Registration

Lego bricks are great building materials. It is very easy to set up its production. You will also need to purchase equipment.

But registration is the most important thing in this case. You can register your business as an individual entrepreneur or LLC

This type of activity as an individual entrepreneur is best suited for a small business. This is exactly what the production of Lego bricks will be like. The company must be registered with the tax office. For the registration procedure, you will need to pay 800 rubles.

You can pay taxes in one of two ways:

- From the proceeds. The rate is 15 percent.

- From income. In this case, the tax rate will be 6 percent.

Of course, this may only be suitable for small-scale sales of goods. In the event that the business will focus on large clients, then it is best to register as an LLC.

Premises

Since you do not need very large areas for equipment for making Lego bricks, it is also possible to try to create this business at home - even an ordinary garage is enough for you.

At first, even 15 square meters will be enough for you. This area is enough for you both for storing finished products and for machine tools. In order to reduce logistics costs several times, you can transport the equipment to the client's construction site and make bricks there. If you have created a small factory for the production of Lego bricks, you will need to competently equip the room, engage in lighting and equip a high-quality ventilation system. Due to the small area, and maintaining the conditions inside it, and you will not need to work in large investments. monthly maximum expenses will be approximately no more than 30 thousand rubles.

Equipment

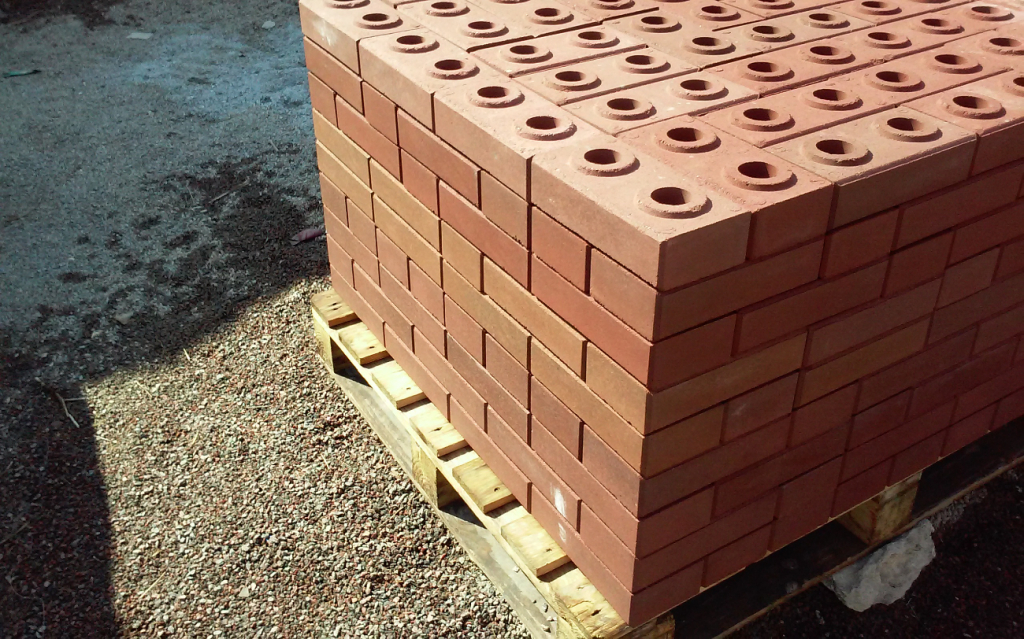

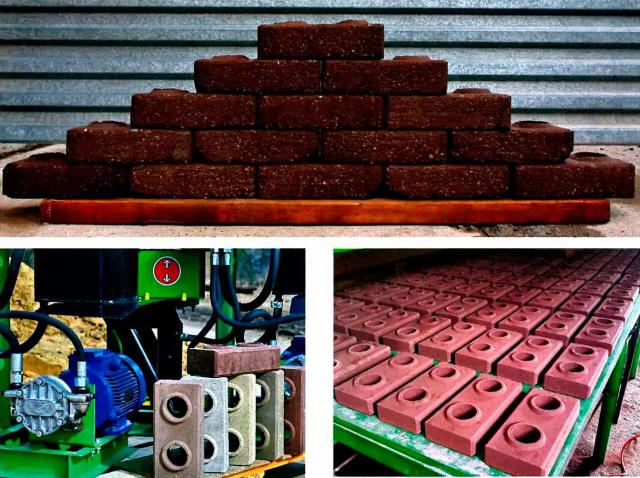

At the very start of your business, you only need one machine for making Lego bricks yourself - in just one shift (8 hours) you can make about 2000 products on it. You can also purchase equipment, both domestic and foreign. In some cases, the kit will include a matrix, but basically, you need to buy it separately.

