How to glue

Before starting finishing work, you should carefully examine the walls and ceiling. If the work surface is uneven and bumpy, it must be leveled with a putty. Old wallpaper can be removed with a sharp knife, and layers of paint with a perforator. Walls or ceilings must be thoroughly cleaned of dirt and pieces of plaster. If it was not possible to align them, a crate made of wooden or plastic battens or metal profiles is used.

Wall decoration

It is worth installing the finishing material once, and in the future there will be no questions about how to glue the plastic panels on the wall.

The order of work is as follows:

- Work is carried out from an inner corner or from doorways. First, the terminal element is installed, from which the subsequent sequential installation of the panels continues.

- The first panel should fit into this fastening element with a narrow fastening shelf.

- A wide mounting shelf on the back is fastened with nails or special brackets.

- Now each subsequent panel must be inserted into the groove of the previous one.

- When there is a small distance to the next corner, the final finishing piece is adjusted in size. At one end it is put into the groove, with the other it snaps into the final link (corner).

Installation of MDF panels is carried out in a similar way. On one side they have a ridge (spike), which must be inserted into the groove (groove).

In this case, a natural question arises: "Which panels are better - PVC or MDF?" In terms of quality, they are equally good, but in conditions of high humidity, polyvinyl chloride material is preferable. Alternatively, you can use both of them by pasting the area above the bathroom with plastic, and the walls with MDF material. But then it is better to choose MDF panels with a top layer impregnated with melamic acid. She will not let the MDF get wet.

Ceiling decoration

PVC panels are attached to the ceiling either directly to the surface, if the ceiling is even, or to profiles, if the ceiling cannot be leveled. The use of lathing is also advisable when spotlights are provided in the ceiling.

How to glue plastic panels to the ceiling when there are no complaints about it?

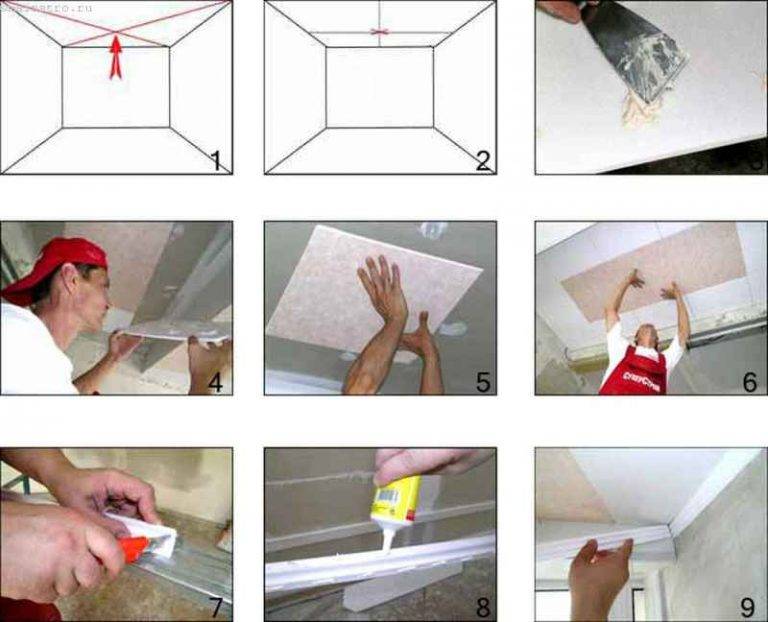

- Twine is pulled diagonally from one corner to another. It also needs to be pulled between the 2 remaining corners.

- The center is marked. Work is underway from him. Tiles are glued to the center.

- The rest of the tiles are glued in parallel rows.

And how to glue plastic panels in the bathroom, if it becomes necessary to install the lathing?

- It is possible to use metal profiles for the construction of the lathing, on which plasterboard sheets are installed. It is necessary to first fix the guides around the perimeter of the bathroom.

- Mark the points where the lights will be located.

- The profile sticks are installed in the guides, then fastened.

- A plinth is installed - it is attached to the guides with self-tapping screws.

- It remains only to install the panels, gradually covering the ceiling surface with them.

Decorative panels for the bathroom look very beautiful on the ceiling. But do not forget that with embossed surfaces can be difficult to care for.

