Composition

Cement is made at specialized enterprises. Cement factories are built in close proximity to the source materials extraction sites.

Raw materials for its production obtained from natural rocks:

- fossils of the carbonate type;

- clay materials.

Carbonates have an amorphous or crystalline structure, which determines the effectiveness of the interaction of the material with other components during the firing process.

Carbonate rocks include:

- chalk;

- marl (marly limestone);

- limestones, including shell rock;

- dolomite-type rocks.

Clay materials are sedimentary rocks. Possessing a mineral base, they are endowed with plasticity, and with excessive moisture they can increase in volume. Clay materials are used in the dry production method.

Clay rocks include:

- clay;

- loam;

- clay-based shale;

- loess.

In addition to raw materials, corrective additives are used in the production of cement.

They are obtained from fossils, which include:

- apatite;

- alumina;

- fluorspar;

- silica.

The additives introduced according to a certain technology improve the quality of the described material.

The composition of the cement depends on the required characteristics, which are determined by the grade assigned to the material.

The most popular Portland cement consists of:

- 60% lime;

- 25% silicon dioxide;

- 10% iron and gypsum oxides;

- 5% aluminum (alumina).

In different brands, the percentage of raw materials is different, as is the composition itself. For example, slag Portland cement contains slag. Quantitative proportions can also vary with the peculiarities of the chosen technology for the manufacture of building material.

For any brand of cement and for any method of its production, limestone and clay remain unchanged components. Moreover, limestone is always three times more than clay. This ratio contributes to the production of high-quality clinker, from which cement is made.

In industry, the following components are used for the production of cement:

- clinker;

- gypsum;

- special additives.

Clinker is the most important component of cement. It determines the strength properties of the final material. The clinker enters the production process in the form of granules. The diameter of the granules varies between 10-60 mm. The heat treatment of the component is carried out at a temperature of about one and a half thousand degrees.

The amount of gypsum is determined by the set hardening period. In the basic version, gypsum in the form of a powder is included in the cement in a volume of 6%.

Peculiarities

When mixed with water, this popular powdered material hardens into a petrified lump. Curing occurs with excessive humidity in the air or the presence of liquid

The presence of water is an important condition for the hardening of the finished product

Several types of cement are distinguished depending on the composition. Each of them has a degree of hardness inherent only to him, according to which the brand and product quality are determined. Cement, which is made from rocks, is quite reliable. It is made only from quality materials.

Portland cement is the most widely used type of mineral composition, which is also called silicate. It hardens in an aqueous environment and in the vicinity of humid air. The gray-green powdery substance dissolves easily in water when mixed. As soon as the mixture begins to set, slow curing begins.

Portland cement is included in the formulation of almost all groups of cement mixtures. The use of this brand in its pure form is a very rare occurrence.Basically, it is included in mixtures, building concretes, mortars.

Plasticized cement has great advantages over other types. Its use helps to reduce waste and time for mixing dry mix. The composition is not exposed to low temperatures, excessive humidity, evaporation and other negative influences of the external environment.

Slag cement contains blast-furnace slag and crushed clinker. This brand contains additional substances in the form of lime powder and gypsum. Such cement is necessary when connecting building mixtures.

High-activity alumina cement has a unique composition. Time to start hardening is only 45 minutes. And until the solution completely solidifies, it takes about 10 hours. The main advantage of this composition over others is that, regardless of the saturation of the air with moisture, it quickly sets. When this type of cement is added to concrete, new qualitative features appear in it: resistance to dampness, corrosion, and large temperature extremes.

The main components of the acid-resistant cement composition are sodium silicofluoride and quartz sand. In ordinary water, a solution from such a substance cannot be obtained. To prepare a mixture from this powder, liquid glass is used, which is based on sodium. The advantages of acid-resistant cement are that it is very resistant to mineral and organic acids. But with their presence and application, the service life decreases very quickly.