What to look for when choosing a machine?

The quality of the manufactured products will also depend on the competent choice of equipment. As a consequence, the amount of your income will depend on the given circumstance.

The main characteristics of the machine:

- Matrix wall thickness - from 20mm.

- The force of pressure on the workpiece - in order to obtain a high-quality brick, it must necessarily be 35 tons.

- Hardness of steel.

- The ability to customize the geometry of the product - depth, size, filling of raw materials.

The volume of production per shift - in addition to the work of the machine, this will also be influenced by the speed of preparation of the workplace and the rest of the workers.

Matrix type

Depending on the range of products you make, you can use the types of matrix for brick production:

- Single.

- Fitting - bricks will be obtained with side couplings.

- Rail-like - you can carry out communications within the material.

Raw materials

The technology for making Lego bricks is slightly different from the production of ordinary ceramic bricks. Primary distinguish raw material used. The basis of the Lego brick component, which occupies up to 95% of the total mass of the product, is limestone screening. The remaining ten percent is water, binder cement and cola. For 1 cubic meter of finished stone, you will need about 1600 kg of the main component and 220 kg of cement. The cost of raw materials is not very high, the cost of 1 unit of production in this case will be approximately 4 rubles.You can sell each of them 3-4 times more expensive on average. If you deduct all of your expenses, you have a 60 percent return. In some cases, clay can still be added to give the material special properties. Of course, you will have to burn the finished products with clay in the composition in order for them to be durable.

Lego brick making equipment - price

For the production of Lego bricks for commercial purposes or to meet the need for this type of building material, you will need to purchase the appropriate equipment. Production machines can be divided into two types: manual and electric. The former do not require additional costs from the owners, however, they differ in less productivity.

Machines, the productivity of which does not differ in high value (production of about 1 thousand pieces during a shift), can be purchased for 78-300 thousand rubles. If we talk about medium-power machines (about 2 thousand pieces during a working day), then they can be purchased for 350 thousand rubles. The equipment, which can be classified as a mini-factory or industrial-grade machine tools, is capable of producing about 750 bricks in one hour. The cost of such devices is more than 2 million rubles.

To organize the production of small volumes, you will need a machine weighing 750 kg. Thus, when creating your own Lego brick production, it is worth choosing a suitable room. The dimensions of a low-performance machine are: width - 1 m, height - 2 m, and length - 1.5 m. To ensure the operation of one such machine, there will be a sufficiently small area. At the same time, when buying more productive equipment, you should initially worry about providing free space. The same applies to business. Over time, the premises will have to be expanded to accommodate new machines.

Advice

When buying a Lego brick making machine, pay attention to the number of working cycles that it can withstand without the need for repairs. Manual ones usually withstand about 500 thousand cycles, while electric ones are more durable in this respect - about 0.6-1 million cycles

An important parameter is the amount of time that needs to be spent on the production of one brick. On average, this will take 15-30 seconds.

In addition, it is important to estimate how many bricks can be produced in one cycle. The more the machine can produce at a time, the faster the cost of its acquisition will pay off.

The strength of the brick depends on the pressure applied during its creation. Some of the machines develop an indicator of 2 tons, which is completely insufficient for the construction of a number of buildings. To obtain a brick that can be used in the laying of load-bearing walls, you need to create a pressure of about 30 tons or more.

Today Russian manufacturers were able to take their place in the production segment lego brick machines, displacing almost all importers of similar equipment. This is a rather rare case, as it is often cheaper to order a supply of equipment for small businesses from China. Some large companies are used, as a rule, to create large batches within a short period of time. Swiss steel is usually used for production. All products of foreign suppliers can be evaluated remotely, since they often leave reviews, which highlight both positive and negative aspects. One thing is invariable - their cost is several times higher than domestically produced machines.

How to choose masonry glue

The choice of adhesive depends on the purpose of its application.

When buying a mixture, you need to pay attention to the following quality characteristics:

- compressive strength;

- adhesive properties;

- density;

- frost resistance;

- drying speed.

For the construction of external walls, compositions with high frost resistance should be selected. Seams made of such glue will not collapse at low temperatures, and due to low thermal conductivity, so-called cold bridges do not form in structures. The walls will reliably keep warm inside the building. For internal partitions, it is better to choose an adhesive with the best environmental performance and a high drying rate.

If you need to lay out the oven, then here you need to take into account such indicators as heat resistance and heat resistance. Heat-resistant glue (Scanmix Fire, Profix) is used for laying furnace elements

It is highly resistant and can withstand temperatures up to + 1400 ° C. For facing a fireplace or stove, heat-resistant glue (Plitonit Superkamin, Terracott, Hercules) is suitable, which is also resistant to heat, but the maximum temperature for it is much lower - up to +500 ° C. In addition, the finishing compound must be very flexible.

