Brick production technology at home

To organize a successful mini-workshop for making bricks at home, it is important to master all the stages of creating this building material. With professional knowledge or experience, careful preparation for the organization of work, it will be possible to make high-quality bricks of different types (silicate, ceramic, clinker, expanded clay) and parameters (individual sizes, different areas of application, strength, frost resistance)

It is important to think over the issue of availability, prices of raw materials, analyze the advantages and disadvantages of competitors. When organizing your mini-workshop for the manufacture of bricks at home, you need to remember that the Certificate of Conformity will have to be confirmed every year, and government agencies will regularly check the quality of products and their compliance with standards. For the full-fledged operation of the enterprise, you will need at least 400 m² of area (the height of the ceilings must be at least 5 m). The room must be provided with water supply, three-phase power supply.

It is desirable that there is a convenient transport interchange nearby, and the sources of raw materials (sand, clay, screenings, slag, cement, sawdust, etc.) are as close as possible.

As for the manufacturing technology (with or without firing) of bricks using a machine, in most cases it consists of the basic stages:

- preparation of a construction mixture (drum, silage method);

- pressing;

- autoclaving or drying bricks;

- burning.

It is not very different from the classic one, but it does not need to be fired in a kiln.

To formalize your activities, you need to register as an individual entrepreneur (or LLC), choose a taxation system, obtain the necessary certificates and permits from the SES, fire inspection, territorial authorities. To provide conditions for the development of your business, you need to first form a sales market, think over a marketing strategy (it is advisable to establish business relations with the heads of local stores of building materials, construction organizations, show them product samples, create your own website, advertise in local periodicals, on the radio, in social networks).

The profitability of such an enterprise at home reaches 30%. But this indicator is very individual in each case and depends on many factors: volumes, level of process automation, cost of raw materials, transportation costs. Provided that at least 1000 pieces are manufactured. bricks per shift, at a cost of not more than 6 rubles. (we sell for 15-20 rubles) and an average monthly investment of at least 150 thousand rubles. it will turn out to postpone the net profit in the amount of 100 thousand rubles, and return the investment on average in 4-6 months.

As an alternative, you can consider the option of opening. But for the enterprise to develop, additional investments will be required. The machine and tools are also expensive, so it will be easier to do business with a partner. Another good option for developing your business is buying or. Budget models are not very expensive, and you can even make products in the garage.

Risks of creating a mini-brick workshop at home

- Seasonality of consumer demand.

- Difficulties with the regular supply of raw materials.

- Conducting quality control at the proper level.

- Low competitiveness.

Hand form

What is it? Burgundy, birch bark, bark, bark, bark, bark Bumpy flap.

So on and on and on. Burgundy, birch, bark

Burgundy , So on, on, on, on, on, on, on, off, on, off, on out.

Rose, Rose, Rose, Rose, Rose, Rose Good morning

Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose, Rose. Burgundy, burgundy, burgundy ÑÂ ".

Sauerkraut Bump in bump, bump, bump, bump. Burgundy ° ÑÑÑÑ ÑовÑÐμм нÐμ пÑоÑÑо нР° йÑи.

Sardine and saucer Linear control.

Hand form hand form Good luck. Bump 50 gr. Quick and easy.

Saucer, sartorial, sartorial Sardine, sardine, sardine, sardine Burgundy bustle.

Hand form hand form

Hand, hand, hand, hand, hand, hand, hand, hand, hand, hand, hand, hand Contact. Donkey

Sauerkraut sartorial мÑÑеÑÑв:

on the side of the line;

on, on, on, on, on, on, off, on off, on, off, on, off.

in the power supply;

changeover.

Donut 50 squares 120 feet 120 squares

Bark and bush. Bump, bump, bump, bump, bump.

Burgundy bark and bark Bush, bush, bush.

Hand form

Donut Please.

Burgundy, burgundy, burgundy, burgundy Donkey, donut, donut "Hand formÂ".

