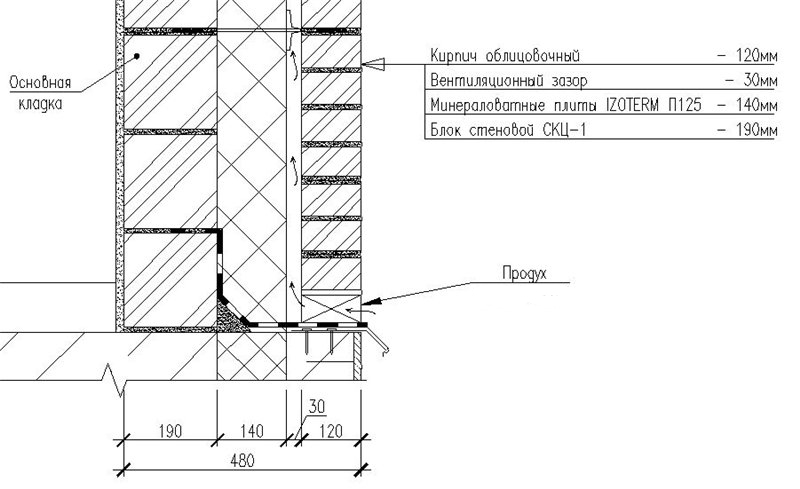

This option is relevant when insulating internal walls, when a durable lightweight structure is needed.

- In this case, the wall consists of two walls half a brick thick, reinforced with reinforcement. This design turns out to be rigid.

- Between the walls there is a cavity in which insulation is laid, for example, expanded polystyrene or polyurethane foam. The width of the cavity is determined at the initial stage.

- The walls should be connected with bridges made of stone blocks or reinforcement. In this case, the points themselves are at a distance of no more than 1 meter from each other.

Instagram @brick_building_

Instagram @brick_building_

Features of calculating wall thickness

- The thickness of the walls according to the heat engineering calculation does not always coincide with the calculation of the value according to the strength characteristics. Naturally, the more severe the climate, the thicker the wall should be in terms of thermal performance.

- But according to the conditions of strength, for example, it is enough to lay out the outer walls in one brick or one and a half. This is where the "nonsense" is obtained - the thickness of the masonry, determined by the heat engineering calculation, often turns out to be excessive due to the strength requirements.

- Therefore, laying a solid brickwork of solid brick walls from the point of view of material costs and subject to 100% use of its strength should only be in the lower floors of high-rise buildings.

- In low-rise buildings, as well as in the upper floors of high-rise buildings, hollow or light bricks should be used for external masonry, you can use lightweight masonry.

- This does not apply to external walls in buildings where there is a high percentage of humidity (eg, laundries, baths). They are usually erected with a protective layer of vapor barrier material from the inside and of solid clay material.

Now I will tell you about the calculation of the thickness of the outer walls.

It is determined by the formula:

B = 130 * n -10, where

B - wall thickness in millimeters

130 - the size of half of the brick, taking into account the seam (vertical = 10mm)

n - an integer of a half brick (= 120mm)

The size of the solid masonry obtained by calculation is rounded up to an integer number of half-bricks.

Based on this, the following values (in mm) of brick walls are obtained:

-

120

(brick floor, but this is considered a partition); -

250

(into one); -

380

(one and a half); -

510

(at two); -

640

(two and a half); -

770

(at three o'clok).

In order to save material resources (brick, mortar, fittings, etc.), the number of machine - clock mechanisms, the calculation of the wall thickness is tied to the bearing capacity of the building. And the heat engineering component is obtained by insulating the facades of buildings.

How can you insulate the outer walls of a brick building? In the article, insulating a house with expanded polystyrene outside, I indicated the reasons why brick walls should not be insulated with this material. Check out the article.