When erecting oven complexes on the street - barbecues, stoves, tandoors - it is necessary to take into account both heat resistance and frost resistance indicators.

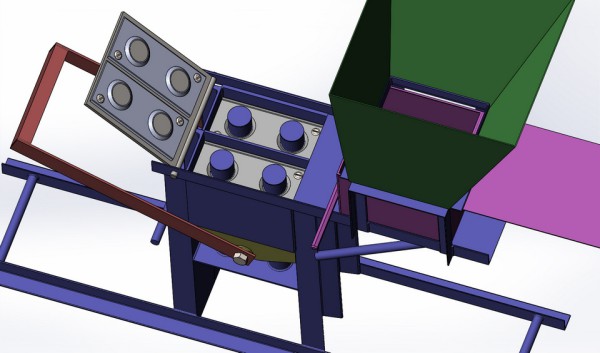

Description of equipment

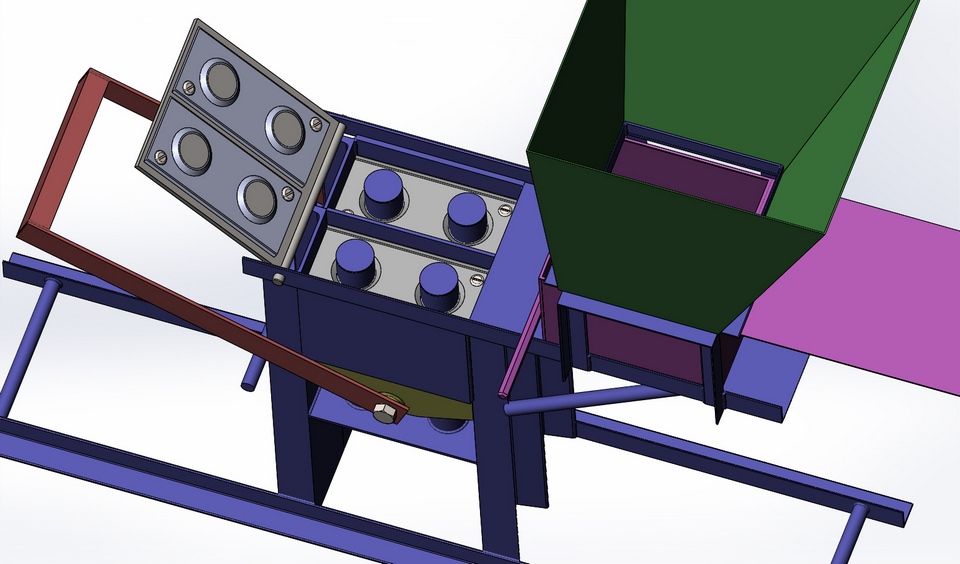

A lego brick making machine is a structure that includes certain units mounted on a metal frame. The Legostanok considered here allows semi-automatic production of Lego standard bricks.

The unit allows you to obtain Lego bricks by pressing under high pressure, without subsequent firing in thermal furnaces.

Operating principle

The prepared mixture for the formation of bricks enters a special hopper, then, with the help of a dispenser, the mixture enters the molding space, then with the help of a hydraulic press, the mixture is compressed under high pressure, as a result, a finished product is obtained.

The prepared mixture for the formation of bricks enters a special hopper, then, with the help of a dispenser, the mixture enters the molding space, then with the help of a hydraulic press, the mixture is compressed under high pressure, as a result, a finished product is obtained.

The machine is equipped with a three-phase electric motor and an oil pump to pressurize the hydraulic cylinder.

In contrast to analogs with a manual pressing mechanism, Legostanok using a mechanized compression process allows you to achieve higher pressure and increase the productivity of the process.

Specifications

The parameters of the machine are optimal for its placement in a limited area. The correct organization of labor and preparatory processes in obtaining the mixture allows you to achieve high performance.

- height - 1200 mm;

- length - no more than 800 mm;

- width - 650 mm;

- press hydraulic pump drive - electric (manual);

- electric motor power - 3000 W;

- required power supply - 380V, 3-phase connection system;

- the maximum developed pressure by the press is not less than - 40 kg / cm2;

- average time of brick formation in the press chamber - 10 s;

- the maximum output of finished products with timely loading of the receiving hopper is about 200 bricks / hour (for machines with a hydraulic drive).