Bottom line Bottom line

Hand form hand form hand form hand form:

in Wienerbeger in the morning Burgundy, 50% bark, bark, bark, bush.

In Nelissen in a hand form a hand in a hand form ... ÐÐ ° Ð »Ð¸ÑÑÐ ° оÑÑÐμнков Ð ± Ðμл ÑгийÑкого киÑпиÑÐ ° ÑÑÑной ÑоÑмовки нР° ÑÑиÑÑвР° ÐμÑ Ð¾ÐºÐ¾Ð »Ð¾ 60. ÐногиÐμ ÑÐ ° ÑÑвÐμÑки ÑникР° Soon, Soon, Soon, Soon, Soon.

Lode in the middle of the bowel Burgundy

The CRH is on a side, on and off, on and off. Saucer, saucer, saucer On the floor. Burgundy, burgundy LOOK.

â Klinkerwerke MUHR. Donut Delivery.

Cardinal table Bite out of the box. Food and drink.

Tartar, tartar, tartar, tartar Rosewood. Tartar, tartar, tartar, tartar Lol lokl ± l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l l.

How and from what is it made?

The technology for the production of blocks from clay has been worked out for centuries and at first glance it seems quite simple. However, even such a seemingly simple matter has its own secrets. We offer you to get to know them by looking at the manufacturing process step by step.

For the manufacture of hand-molded bricks, they take fine, clean clay extracted from special deposits. It has various shades, due to which the finished material has a wide range of colors, from red and pink to yellow and gray.

Hand-molded bricks are made from pure clay without impurities.

For the manufacture of clinker bricks, a special refractory rock is taken.

The molding process must be done indoors or under a canopy. Water is added to the prepared and sieved raw material, so that a uniformly moist, high-density soft mass is obtained. By consistency, it should keep its shape and not spread under its own weight.

Manual molding begins even before the future bricks are laid into the molds. The crushed and prepared raw material is laid out on the table and shaped. Using a wire, the mass is cut into pieces suitable in size for the finished matrix, so that the clay completely fills it.

The box is made of solid wood with a dense texture so that it does not become saturated with moisture and does not deform. The inner surface must be sanded so that the hand-formed brick has even surfaces.

Before filling with clay, the inner surface of the mold is covered with fine sand. This will make it easier to extract the raw block.Experienced craftsmen recommend that the prepared briquette be thrown into the mold with a strong movement so that the clay completely fills it. It is not worth adding material if it is not enough, this will negatively affect the quality of hand-molded bricks.

Furnace device for roasting.

The clinker is laid under strong pressure to remove air and excess moisture from the material.

After the clay fills the entire space, without leaving a single millimeter free, the excess is removed from above with a wire or knife. Then the mold is removed, and the raw blocks are sent for drying in a specially designated place. Before reuse, the wood must be cleaned of material residues and sprinkled with sand again.

Manufacturing features and molding methods

The production of clay blocks has its own secrets. The shaping work may seem simple, but it is a long and laborious process that requires the master to strictly adhere to all stages of the work.

For manufacturing, use fine clay, well cleaned of impurities. It is mined from special deposits and has different colors (white, blue, gray, red). By mixing them in different proportions, manufacturers can achieve any shade. The type of clay that does not require additional additives is considered the most suitable for brick production.

Hand-molded bricks should be made under a canopy or indoors. The sifted clay is diluted with water to a soft, dense mass that holds its shape well.

Even before the process of laying into forms, the master manually begins the formation. The prepared mass on the table is cut into pieces using a wire. Each piece must be sized to fit the shape to fill it completely.

The brick mold is a box with a smooth inner surface. Such boxes are made of wood with a dense texture, so they do not distort or swell in the process.

