How to remove an anchor

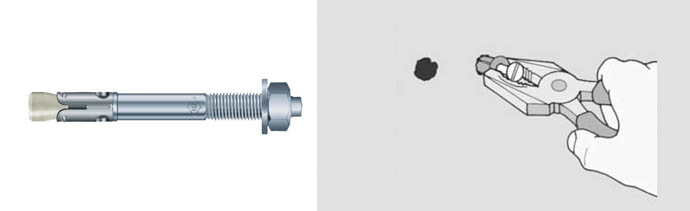

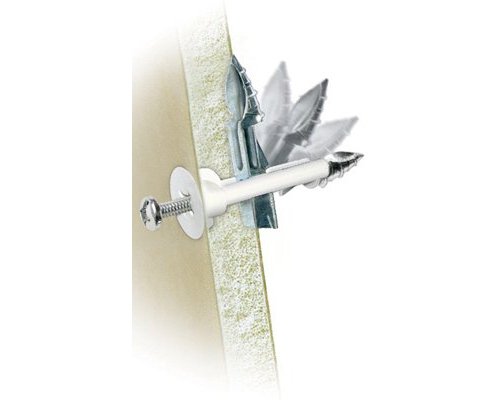

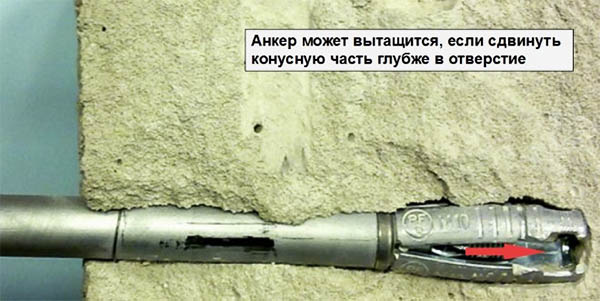

It is usually not a screw or bolt that is inserted into the anchor, but a hairpin (the same bolt, only without a head) or a hook. A bolt is screwed into the frame anchors, at the lower end of which the expanding element is held by means of a thread.

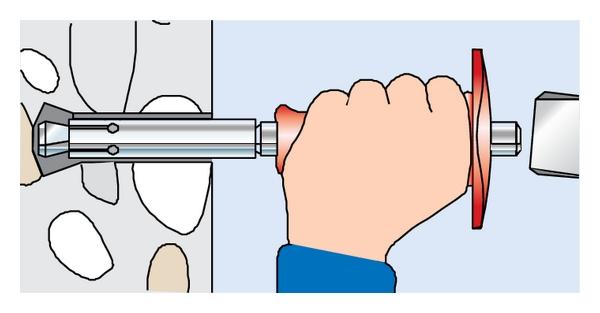

In general, the anchor is pulled out with pliers:

- Remove the nut.

- Hit the pin with a hammer and push it into the hole.

- Grasp the sleeve with pliers and remove.

Frame anchor:

- Remove the bolt.

- Use pliers or pliers to remove the anchor sleeve.

- Insert the bolt into the vacant hole and turn clockwise to push the wedge onto the bolt.

- Take out both elements.

If the bolt is rusted

If you cannot remove the bolt because it has oxidized, you should try to reanimate it. For this, the parts are well moistened with a rust converter, kerosene or WD-40. Leave for the time indicated on the package, or longer (up to half a day). During this time, the oxides should go away. After cleaning the bolt, you need to try to remove the nut or unscrew the bolt.

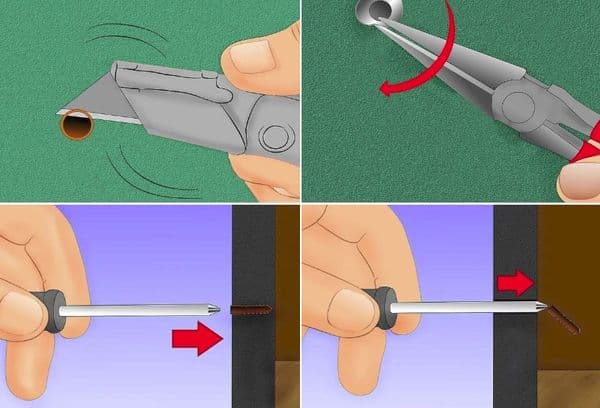

If the bolt is broken or has a ripped slot

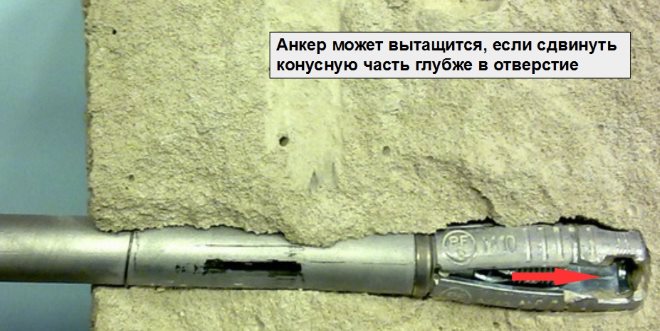

If you tighten a bolt, screw or screw too quickly or with the wrong screwdriver, it is easy to rip off the grooves. Less often, but it happens that the head breaks off at all or partially - in particular, in case of an unsuccessful attempt to pull out the frame anchor without removing the conical "anchor".