The main components of the machine include:

- loading hopper;

- hand-operated mixture dispenser;

- forming chamber;

- a matrix that allows you to get the proprietary geometry of the holes of the Lego brick (located in the molding chamber);

- electric motor;

- oil pump;

- hydraulic press (powered by oil pumped by a pump);

- machine frame.

Modes of operation

The machine can operate in manual and semi-automatic modes. Manual mode provides for the process of forming products by using a lever mechanism capable of creating the required force in the press sole. The semi-automatic mode of operation allows the operator only to open the valve on the hydraulic line at the right time, forming is carried out using a hydraulic press.

Semi-automatic mode increases the productivity of the machine by 1.5–2 times. The finished product is of a higher quality, since it is possible to achieve the required pressure for the adhesion effect of the substance at the molecular level. Characteristics of bricks that can be produced on the machine

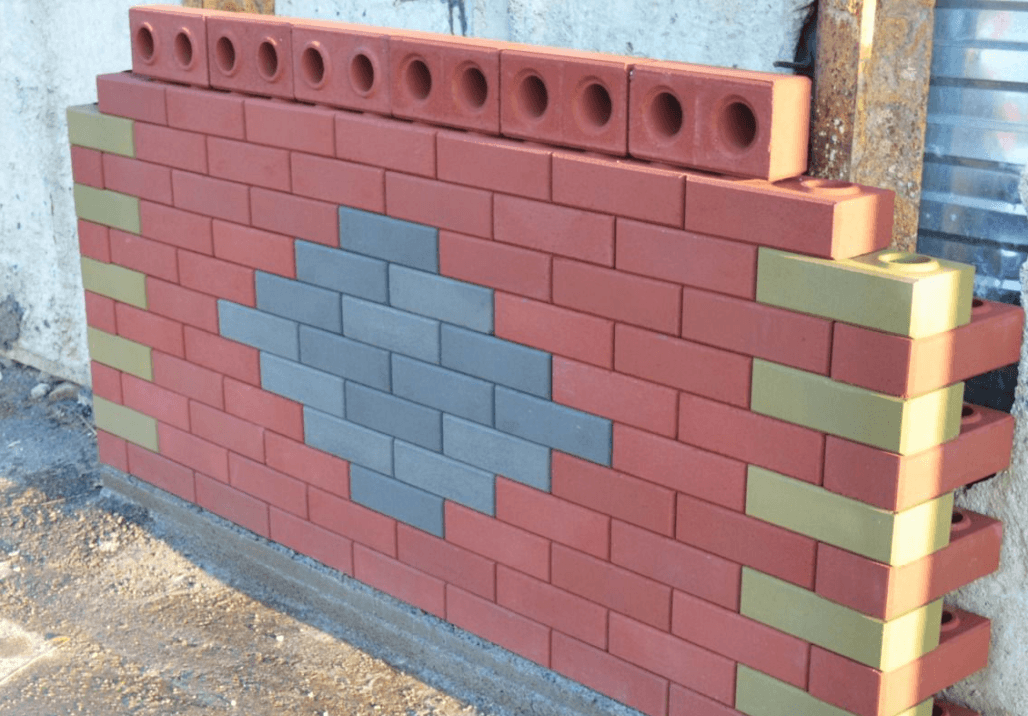

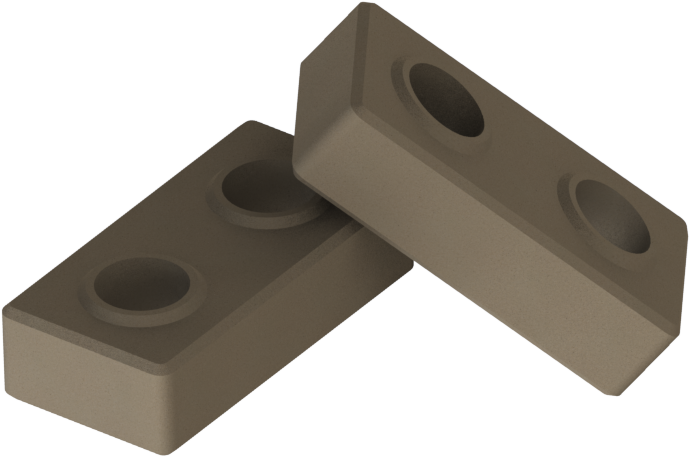

The brick obtained on the machine has two convex spherical holes on its upper plane, and two holes with a concave sphere on the lower plane. This is the hallmark of the Lego standard. This geometry allows you to clearly fix products during construction using adhesive solutions.

Geometric dimensions of the finished product:

- length - 250 mm;

- width - 125 mm;

- height - 45-80 mm;

- weight - 3.5–4 kg (depending on the component composition);

- maximum withstand pressure - 300 kg / cm2.