Finishing corners

When the repair of the walls and ceiling is completed, all that remains is to cover up the cracks and gaps with a sealant. But what about the corners where ugly joints have formed? For these purposes, plastic bath corners are sold. They are perfect for decorating walls in corners.

To firmly fix the material in the corners, a colorless sealant is applied to its back. Thus, the work takes on a finished look.

Before thinking about the question of how to glue MDF and PVC panels to a wall or ceiling or a finishing material made of polyvinyl chloride, you need to assess the temperature conditions in the bathroom, the level of humidity, and the possibility of mechanical damage. I would like the panels to last a long time. And this is possible if you carry out the correct preliminary processing of the working surfaces and perform all the work sequentially.

Types of bathroom panels

A large amount of material presented for sale has different external and quality characteristics.

By material

Bathroom panels can be made of different materials. The choice takes into account its service life, ability to withstand a humid environment, strength, design and ease of installation. The material used to make them:

- PVC (polyvinyl chloride);

- MDF (small wood fiber, shavings pressed with the help of special compositions);

- wood (base - solid wood material).

PVC material is preferable for finishing the bathroom, as it meets all the requirements of small rooms with high humidity.

A hurried job can lead to the panels peeling off and the formation of mildew and mildew underneath. To prevent this from happening, you need to accurately select the material for the appropriate conditions and carry out repairs only after preliminary acquaintance with the work procedure. Otherwise, efforts will be wasted.

By sight

Depending on which work surface (walls, ceiling) the finishing material will be glued to, the panels have a different look:

- leafy;

- rack;

- tiled.

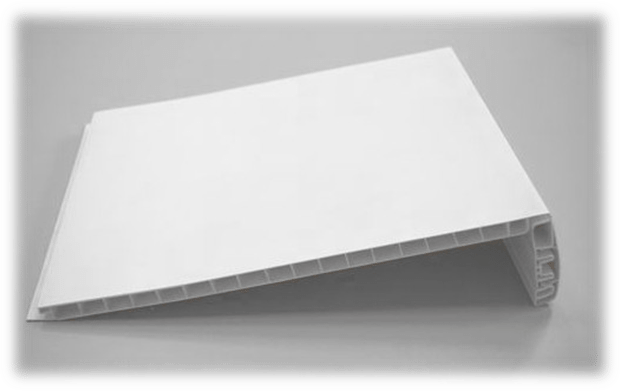

Rack and tiled panels are lightweight, quickly "set" with glue, you do not have to tinker with them for a long time during installation. The dimensions of standard slatted panels are from 12.5 to 30 cm in width and 2.4-3.7 cm in their length. Outwardly, they look like lining. Tiled material is produced in the form of squares with sides from 30 to 90 cm.

By appointment

It is convenient to use PVC sheet panels for the bathroom for pasting walls, since one sheet can cover a large area at once. The finished surface looks great as there are few joints and visible seams. Possessing the skills in this work, it is not difficult to make repairs.

Plastic bathroom wall panels are also used in the form of slats. Their ease of installation is ensured by the presence of grooves on one side and shelves on the other. Collecting them resembles a construction set game.

For ceilings, both slatted and tiled panels are equally well suited. Both are lightweight. When glued, they are not carried down by their own gravity. A beautiful and varied design allows you to create a magnificent ornament. Bathroom ceiling panels are an inexpensive and not time consuming option that allows you to get high quality results.

What wall panels are used for the toilet: varieties

There are 4 types of panels:

- PVC sheet.

- Wall MDF.

- From fiberboard.

- On the basis of chipboard.

Plastic for a bathroom has a pattern of tiles or mosaics with imitation of seams, but recently the popularity of matte ceramics, which is more practical in maintenance, has been growing, and traces of water splashes are hardly noticeable on it.

Plastic for a bathroom has a pattern of tiles or mosaics with imitation of seams, but recently the popularity of matte ceramics, which is more practical in maintenance, has been growing, and traces of water splashes are hardly noticeable on it.

Imitations for stone, brick, wood, leather are also offered.

Panels from MDF, fiberboard and chipboard are produced in three varieties:

- Planks or slats of small width, docking is done with a lock.

- Square and triangular tiles 50x50 or 100x100 centimeters. They are connected during installation butt, profile connections or with a lock.

- Sheets with dimensions of 120x250 centimeters.

