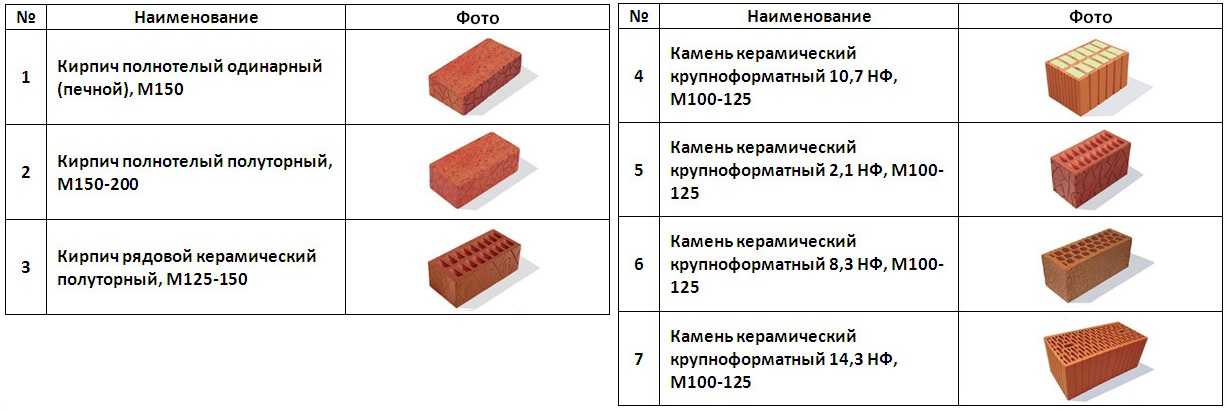

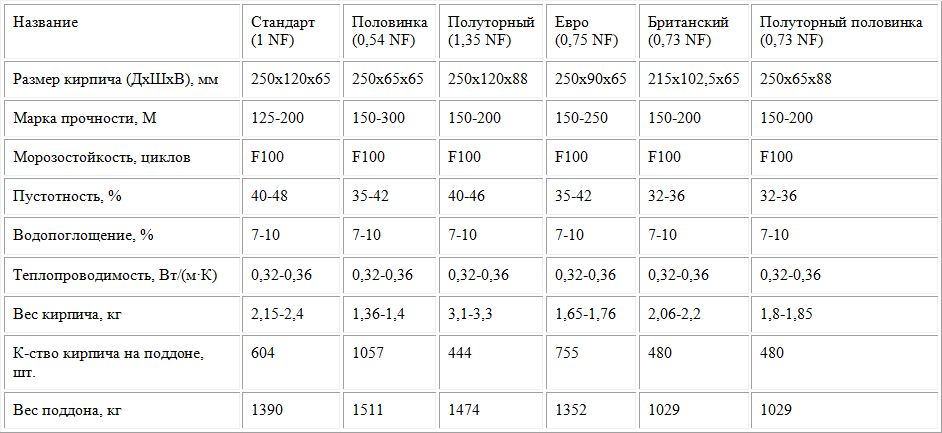

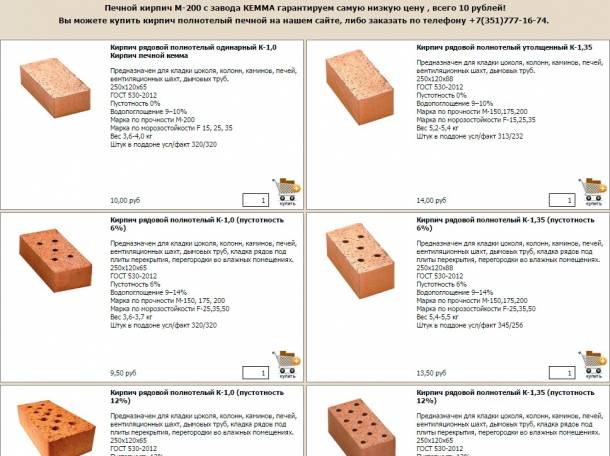

Examples of hollow and porous bricks produced and:

| Size (mm)

: 250x120x65Weight (kg) : 3,4Density (kg / m³) : 1700Brand : M175, M200, M250Frost resistance : F35, F50Water absorption (%) : 6Thermal conductivity (W / m ° С), at 0% humidity : 0,53 |

| It is used in building structures with increased requirements for strength and reliability. Recommended for the construction of high-rise brick buildings. |

| Size (mm)

: 250x120x65Weight (kg) : 2,3Density (kg / m³) : 1120–1190Brand : M125, M150, M175Frost resistance : F35, F 50Water absorption : (%) 6Thermal conductivity (W / m ° C) at 0% humidity : 0.24 (on light solution) |

| Used for the construction of internal and external walls. |

| Size (mm)

: 250x120x65Weight (kg) : 2,2–2,5Density (kg / m³) : 1100–1150Brand : M 125, M 150 (M 175 on request)Frost resistance : F35Water absorption (%) : 6–8Thermal conductivity (W / m ° C) at 0% humidity : 0.20 (light solution) / 0.26 |

| It is used for the construction of external and internal walls of buildings and structures. It features five rows of voids, which reduces the consumption of masonry mortar by 20%. |

| Size (mm)