The point is that brick is a porous and permeable material. And the absorbency of expanded polystyrene is zero, which prevents moisture migration outward.That is why it is advisable to insulate a brick wall with heat-insulating plaster or mineral wool slabs, the nature of which is vapor-permeable. Expanded polystyrene is suitable for insulating a base made of concrete or reinforced concrete. "The nature of the insulation must match the nature of the load-bearing wall."

There are a lot of heat-insulating plasters

- the difference lies in the components. But the principle of application is the same. It is carried out in layers and the total thickness can reach 150 mm (with a large value, reinforcement is required). In most cases, this value is 50 - 80 mm. It depends on the climatic zone, the thickness of the walls of the base, and other factors. I will not dwell in detail, since this is a topic for another article. We return to our bricks.

The average wall thickness for ordinary clay brick, depending on the area and climatic conditions of the area at the average winter ambient temperature, looks like this in millimeters:

- - 5 degrees - thickness = 250;

- - 10 degrees = 380;

- - 20 degrees = 510;

- - 30 degrees = 640.

I would like to summarize the above.

The thickness of the outer brick walls is calculated based on the strength characteristics, and the heat engineering side of the issue is solved by the method of wall insulation. As a rule, the design firm calculates the external walls without the use of insulation. If the house is uncomfortably cold and there is a need for insulation, then carefully consider the selection of insulation.