Depending on the shape, the installation method may differ, the slats will require lathing devices, the rest can be glued directly to the surface with a flat wall, but it is also possible on the frame.

The material from which the panels are made gives different resistance to moisture, from PVC they are not afraid of contact with water, from MDF and fiberboard depend on the preservation of the integrity of the film covering them. Chipboard materials are the least resistant to water, but they are quite suitable for a toilet.

Types of liquid nails

Liquid nails are a good alternative if PVC panels and other lightweight products will be glued. Liquid nails are versatile and can be applied to any surface and are applied internally and externally.

There are two groups of liquid nails:

- Neopropylene. They are based on organic solvents. Such nails for fixing wall panels have a high quality of adhesion to any material, be it concrete or plaster. They are not afraid of temperature fluctuations and moisture. However, liquid nails have a specific and persistent odor that will completely disappear after a few days. Better to use it for outdoor use.

- Acrylic liquid nails. They are water-based, odorless, environmentally friendly. However, the resistance to moisture and temperature fluctuations is insufficient. It is better not to use glue in the bathroom.

Liquid nails for wall panels are good because they dry quickly, do not harm plastic parts (no need to make holes), they are not afraid of corrosion and they serve for a long time.

Technical features of PVC panels and wallpaper

For gluing wallpaper on PVC, you need to choose the right primer

For gluing wallpaper on PVC, you need to choose the right primer

It should be said right away that it is quite acceptable to paste over plastic panels with wallpaper. With the modern development of technical progress, there are practically no absolutely incompatible finishing materials left. It is only necessary to observe the technology of their combination: choose the right primer and cool composition.

PVC panels

Plastic panels have earned such widespread popularity in interior design due to the following properties:

Plastic panels have earned such widespread popularity in interior design due to the following properties:

- Affordable price. According to this indicator, PVC panels are among the leaders in the segment of wall panels.

- Excellent resistance to high humidity. Thanks to this, PVC wall panels can be used for decorating bathrooms, toilets and open balconies.

- UV resistant. PVC panels withstand exposure to sunlight, practically without losing their brightness and color saturation.

- Ease of installation. On their edges, the panels have special locks for ease of connection. With the help of "liquid nails" and self-tapping screws, the panels can be glued to the wall or screwed to the lathing frame.

The glossy surface of the panels makes wallpapering difficult

The glossy surface of the panels makes wallpapering difficult

This representative, like any other finishing materials, has its own shortcomings. First of all, it is a low resistance to an open flame, as well as the release of toxic chemical components during combustion.

As a result, it is not recommended to use them for wall cladding in rooms with a high probability of their ignition - kitchens, switchboards, production halls, etc.

But the main feature of PVC panels is their smooth glossy surface. On the one hand, this gives the cladding high decorative qualities, but on the other, it makes it very difficult to finish them with any material, both paints and varnishes and wallpaper.

Wallpaper

This type of decorative wall covering has been at the peak of popularity for more than a decade. The wallpaper is able to keep up with the trend thanks to the regular updating of the offered assortment. Today wallpaper is not only paper rolls with a pattern applied to them.

This type of decorative wall covering has been at the peak of popularity for more than a decade. The wallpaper is able to keep up with the trend thanks to the regular updating of the offered assortment. Today wallpaper is not only paper rolls with a pattern applied to them.

Modern wallpaper also includes such high-tech types that have practically nothing to do with their paper predecessors. Today the following types of this finishing material are presented to the attention of the buyer:

- paper. The simplest variety, characterized by low cost and low resistance to external influences;

- non-woven.Multilayer variety, where a dense polymer fabric - non-woven fabric - acts as a base. The top decorative coating can be made of almost any material - from paper to vinyl and fiberglass;

- vinyl. Another version of multilayer wallpaper, the main layer here is a polyvinyl chloride film. Depending on the base material and the number of layers, it can be either "light" or "heavy".

In addition to these three main types of wallpaper on our market, there are also more "exotic" varieties: glass cloth, jute, "liquid wallpaper", textile, etc.

In addition to these three main types of wallpaper on our market, there are also more "exotic" varieties: glass cloth, jute, "liquid wallpaper", textile, etc.

