Carrying out works

This type of paint can be applied by brush or roller. Some types of coloring composition are sold in special spray cans.

It is desirable to apply the coloring composition on a horizontal surface. This means that it is advisable to remove vertical surfaces (doors, gates) and provide them with a horizontal position. If this is not possible, you should choose a hammer paint with a higher viscosity and cure rate to avoid smudges.

Procedure:

The surface on which the paint will be applied must be well cleaned of dust, debris and other contaminants.

It is also important to remove any greasy or oily residue from the surface.

Stir the paint thoroughly. A precipitate forms in the coloring composition during storage, it is necessary to bring the solution to a uniform distribution of particles and elements in it.

Apply the coloring compound evenly

The paint should be applied quickly enough, as it sets and thickens rather quickly in the open air.

After application, you must wait 30-40 minutes for the applied layer to harden.

Another layer is applied to the surface with the hardened layer.

Then the algorithm is repeated: after applying the layer, a break is made, then the surface is again covered with paint.

Usually 2-3 coats are required.

Advice:

- Apply the dye composition with a hammer effect using a fur roller. Foam roller can corrode paint.

- It is best to use a spray gun to paint gates or doors in an upright position. This device sprays paint in micro-droplets for quick drying and no smudges.

- You can control the color decorative effect. For example, taking one color as a basis, highlight the various structural elements with a different color, applying it last.

- Complete drying of all layers occurs after 24 hours. Before the expiration of this time, it is necessary to exclude mechanical impact on the painted surface.

- Do not work with this dye composition in conditions of high humidity or temperature. If the work is carried out indoors, it is necessary to provide constant adequate ventilation.

- It is better to sand glossy surfaces before using hammer paint to achieve a slight roughness.

- If the product you intend to paint is new, then take care to thoroughly remove the factory grease. Greasy and oily contaminants prevent the adhesion of the coloring composition to the surface.

How to paint metal with hammer paint, see below.

How to paint a car

How to paint flat surfaces is understandable, but how to paint a car? First of all, you need to prepare tools and materials:

- directly hammer enamel;

- short-haired roller or spray;

- solvent # 647;

- enamel primer;

- abrasive material.

Attention! Prepare all the necessary items in advance, they should be nearby, as they may be needed at any moment. The enamel dries very quickly, so delays in working with it are excluded

Although blacksmith paint does not imply preliminary priming, experts still recommend doing this to achieve the highest quality painting.

Stages of staining:

- Clean parts and car from dirt and dust.

- Degrease surfaces with special solutions.

- If there is heavy rust, get rid of it. To do this, you will need abrasive paper (sandpaper).Even if there is no rust, still use sandpaper, as the enamel adheres better to a rough surface, plus adhesion increases.

- A rust converter can be used to remove large areas of corrosion. If you bought Hammerite enamel, then don't worry about corrosion. Because the paint contains substances that envelop rust.

- Treat the surfaces with primer enamel, which must first be diluted.

- Now pour the paint into the building ditch, dip the roller into it. When it is soaked, roll it over the ribbed surface of the cuvette. Or prepare the spray gun for work.

- Further, you can paint large surfaces. After applying the first coat, wait 30 minutes and only then can you paint with the second coat.

Complete drying of the mixture is achieved after seven hours, but it is permissible to operate the machine only after three days.

You can cover the last coat with regular varnish. This will improve the decorative qualities of the painted surface.

Important! The glossy coating of the car must be removed - the paint does not adhere to such a surface, only matte.