To unscrew a broken self-tapping screw or bolt, it is drilled out and a chopik is driven into it (extractor: a wedge-shaped screw with a left-hand thread), fixed in a drill, screwdriver or pliers. Then the whole structure is rotated counterclockwise.

If the sleeve is installed incorrectly

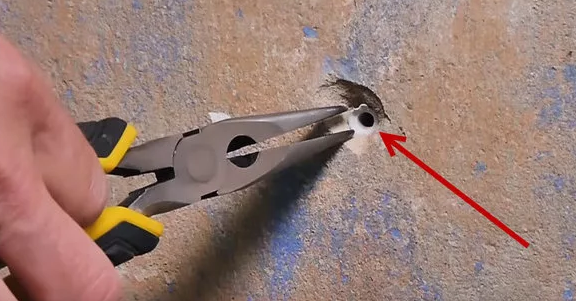

The most common problem with anchor dowels is that they cannot be hooked onto the edge with pliers or even narrow-nose pliers. To avoid this, it is sufficient to install the anchor correctly: leaving at least 2 mm above the wall level. This length is enough to pick up the sleeve, but it can be easily closed with plaster or any profile.

What to do if the sleeve cannot be hooked:

- Screw in the self-tapping screw between the sleeve and the stud and pull it out, grabbing the stud if possible.

- Remove or push the pin / bolt, drive a self-tapping screw or other tool between the wall and the sleeve, breaking and bending the edge of the anchor with an angle. Then pull on the resulting metal corner.

- Drill out the top layer of the wall around the dowel to free the edge of the sleeve.

In extreme cases, the anchor is cut with a circular saw and its parts are taken out separately.

As a rule, metal dowels and anchors are installed where their dismantling is not required, and the load will be significant. In some cases, it makes sense not to pull out the sleeve, but to hammer it deeper and close it with cement or other mortar or a plastic / wooden chock. In any case, there are no unsolvable problems: the dowel or anchor is almost always removed, it is worth putting in patience and effort.

Video: Types and purpose of dowels

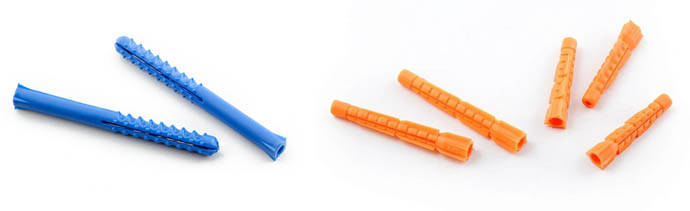

Plastic dowels

To get a plastic dowel, you may need certain tools and skills. But often the removal of such fasteners is quick and easy. Plastic dowels can be made from nylon, plastic, and other resilient materials. They are produced with different profiles, any depth of pins, can be made with a mustache fixing the sleeve in the monolith.

The main ways to remove plastic dowels:

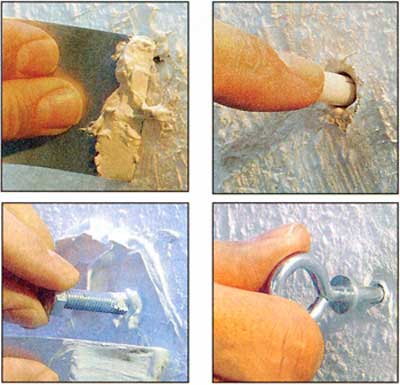

Driving into the wall - if the dowel sticks out strongly and it is not possible to pull it out, the element can be driven in. To do this, you need a hammer and a punch, a putty and a spatula. The kernel is placed on a protruding mount, knocked with a hammer, and then the hole is sealed with putty.

- Removing the dowel with pliers, nippers - for this you need to fix the tool on a plastic element, and then gently pull with force and at the same time loosen.

- Melting with a soldering iron - there is also such a method for removing the dowel. Suitable for cases where the plastic element is broken. It is melted with a soldering iron, then removed or hammered into a monolith of the wall.

- Using a metal tube - find a pipe that is suitable in size, stuff it onto a plastic rod and just take it out.

- Screwing in a suitable self-tapping screw 2/3 of the length of the dowel, then abruptly pulling out.

- With the use of a drill and a drill equal in length to the dowel, several holes are made around the element with a drill, then the loose rod is picked up with pliers / pliers and it remains only easy to remove it.

If you plan to pull out the plastic dowel from aerated concrete, then you need to dismantle it more carefully, since the monolith is very fragile and capricious, the mounts for it are equipped with special blades going in a spiral

You need to work with such a dowel carefully.

How to remove the dowel from wood material?

In the modern market, plastic dowels are mainly used, they are reliable and durable, have a long service life, but instead of them wooden elements are sometimes used, they are also called chopiks.

The wooden dowel is removed in much the same way as a plastic object. That is, a self-tapping screw is screwed into it, which is pulled out with a nail puller or pliers.

Inside the wall, you can pick out a piece of wood that will fall apart, and then pull it out. Splitting is performed with a hammer and chisel, and then the fragments and large parts are removed with a screwdriver.