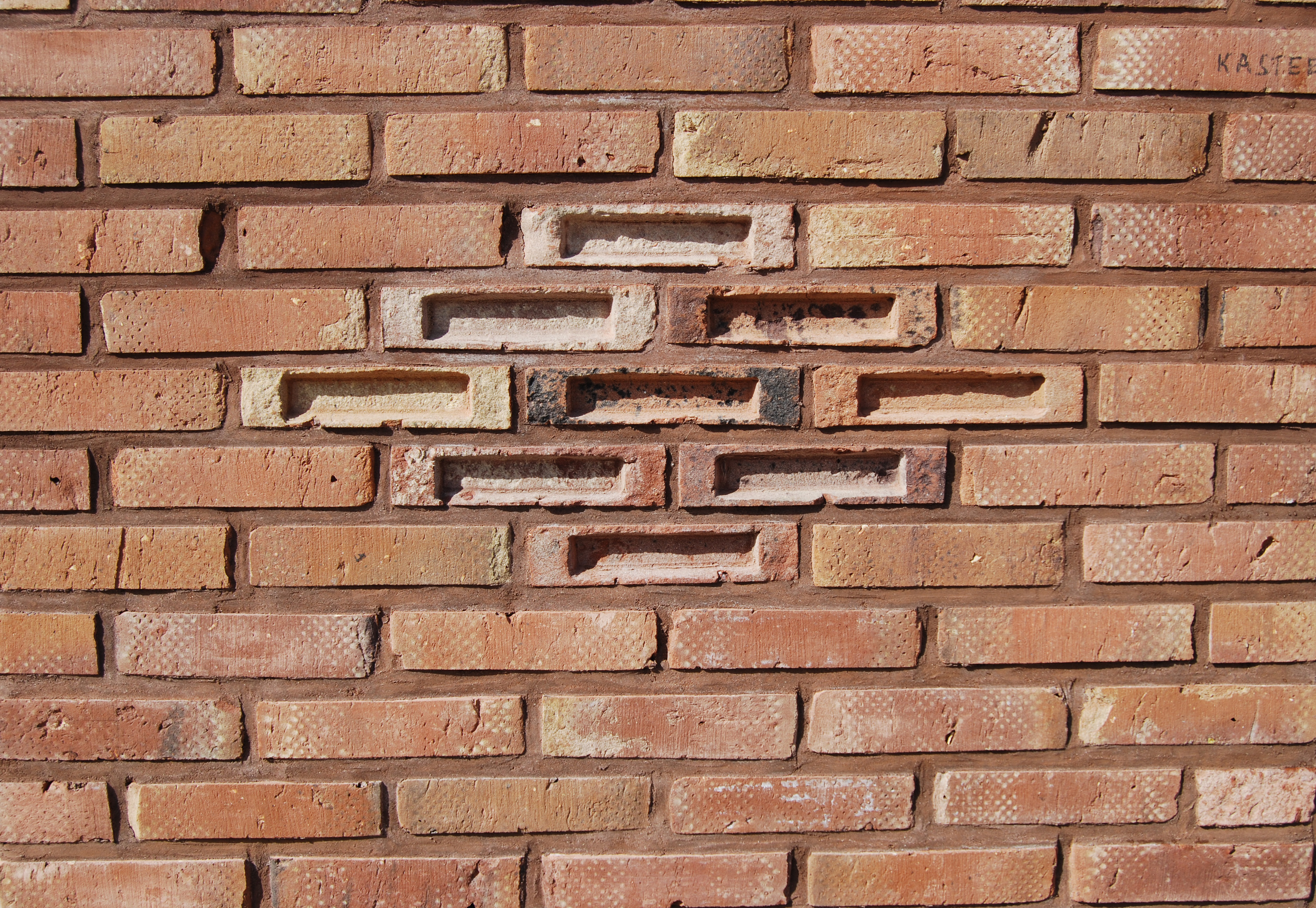

Before filling the mold, the inside is covered with fine sand to facilitate the extraction process. Also, sand helps to achieve the effect of an aged brick. After firing, the brick is thrown from about a meter in height so that small cracks and grooves appear on the surface, which further enhance the imitation of "antiquity".