Peculiarities

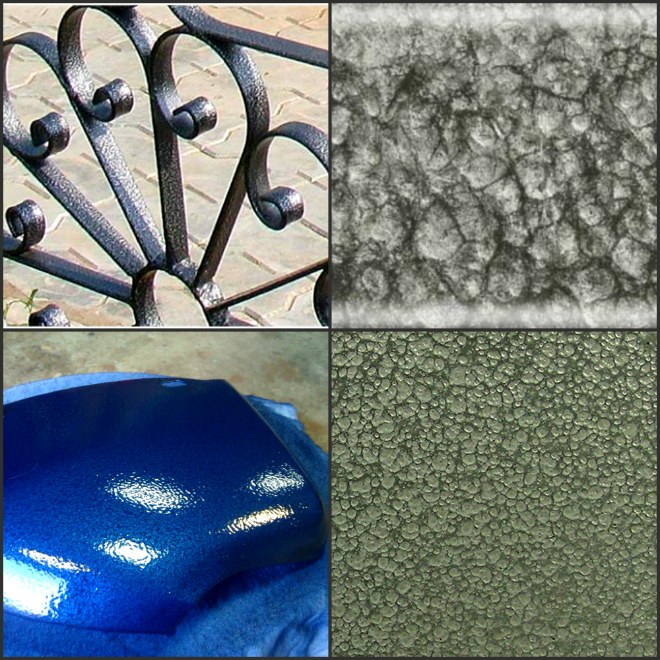

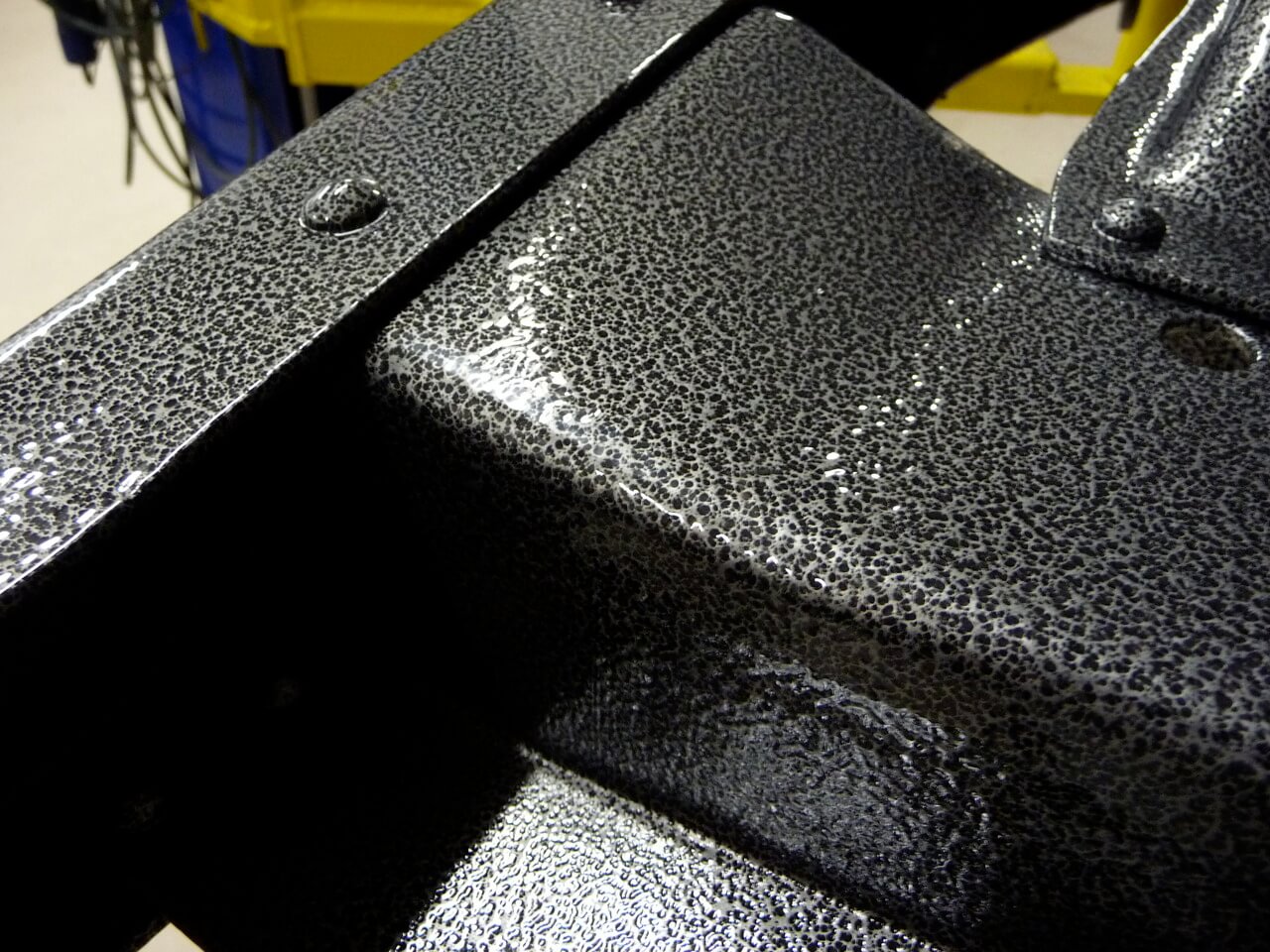

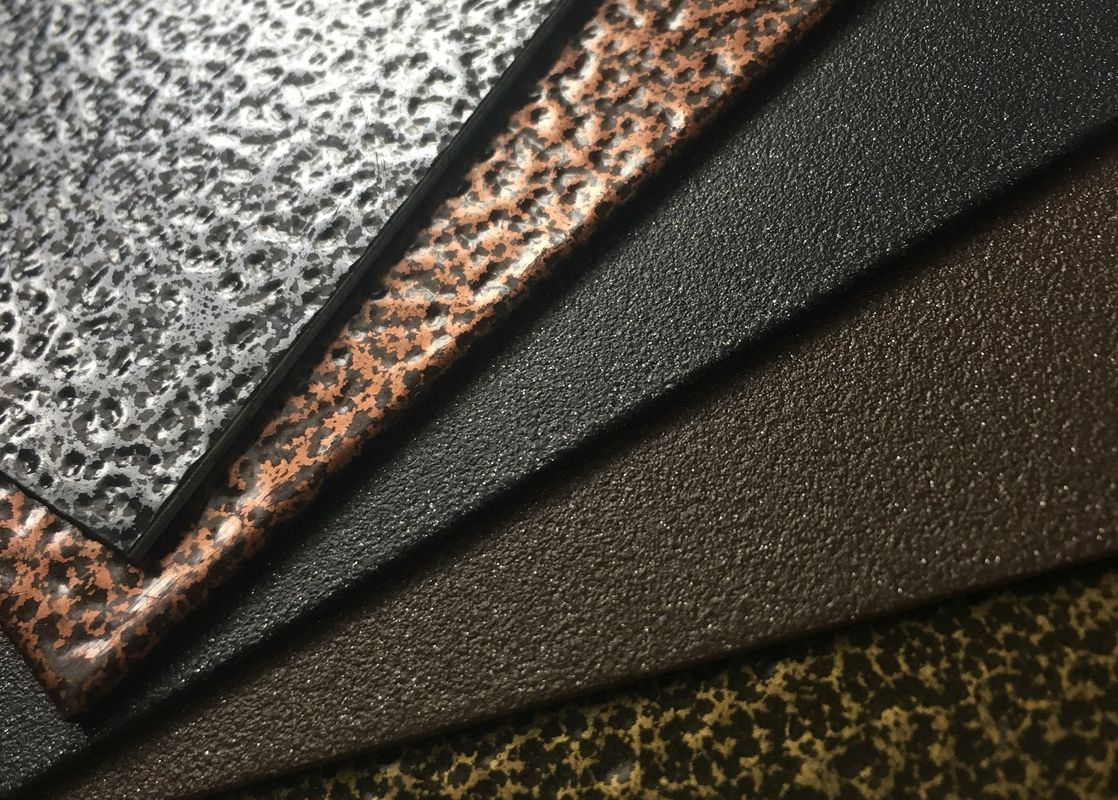

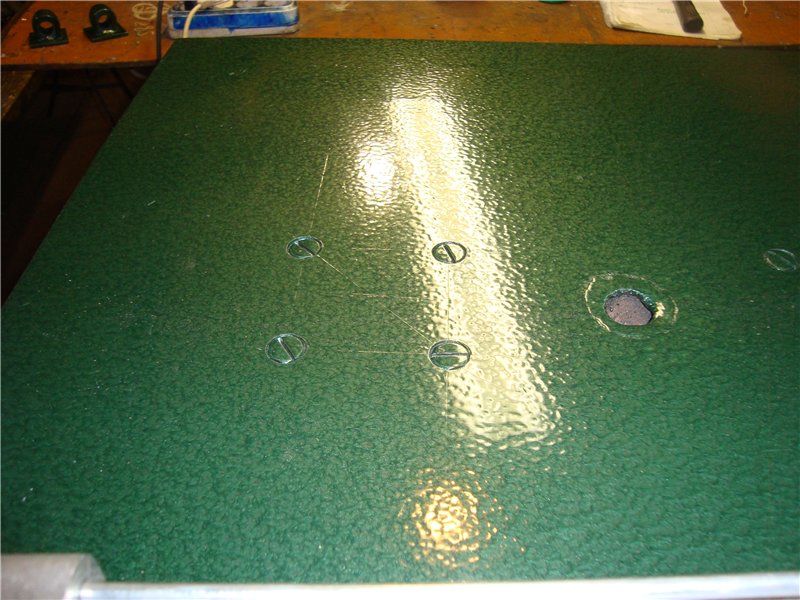

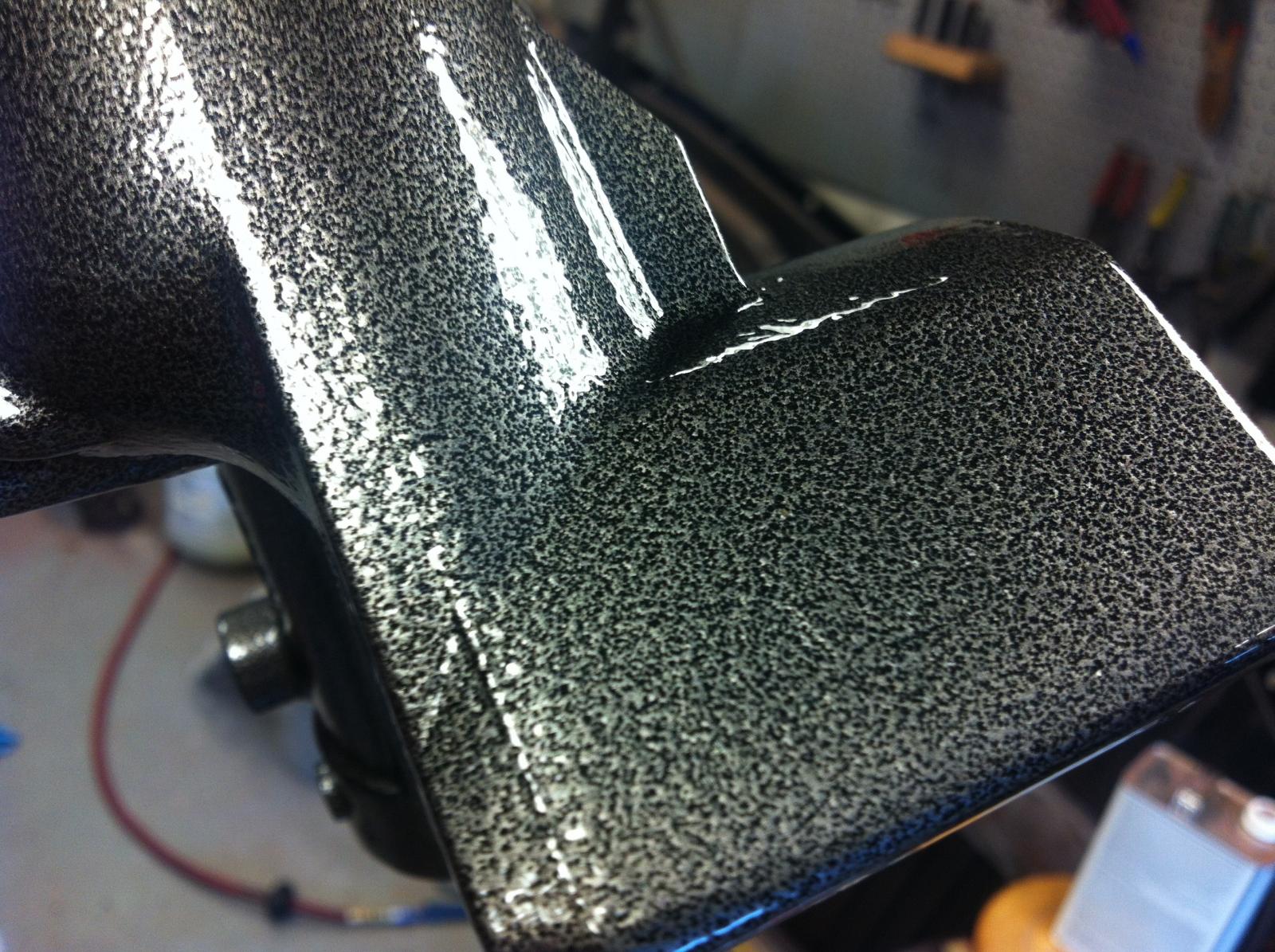

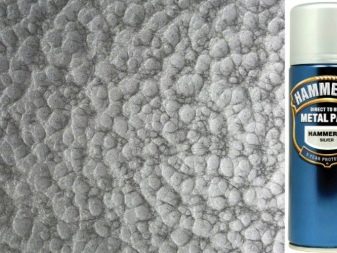

Hammer paint is intended for painting rusty surfaces. The presence or absence of the original layer of another paint, as well as the performance of external or internal work does not matter. In all cases, the dye composition shows itself with dignity and quality. It got its name from the external appearance of the applied coating. It seems to be made of metal that has been hand-minted with a blacksmith's hammer.

Initially, hammer paints were used to cover industrial and laboratory equipment, for which external beauty is less important than service life. Until recently, no other hammer paint colors (except gray) were produced.

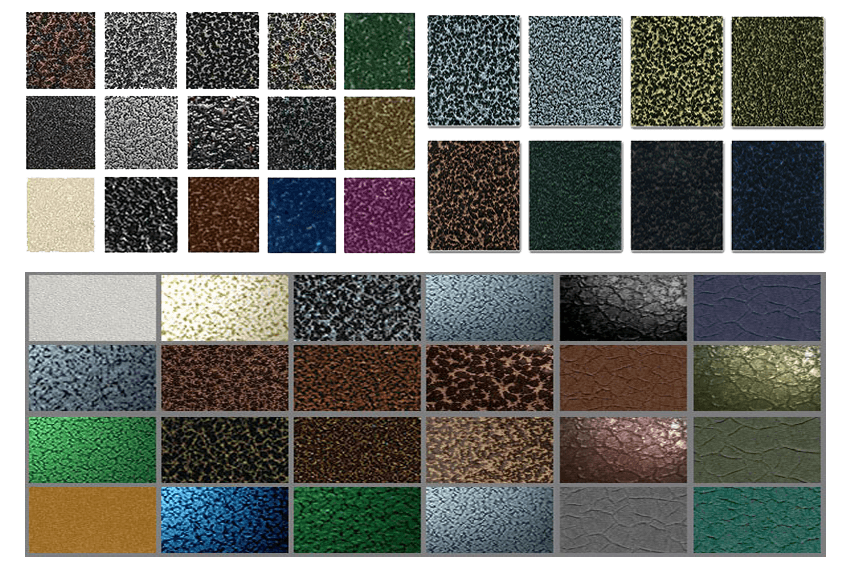

It is capable of masking significant surface differences and can also be used for re-painting. In recent years, technologists have corrected the flaw of their predecessors, and now this material is made in a variety of colors and shades.

Main characteristics

Hammer paints for metal are formed by a combination of acrylic, epoxy and alkyd-styrene substances. To bind them together, finely crushed glass and aluminum powder are used. The liquid colorant has a high level of adhesion. As soon as it hardens, the strongest protective layer appears on the metal surface.