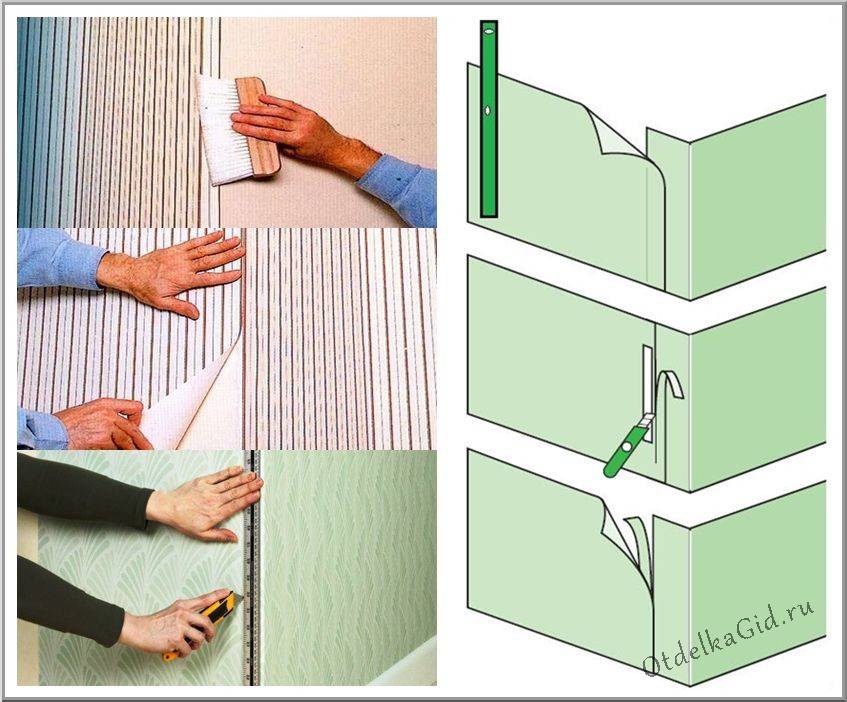

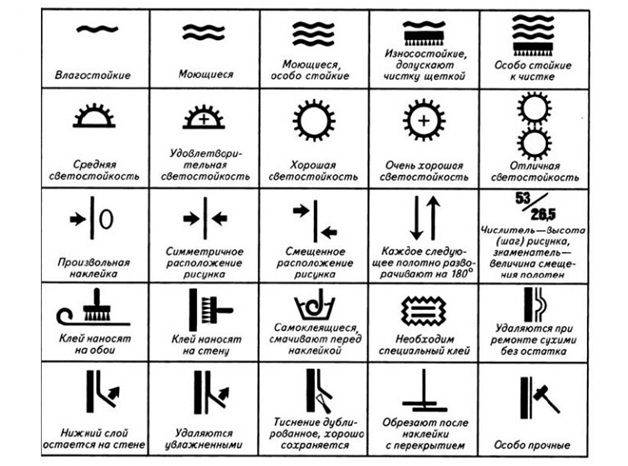

Almost every type of wallpaper has its own gluing technology, as well as glue designed specifically for a particular type of wallpaper.

The most complete information about the technical features and method of application can be obtained by carefully reading the instructions on the package.

The table shows some of the symbols applied to the wallpaper when marking them, and their decoding.

Various technologies can also be applied. When pasting some types of wallpaper, for example, paper or vinyl, the adhesive is applied both to the canvas and to the wall. When gluing non-woven ones - only on the wall, etc.

Some glue solutions quite firmly cling to the base and the wallpaper, so that when gluing, you should act as accurately as possible.

Adhesive bonding recommendations

It is quite easy to glue the panels, if you follow some recommendations and choose the right means. As an adhesive, one that is applied with a special thermal gun is suitable; for example, so-called "liquid nails" perfectly interact with PVC surfaces. The decorative coating is also perfectly attached using the "Moment-Montage" or "Titan" adhesives. In addition, polyurethane sealant has excellent adhesive properties, which does not expand during use.

When choosing an adhesive, you should consider the following qualities:

- After drying, it should become transparent.

- The bonding quality of the surfaces must be high.

- The glue must be resistant to cold, humidity, alkalis, temperature changes and exposure to sunlight.

- It must have the property of durability.

- It should set in a short time.

- It must be environmentally friendly.

- The glue should not have a strong unpleasant odor; formulations with increased toxicity should be avoided.