Chopik can be removed with a drill or punch by drilling. But the work must be done with special care so as not to greatly enlarge the holes in the wall. Usually wooden dowel nails are used when installing wooden windows. To fix a wooden window sill to concrete, you need about four of these elements. The dowels are removed when they plan to replace them with plastic windows. In this case, they take plastic dowels, so they are more reliable for this material.

If the hat breaks off, how to get it

In the case when the cap is broken off, and the main part is in the wall, you can not get the dowel. It is hammered deeper. You need to take a thin, blunt object and hammer a dowel into the wall with a hammer. Place to putty.

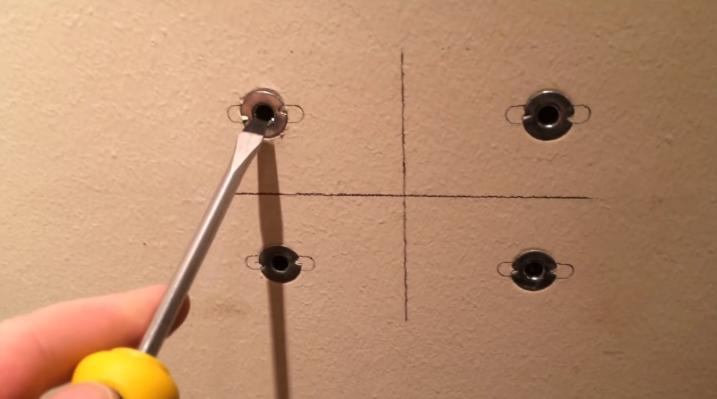

You can remove a broken item with a drill. To do this, 3-4 holes are made around the nest, end-to-end with the dowel. It weakens, can be easily removed with pliers. The holes made are filled with putty.

When filling, a mesh is used so that cracks do not appear.

It is not necessary to remove the interfering object from the wall. It can be cut, hammered deeper. One has only to remember that metal objects give rusty spots. If you need to get the dowel off the wall, use self-tapping screws, drills, a corkscrew, a hammer.

It is not difficult to get an object off the wall, you just need to spend a little time and patience. And also have a good hammer and pliers on hand, you can have a nail puller. After removing the holes that have appeared, it is advisable to cover with a reinforcing mesh, putty.

When it is necessary to re-attach the dowel

Often, the fasteners in the wall will dangle, even if you have used the correct drill for the hole. Because of this, a self-tapping screw or screw is scrolled along with the dowel. In this case, it is better to take a drill with a smaller diameter. For example, for an 8 mm screw. you need to make a recess with a diameter of 6 mm. When driven in, the mount will fit tightly inside and will not scroll.

Fasteners that are too short fall out under heavy load. For example, a 3 cm long mount will not withstand a massive hanging cabinet. If not immediately dropped, it will do so over time. The problem is solved by replacing it with a longer mount.To prevent shelves and cabinets from falling, during installation, fix the falling dowel in a soft wall.

How to remove the plastic dowel?

In some cases, the nail is removed, and the plastic itself remains inside the wall, and you can use several methods to remove the element.