The introduction of metallic powders increases the strength of the paintwork, but makes this mixture unsuitable for spray application. We'll have to work by hand (with a brush). Modern examples of hammer paints contain various types of colored dyes.

This material is very resistant to temperature extremes, so it can be used safely up to 80 degrees Celsius. There is no need to scrupulously clean and prime a rusty surface (while other varnishes, paints and enamels necessarily require such preparation, but even with its careful execution, they do not always fit well and steadily).

The painting process is very simple and easy, and the painted layer is not sticky.

Even vibration will not be able to destroy its layer, and the anti-corrosion properties remain for at least 6-7 years. Hammer paint is safe for humans. If she tints the defects of the main coating, the difference in their tone will be barely noticeable.

Uncommon

After drying, she again surprises with her unusual properties inherent only to her.

Differences between hammer paint and conventional and nitro enamels:

- does not require preliminary surface treatment before painting;

- moisture and heat resistant;

- resistant to UV radiation, does not fade in the sun;

- painted surfaces are resistant to any detergents;

- simplicity of the painting process, available even for beginners;

- allows you to paint not only metal, but also any other material.

Let's consider the listed differences in more detail:

- Pretreatment of painted surfaces.

It has been reduced to a minimum. This is because hammer paint includes an additional rust removal function. This means that there is no need to spend time and effort to clean out all the rust spots before painting. The paint itself is able to neutralize them.

Of course, if the rust flakes off in pieces, then this place must be cleaned up. Otherwise, the paint will hide it completely, but the corrosion process will continue. What this will lead to is not difficult to guess.

- Moisture and heat resistance.

It will be appropriate to include here also such an indicator as the strength of the paint. The whole highlight lies in the fact that the composition found a place for acrylic, alkyd-styrene and epoxy bases. In combination with aluminum powder and finely dispersed glass, all these components work truly miracles. The paint acquires increased resistance to moisture and temperature changes.

Changes in its properties begin at temperatures above 130ᵒ С. Due to increased adhesion (ability to adhere to other materials), it adheres very firmly to the painted surface. For example, during repairs, no one has yet been able to remove the bottom layer of paint.

- UV resistant.