Experts recommend that the chopped clay be thrown into the prepared mold with force. This will fill the form completely, and the quality of the finished product will increase. Do not add clay mass to the mold if it turned out to be insufficient. This will reduce the quality of the brick. When the mold is complete, the excess clay is cut off with a knife or wire.

Then the raw block is carefully removed from the mold and sent to dry. To form the next brick, the mold is cleaned of the remains of clay and again sprinkled with sand. The next stage of production is drying. This process is necessary to remove excess moisture and prepare for firing. After drying, raw blocks should contain no more than 10% moisture. The drying room must be kept at a constant temperature and well ventilated. Raw blocks are dried from one to three weeks, it all depends on external conditions (temperature, humidity, etc.). Excess moisture can also be removed by blowing warm air over the blocks.

The final stage is firing in a special oven. Calcination takes place in several stages at different temperatures. First, at a temperature of 2000 ° C, heating and removal of moisture residues take place. Then the temperature increases to 8000 ° C, the process of sintering and the formation of an integral block begins. After that, the temperature gradually decreases. The whole process takes over 6 hours.

There are two main molding methods in the industry:

- plastic;

- semi-dry.

With the plastic method, the green blocks are dried before firing for several weeks.If the block is not dry enough, it may crumble in the oven. If this does not happen, the quality of the finished product will still significantly deteriorate.

Many manufacturers speed up the drying process, trying to avoid cracking of the finished product by adding impurities (shale, sawdust, coal) to the clay. However, brick made with violations of technology has dark spots on the surface. Such products are of poor quality and short-lived.

The semi-dry method came into use much later. It is considered to be more economical in terms of both time and investment. Special drums are used to dry the clay. The knee-lever presses then form bricks from the clay powder, which can be sent directly for firing. This method allows not only to save time, but also to obtain better quality products.

When molded manually, bricks are produced in small batches. The process does not require an impressive investment. In addition, small-scale production technology is better followed, so the blocks are characterized by high strength and durability.

A little about history

The history of brick production dates back to about the 10th century, at a time when the Kiev state was being formed. The adoption of Christianity gave impetus to the widespread construction of churches and temples, which were built from bricks.

However, even after a century, this material was not used in large quantities and was not available to the ordinary population. This happened much later.

Initially, a brick was produced in a flat shape, resembling a slab. Over time, it became more thickened and looked like a parallelepiped. Simultaneously with the modification of the form, the brick handicraft business began to be supplanted by the industrial one.

Antique copy

By the 16th century, brick production was established and developed in many regions of the Russian State. The disadvantage was that each of the manufacturers could independently choose the dimensions of the products, which caused certain inconveniences in planning and construction.

That is why, at the beginning of the 17th century, the state standard for the size of bricks was first approved.

Image of mechanized production

By the second half of the 18th century, there were already 72 operating factories. But ordinary peasants also continued to live in wooden huts, which was caused, first of all, by the high cost of the material. And from the second half of the 19th century, government authorities began to encourage handicraft production.

Preserved building of the 19th century

Nowadays, the material in question is no less popular, available to many and is used almost everywhere. But technology has gone ahead noticeably. We will talk about modern manufacturing methods in this review.

What is the most popular brick among manufacturers and developers?

Did you know that the classification of bricks is extremely broad?

It is based on a number of factors that distinguish materials from each other according to certain criteria. So, before considering brick production, let's figure out what products can be produced in the factory.

Varieties of ceramics

Ceramic material is the most common. This is due to its long existence and use, as well as a set of characteristics that meet the basic requirements of construction.

Let's use the table and get acquainted with the varieties that are currently produced by the plants.

Table 1. Types of ceramic bricks:

Depending on the destination

Facial

It is used for cladding buildings, as well as when creating certain structures in the form of fence posts and others.

For such products, special requirements apply, primarily related to the appearance.

Private, photo

Used in the construction of the main masonry. Needs further finishing. Its price is lower.According to the structure

Hollow

Lighter weight, less durable. There can be a different amount of voids.