Colored cement in the composition has a simple Portland cement, to which pigments are added. This brand is used for decorating buildings and is part of the compositions that are used in the construction of highways based on concrete mixtures. When mixed with water, Portland cement forms a material of plastic structure. During the drying process, it turns into stone.

The advantages of such a substance:

- hardening without extraneous efforts;

- high strength and solid after hardening;

- increased chemical safety;

- it is an environmentally friendly product;

- fire safety;

- low cost;

- versatility.

White cement is a powder that acquires its light color with a specialized production technology and a certain composition. Its formulation contains clinker with a low iron content, contains mineral additives of limestone, chloride compounds, and gypsum. This composition gives the mixture light shades.

Decoding of cement marking according to new standards

The coding of product information in accordance with GOST 31108-2003 is based on the division of cement types into 5 groups, denoted by Roman numerals. The first 3 letters are taken from the name of the powder - CEM.

Each association has signs indicating the peculiarities of manufacturing:

- I - no additives Portland cement, consists of 95-100% of cement clinker;

- II - this group is subdivided into subclasses A with additives of 6-20% and B - 21-35%. There are also pozzolanic cements containing

- III - slag Portland cement with a slag content of 36-65%;

- IV - pozzolanic cement with the addition of 21-35%;

- V is a composite powder containing 11-30% slag and, within the same range, pozzolan.

Each of the additives has its own letter in the designation: I - limestone, Z - fly ash, MK - microsilica, K - composite additive, G - glezh, W - slag, P - pozzolan. This is followed by the number of the strength class, followed by the letters: H - normal hardening time, B - fast setting. Example: slag portland cement CEM III / A 32.5N GOST 31108-2003. It stands for this: the strength of the cement is 32.5 MPa, it is normally hardening, it contains 36-65% slag.

How cement is prepared in production

The main substances from which cement is produced are limestone and clay. From these two components, clinker is prepared in a special way, which is subsequently mixed with other additives that determine the quality, brand and properties of the mortar.Among the required additives are: gypsum, dolomite, cementite.

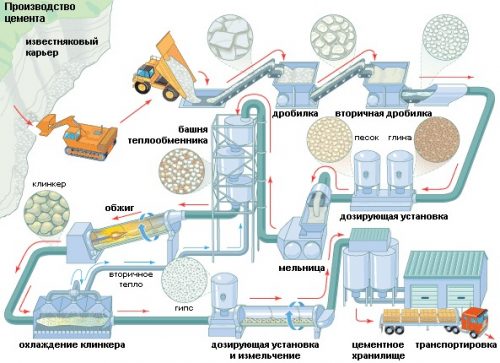

Cement production stages.

Cement production stages.

In nature, there is clinker in its pure form - marl, but due to the small reserves of this mineral, it is impossible to use it on an industrial scale, therefore, domestic and foreign manufacturers prepare clinker from traditional materials.

Marl.

Marl.

Cement production is broken down into the following stages:

- To prepare the clinker, it is necessary to thoroughly mix the ingredients in special large capacity drums.

- At the next stage, the prepared mass enters the furnace, where it is fired for 3-4 hours at a temperature close to one and a half thousand degrees. As a result, clinker is formed in the form of small fractions (up to 5 cm in diameter).

Sludge firing.

Sludge firing.

- Further, the resulting clinker grains are crushed in drums using ball screens. In the process of processing the material, it is necessary to achieve a powdery state of the mixture.

- At the final stage, the necessary additives are added to the finished cement and sent for packaging in bags or hopram.

There are three ways to make cement. They differ in the methods of clinker processing.

- Wet way. Clinker is produced using water, chalk and clay. As a result of mixing substances in the drum, a wet mass is formed - a charge. It is sent for roasting, after which the resulting granules are crushed and mixed with the necessary additives. This method is considered quite costly, therefore, other methods are more often used now.

- Dry method. It allows you to shorten the stage of mixing the ready-made mixture with additives, since the whole process is reduced to the preparation, crushing and mixing of ready-made ingredients. This technology is becoming more and more popular, as it can significantly reduce production costs and the final price of the product.