Among the good proven products, "Kleiberit 636" can be distinguished, it is safe for health, resistant to moisture, applied on one side, and dries quickly. Moment Kristall is perfect for decorative coating. It perfectly withstands low temperatures, moisture, has the property of transparency and quickly glues surfaces.

Procedure for gluing panels:

- Remove old wallpaper and paint from the walls.

- Level the surface.

- Degrease the entire surface of the wall to which the panels will be attached.

- Degrease the inside of the PVC product.

There are tools that are not recommended to be used; it is better to pre-test and see how the glue will behave. In particular, you should not use the "Moment", which can lead to swelling of the surface or delamination of the panel.

Today on sale you can find a special glue designed specifically for plastic panels, it is best to use it. It is quite economical in terms of cost and expense. The glue is not applied to the entire surface of the panel, but only in 5 points - in the center and at the corners. This will be enough to keep the panel firmly on the wall.

What kind of glue to glue pvc panels

On a dry and flat surface, you can install panels without brackets and self-tapping screws directly on the glue. But this option is suitable for lightweight materials. Liquid nails and special compositions are suitable for work.

Universal adhesive for pvc

High-quality adhesive composition for PVC panels has the following properties:

- after drying it becomes transparent, forms a film,

- gives a strong seam,

- not afraid of moisture, cold, heat, temperature changes,

- durable,

- sets quickly.

We recommend the following options:

- Universal glue for pvc Kleyberit 636. It contains synthetic resins, it is safe, dries quickly, is not afraid of moisture.

- Glue Moment Crystal, which has no color, securely attaches panels to different surfaces.

- Emficol 34012A is a viscous, colorless, durable composition designed to work with PVC.

- MitreFix is moisture resistant, transparent and has a strong seam.

If you do not know how to glue pvc wall panels, contact a consultant in a hardware store for help, and he will help you choose a composition that suits your goals.

To mount panels using a crate, you need:

- dowel-nails,

- hacksaw for metal or wood,

- miter box for adjusting panels,

- level to control the position of the panels,

- drill,

- furniture stapler, screwdriver, hammer, nails.

Profiles and skirting boards are used as framing materials.

First, you need to calculate and determine how many panels and rails are required.

Their length should be equal to the height of the room.

The calculation is made according to the formula: wall length / panel width.

Additionally, the number of rails is calculated.

They are placed perpendicular to the panels, and the minimum section is 20x20 cm, the distance between them should be no more than 50 cm

That is, in order to calculate how many beams are required, you need to divide the height of the room by 70, and take into account that the floor and ceiling should have a bar each.