: 250x120x138Weight (kg) : 3,7–3,9Density (kg / m³) : 890–940Brand : M 125, M 150 (M 175 on request)Frost resistance : F35Water absorption (%) : 6,5–9Thermal conductivity (W / m ° C) at 0% humidity : 0.16 (light solution) / 0.18 |

| Advantages: excellent thermal insulation properties, soundproofing, less weight. It is used in the construction of external and internal walls, significantly increasing the heat-shielding properties of the house. Exterior walls made of porous stone are erected faster than walls made of ordinary hollow bricks, and the number of mortar joints is reduced. Its density is 30% less, it is lighter, which leads to a decrease in the loads on the foundation structure. With a smaller wall thickness of 640 mm, porous ceramic gives the same thermal insulation effect as a conventional brick wall of 770 mm. |

Types of solid bricks

Brick house

So, what do we know about brick:

- That it is a strong, durable and reliable material, buildings from which stand for 100 years or more.

- The brick houses are warm, the facades are beautiful.

- Laying bricks is easy and pleasant, but long.

- Brick is made from natural components, therefore it is an environmentally friendly material.

Natural clay for ceramic bricks

The cost of bricks is relatively affordable.

This is general knowledge about this material. We want to tell in more detail what types of solid bricks are produced, the characteristics of which mainly affect the choice of bricks for the construction of various objects.

What is a solid brick in composition

Bricks differ in composition, technical and operational characteristics, and are of the following types:

Ceramic.

Red solid brick

It is made of clay, molded, dried and fired in an oven at a temperature of 950-1000 degrees. The high processing temperature gives the raw material special strength.

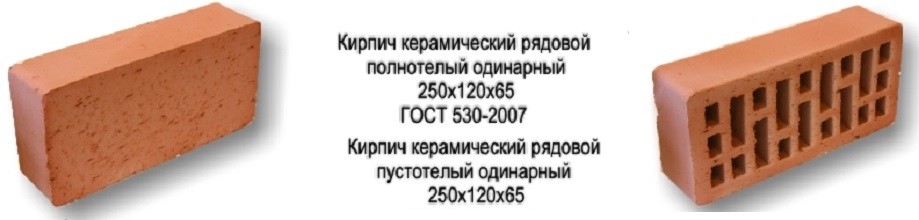

The structure of the final product is light and porous. Solid brick is a monolithic product, according to GOST 530–2012 the presence of voids should not exceed 13%. If this parameter is higher, then such an instance is referred to as a hollow version.

Colored ceramic bricks

The red color of the product is due to the iron present in the clay. The more it is, the more saturated the color of the brick. Although now they produce bricks of various colors, which depend little on the presence of iron, from pale pink to emerald. This is achieved by adding organic dyes to the mixture.