Ultraviolet rays destroy any enamel and paint, but not hammer. Due to its special properties, it does not fade in the sun. Color remains constant

Motorists pay special attention to this parameter. They are no less pleased with the fact that the paint is resistant to any detergents.

- The ability to paint any materials.

, concrete

On the one hand, the main determining factor in this case will be that the paint is more expensive than conventional enamels. And the hammer effect on such surfaces is less prominent, not at all the same as on iron.

On the other hand, dyed products acquire reliable protection from any atmospheric conditions for 8 years without changing their appearance.

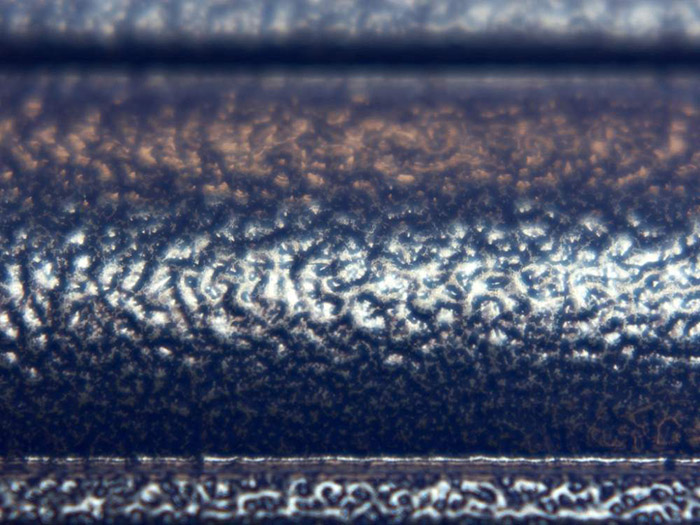

The surface painted with this paint acquires a textured metallic sheen and a barely perceptible roughness. This can be clearly seen in the photo. The color range of hammer paint is quite extensive. It is not difficult to find any desired color.

How to paint with hammer paint with a roller: video

From the above, it can be understood that enamel has many positive qualities and is now used even on wooden surfaces. The best way to work with a helmet is with a roller. It seems that everything is clear, but in order to fix everything, I suggest watching a video about applying the mixture with a roller. Happy viewing.

Acrylic and water-based paints are widely known to consumers. Many people have enough experience to apply them without paying too much attention to the manufacturer's instructions. But the same cannot be said about hammer paint, although its merits are not in doubt. In some cases, only such a coating has to be used.

Painting with hammer enamel

The application of hammer enamel to the surface is somewhat different from conventional paints and varnishes. How to properly paint with such enamel?

The application of hammer enamel to the surface is somewhat different from conventional paints and varnishes.

The application of hammer enamel to the surface is somewhat different from conventional paints and varnishes.

Preparatory stage

Hammer paint does not imply complex preparatory processes, but at the same time there are important nuances that make it possible to carry out the work with high quality:

- if the coating will be carried out on a new metal product, then it must be cleaned of factory grease using a degreasing agent (white spirit, solvent or acetone). To improve the adhesion to the surface, after cleaning it must be brushed on metal or sandpaper;

- when painting products that already have a paint and varnish layer, it is recommended to eliminate peeling areas, rinse the surface with soapy water and clean water and dry well;

- before painting galvanized, aluminum surfaces or stainless steel products, it is recommended to pre-apply a special primer for non-ferrous metals;

- wooden surfaces are pre-treated with acrylic primer, which prevents the penetration of the coloring agent into the pores;

- peeling and obviously loose rust is removed with a metal brush.

Paint application

First of all, it is recommended to comply with the temperature regime (the permissible range ranges from + 10- + 25 ° С) and air humidity (up to 85%). The most suitable layer thickness for the proper anti-corrosion effect is at least 100 microns.

The main methods of application:

Coloring with brushes. The most popular method for dyeing small areas and products with complex shapes

The paint is applied in 2-3 coats, with special attention paid to the careful processing of corners, edges and edges. Natural bristle brushes are most suitable for such work.

Roller painting

This is the ideal way to paint large surfaces. First of all, the substance is applied to the edges and corners, after which they proceed to the main array. It is best to use wool or fur rollers. For uniform application, a small amount of the dye is poured onto the product, and then gently rolled out with a roller.

Spray paint is best used for correcting small defects and when painting small areas. Before starting work, the can with the substance must be shaken vigorously for three minutes after the sound of the mixing ball is heard. The paint is applied in 3-4 layers, while the spray should be kept at a distance of 20 cm from the surface to be treated. The first layer is allowed to dry for two to three minutes, and each subsequent layer should dry for about twenty minutes.

Spray painting. It is used for processing large areas. The key to successful painting is the correct calculation of the viscosity of the paint. As a rule, the composition instruction contains detailed recommendations on the proportions of the compound with the solvent (most often 2: 1)

It is important to take into account that such a ratio is effective only at an air temperature of 18-22 ° C. Exceeding the temperature requires more solvent - otherwise the formation of the so-called "web" is possible

If paintwork is carried out at temperatures below 17-18 ° C, then the amount of solvent must be reduced, since the paint will spread.

Painting with airless spray. Suitable for painting impressive flat and embossed surfaces. Before starting the procedure, the enamel is diluted with a solvent in a ratio of 9: 1, after which the spray bottle is shaken to obtain a homogeneous composition. The further principle of operation does not differ from painting with a spray gun.

If there is no experience in carrying out such work, then you can familiarize yourself in detail with all the subtleties by looking at the corresponding photos and videos, or even turn to professional painters for help. After all, it is very difficult, and often expensive, to correct any mistakes when applying hammer paints.