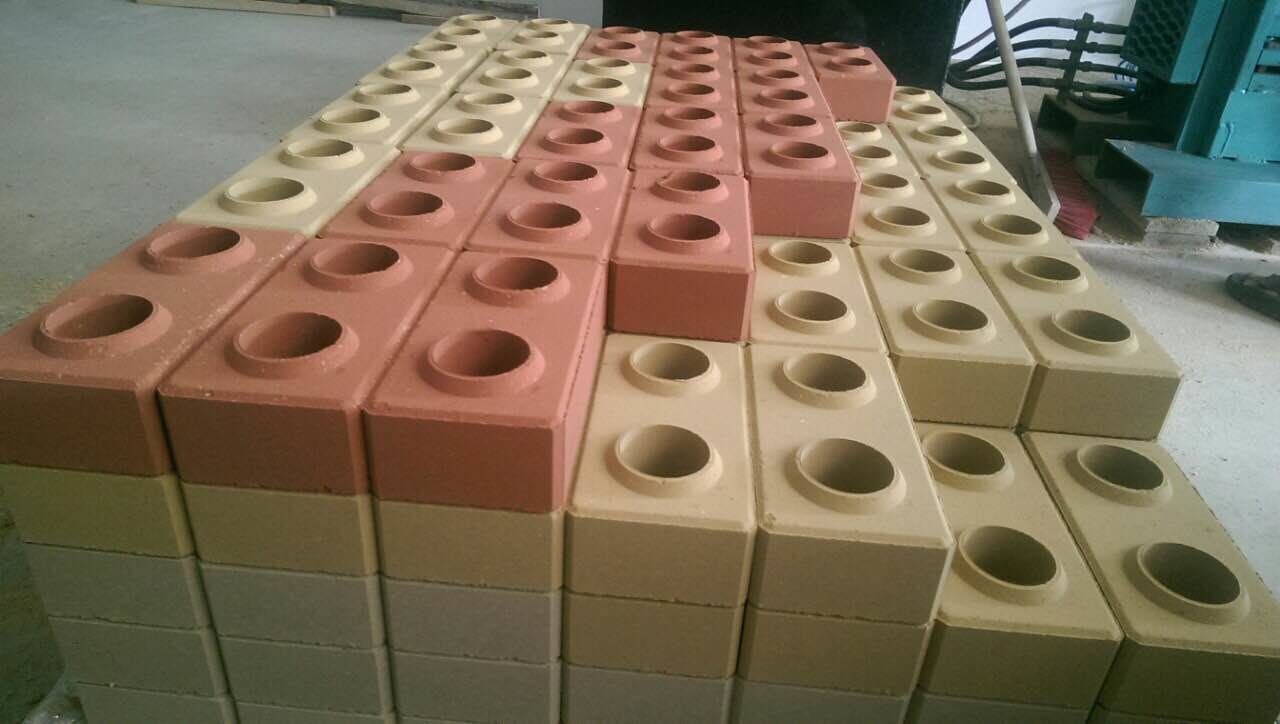

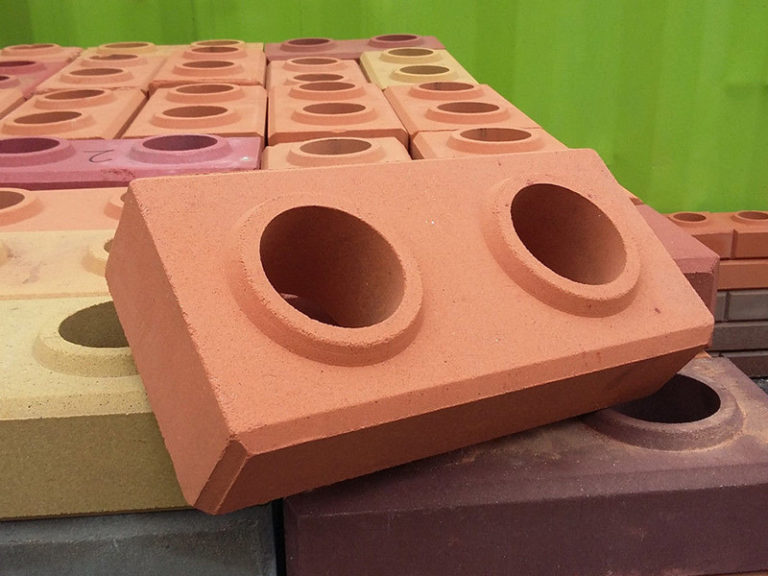

The material from which the products are made usually has the following varieties:

- clay-cement composition (90% clay, 8% cement and water);

- clay-sandy composition (35% sand, 55% clay, 8% cement and water);

- composition based on various screenings (85-90% screenings, 8% cement and water).