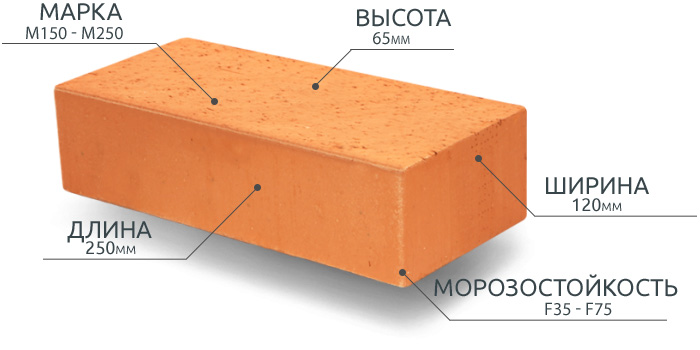

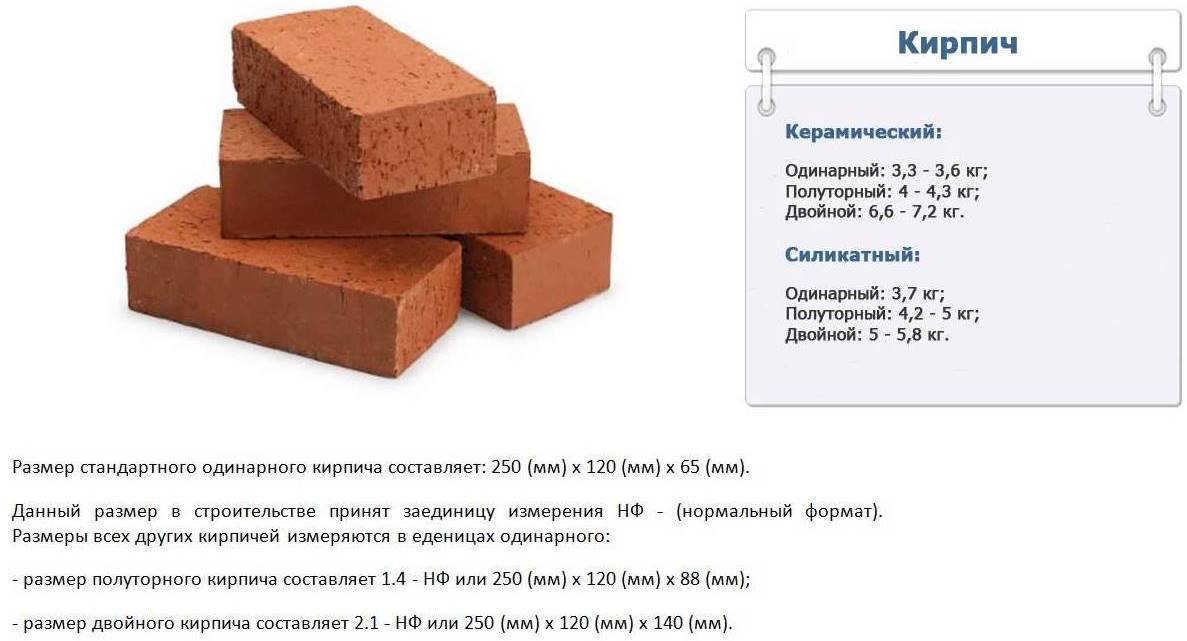

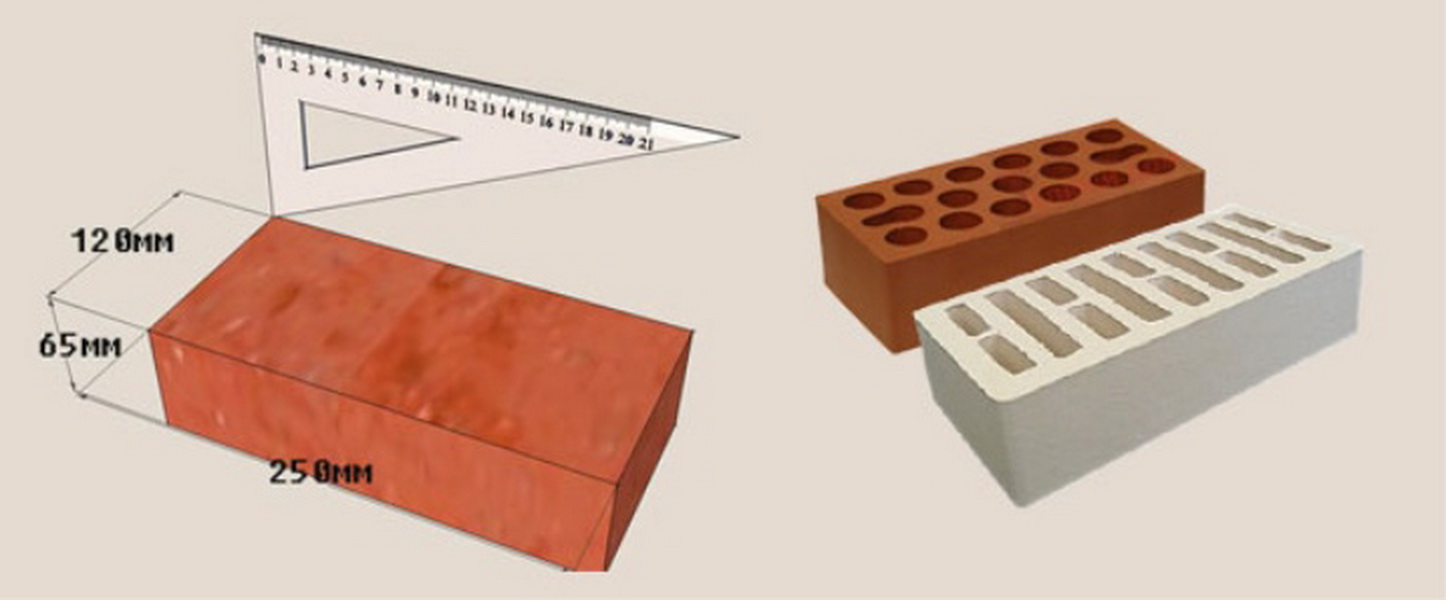

Standard dimensions of solid bricks: 250 x 125 x 65 mm (length, width, thickness).

Silicate.

Silicate brick

It is produced by semi-dry pressing of a mixture consisting of lime, quartz sand and water. Raw brick is subjected to further autoclaving with steam under pressure and high temperature, giving it a monolithic structure.

Colored silicate brick

Silicate brick is available in several colors: black, white, yellow, blue. Various shades are obtained by adding organic or mineral dyes to the mixture.

In turn, sand-lime brick can be single and one and a half.Dimensions of a solid single brick - 250 x 120 x 65 mm; one and a half - 250 x 120 x 88 mm.

Hyper-pressed.

Colored hyper-pressed brick

It is made from a mixture of cement, limestone and dye. The mixture is pressed under high pressure in special molds. The result is a solid brick with perfect geometry and uniform deep color.