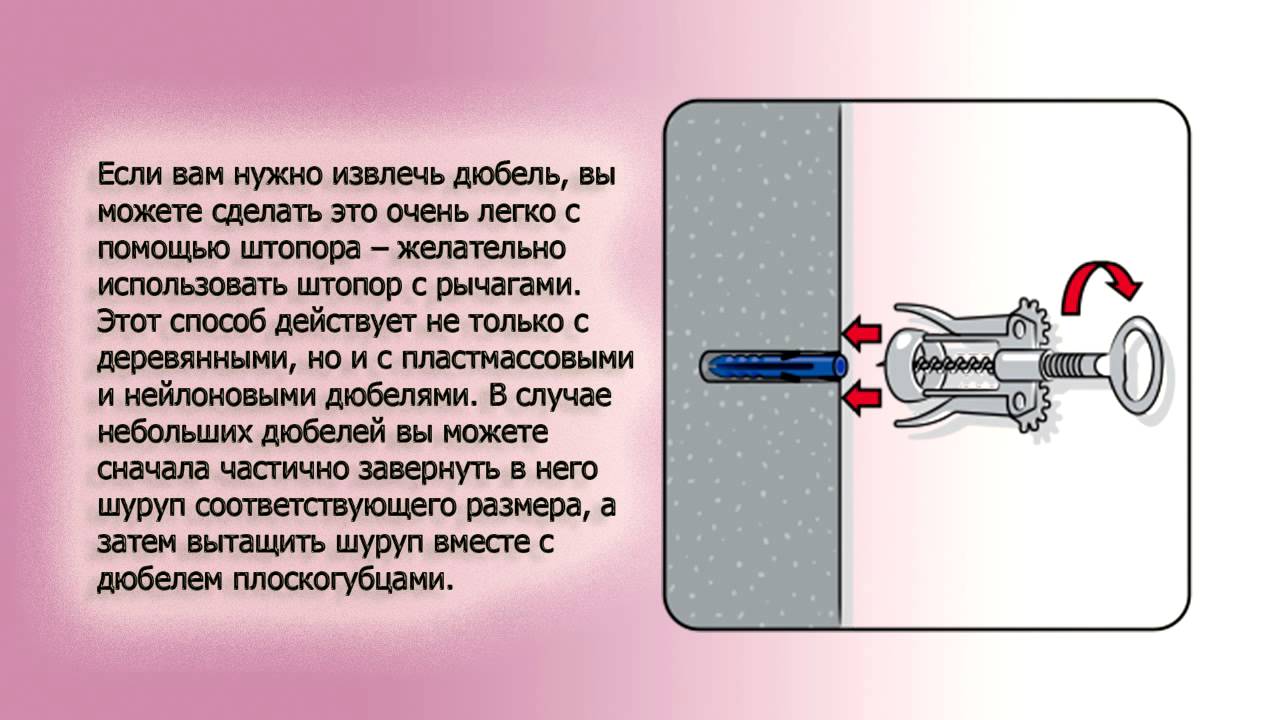

- The most suitable way to remove an object from the wall is to use a suitable self-tapping screw, it must match the size of the dowel. It is screwed into the plastic element 2/3 and then pulled out with pliers or other suitable tool. In the absence of a self-tapping screw, you can use a regular corkscrew, screw it into the wall, and pull out the dowel.

- If the previous method does not help to cope with the problem, then several holes are made around the object stuck in the wall, while the distance from it should be minimal. Then they try to pull out the element, but the hole will increase significantly, this must be taken into account immediately.

- If you cannot remove the plastic plug. It can also be driven inside, but this will not be easy. The dowel head can be cut off with a knife, and then hammer in the element as deep as possible, fill the hole.

- You can also try drilling the dowel with a drill. The drill should be of the same or slightly larger diameter than the dowel itself. After the procedure. The hole is closed with a putty mixture.

The sequence of removing the dowels, the basic rules for each method

To pull the dowel out of a concrete wall, you need to follow the sequence of actions, subject to all the rules, you can achieve an ideal result, and the surface will remain unharmed.

- To pull the base out of the plastic for the fastener, pick up a self-tapping screw, which is screwed in and pulled out with pliers. If such a tool is not at hand, you can use a nailer. When pulling out, it is necessary to take into account that some sections of the wall may be damaged, so the work is carried out carefully.

- The nailer helps to extract even such fasteners that are firmly held inside the concrete. Pressure is applied to the lever, thereby removing the fasteners from the inside of the concrete surface. The self-tapping screw cap must be securely fixed at the end of the tool, otherwise, if it slides off, you can damage the wall surface or harm yourself.

- You can remove the wooden dowel with an awl or knife, but first you need to break it and then remove it in parts. When installing new plastic windows, such elements will not reliably serve as their fastening, therefore, high-quality cleaning of the holes will be required.

- The piece of nail remaining inside the concrete wall is pulled out by heating the plastic element with a blowtorch. At the same time, the concrete wall is not damaged, but the work is carried out with particular speed, otherwise the plastic will harden, and you will have to do everything again.

- Metal dowels are fixed in the wall with a special gun, so they are not easy to remove. They need to be loosened for a long time, hitting with a hammer so as not to damage the surface of the wall, it should not break off. After that, you can also use a nailer, pliers will not cope with this type of task. If this method turned out to be ineffective, then holes are drilled near the element, and then extraction is performed. In case of unsuccessful pulling out, the protruding part can be cut off with a grinder, and the hole is putty.

If pulling out the dowel takes a lot of time and effort, or all of the above methods are not effective, then you can leave the element inside, and cut off its protruding part with a sharp object. The metal element is cut off with a grinder, the rest of the dowel is driven as deep as possible into the wall. Then the surface is smoothed with a putty material.

Pulling Algorithm

A protruding nail disturbs the aesthetic appearance, so it must be removed or hidden.Pulling old fasteners out of the wall, quick wits and the ability to use electric tools will come in handy.

- The element towering above the surface can be removed by swinging and unscrewing. Loose with a hammer, hitting it on the protruding part from different sides. Then you should grab with pliers or wire cutters and pull out. You will not be able to get it if you pull it out of the hole using only translational force. If the fasteners are large, it is advisable to use a nailer, which will help to remove with less effort.

- Much more patience is required when it is necessary to remove a broken dowel, if it is difficult or impossible to grasp, hook. The plastic case must be heated, melted with a hot soldering iron. This allows you to remove it from the wall with round nose pliers or other similar tools.

- A metal tube, the diameter and length of which should be slightly larger than the fastener, often helps to reach it. It is hammered so that the sleeve is inside. Then, at the same time, pull out the nail.

- In the most hopeless situations, the dowel is removed with a hammer and a drill. With a drill of the required size, several holes (recesses) are made directly around the nest. As a result, the strength of the adjacent part of the wall decreases. The element is easy enough to remove with a suitable tool (pliers, nippers, etc.), then the surface is leveled

putty or plaster.

Often it is necessary to get the plastic case remaining in the wall without a metal rod. Masters advise to do this:

select the appropriate self-tapping screw of the required size for the sleeve (about the types of screws for concrete), screw in three-quarters of the length, then loosen and remove;

pull out the dowel with a manual corkscrew, carefully

twisting;

if it is not possible to pull out with the listed methods, you should try to cut off the protruding parts with a knife, hammer the rest into the wall;

drill out the plastic sleeve using a tool of equal or larger diameter.