Production planning takes into account the availability of raw materials. The bricks obtained by the pressing method require raw materials of a fine fraction, this must be taken into account in order to achieve the required strength.

Products made from screenings have the highest strength characteristics. High sand content degrades the strength index due to the presence of coarse sand fractions.

Products made from screenings have the highest strength characteristics. High sand content degrades the strength index due to the presence of coarse sand fractions.

The production of lego products should include the presence of special molding dies, with the help of which a surface is created with the required smoothness and given geometric dimensions.

For a full-fledged production, it is necessary to have the entire set of matrices that allow you to obtain halves of bricks and fitting products used in finishing work.

Business organization by stages

To start a production from scratch, you first have to register with the tax office. Then the entrepreneur needs to find premises, buy equipment, raw materials and hire workers.

Legalization of activities

It is convenient to register a small business as an individual entrepreneur. The documents are submitted to the tax service at the place of registration:

- passport and copies;

- TIN;

- application (form Р21001);

- receipt of payment of state duty.

It is important to immediately choose a convenient tax regime. In this case, a simplified

Rates are available on it - 6% of income or 15% of the difference between the income and expenses of the enterprise. The second option is preferable, since about half of the proceeds will be spent on the purchase of raw materials, rent, utilities and workers' wages.

The statement indicates the OKVED code 23.32. It allows the production of non-refractory building materials from clay - bricks, tiles, deflectors and floor blocks.

Premises for workshop and warehouse

A small production hall can be set up in an area of 80–100 m2. Most of the space will be reserved for the finished product warehouse. Workshop requirements:

- location on the outskirts of the city, as this will save on rent;

- availability of a convenient entrance and a platform for loading and unloading raw materials and bricks;

- serviceable wiring 380 V;

- ventilation system;

- connection to the central heating system.

Equipment

Machine tools for the production of paintwork are manual, semi-automatic and automatic (mini-factories). They differ in performance, press pressure, energy consumption indicators. On automated lines, it is possible to change the settings and parameters of the brick with millimeter precision. Equipment prices are different, let's look at this example:

- The cost of manual (mechanical) machines varies from 36,000 to 55,000 rubles. Capacity - 100-110 items per hour, 800-900 per shift. Pressure - 9-10 tons.

- A hydraulic machine with a capacity of 160-170 bricks per hour or 1200 per shift will cost an entrepreneur 155-170 thousand rubles. Power consumption of the unit - 11 kW, pressing force - 20 tons.

- Hydraulic equipment with a capacity of 350 pieces per hour costs more than 300 thousand rubles.The pressing force can be adjusted independently - 16–30 tons.

- A mini-plant with a capacity of 600 items per hour costs 400–550 thousand rubles.

To make bricks of different shapes and sizes, you need dies. These are the forms due to which products are obtained in the form of a cube, parallelepiped, with two or four holes. For a small plant, 4–6 types of dies are sufficient. The appearance of the finished product largely depends on their quality.

To prepare the mixture, you need a concrete mixer. The price for it depends on the volume and manufacturer and varies between 60,000-250,000 rubles. Other equipment:

- shipping belts;

- pallets;

- shovels;

- containers for water, cement;

- brushes for cleaning the hopper.

A total of 550,000 rubles will be spent on equipment with a capacity of 3,000 bricks per shift.

Raw materials

Success in the lego brick business depends on reliable suppliers. The task of the entrepreneur is to find partners who do not fail on the delivery time and set reasonable prices for the goods. Types of raw materials:

- screening of crushed limestone is 80–90% of the mixture;

- astringent components - cement or Portland cement;

- pigments - dyes for imparting color to products;

- plasticizers - used to increase the strength of the material.

Staff

1 person can work on one machine, but he needs an assistant who will prepare the mixture and put it into the bunker. You will also need a worker to carry out loading and unloading operations.

The position of the director of the enterprise will be occupied by the organizer of the project. His responsibilities include monitoring employees, finding suppliers and distribution channels for products. Accounting is outsourced. When the volume of production increases, you can buy an additional machine and expand the staff.