- Combined method. This technology uses various forms of clinker production, combining production steps used in dry and wet methods.

2 Dry method

The dry process requires any raw material to be processed without the use of water. In this case, clay, limestone and other components are crushed, then ground to a state of dust and mixed using air supply in closed boxes.

In the manufacture of dry cement, ready-made raw materials enter the kiln for firing,

not having, moreover, water vapor. Therefore, after heat treatment, we get ready-made cement that does not require crushing.

The dry method significantly reduces the cost of time, heat energy and other resources. It is very beneficial and effective in high slurry uniformity.

2.1

Combined

The production can be based on the wet method and supplemented with a dry one, or dry, supplemented with a wet one.

In cases where the basis is the wet method, the raw materials after mixing are dehydrated with special dryers with filters and sent to the oven almost dry. This allows you to reduce the cost of thermal energy, since it significantly reduces evaporation during the firing process. If the production of clinker is based on the dry method, the finished mixture is granulated with the addition of water.

In both cases, the clinker enters the kiln with a moisture content of 10 to 18%.

2.2

Clinkerless production method

In addition to the traditional methods listed above, the production of cement can take place in a clinker-free way. In this case, the raw material is blast furnace or hydraulic slag, which is combined with additional components and activators. At the exit, a slag-alkaline mixture is obtained, which is crushed and ground to the desired consistency.

Clinkerless cement production technology possesses the following positive qualities:

- the final product is resistant to any environmental conditions;

- the costs of heat energy and other energy costs are significantly reduced;

- waste from the metallurgical industry is used as a raw material for high-quality cement production, which has a positive effect on the cleanliness of the environment;

- makes it possible to produce the final product with different properties and in different colors without changing the production method.

2.3

Cement production (video)

2.4

Equipment for the production of cement

Since the entire production process is divided into stages that are inherently very different from each other, then equipment for producing cement requires a variety of different types. It can be divided into the following subgroups:

- equipment for the extraction and transportation of raw materials;

- for crushing and storage;

- kilns for roasting;

- clinker grinding and mixing machines;

- machines for filling ready-made cement.

Since the production of cement is done in different ways, and raw materials are used differently, the equipment in factories can also be different.

Recently, private mini-factories for the production of cement have been very popular. Sometimes it is even made at home, but we'll talk about that later.

The thing is that the equipment for such plants is not very expensive, they can be installed on relatively small areas, and pay for themselves amazingly quickly.

In addition, assembly, disassembly and transportation of the production line is straightforward. Therefore, it is possible to set up a private plant at any unpromising raw material deposit, and, having worked it out, it can be transported to another place. This option will free the manufacturer from the task of transporting raw materials, which will significantly save money.

2.5

What does a production line consist of?

- Auger crushers. Designed for coarse crushing and crushing of raw materials.

- Hammer crushers.

- Screens or vibrating sieve. Needed for sifting crushed material.

- Material feeding device for the first stage.

- Conveyors. They perform the function of feeding raw materials to the next stage.

- Sorting machine.

- Threshing and threshing-dosage machine.

- Mill with millstones.

- Sludge mixing machine.

- Rotary drum kiln.

- Drying plant.

- Refrigeration unit.

- Clinker mill.

- Bucket elevator with augers.

- Weighing and packaging equipment.

How cement is made in production

Today there are several production methods:

The wet method was the first technology used to make cement. They work on it to this day, albeit a little according to an improved method.

Dry method is a more modern method of binder production, which is characterized by greater economy of raw materials and energy resources.

But, most importantly, it is with this technology that emissions into the atmosphere are reduced.

Combined techniques are rarely used in Russia, mainly at enterprises working with foreign partners. For example, like the Volsky cement plant.