Before carrying out work, builders recommend assessing their feasibility. Thinking about pulling out is really necessary if you need to make a new hole next to it. For example, if you want to hang a new cornice in the same place, but the old fasteners are not suitable.

The resulting indentation, after the removal of the nail, will become large and will have to be repaired. To do this, fill with putty or gypsum, apply a masking net, clean, level the surface with sandpaper after drying.

What to do if the dowel falls out of the wall?

The condition of the concrete does not always correspond to the proper level, since a poor-quality solution was used during construction. Interior partitions, openings for windows are made of material that after decades has become loose, free-flowing. In such houses, nails fall out.

There are several ways to solve this problem:

- Drill a hole in the concrete, remove particles, fill it with liquid nails or epoxy glue. After thickening, install the dowel. You can hang objects after making sure the final cure.

- Wind a layer of electrical tape in the direction of the thread (ordinary cellophane is suitable), the resulting thickness should ensure a tight entry into the hole. Then drive the element into the plastic case, due to this, it will move apart, which will increase reliability.

- Wrap the dowel with a damp bandage (it is enough to wet it) until the required diameter is obtained and install it into the walls, you can immediately drive in a nail. Use fasteners as directed after complete evaporation of the liquid.

The main thing is to adhere to the rules that ensure reliability and durability during operation: make additional reinforcement, select an element with dimensions larger than usual.

| Articles |

Quite often, when performing various kinds of repair work, you can stumble upon certain difficulties. It so happens that a seemingly simple and straightforward procedure gives rise to a lot of problems. So, for example, not everyone can answer the question of how to pull the dowel out of the wall without preparation. The thing is that the design of this fastener element is precisely aimed at keeping it firmly in the wall and preventing easy removal. However, there is a way out of the situation and not even one, which will be discussed below.

Let's work with the tree

Today, most people use plastic dowels, but some prefer wooden caps. The difference in their extraction is not particularly great. The cap can also be pulled out using a self-tapping screw, which is screwed into a wood product, then the removal process is performed using pliers. If they are not at hand, then a nailer or other construction tool will do.

Another method is especially popular - pulling out in parts. This will require a chisel and a hammer, with which the dowel is split along the fiber. Then the resulting fragments are removed with a knife or screwdriver. A drill can also be used. This option is available for softwood dowels. The drill can be replaced with a hammer drill

Care should be taken to avoid large diameter holes in the wall.

In most cases, wooden dowels are used for mounting wooden windows. To do this, take 3-4 fasteners with which to fix the window sill, and several pieces for installing the window frame.

Metal dowels are not as widespread as plastic ones, because their use implies that special equipment is available. There are two options for removing such fasteners.

One way is twisting. The second is loosening with a hammer. If it was not possible to carefully unscrew the dowel, then you can try to loosen it with a hammer. When the fasteners are flush with the wall, they can be removed by making a few small holes around them. Then the extraction takes place directly.

Removing a dowel from a concrete surface is not an easy task, but using the right method, you can quickly pull out fasteners with minimal losses to the surface. To complete the procedure in the shortest possible time, you just need to prepare the necessary tools and choose the right way to pull it out.

How to quickly pull out a dowel from a concrete wall?

updated: Nov 11, 2016

author: Artyom

Few know how to properly remove the old dowel from the wall. The main thing is to try to choose a simple, reliable and economical way. The skills of installing and dismantling fasteners will help to achieve the result; experience in owning electric and hand tools will be useful.

Several types are produced specifically for concrete; a nail is always used as a rod in them. Reliable operation can be guaranteed if you are able to choose the right version based on the dimensions of the plane and the massiveness of the suspended structures, and perform high-quality installation.

Before starting work, it is necessary to assess the quality and thickness of the surface. The presence of hidden electrical wiring and metal fittings is the basis for a change in location. Sometimes it is not easy to hammer in the dowel carefully without damaging the adjoining part of the wall.