A brick is produced with a smooth or front side, and is mainly used for decorative finishing and cladding of buildings.

Scope of full-bodied brick

Depending on the type of brick, the places of its application also differ:

Solid ceramic bricks

Construction of houses

Building

Facade cladding

Facade cladding with decorative bricks

Construction of stoves and fireplaces

Roasting pans and barbecues with low temperature load

Construction of fences

Arrangement of fences and decorative elements

Installation of pipes and chimneys

Construction of internal partitions

Foundation and basement masonry

Plinth construction (dry climates only)

In addition, the brick is divided into:

An ordinary person who has deliberately unprocessed rough surfaces for better adhesion to finishing materials (plaster, putty, etc.). Such a brick is suitable only for laying partitions, do-it-yourself main walls, subject to subsequent decorative finishing.

Ceramic brick, corpulent, ordinary

Front, in which all sides have a smooth, even surface, as well as geometrically accurate dimensions. Such bricks are used for facing facades, arranging fences and light decorative buildings.

Face brick

Facade, its front side is covered with a decorative finish imitating natural materials (stone, wood, marble, etc.).

Facade brick

As you already understood, the areas of application for both red ceramic and white silicate bricks are almost the same. But there are some differences in material specifications. This is exactly what we'll talk about in the next section.

How to distinguish brick m125 from m150?

"Other"

A question for connoisseurs: and what is a brick made of? Can you give any links to all this info? Thanks

Best Answers

This is an indicator of strength, the brand of brick determines the load (in kg) per 1 sq. cm, which a brick can withstand.In industry, brick grades are produced: 75, 100, 125, 150, 200, 250, 300.

More details .strdom / page_0049 / page_0063 /

according to the tensile strength of kg per centimeter squared and m is simply the naming of brands. made in my opinion usually from red clay

Answers from experts

As a rule, strong brands of bricks are more direct to CERAMICS, if you hit it with a hammer, it sounds! And if you break it, then it will have sharp strong fragments, which can cut yourself, or rather ceramics! You can visually distinguish it!

but throw it from a height of 10 meters and see

If it falls apart easily in the hands, then M50, if with difficulty, then M100, if it does not fall apart, then M150 and higher. And why do you need M250, if the strength of the masonry mortar is usually not higher than M150?

by weight. with the same dimensions, the one that is stronger, weighs much heavier.

Visually, by the number of pores, cracks, voids, the structure of the cut section.

To determine the grade of brick by strength in accordance with GOST, 5 bricks are taken from the batch and tested for compression and bending, and the grade is established according to the data obtained. The standard provides for 8 grades of bricks in terms of strength from M 75 to M 300 (kgf / cm2).

stroy-spraa / opredelenie-marki-kirpicha-po-prochnosti In accordance with GOST 530-95, the following frost resistance bricks are established F15, F25, F35 and F50. There is no F15 facing brick.

The number after the letter F indicates the maximum number of freeze / thaw cycles that a brick of this brand can withstand without signs of destruction. kirpich / 6

determination of the grade of bricks in structures - .ideasandmoney / Ntrr / Details / 113963

ceramic is clay brick, natural color is red (if without dyes), but clay is not always ceramic, clay can also be refractory - then the color is yellow

sand-lime brick - white

you can't just define a brand, without a certain skill. especially if it's a red brick.

* To check the quality of ceramic bricks, you need to knock on them with a hammer. A well-fired brick is not afraid of blows and rings like glass. If the sound is dull, then the brick is badly burnt.

And if the sound is peculiar, damn it, I cannot depict it with the help of Russian letters and symbols, but it cannot be confused with anything, then there is an internal crack in the brick and it is undesirable to use it, but in a heating place it is not at all possible.

Fired brick is less common, but you can see it right away - it is crooked and the color is slightly different from normally fired

Ceramics is clay. Normal ceramic brick is like ceramic, if you hit it, it sounds. If split, then its fragments have sharp edges, which can cut you.

Any brick must have a document in which all brands are indicated for different indicators. It is difficult to determine them yourself. Since, for example, the compressive strength is checked using a press, several samples are pressed and an average strength is obtained.

Other parameters, such as frost resistance, water absorption, thermal conductivity, can be determined only in the laboratory.

Theoretically, you can try to use a device to determine the strength of concrete, there are many such devices, they are not large, there are even pocket ones, of different types, you can rent it. The current does not know how much the data will be correct, and they can only determine the compressive strength.

Ischo, for low-rise construction, great strength is not needed at all, M70 will suffice, while the brick usually has the M100-150 grade, but frost resistance is a rather important parameter.

Delicate brick is very capricious to external influences, it has poor frost resistance, and the State Construction Committee prohibits its use for underground structures, since it is not resistant to aggressive groundwater.

This is the same. Density can be calculated in terms of mass.