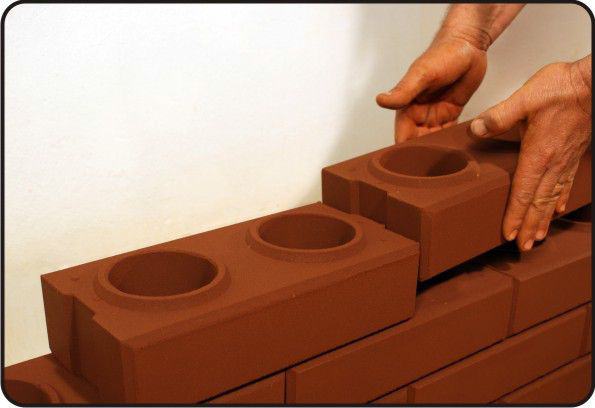

Working with lego bricks

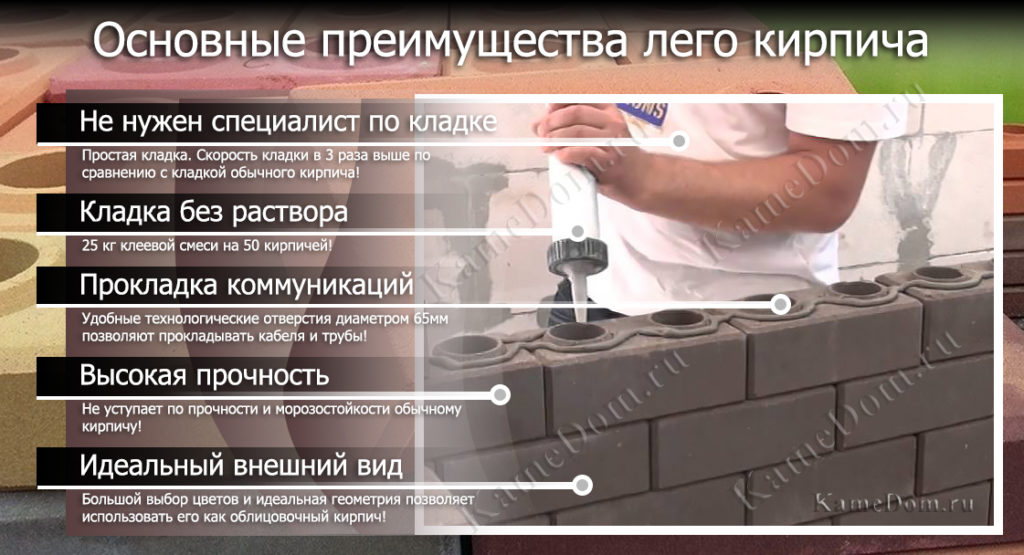

One of the key benefits of working with Lego bricks is the ease of installation. Unlike the "classic" analogue, for the installation of which it is necessary to master the rather complicated profession of a bricklayer, the installation of Lego does not cause any difficulties. Thanks to the special shape of the brick with two pilot holes, installation is greatly simplified.

It is enough to lay out only the first row according to the level and guides - all other rows will be installed by themselves during the laying process thanks to the guides.

A minimum of glue is required for masonry: the bricks fit perfectly to each other, therefore, no more than 25 kg of glue is used for 500 bricks.

Even an inexperienced master will get the perfect dressing of the seams, since laying along the guides completely eliminates the traditional mistakes of an inexperienced bricklayer.

The laying speed is 2-3 times higher than that of conventional bricks.

Due to its low water absorption and high density, the brick is not afraid of dirt. If excess glue leaks outside the seam, it can be removed with a slight movement of the trowel after the glue has dried.

Since the new type of brick provides through holes through the entire masonry, it is very convenient to carry out reinforcement. If it is planned to erect low structures (for example, fence elements), you can carry out the masonry without any mortar or glue at all. The brick is laid out on dry, after which reinforcement is inserted into the holes in the masonry and the cement is poured.

The use of Lego bricks involves filling the holes with concrete and reinforcing with rods with a diameter of 10-20 mm. As a result, an increase in the strength of the masonry is achieved, the reliability and stability of the wall geometry is ensured.

It is worth noting that the filling must be carried out in stages - no more than six rows at a time. Filling with concrete, say, the entire finished wall (more than 10 rows) can lead to violations of the geometry of the masonry

Holes in the masonry are also convenient to use for the installation of utility networks.The presence of a cavity in the walls makes it possible to lay all engineering networks without making additional holes, after which it is possible to fill the holes with concrete.

Valeria Petrova

Business registration features

Before starting an enterprise, it must be registered with the tax authority.

The owner chooses the form of organization at will.

What documents are needed for registration

The type of organization (LLC or individual entrepreneur) will not affect the work of the enterprise. This will affect the number of documents required to register a company.

If you open an individual entrepreneur, the main package of documents will be:

- a completed application - not only personal data (full name, place of residence by registration, passport data) are entered into it, but also OKVED;

- copy of a civil passport (all pages);

- copy of TIN;

- copy of SNILS;

- confirmation of payment of the state fee.