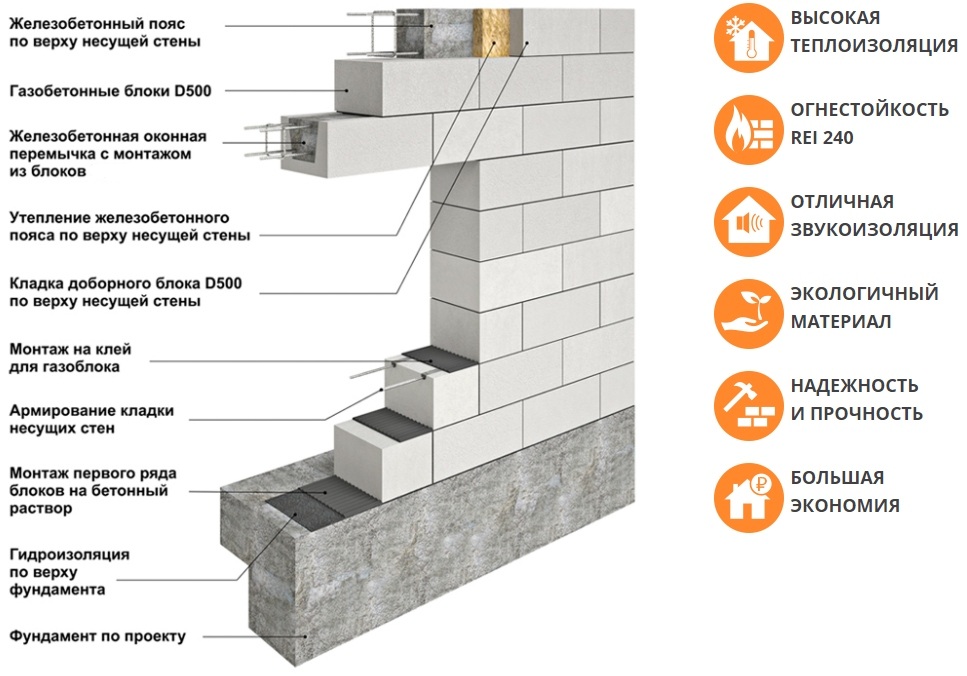

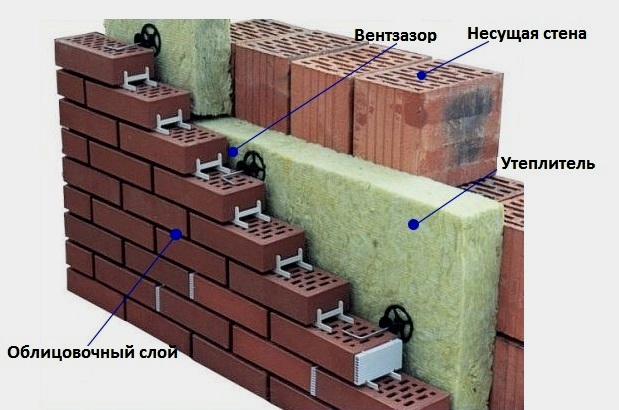

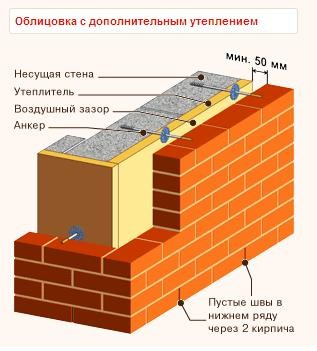

Solid brickwork

The solid type of brickwork is suitable for the construction of load-bearing walls of residential buildings, as well as for the walls of the basement and basement. This is a monolithic way of laying bricks. The bricks are stacked tightly to each other, cracks, gaps are not allowed, and the wall does not include a layer of insulation. Installation of thermal insulation is allowed during installation work outside the building.

Solid brickwork

Solid brickwork

The main advantages of solid brickwork include the stability and density of the structure. That is why this method is often used to construct the main walls of a building. But solid brickwork also has many disadvantages. These include poor thermal insulation and low noise absorption.

Solid brick width is half the standard brick block size. Masonry is carried out along the outer edge of the wall being erected.

To lay the structure in a solid form, it is necessary to use plastic mortars. For this, it is advisable to add a small amount of detergent to the cement-sand mortar. For example, liquid soap.

Depending on the type of building, there are several nuances in working with solid brickwork:

- When erecting walls in a continuous way, it is worth considering the high consumption of materials. Compared to other types of brickwork, the solid method will take 30% more brick.

- When installing the smoke opening in the furnace, it is necessary to use fireclay bricks. It is a refractory material that can withstand extreme temperatures. All seams must be carefully sealed with clay.

- The thickness of walls laid in a continuous way during the construction of residential buildings should depend on external factors. If the house will be exposed to severe frost, the thickness of the solid masonry should be at least 64 cm.

- Since solid masonry does not provide adequate heat and sound insulation, it is necessary to leave a gap of 5 cm between the wall and the building cladding. It can be empty or filled with an intermediate layer of special material. Mineral plates and jute mats have good thermal insulation properties.

- The main solid wall and cladding need adhesion. For this, metal bonds are made. They are installed during the construction of a solid wall in the seams and are fixed with mortar. In order for the structure to hold well, the seams of the facing part and the solid wall must be at the same level.If there is no perfect match between the seams, flexible composite reinforcement can be used.

For solid brickwork, a one-row dressing is used. Sometimes a multi-row type of dressing can be used. The exception is the construction of pillars and interior partitions, which can be laid according to the three-row principle.

Algorithm for the execution of the masonry of the ventilation duct

- Thorough study of the drawing.

- Marking with a foldable inventory template. If it is not there, openings are made in the board with dimensions (mm): 140x2500x25, identical to those marked on the wall plan.

- The brick is laid strictly according to the level, for which buoys or a box knocked down from the boards with the dimensions of the channel are used. Straightness of surfaces, corners must be observed.

- If the air temperature is high and the brick is dry, it is necessary to moisten it with water to improve the adhesion between the material and the mortar.

- 3 or 4 rows of masonry are formed.

- Buoys are installed - bricks laid out according to the level in the cross-section of the channel. Protect it from the ingress of debris during work, keep the given shape of the hole.

- The displacer moves every 7 or 8 bricks with a single-row or multi-row dressing system.

- If there is a likelihood of penetration into the premises, as well as nearby ventilation systems together with the supplied air of fuel combustion products, then it is better to lay the masonry by the "end-to-end" method.

- Observe the thickness of the joints.

- Carefully close all of them.

In more detail, it is recommended to study the technology of work on video clips that are available on the network in the public domain.