Specifications

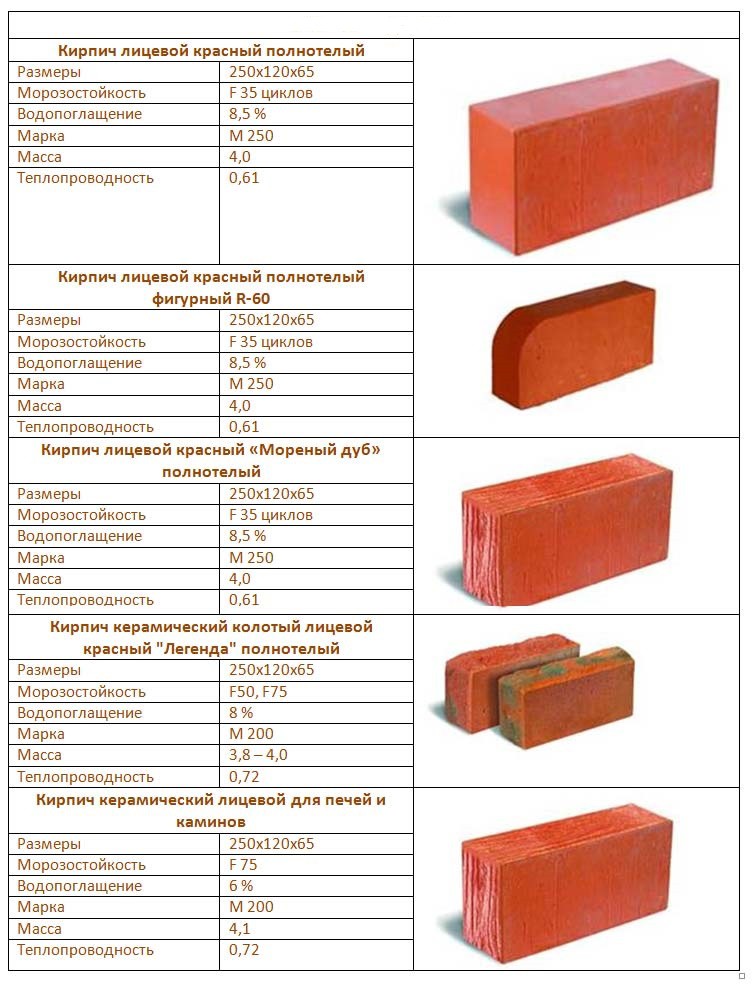

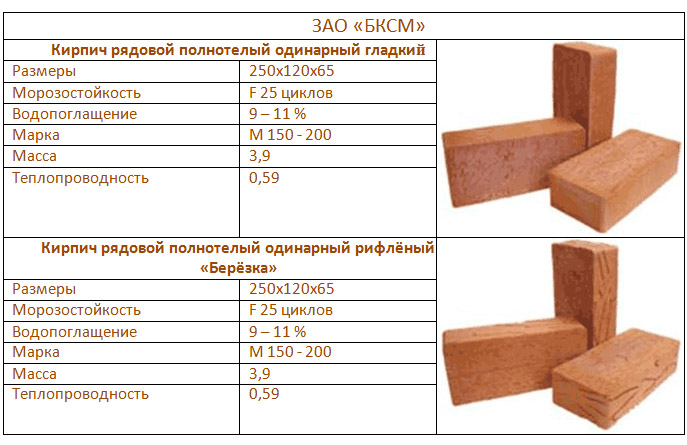

Red solid brick is a type of ceramic brick and has high performance properties. The material is used in the construction of objects, the walls of which will be subjected to regular or periodic weight, shock and mechanical loads. Solid products are often used to erect columns, arched structures, and pillars. The ability of the material to withstand heavy loads is due to the high strength of the clay composition from which it is made.

Each of the types of solid bricks is assigned a certain strength index, which greatly facilitates the selection of the required material. The index consists of two characters, the first of which is denoted by the letter M, and the second has a numerical expression and shows the degree of strength of the material.

The strength of a material is greatly influenced by its density, which indicates how much mass of a substance is contained in one cubic meter. Density is inversely proportional to porosity and is considered the main characteristic of a material's thermal conductivity. The average density of solid red brick is 1600-1900 kg / m3, while its porosity varies in values of 6-8%.

Porosity is also an important performance indicator and affects thermal conductivity and frost resistance. It is measured as a percentage and characterizes the level of filling the brick body with pores. The number of pores depends entirely on the purpose of the material and the technology of its manufacture. So, to increase porosity, straw, peat or crushed sawdust are added to clay, in a word, all those materials that, when burned in a furnace, leave small cavities filled with air in their place.

As for the thermal conductivity, its values for full-bodied models are quite high. This imposes certain restrictions on the construction of residential buildings from solid material and requires additional measures to be taken to insulate the facades. So, the thermal conductivity index of solid products is only 0.7, which is explained by the low porosity of the material and the absence of an air gap inside the brick.

Solid ceramics are widely used in the arrangement of structures, which are subject to increased fire safety requirements. This is due to the high fire resistance of the material and the ability of some of its modifications to withstand temperatures up to 1600 degrees. In this case, we are talking about fireclay models, for the manufacture of which a special refractory clay is used with a higher firing temperature during production.