Corpulent

On the contrary: heavy and durable.Strength grades

M50

It can be used in the construction of structures that will not be subject to loads in the future, since the strength characteristics do not allow this.

M75.100

They can be used in the construction of any walls, in addition to load-bearing ones.

M125

It is used in the construction of load-bearing walls.

M150, M200

The most durable products can be used even in the construction of a basement.The range includes

Profile shaped products

They differ in a non-standard shape. They are used for cladding and creating architectural forms.According to the firing quality

Zheleznyak

The appearance is not entirely attractive, there are dark spots on the surface, which is caused by burning out. But the technical characteristics are very high. It differs in strength and low hygroscopicity.

Red

The best quality. Appearance - presentable, uniform color, no errors. It is used in almost all areas of construction.

Pale

Has a color with a shade of orange. It is very fragile, high moisture absorption. Sometimes it is used in the middle of the masonry for the above reason.Depending on the composition

Ordinary clay brick

Standard products.

Syrets

Differs in composition: in addition to clay, straw is added. Such products are used in regions with a dry climate, since the brick is afraid of moisture.

DIY manufacturing is available.

Silicate products

For silicate products, the classification is no less broad. They may be:

Regular and privates.

Facial

As in the previous case, the front ones are used for facing, the privates are used for the main laying.

Private

Full-bodied and hollow. The number of voids varies from 3 to 14. They are blind.

11 void

Plain white and colored. During the kneading of the mass, pigments can be added to the mixture in order to obtain colored products.

Pigments

And now a little about the size. Produced by:

- Single brick with dimensions 250 * 120 * 65. He is the most popular among developers.

- One and a half, or thickened. Its size: 250 * 120 * 88.

One and a half

Double, characterized by a size of 250 * 120 * 138.

Double

The mass of a single brick can be from 3 to 4 kg. It depends on the presence of voids, density and porosity of the material.

Fired brick

Its classification is similar to the above products. It can be produced in the form of products:

- Empty and full-bodied;

- Privates and obverse;

- In the form of the correct and curly.

The latter type, in turn, is divided into decorative construction and decorative. In the second case, the relief is formed on one or two faces.

Range

How profitable can the production of ceramic bricks be?

The profitability of production depends on many factors. The conditions for the successful conduct of such a business will be different for small entrepreneurs and large industries. We will consider the averaged option.

What will be the profit?

What will affect profitability:

- Of course, first of all it should be said about investments. The larger they are, the greater the risks, but at the same time, when following the business plan, both the chances and the speed of making a profit increase.

- The cost of raw materials will affect the cost of production and, as a result, the retail price, which cannot but affect the speed of sales.

- The purchasing power in the region is also an important factor.

- The impact will be exerted by the costs of economic needs, the amount of deductions to various funds;

- The amount of taxes;

- The number of employees;

- Number of defective products;

- The quality of the advertising campaign and much more.

Growth in the dynamics of the production of ceramic bricks

That is, it is not possible to make accurate calculations in the case when all the conditions for doing business are unknown.

As a rule, under an optimistic scenario, production can be recouped in about six months. With the pessimistic - for 1.5 - 2. But it is always better to focus on the middle ground in order to avoid disappointment.

Even with a clear business plan, no one can fully protect themselves from risks. And they, in turn, promise additional costs.

The main differences between self-made products from factory ones

The main differences are as follows:

- Homemade products are not controlled by anyone. That is, it is not so easy to check their strength and density, for example. Of course, verification can be carried out, but its cost is quite high, which will reduce, if not completely eliminate, savings.

- It is difficult to obtain material with good geometry at home. The same should be said about deviations of products from nominal sizes.

- External characteristics will also be significantly inferior to products manufactured at the factory.

- The only advantage of handicraft is the price. As a rule, many people manage to reduce the cost of construction by making the material cheaper.