Varieties

There are these types of hammer paint:

ML-165. It is produced on an alkyd-styrene base. It is characterized by good adhesion and heat resistance (withstands up to + 130 ° С). Suitable for painting all surfaces

Among the disadvantages, one can single out a negative effect on the respiratory system during the application process, as well as a high fire hazard, therefore, precautions must be taken.

NTs-221. Designed for decorative purposes, ideal for exterior and interior renovation work, has a fairly low price

At the same time, it does not protect painted products from corrosion or heat.

EP-1323 ME. 2 in 1 epoxy (i.e. primer and paint). Excellent paint for metal with anti-corrosion effect and thermal properties. It is used for painting construction equipment, cars, gates, doors, fences. Application on rust, cast iron products is allowed.

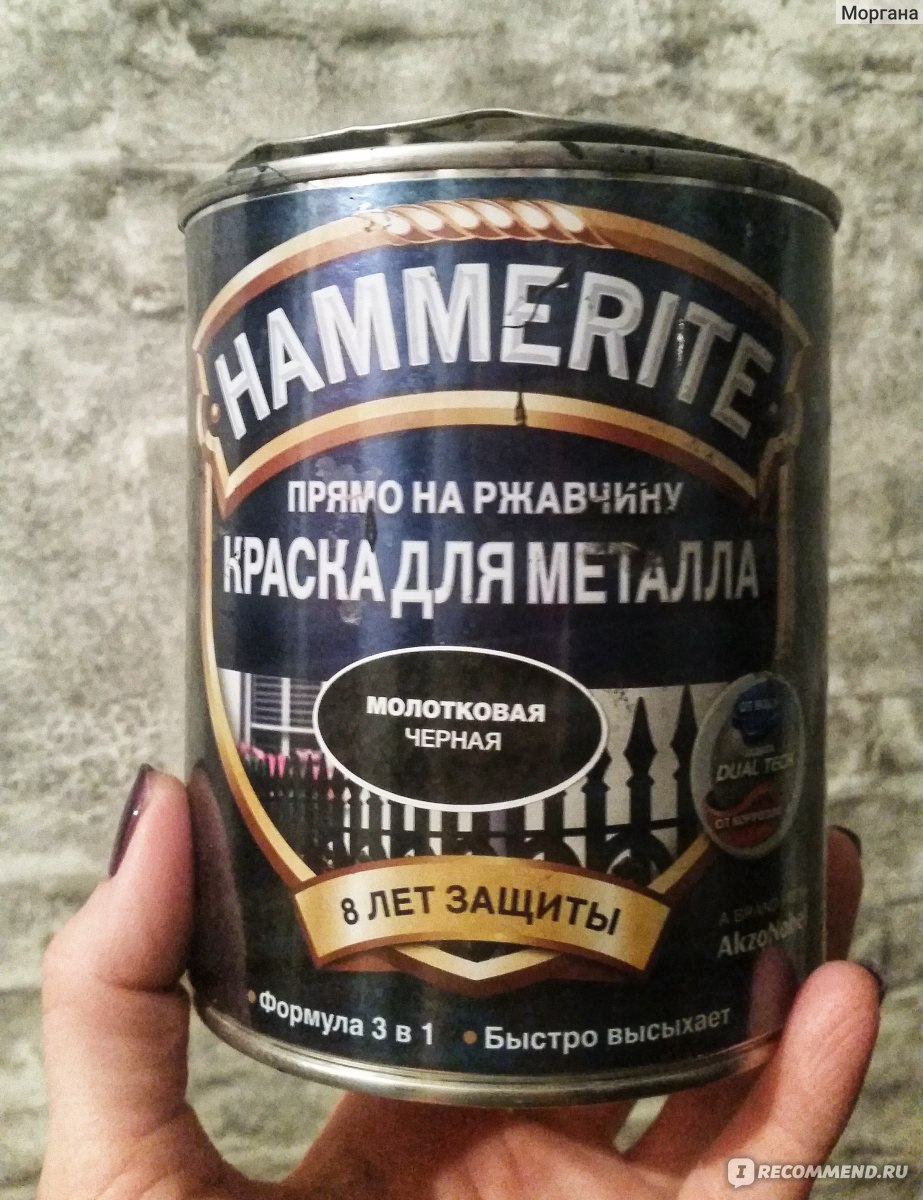

Hammerite. A very expensive and high quality English-made colorant. Made on the basis of alkyd resins and silicone additives, thanks to which the protective effect is significantly enhanced. It is not recommended to apply the composition with a spray gun, since this device will not provide the desired effect, and besides, it will increase the consumption of the dye.

Making hammer paint at home

Some craftsmen got used to making hammer enamel on their own. To do this, you need to prepare the following ingredients:

- varnish (UVL-1) - 96.8%;

- aluminum shavings - 3-6% - provides a hammer effect;

- soot - 0.2-0.5%. This component gives the coating a dark shade;

- silicone oil - forms a relief.

Enamel ml-165

Enamel ml-165

The first three components are mixed until the chips stop floating. To change the shade, add colored enamel (no more than 30% of the total mass of the composition). Then a few drops of silicone oil are added. Painting should be started immediately after production. Most often, homemade hammer compounds are used for painting vehicles.