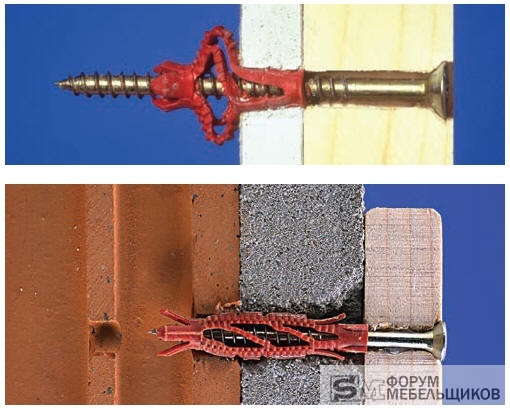

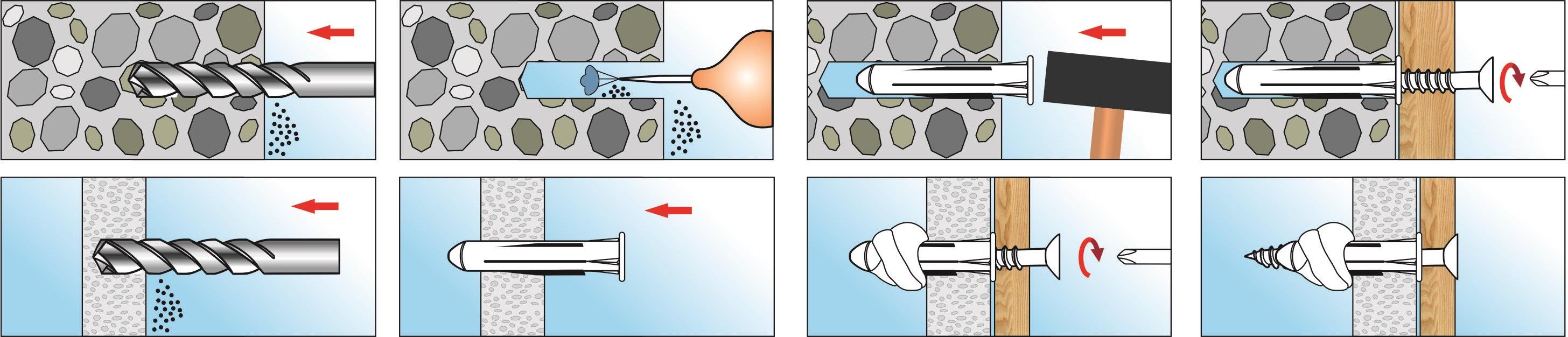

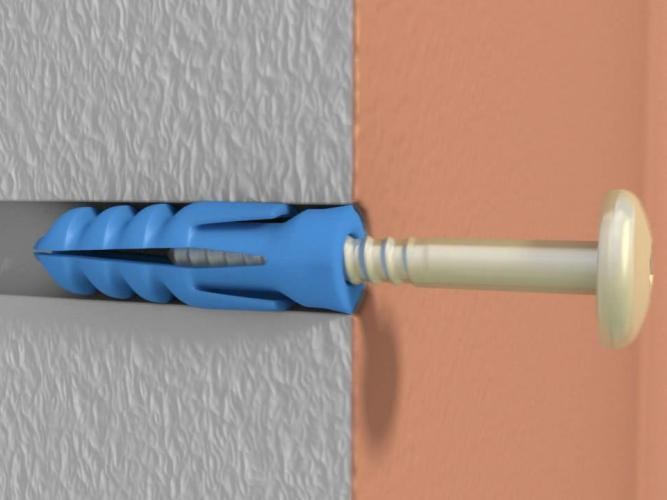

The most commonly used options are:

- Spacer, suitable for a solid wall. It will establish itself inside it due to the expansion of the plastic case. The plastic sleeve is made with a tapered metal core or threaded.

- Universal. The embedded nail fits snugly against the walls of the hole. Suitable for loose, hollow partitions.

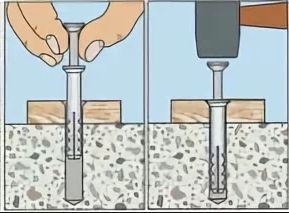

You can insert the dowel with a drill with the function of a hammer or punch, drill for concrete, hammer.Correctly perform work in the following sequence:

- using a punch, punch a hole with a diameter similar to the sleeve and a depth exceeding the length of the fastener by 0.5 cm;

- clean the resulting recess from dirt and dust;

- fix the dowel body with a hammer until its edge aligns with the wall surface;

- hammer a nail into the body until it stops.

If you follow all the installation rules, it will be difficult to get it.

Removing metal dowels

Elements of a metal type are used very rarely, since special equipment is required for fastening, therefore it is also not easy to pull out such dowels. It will not be possible to break it with any tool or device; the element must be removed from the wall with special care.

If the object looks out a little above the surface, it is loosened with a hammer, usually the dowel is fixed in the wall securely and firmly, so that it will simply not be possible to get it out. With a deeper immersion, several holes are made around the element, at a minimum distance from it, removed using pliers or a nail puller.

Such methods are most suitable for removing metal objects from the wall, after which all holes are filled with putty material flush with the surface.

Pulling Algorithm

A protruding nail disturbs the aesthetic appearance, so it must be removed or hidden. Pulling old fasteners out of the wall, quick wits and the ability to use electric tools will come in handy.

- The element towering above the surface can be removed by swinging and unscrewing. Loose with a hammer, hitting it on the protruding part from different sides. Then you should grab with pliers or wire cutters and pull out. You will not be able to get it if you pull it out of the hole using only translational force. If the fasteners are large, it is advisable to use a nailer, which will help to remove with less effort.

- Much more patience is required when it is necessary to remove a broken dowel, if it is difficult or impossible to grasp, hook. The plastic case must be heated, melted with a hot soldering iron. This allows you to remove it from the wall with round nose pliers or other similar tools.

- A metal tube, the diameter and length of which should be slightly larger than the fastener, often helps to reach it. It is hammered so that the sleeve is inside. Then, at the same time, pull out the nail.

- In the most hopeless situations, the dowel is removed with a hammer and a drill. With a drill of the required size, several holes (recesses) are made directly around the nest. As a result, the strength of the adjacent part of the wall decreases. The element is easy enough to remove with a suitable tool (pliers, nippers, etc.), then the surface is leveled

putty or plaster.