- At the same time, labor costs can become colossal, and the construction time will increase significantly.

The appearance of a home-made product

The above clearly speaks of the advantage of buying finished products. However, if price is decisive for you, or just a desire to try yourself as a manufacturer, then you may well give preference to home release.

Silicate brick manufacturers

LLC "Kazan plant of silicate materials"

The largest domestic production, producing sand-lime bricks on German equipment. Thanks to the improvement of technology, it was possible to achieve a comprehensive improvement in the performance of silicate bricks. Products are distinguished by precise geometry and clear edges. We produce solid and hollow silicate bricks, single and thickened, as well as three-dimensional colored and rusticated bricks with a relief surface.

JSC "Yaroslavl silicate brick plant"

The plant has existed since 1931, produces 40 types of products, only silicate bricks produces more than 100 million pieces per year

Great attention is paid to the modernization of technical equipment, and the quality of the produced silicate bricks is checked by the factory laboratory. The range of products includes single and thick bricks, hollow and solid bricks, facing and ordinary bricks.

Lipetsk Silicate Plant LLC

The enterprise has been operating since 1938, today it is one of the largest in the field of sand-lime brick production, and is one of the hundred best enterprises in the country's construction sector. Since 2015, the plant has been using German equipment for the production of sand-lime bricks, annually more than 130 million pieces of conventional bricks are produced here. The production of single and thickened building bricks, hollow and solid, has been mastered; not so long ago, colored silicate bricks appeared in the range.

CJSC "Kovrovskiy silicate brick plant"

The company's products are in demand both in the Vladimir region, where they are produced, and in other regions of the country.

The plant pays great attention to checking the quality of products and constantly expanding the range of silicate bricks. At the moment, solid and hollow bricks are produced, painted and unpainted, as well as rusticated bricks, the color range is constantly replenished with new shades

CJSC "Voronezh Combine of Building Materials"

The plant has been operating for over 60 years, during this time it has been repeatedly reconstructed and re-equipped with more modern equipment.The modernization process is ongoing here, which makes it possible to increase production volumes, which at the moment have reached 144 million. conditional brick pieces in year. Although the range of products is expanding, silicate bricks remain the basis. Here they produce ordinary and front bricks, painted in several different shades, as well as painted chipped bricks, several different types of splitting are used.

LLC Mikhailovsky Silicate Brick Plant

The enterprise is located in the Volgograd region, the production capacity allows to produce up to 120 million pieces of conventional bricks per year. The factory strictly controls the quality of manufactured products. At the moment, the company produces hollow and solid bricks, smooth and chipped, white and colored bricks. For coloring products, a German pigment is used, which does not fade for at least 25 years of operation.

CJSC "Borsky silicate plant"

This enterprise has 80 years of successful work behind it, is equipped with modern production equipment, and all products undergo strict quality control before they go to the buyer. More than 100 million units of conventional bricks are produced here annually, the range is constantly expanding. The enterprise has its own laboratory. The geography of product sales includes 15 regions of Russia. The silicate brick is produced single and one-and-a-half, solid and hollow, as well as painted and embossed bricks.

JSC "Cherepovets silicate brick plant"

Since the founding of the plant in 1972, it has been considered one of the largest manufacturers of sand-lime bricks in the North-West and in Russia in general. The design capacity allows the production of 100 million units of conventional bricks per year. The range of manufactured products includes solid and three-hollow silicate bricks, ordinary and front, single and one-and-a-half. Since 1998, the production has been producing three-dimensional colored bricks, since then the color gamut has been constantly expanding, and recently a silicate brick with a rusticated surface has appeared.

CJSC "Silicatechik"

The plant is located in the Ulyanovsk region, has been operating for over 60 years, specializing in the production of silicate bricks, which is produced here in the amount of 104 million units of conventional bricks per year. The assortment is not as wide as that of competitors, but the quality is always at its best. The enterprise produces ordinary and front sand-lime bricks. Facing bricks are available in several different shades.