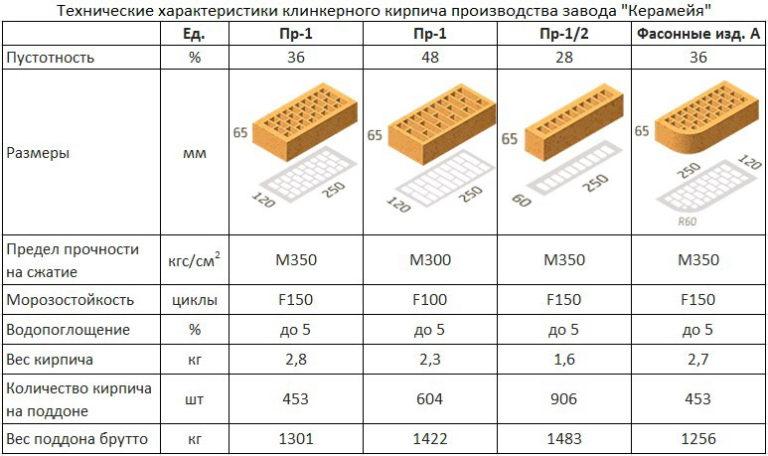

An equally important indicator is the frost resistance of the material, which is also indicated in the marking and denoted by the symbol F (n), where n is the number of freeze-thaw cycles that the product can withstand. Solid brick has an F75 index, which allows it to last up to 75 years, while maintaining its basic performance characteristics and not undergoing deformation. Due to its long service life, the material is often used for the construction of fences, open gazebos and outdoor stairs.

Water absorption also has a large effect on the performance of a material and refers to its ability to absorb and retain moisture. The hygroscopicity of a brick is determined empirically in the process of selective test tests, in which a dry brick is first weighed and then placed in water for 38 hours. Then the product is taken out of the container and weighed again.

Technical characteristics of solid bricks

Let us now consider the positive parameters of red and silicate bricks, as well as their disadvantages. To do this, we will compile a comparative table of materials.

Solid brick, characteristics:

Parameters of ceramic brick, silicate brickStrength, kg / cm2 M75, M100, M125, M 150, M200, M250, M300.M150, M200 Density, kg / m3 1600-1900 1600-2000 Thermal conductivity, W / m * K0.5-0.60.7-0.9 Frost resistance.F25 , F35, F50, F75 F35, F50, F75 Heat resistance. Up to 1000 degrees up to 800 degrees Water absorption,% 9–128–15 Weight of 1 solid brick, kg 3.93.7

Let's take a closer look at the characteristics of a solid brick, as well as analyze what each parameter means:

Strength.

The ability of a material to withstand certain loads without collapsing. The letter "M" denotes the brand of brick, and the numbers next to it - the magnitude of the compressive, tensile and bending pressure. In other words, the higher the number, the more pressure the brick can withstand, the stronger it is.

Brick multi-storey house

For small one-story buildings, it is permissible to use brick M100, M125, for taller buildings, you need to take the M150 grade and higher. M75 is usually used for the construction of fences and other lightweight construction forms.

Density.

With an increase in density, other parameters of the material decrease.

The higher this indicator, the worse the heat and sound insulation properties of the material. If we take, for comparison, solid and hollow bricks, the use of which is almost the same, then due to the presence of voids in the body of the latter, the thermal conductivity and sound permeability of the material will significantly decrease.

This factor is directly proportional to strength: the higher the density of a solid brick, the more durable the structure will be, but other parameters will deteriorate. For comparison, the density of hollow bricks is 1200-1500 kg / m3.

Thermal conductivity.

The ability of a material to retain and transfer heat at different temperatures. The lower this indicator, the less heat will penetrate through the walls, and the more comfortable living in such a building will be. Accordingly, heating costs will decrease.

Well masonry walls

To reduce the thermal conductivity of walls, you can use various types of masonry, for example, apply the "well" method. This is when the outer and inner planes of the walls are laid out of solid bricks, and a gap is left in the middle, a "well", the width of a brick. The quarry is laid in the interval (hollow and chipped bricks, various types of insulation).

Frost resistance.

The property of a material to withstand many freeze-thaw cycles without changing technical parameters. It is designated by the letter "F", the numbers next to it indicate the number of these same cycles. The higher this indicator, the more durable the structure will be.

Frost resistance of bricks

The frost resistance characteristics of solid bricks, regardless of the type, are the same, but experts advise using ceramic bricks in cold regions. In central areas, it is recommended to use bricks with a grade of at least F35, and in cold areas - with an even higher one.

Heat or fire resistance.

Brick is practically not subject to destruction even after prolonged contact with an open fire, and of course, it is completely non-flammable, completely fireproof. Fireplaces and stoves are made of special heat-resistant red bricks, the service life of which reaches 30 years without repair.

Refractory bricks for fireplaces and stoves

But temperatures above 800 degrees act destructively on silicate bricks, therefore the instruction does not recommend using it for laying stoves and the inside of chimneys.

Moisture absorption.