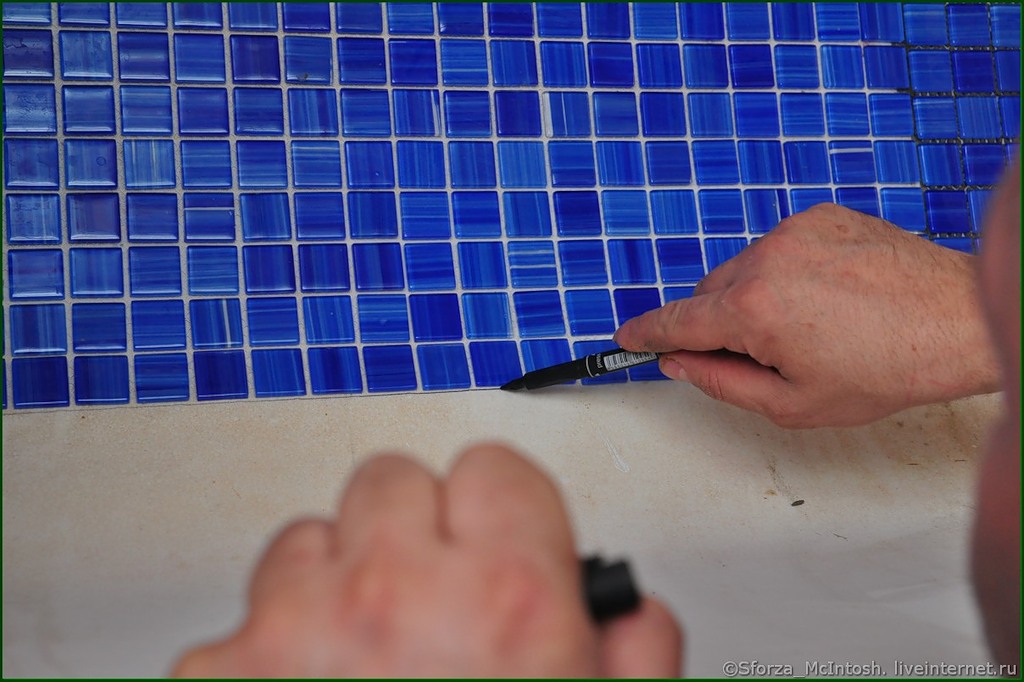

When laying the lathing, it is important to remember that the beams must be positioned exactly either horizontally or vertically. To do this, use a level and a tape measure, along which marks are applied to the wall with a pencil. In order for the lathing made of wood not to deteriorate from moisture, it is treated with special means, or a galvanized profile is often used instead of wood.

The slats are attached to the wall with dowel-nails, and corners are installed in the corners

A finishing profile is mounted on the staples to the lower and upper rail.

When laying on the crate, the panels themselves begin to be mounted from the bottom corner to the left. The first panel is the most important, it should stand strictly upright. To fix the sheet, clasps are used - metal holders that are fastened with nails to the crate. Next, the panels are attached to the groove from the previous one.