Additional package of documents:

- notification of the transition to the simplified tax system - it is drawn up in 3 copies when choosing a simplified taxation system;

- power of attorney - useful if another person will register the individual entrepreneur;

- parental consent - only minor citizens need.

When registering an LLC, add to this list:

- articles of association;

- decision to establish LLC;

- minutes of the meeting of founders.

Which OKVED to indicate

In the registration documents, the entrepreneur indicates OKVED (classification of the type of activity). Their number is not limited, you just need to highlight the main activity code.

Lego building materials are produced from several types of materials. Therefore, OKVEDs may differ (23.20, 23.20.1, 23.61). If you sell finished products through specialized stores, add clause 47.52.72 to the registration documents.

Which taxation system to choose

The choice of taxation system will directly affect the profit of the firm. When opening a small workshop or garage production, it is worth stopping at a simplified system (USN).

You decide which kind of "simplification" to prefer by calculating the business plan, just as we did in our example.

DIY brick lego machine

You can make your own lego brick making machine. Before starting work, it is necessary to prepare certain materials that will become the basis for the machine. These include:

- channel;

- sheet steel;

- metal corner;

- a pipe for creating a handle and a piston;

- bolts and nuts.

You will also need a tool. At the very least, a grinder and a welding machine will come in handy. The legs of the cylinder must be made from sections of the channel, the length of which is approximately 1 m. The width of the cylinder will correspond to the length of the brick to be produced. Two metal rectangles must be welded between the posts in the upper part, which will form a cross-section.

Homemade Lego Brick Making Machine

Homemade Lego Brick Making Machine

A channel is applied to the resulting structure, the length of which is approximately 0.7 m. It must be placed with the ribs up. It should be welded on one side, and under the protruding part, fasten it with supports. After that, a hole is cut above the cylinder, corresponding to its perimeter. The hopper will be welded from sheet metal

It is important that its width and length fully correspond to the dimensions of the final form. The hopper is mounted on 4 legs, the basis of which will be metal strips welded to the protruding part of the channel

We make the piston from a metal sheet. Two pipes must pass through this rectangle.

We make a handle from trimming pipes and metal strips, with which the lid will open and close. The handle is secured with long bolts. The corner is needed to make the base for the machine. A homemade machine will make it possible to independently make two types of bricks. It can be either lego with holes or corpulent.It is not worth making a matrix. It is much wiser to purchase a ready-made one.

Lego brick is actively spreading on the market today, but consumer confidence in it is low due to little operating experience. It is difficult to say how long a house made of this material will last, since its active use began relatively recently. Today there are a number of reviews from builders who used machines to make this brick.

Many emphasize that this is quite simple, but at the same time, some emphasize the low thermal insulation qualities of bricks.

A number of manufacturers emphasize the quick return on investment of the production line. In some reviews, values are indicated in 6-7 months due to the organization of work for large-scale and projects that require a large number of bricks for construction. The line can be assembled at a cost of about 700 thousand rubles. It should be noted that the organization of work from the point of view of legislation also affects the payback period.

It is important to understand what types of taxation exist for an LLC. so that you do not have to give all the profit to government agencies

For a successful sale, it is recommended to use a large warehouse, since it is a solid stock of the product that attracts a large buyer. Many builders do not risk using Lego bricks to create houses, but they willingly buy it for the construction of fences.

Production equipment

To start production, you will need a set of equipment that allows you to prepare raw materials and shape products. The following types of aggregates are presented on the market.

- Manual machine.

Works by the method of semi-dry hand pressing. The unit is designed for the processing of cement-clay and cement-sand mixtures under a pressure of 16 MPa, it only forms finished products. The previously prepared mixture is poured into the hopper. For its preparation, the purchase of a crusher and a mixer is required. The working cycle of the machine takes about 20 seconds. Estimated productivity of the machine - up to 1500 pieces per work shift. Not suitable for making high-strength bricks for outdoor use.

- Semi-automatic hydraulic machine.

Pressing is carried out under a pressure of 70 tons. The machine is equipped with an automatic dispenser, concrete mixer and a trailer. Its productivity is much higher - up to 250 pcs / h. or up to 2000 pcs. per shift. Designed for any shape, composition, size and purpose. The only inconvenience is the laborious removal of the finished product.

- Automatic machine.

Fully automatic line, producing up to 400 items per hour and up to 3600 per shift. The full production cycle is 8 seconds. The equipment is equipped with electronics that optimize the control process. Automatic lines make it possible to produce a wide range of products due to simple replacement of dies and the use of raw materials of different composition.