This is a value that shows how much moisture a given material is able to accept and retain. The higher the percentage, the lower the frost resistance of the brick, the greater the risk of material destruction. The most acceptable moisture absorption is considered to be 6–12%.

Moisture absorption of bricks

The weight of a single solid silicate brick differs little from the weight of a ceramic brick. Therefore, their densities are almost the same, and, accordingly, the strength indicators are almost at the same level.

Brick weight

By the way, it is rather problematic to say exactly how much a solid brick weighs, here we took the average figure. Samples weighing from 3.2 to 4 kg can be found from different manufacturers.

Separately, it must be said about the cost of materials. The price of silicate bricks is 30 - 40 percent lower than that of ceramic. This is due to lower labor and energy costs in its manufacture, as well as the comparative cheapness of raw materials.

Brick house

Silicate brick weight: how to make calculations

The construction of houses, cottages and summer cottages is the laying of building materials

Sometimes it is very important to know not only their dimensions, but their weight in order to calculate the load on the foundation. Not all manufacturers provide such data, it is believed that they are in standards and GOSTs

If silicate brick is chosen as the main material for building a house, then in this article you can find the main calculated data: its size and weight, it depends on the type of product selected.

Due to its affordable cost and good looks, it is very popular. Lime, sand and special additives are used for its production, therefore it has a white color that looks good on the facades of buildings.

You can find out about what size of red brick the standard is from this article.

Now it is produced in a different color scheme, this variety is widely used for cladding external walls. The product takes on a hue due to the special composition of the clays. This material, which is part of its composition, after annealing can acquire white, yellow, apricot and pink colors, in which the final product dyes. It can be easily dyed in other colors by adding various pigments during the production process.

But silicate brick differs not only in color, but also in size.

There are three types:

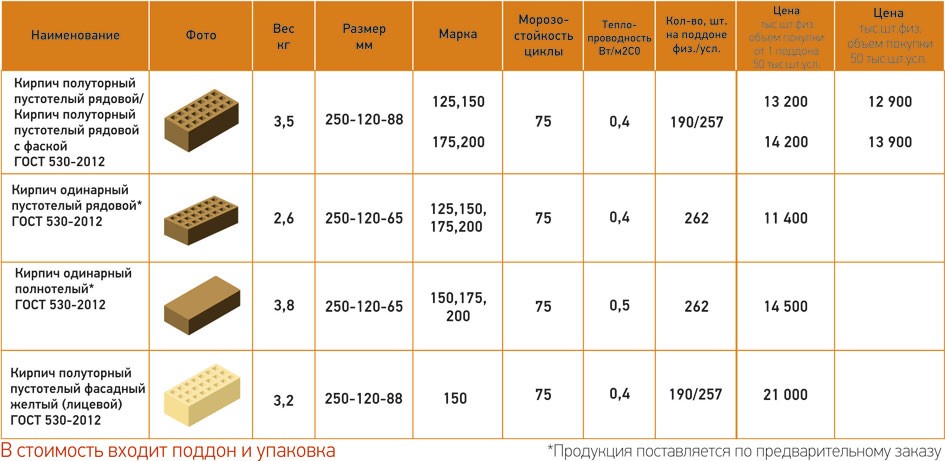

- Single. Its parameters are 250 × 120 × 65 mm.In terms of its dimensions, it suits bricklayers quite well, it is easy to work with it, it is perfectly gripped with one hand, moreover, it is a multiple of a meter.

- One and a half. It is larger than the previous type. It is made thickened, and, despite the name, its parameters are the same as in the previous type, only the thickness is increased by 35% and is equal to 88 mm.

- Double. Naturally, it is large in size, its height is an impressive parameter and indeed doubles the single-view parameter - 120 mm.

Depending on the density of bodies, it repeats the division of its counterparts and can be:

- Corpulent. It has high durable characteristics, therefore it is used in the construction of external walls more often than other types. There is a tinted version of it, such products are used for facade cladding.

- Hollow. It has special drains, which serve not only to lighten the weight, but also for better thermal conductivity. Due to the holes made in the brick, warm air is retained in them and does not leave the building. Therefore, structures of this type are characterized by high thermal insulation characteristics.

In addition, the small mass of such a brick does not exert strong loads on the foundation, so it can be made not very deep.

Porous. The lightest kind. Differs in high noise-absorbing properties. The pores are laid by production technology. They depend on the mortar for preparing the building material. This is the most modern look.

According to the method of application, it is known for the following types:

- simple or ordinary;

- facing (front);

- hollow construction.

In the video - sand-lime brick with dimensions of 250x120x88:

This article will help you find out what types of ceramic bricks exist.