VIDEO ON TOPIC

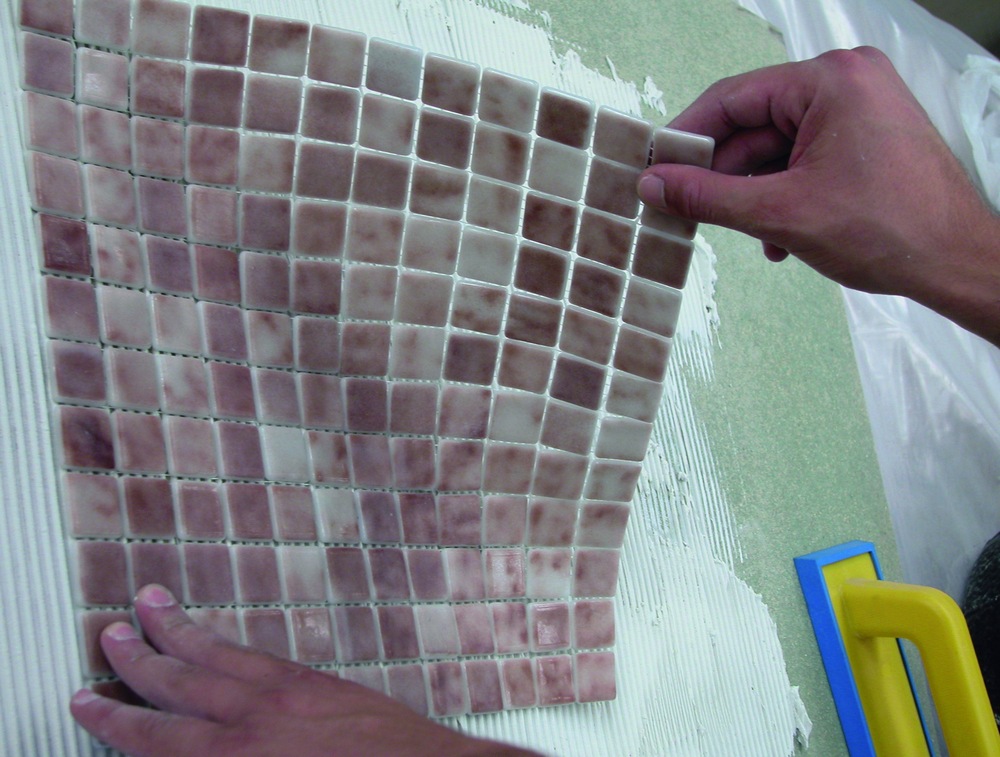

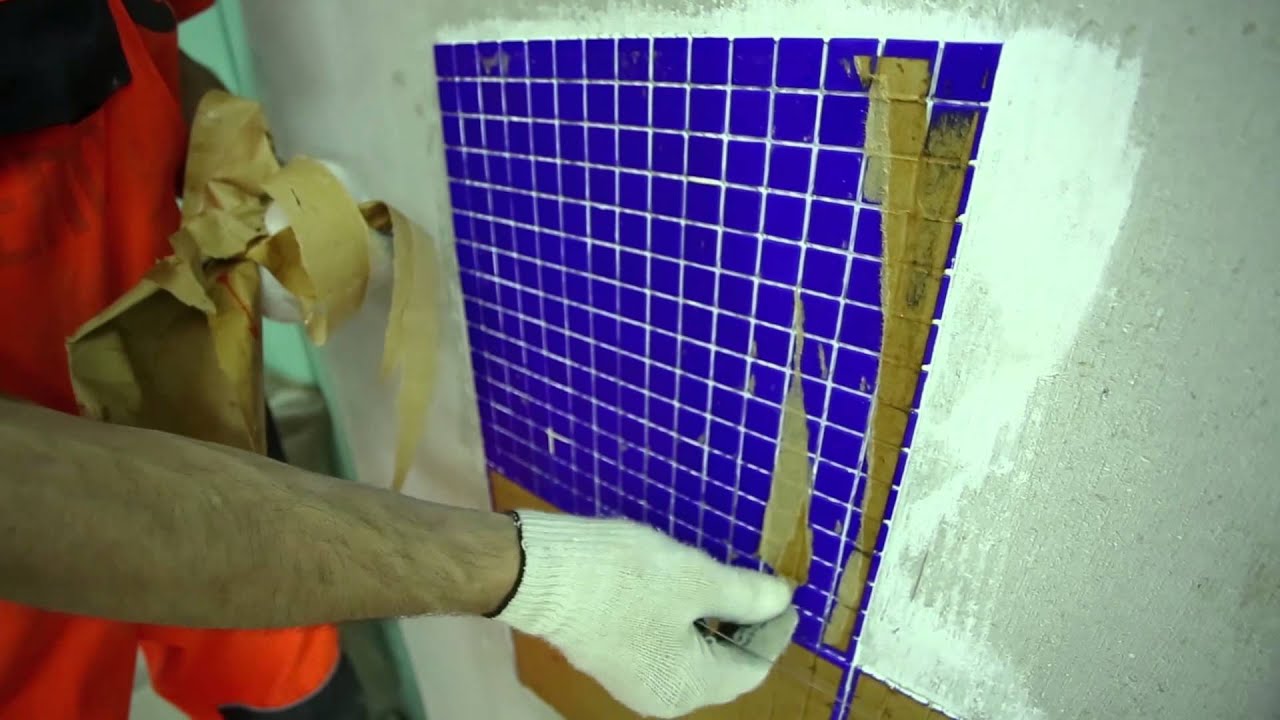

Laying Pvc Mosaic Panels

Mosaic masters have been appreciated at all times, and the material itself was distinguished by its incredible beauty and practicality. But the price of natural materials is not available to everyone, therefore, as an alternative, manufacturers today offer PVC mosaics, which can be used not only in the kitchen, but also in rooms with a high level of moisture, for example, in the bathroom.

This is a good alternative to tiles. It is difficult to say whether it will be more durable than ceramics, but it is much cheaper, it is not afraid of humidity and temperature extremes, and installation can be done on your own. Installation can be performed on walls, ceilings and even floors. Consider how this material is attached to the wall.

Installation is carried out directly on the wall or on the lathing.

Be sure to comply with the following requirements:

- the surface should be flat, without pits and bumps,

- requires thorough cleaning of the walls from dust and dirt.

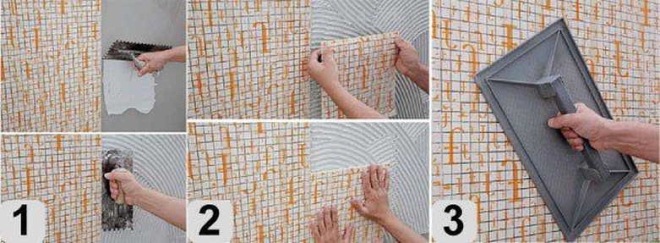

How to properly glue the panel with a mosaic - the algorithm of actions

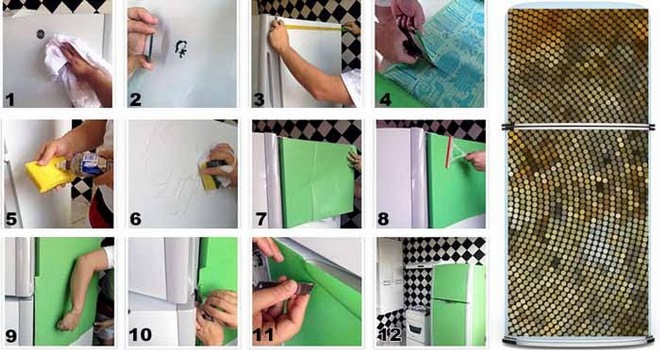

The application technology is such that the glue drips at a distance of 25-30 centimeters from each other. After the drops dry, the plate is firmly pressed against the wall, then disconnected, wait about a minute and reapplied.