Often it is necessary to get the plastic case remaining in the wall without a metal rod. Masters advise to do this:

select the appropriate self-tapping screw of the required size for the sleeve (about the types of screws for concrete), screw in three-quarters of the length, then loosen and remove;

pull out the dowel with a manual corkscrew, carefully

twisting;

if it is not possible to pull out with the listed methods, you should try to cut off the protruding parts with a knife, hammer the rest into the wall;

drill out the plastic sleeve using a tool of equal or larger diameter.

Before carrying out work, builders recommend assessing their feasibility. Thinking about pulling out is really necessary if you need to make a new hole next to it. For example, if you want to hang a new cornice in the same place, but the old fasteners are not suitable.

The resulting indentation, after the removal of the nail, will become large and will have to be repaired.To do this, fill with putty or gypsum, apply a masking net, clean, level the surface with sandpaper after drying.

What to do if the dowel falls out of the wall?

The condition of the concrete does not always correspond to the proper level, since a poor-quality solution was used during construction. Interior partitions, openings for windows are made of material that after decades has become loose, free-flowing. In such houses, nails fall out.

There are several ways to solve this problem:

- Drill a hole in the concrete, remove particles, fill it with liquid nails or epoxy glue. After thickening, install the dowel. You can hang objects after making sure the final cure.

- Wind a layer of electrical tape in the direction of the thread (ordinary cellophane is suitable), the resulting thickness should ensure a tight entry into the hole. Then drive the element into the plastic case, due to this, it will move apart, which will increase reliability.

- Wrap the dowel with a damp bandage (it is enough to wet it) until the required diameter is obtained and install it into the walls, you can immediately drive in a nail. Use fasteners as directed after complete evaporation of the liquid.

The main thing is to adhere to the rules that ensure reliability and durability during operation: make additional reinforcement, select an element with dimensions larger than usual.

| Articles |

Before finishing the walls, the surface must be carefully leveled, remove all protruding elements, nails, screws and dowels

It is very difficult to get the last element, it is important to know the basic rules on how to do it. It will not be possible to pull out the dowel with your hands, in any case you will have to resort to using tools

How to remove the dowel

For the renovation of an apartment or office, a high-quality finish is always required. Preparing rooms for painting or wallpapering involves careful alignment of the walls, often associated with the need to dismantle old fasteners. During the preparation, beginners often cannot figure out how to pull out the dowel. Depending on the material of the dowel, there are some tricks to get rid of the unnecessary fasteners.

Instruments

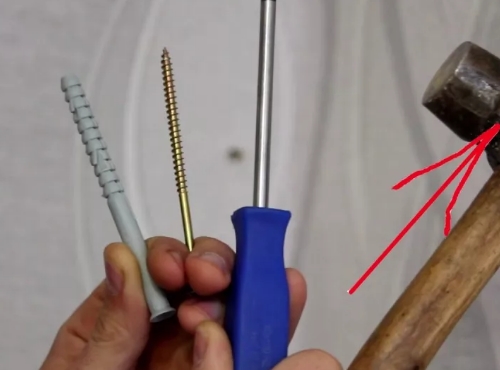

The list of tools required to pull out the dowel depends on the material from which it is made. In the process of work, you may need:

- self-tapping screw or corkscrew,

- chisel, hammer,

- pliers,

- nail puller,

- knife or awl,

- soldering iron,

- "Bulgarian",

- punch or electric drill.

Such a small dowel and so many tools are needed to remove it from the wall! In fact, the above list applies to all types of dowels. Therefore, in the process of work, you will use exactly the tool that is necessary to pull out exactly those dowels that are firmly embedded in your walls or ceilings. Perhaps let's move on to the process of extracting the dowel itself.

Which way to choose?

In a situation where the fasteners remain in the wall along with the nail, everything is very simple. To do this, you need to loosen it - apply a few blows with a hammer to the dowel-nail from all sides. Next, you need pliers, with which you need to sharply pull it out of the concrete.

In this case, it is worth considering whether this operation will not damage the top layer of plaster, which may come in handy. If you cannot do without losses, then you can drive the dowel into the wall along with the nail. The procedure should be successful, because the depth of the hole is always greater than the length of the dowel itself. After that, this place is leveled with mastic or gypsum plaster.

In many situations, it is necessary to pull out the dowel, which was removed long ago, but its plastic part remained in the wall. In such a situation, you can choose the most suitable pull-out option.

Methods for removing a plastic dowel:

- The most famous method is to calculate the anchor for pulling out, that is, a self-tapping screw suitable for the dowel is selected in size, screwed into the dowel by two-thirds of its length.Then you need pliers or another tool to pull it out. If the self-tapping screw is not at hand, then a manual corkscrew will do. The dowel is pulled out like a cork from the neck of a bottle.

- You can remove the dowel in another way. To do this, you will need to drill several holes around it at a short distance. After that, using a special tool, you need to unscrew it. The disadvantage of this technique is that the result should be a hole of much larger diameter than it was before.

- If it was not possible to remove the dowel for pull-out, then you can drive it into the wall. The process is not as easy as it might seem at first glance. To simplify the situation, you can cut off the protruding edges of the dowel, then drive it in, and then putty this place.

- When a drill is available, the dowel can be drilled out. The main thing is to choose the right drill. It must be of the same or larger diameter. The dowel should come out of the hole like plastic shavings. After the hole needs to be putty.