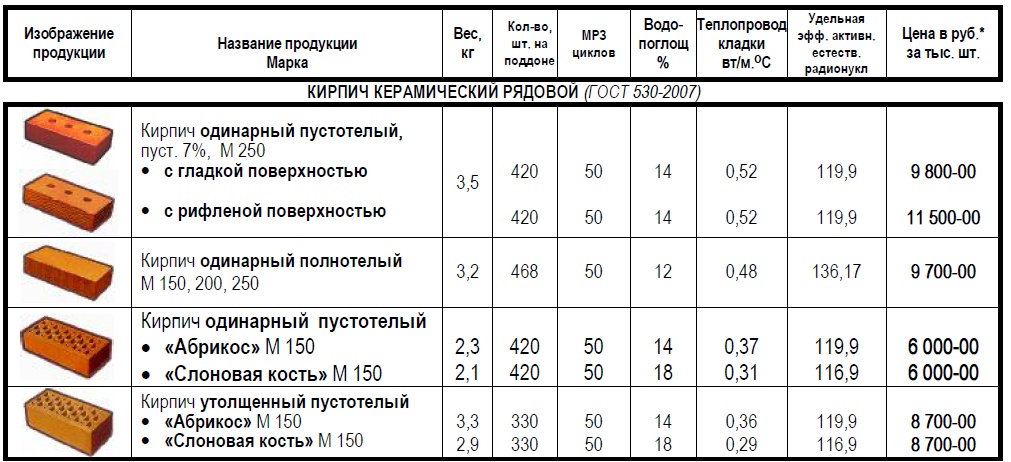

What buyers and builders need to consider

According to the requirements of GOST 530-2007, single ceramic bricks are produced only with a size of 250x120x65 mm. A similar material is used if you need to lay out load-bearing walls and a number of other structures. Its severity differs depending on whether hollow or full-weight facing blocks will be laid. A red facing brick that has no voids will weigh 3.6 or 3.7 kg. And in the presence of internal grooves, the mass of 1 block will be at least 2.1 and maximum 2.7 kg.

When using a one-and-a-half facing brick that complies with the standard, the weight is 1 pc. is taken equal to 2.7-3.2 kg. Both types of decorative blocks - single and one and a half - can be used to decorate arches and facades. Full weight products can contain a maximum of 13% voids. But in the standards for material including voids, it is indicated that cavities filled with air can occupy from 20 to 45% of the total volume. The lightening of the brick 250x120x65 mm makes it possible to increase the thermal protection of the structure.

Additional Information

All of the above applies to ceramic facing bricks. But it also has a silicate variety. This material is stronger than an ordinary product, it is created by combining quartz sand with lime. The ratio between the two main components is selected by technologists. However, when ordering sand-lime bricks 250x120x65 mm, as well as when buying its traditional counterpart, the weight of the blocks must be carefully calculated.

On average, 1 piece of building material with such dimensions weighs up to 4 kg. The exact value is determined:

-

product size;

-

the presence of cavities;

-

additives used in the preparation of the silicate block;

-

geometry of the finished product.

A single brick (250x120x65 mm) will weigh from 3.5 to 3.7 kg. The so-called one-and-a-half corpulent (250x120x88 mm) has a mass of 4.9 or 5 kg. Certain types of silicate, due to special additives and other technological nuances, can weigh 4.5-5.8 kg. Therefore, it is already quite clear that a silicate brick is heavier than a ceramic block of the same size. This difference must be taken into account in projects, to strengthen the foundation of the buildings under construction.

Hollow silicate brick measuring 250x120x65 mm has a mass of 3.2 kg. This makes it possible to significantly simplify both construction (repair) work and the transportation of ordered blocks. It will be possible to use vehicles of lower carrying capacity. In addition, there is no need to reinforce the walls. And therefore, the foundation of the building being built will be easier to make.

The situation is slightly different with hollow products. Such a single sand-lime brick weighs 3.2 kg. Standard packaging includes 380 pieces. The total weight of the pack (excluding the substrate) will be 1110 kg. Weight 1 cub. m. will be equal to 1640 kg, and this volume itself includes 513 bricks - no more and no less.

Now you can consider one-and-a-half silicate brick. Its dimensions are 250x120x88, and the mass of 1 brick is still the same 3.7 kg. The package will include 280 copies. In total, they will weigh 1148 kg. And 1 m3 of silicate one-and-a-half brick contains 379 blocks, the total weight of which reaches 1400 kg.

There is also chipped silicate 250x120x65 with a weight of 2.5 kg. In a regular container, 280 copies are placed. Therefore, the packaging is very light - only 700 kg exactly. Regardless of the type of bricks, all calculations must be carried out very carefully. Only in this case will it be possible to ensure the long-term operation of the building.

If you need to determine the weight of the masonry, you can skip calculating its volume in cubic meters. You can simply calculate the mass of one row of bricks. And then a simple principle is applied. At a height of 1 m there are:

-

13 rows single;

-

10 bands of one and a half;

-

7 strips of double bricks.

This ratio is equally true for both silicate and ceramic varieties of the material. If you have to clad a large wall, it is more correct to choose a one-and-a-half or even double brick. It is recommended to start your selection with hollow blocks because they are lighter and more versatile. But if there is already a solid, solid foundation, you can immediately order full-weight facing products. In any case, the final decision is made only by the customers of the construction or repair.

See below for details.