Technology

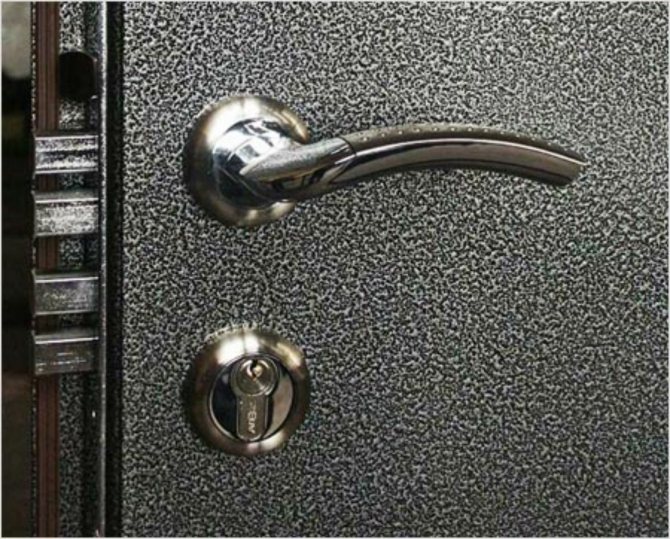

First of all, you need to carry out the necessary preparatory measures. First of all, you need to clean the door from dirt and oil stains.

For this you will need:

- brush;

- rags;

- detergent;

- white spirit or acetone.

It remains to wash the front door and degrease it.

The next step will be the treatment of the entire surface. Not a complicated process that requires only a metal brush and abrasive paper (sandpaper). Remaining old paint and deep rust must be thoroughly removed. The essence of this work comes down to preparing the cleaned places on the metal for tougher adhesion of hammer paint to it. This completes the preparation of the door for painting.

How to paint the door - with a roller, brush or spray gun, there is no fundamental difference. In any case, you need to follow the technology for performing paintwork. The ideal temperature for painting will be within the range of +5 - + 30ᵒC with air humidity up to 85%. You need to paint in 3 - 4 layers.

Please note: after applying each coat of paint, allow time for it to dry. The duration is indicated in the manufacturer's instructions .. Each subsequent one is applied perpendicular to the previous one.

Stir the paint well before painting. This is best done with a clean wooden stick. For ease of use, the paint is poured into a tray if painting is done with a roller or brush. The main thing is not to forget to dilute the paint with a solvent before use.

Each subsequent one is applied perpendicular to the previous one. Stir the paint well before painting. This is best done with a clean wooden stick. For ease of use, the paint is poured into a tray if painting is done with a roller or brush. The main thing is to remember to dilute the paint with a solvent before use.

Expert advice: before painting, lay the door on a horizontal surface and remove the fittings (handles, locks).

Gate painting is carried out using the same technology as for doors.

This requires certain skills and experience in performing such work.

The difficulty lies in the fact that not everyone can choose the right color, make the desired paint consistency.

Not everyone can adjust and adjust the spray gun for operation either.

Please note: it is better to entrust such important work as painting a car to a specialist.

As a rule, at home, touch-up is done after minor repairs or the elimination of scratches, scuffs. The easiest way to do this is to use ready-made paint from an aerosol can. The work itself is performed using the same technology as described above.

On the Internet, you can find a lot of information and video material about hammer paint. Sometimes there are different numbers for the same parameter. For example, there may be different drying times for the paint layers. How to understand this? It's simple - it means that the paint belongs to different manufacturers. By the way, this does not affect its quality at all.

Watch a video in which a specialist gives advice on how to paint a gate with hammer paint:

Hammer paint technology

| Adaptation | Application | Tool selection | Application technology |

|---|---|---|---|

| Brush |

For painting small surfaces and objects with complex relief, such as forged metal fences.

It is advisable to choose brushes with natural bristles.

On horizontal surfaces, two layers of enamel are applied, on vertical surfaces - three, but thinner. When painting, special attention is paid to corners, grooves and edges, which are most susceptible to corrosion.

Roller

For processing large flat surfaces.

A short-haired velor or fur roller will do. Foam products cannot be used - solvents corrode them, and stains remain on the painted surface. In addition to the roller, you will need a small brush.

Apply in two or three layers. The enamel for the first layer must be thinned (1 part solvent for 9-10 parts of paint). The rest of the layers can be applied with undiluted paint. First, the corners, edges and other places with a complex relief are painted with a brush, and then, with the help of a roller, they cover even areas.

Aerosol can

For painting small items and painting defects on long-painted surfaces.

If you buy enamel in a spray can to paint over defects, you need to accurately select its shade. It is advisable to do a test application on an inconspicuous area of the surface to be painted to ensure that the colors match.

Apply in three to four as thin layers as possible. Shake the can for about three minutes before starting work. The paint is applied from a distance of 15–20 cm. After the first layer, wait 2-3 minutes, after the second and third - 15–20 minutes each.

Pneumatic spray gun

For painting large flat and embossed surfaces.

Staining is carried out in two or three layers, with the first layer being as thin as possible, and the last one being the thickest. The paint is diluted in a ratio of 2: 1 and applied at a temperature of + 18 ... + 22 ° C. In other conditions, the viscosity must be corrected empirically (at a lower temperature, the enamel dries more slowly, and the solution must be thicker so as not to drain from the surface).

Airless spray

For painting large flat and embossed surfaces.

Before application, the enamel is diluted with a solvent (9: 1). The spray bottle is shaken thoroughly to obtain a homogeneous emulsion. Then they are painted in the same way as with a pneumatic spray.

Thus, knowing how to paint with hammer paint, you can get a reliable protective coating and an interesting decorative effect on almost any surface.

Hammer paint is one of the most durable compounds for metal processing. The substance is actively used in many areas: equipment processing, coating of instruments in laboratories, technology, household devices (doors, fences) and any other metal products used in difficult conditions or in places with increased requirements for wear resistance. Hammer paint for metal is sold exclusively in one color - gray, and the color change is carried out using enamel.