What to do if there is a fragment of a self-tapping screw or a nail in the fastener?

The main cause of nail or screw breakage is high pressure, so pulling out with pliers will not be effective. In such a situation, a soldering iron or a gas torch is needed, any of these devices will help heat the plastic dowel so that the material becomes plastic and soft. The procedure should take place quickly, while the plastic is still warm. If the first attempt was unsuccessful, then it is recommended to repeat the procedure until the dowel with the splinter is removed.

How to remove an anchor

Usually, it is not a bolt or a screw that is inserted into the anchor, but a stud (bolt without a head) or a hook. A bolt is screwed into the frame-type anchor, and a expanding element is held at its lower end on the thread.

General anchor removal scheme:

- Removing the nut.

- Hit the hairpin with a hammer, pushing it into the hole inward.

- Gripping the sleeve with pliers, removing fasteners.

Removing the frame anchor: unscrewing the bolt, dismantling the anchor sleeve with pliers or pliers, inserting the bolt into the vacant hole, turning it clockwise (for inserting a bolt or wedge), removing both elements.

If the bolt is rusted

In this case, it is worth trying to reanimate the bolt - lubricate it with a rust converter, WD-40 or kerosene. Then you can leave for the time specified in the instructions or longer (up to 12 hours) so that the oxides go away. The bolt will be clean, you can try to remove the nut or unscrew the fasteners

Rusty elements must be handled very carefully so as not to break parts of the product.

If the bolt is broken or has a ripped slot

It happens that fasteners break due to screwing in too quickly when the wrong tools are used. In this case, special measures are needed - to unscrew the broken fastener, it must be drilled out, driven in a chopik fixed in a screwdriver, drill or pliers. Then the whole structure is carefully turned in a counterclockwise direction.

You cannot re-drill dowels for construction guns, as they are made of very strong (often hardened) steel and you can simply break the drill, injure yourself by shrapnel. It is better to knock out or heat such fasteners.

If the sleeve is installed incorrectly

The most common problem when working with anchor dowels is the inability to catch on their edge with pliers. The installation of the anchor must be carried out correctly: usually at least 2 millimeters are left above the wall level, which is enough to hook the sleeve, along with the ability to easily close the fasteners.

If it is not possible to hook the sleeve:

- It is necessary to screw a self-tapping screw between the sleeve and the hairpin, try to pull it out, if possible, catching on the hairpin.

- Push or remove the bolt / stud, drive the self-tapping screw between the sleeve and the wall, bending or breaking the edge of the anchor. Then you need to pull the formed corner of the metal.

- To free the edge of the sleeve, you can drill the top layer of the wall around the dowel.

- If nothing can be done at all, the anchor is cut with a circular saw and taken out in parts.

- You can not pull out the sleeve, but drive it even deeper and mask it with concrete mortar or a wooden / plastic chock.

Usually, the question of how to remove the dowel from is not worth it, because this type of fastener is used where it is not planned to dismantle it. But situations are different and knowing how to do everything right is useful for every master.

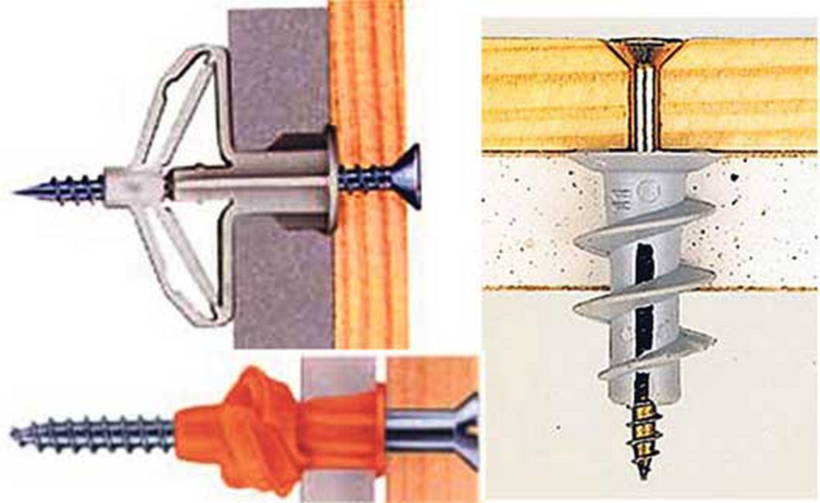

Plastic dowels

The most popular plugs today are plastic, nylon or other soft elastic material. They are produced with different profiles, different depths of "spikes", the best options have "mustaches" that fix the sleeve in the wall.

Such dowels can be easily removed with a strong corkscrew:

- Unscrew the self-tapping screw or screw that was installed in the dowel.

- Turn the corkscrew clockwise, allowing the tip at the end to fit securely into the plastic dowel.

- While continuing to turn, pull towards you (sometimes you have to additionally swing the tool and the dowel).

- The sleeve will come out of the wall without breaking it.

Plastic for aerated concrete

For this capricious and fragile material, ordinary dowels are categorically not suitable - those that have a larger contact area are needed. This is usually achieved by using "blades" that spiral along the sleeve. Dismantle the Fischer type dowel for aerated concrete in the same way as usual: twist, pull and gently loosen.