In order for the glue to lie flat, it is necessary to apply it only on one of the surfaces and wait about 48 hours for the composition to fully set.

The author of the article is Kristina Sekushina

Why choose plastic products

Plastic is the most common and versatile material.

This is due to its performance and ease of installation. The advantages of plastic slopes include:

- Ease of surface care - it is enough to wipe the plastic with a cloth and soapy water;

- High-quality plastic does not fade when exposed to sunlight;

- Plastic is best combined with the surface of the profile of plastic windows;

- The service life of these products is calculated in decades;

- For plastic slopes, when insulating them, you can use mineral wool. In this case, heat loss through the window structure is reduced and the effect of fogging of the window is excluded;

- The moisture resistance of plastic is obvious, so it does not collapse under the influence of condensation;

- Simple installation - it is enough to treat the parts with an adhesive and fix them on the surface of the base.

Mounting

Plastic slopes can be glued in the traditional way - on polyurethane foam. This installation has some differences from the one used for drywall slopes.

How to glue pvc mosaic and choose glue

The most correct option for gluing pvc is the "Moment" assembly glue, which is intended for technical and decorative gluing of parts.

When using this glue, the pistol technique is used, which allows it to be applied in a dotted manner.

In addition, there are also such adhesives: liquid nails, polyurethane foam and tile adhesive (cement). All of them easily fulfill their immediate function, but each of them is not perfect.

Liquid nails do not cause such situations, but it is best to use a non-expanding sealant, which is sold in every hardware store. It is plastic and heat resistant. Professionals only use it.

How to choose?

The correct choice of the means to be used for gluing the PVC panels ensures a long-term and uninterrupted service of the cladding. If the material is firmly connected to the walls or ceiling, then it will not only not come off, but also will not allow the appearance of gaps. A high-quality adhesive used to solve this problem must demonstrate a high ability to bond the panel to the surface to be formed.

In addition, he will have to successfully withstand temperature changes, not react to high humidity, be environmentally friendly and safe for human health. For the installation of PVC panels, it is recommended to choose exclusively transparent adhesives. Antibacterial properties are also considered important, otherwise regular attacks by bacteria and fungus can be expected.

Usually, the choice of glue is based on the following indicators: drying speed, ease of application, strength of connection with the surface and convenient form of release.

These criteria are fully met by liquid nails recommended by many experts - construction glue based on synthetic rubber with the presence of polymers. They can be used even at low temperatures, down to minus 40 degrees, they can withstand significant loads, work with any materials and quickly solidify. In addition, their use is economical, because, thanks to the dispenser, the solution can be applied in dotted or dotted lines, in a grid or in zigzags.

Among the products in this category, there are "Liquid nails 901" (they cope with fastening heavy panels; they can be used both inside and outside the building) and "Liquid nails 915" (special composition for bathrooms). It should be recalled that, in addition to numerous advantages, liquid nails also exhibit several disadvantages. They consist of chemically aggressive substances, so work with them can only be carried out under the protection of a respirator and gloves.

- In addition to liquid nails, such products as Emficol 34012A are considered good (durable, transparent and environmentally friendly, practically does not smell and is ideal for fastening plastic structures), Moment Crystal (in addition to basic characteristics, it also has heat resistance, colorless and universal ) and "Kleyberite 636", created on the basis of synthetic resin, which means that it is safe for human health (it is inexpensive, dries quickly and fixes materials with high quality).

- Alcohol-based substances such as Naset, Dragon and Titan are also recommended. In general, the glue should first be tested in "combat conditions" - attach a small piece of facing material, and try to peel it off in a day. It will become clear how well it works. It should be mentioned that virtually all manufacturers of PVC panels indicate in the instructions which glue is most suitable for the job.