Types and features of hammer paint

Now the industry produces different types of hammer paint, so you can buy:

1. alkyd-styrene enamel, withstand temperatures up to 130 degrees in both directions from zero, dissolving only in xylene and suitable for any type of work, for example - ML-165;

2. epoxy enamel for external work "2 in 1", intended mainly for construction vehicles and street metal objects - lamps, gates and so on, it is applied to rust and perfectly masks chips, is resistant to all weather conditions, dissolves with solvents No. 648 and No. 667, example - EP-1323 ME;

3. nitro enamel intended for "home" use, that is, suitable for pieces of furniture and fragments of interior interiors, with a pronounced decorative effect and lower technical properties in heat resistance, resistance to precipitation and other external influences, is dissolved by common solvents for enamels, for example - NC -221;

4. hammer paint hammerite - English enamel, with very high technical and decorative properties, as well as full versatility in use and the absence of a strong specific odor.

In addition, the paint is divided into ordinary in cans and sprayed aerosols in cans.

Hammer paint has various forms of release, which allows the consumer to choose the most convenient method of application

How to paint hammer paint correctly?

Painting with hammer paint does not require any special skills, tricks or tricks. Although the "blacksmithing" and undemanding, but some preparatory work is worth doing:

- if on the surface there is a layer of crumbling, swollen, crumbling old paint - oil, bitumen-containing or powder, then it must be cleaned off;

- new products must be degreased, completely cleaned of grease using any technical means, for example, white spirit, solvent and acetone;

- the surface must be freed from loose, falling rust and falling off layers of paint;

- for wooden surfaces or products, a primer is needed, water-based acrylic is ideal, this is necessary in order to obtain a decorative effect, without primer, the paint is simply absorbed into the wood;

- glass, plastic and other materials must be degreased and clean.

The technology and method of painting itself depends on which tool you plan to use:

The brush must be chosen carefully, checking before buying for convenience and for "shedding", that is, buy with stubble that does not come out. This tool is irreplaceable for complex surfaces, with details or hard-to-reach places.

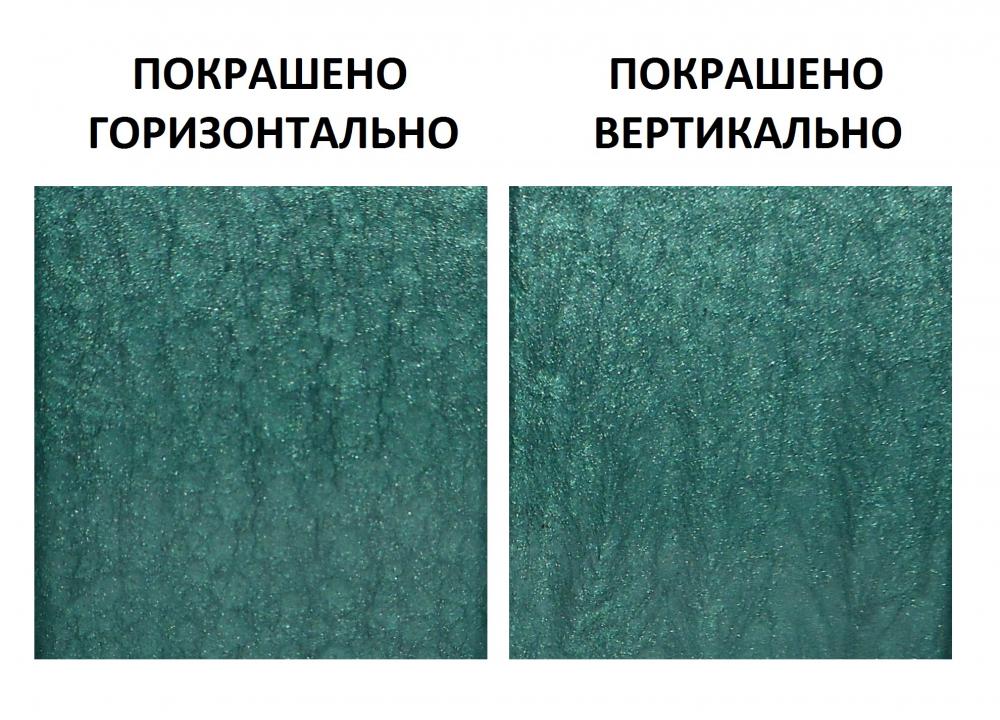

The painting itself should be carried out as follows - two layers on horizontally located surfaces and three on verticals. This will provide maximum decorative effect.

Ideal for large and flat surfaces such as walls or countertops. It is necessary to purchase one made of velor or fur with a short medium-hard pile, the paint corrodes the foam rollers.

The paint is applied in two or three layers. Depending on where the work is going - horizontally or vertically.

3. Aerosol can

Good for painting defects, decorating complex artsy surfaces or individual elements, as well as when performing artistic images on cars.

It is applied in 3-4 layers from a distance of 15 to 25 cm. Anything that cannot be stained must be securely covered. The first layer dries from 2 to 5 minutes, the next from 20 to 30 minutes.

4. Pneumatic spray gun

Good for working on large areas with decorative elements, both protruding or convex, and sunken. Due to the fact that the spray gun will not be able to paint exactly any surface, a good additional reinforcing decorative effect is created. Coloring is carried out in 2-4 layers, be sure to thoroughly dry each of them.

Airless and pneumatic spray guns are not the best choice for this paint as the enamel is very heavy. The use of this tool will require dilution and a change in its density, which will inevitably lead to a loss of technical and decorative qualities.

The average material consumption, if hammer paint lays down on rust and other difficult surfaces, is from 100 to 150 grams per square meter.