Still, I wanted to cover in more detail the wet method of cement production, since practically all cement plants in Russia and the CIS countries operate on it. The photo below shows the production facilities of Uralcement in the Chelyabinsk region, which began operations in 1957. Here the binder is produced on the basis of limestone and clay using the wet method. Gas is used as fuel. Production in the open pit begins with the extraction of the main raw material.

Limestone and clay mining

Limestone and clay mining Limestone quarry

Limestone quarry

Further, the extracted raw material is additionally processed and enters the wet grinding furnace, where it turns into sludge. After that, the sludge goes further to the raw mills and sludge basins.

Raw material processing

Raw material processing

The resulting fine sludge is sent to a rotary kiln, where it is fired at a temperature of + 1450 ° C. The result of this process is clinker.

Sludge firing

Sludge firing Firing control

Firing control

The resulting clinker is cooled in special refrigeration units, after which it is transported for further grinding in the mill.

Clinker transportation

Clinker transportation Clinker mill

Clinker mill

Fine gypsum and mineral additives are also added to the crushed clinker.

Mixing process of ingredients

Mixing process of ingredients

The finished cement is sent to storage in special bins.

Bunkers

Bunkers

In such a large manufacturing enterprise, there simply cannot be a laboratory, whose employees closely monitor each production process and the quality of cement.

Cement testing

Cement testing

These are the main production processes for wet technology. They are identical in all factories. The only thing is that corrections are made for raw materials and equipment specifics. From what and how cement is made, the video will tell in detail.

How cement is made

Manufacturing technology consists in obtaining and subsequent grinding of clinker. The so-called granules, which are an intermediate product of production. Their composition is always unchanged. It is limestone and clay mixed in a 3: 1 ratio. In nature, there is a mineral that is completely identical in composition to clinker. It's called marl. However, its reserves are limited and cannot meet the production demand.

Therefore, factories use an artificial analogue of marl. To obtain it, the necessary ingredients are thoroughly mixed in large containers with special drums. The mass prepared in this way is fed into the furnace, where it is fired for about four hours. The process temperature is about 1500 ° C. Under these conditions, the powder begins to sinter into small granules. After cooling, the clinker grains are sent for grinding. They are crushed in large drums with ball sieves.

At this stage, it is important to grind the granules and obtain a powdery product of a certain size. Grinding is determined by the mesh size of the sieve

The resulting powder is mixed with the necessary additives that determine the brand and properties of the product.

Instagram tsement_82

Instagram tsement_82

The finished cement materials are delivered to storage or to the packaging area, where they are distributed in containers of various capacities or loaded into special cement trucks.

Despite the general technology, for the production of the composition, depending on the properties of the raw material, three methods can be used.

Dry method

This method can significantly reduce the time and cost of making a cement mixture. It involves several stages:

- Raw materials are crushed to obtain fine grains.

- The prepared granules are dried until the desired moisture content is reached. This is done to facilitate subsequent operations.

- The ingredients are mixed in certain proportions. Then they are crushed, receiving flour.

- The powder is fed into a rotary kiln where it is fired but not sintered into granules.

After cooling, the finished product is sent to the warehouse or to the packaging area.

The dry method is considered the least energy-consuming, and therefore very beneficial for manufacturers. Unfortunately, it is not applicable to all categories of raw materials.

Wet way

In some cases, it is necessary to moisten the material prepared for production. In such cases, the wet method is used. To prepare clinker, which consists of limestone and clay, a mixture of the main components is mixed with the addition of water. The result is a viscous mass called sludge.

It is placed in a kiln where firing takes place. In this process, granules are formed from the sludge, which, after cooling, are sent for grinding.

Instagram tabys.cement

Instagram tabys.cement

Powder obtained from clinker is mixed with milled additives. Only then is the product ready for packaging and storage. The composition produced using this technology has the highest cost price.

Combined method

It is used to reduce the cost of finished products. It is a kind of symbiosis of dry and wet technology.Initially, the sludge is mixed, which is subsequently dewatered. This is how clinker is made. It enters the dry kiln. Further, if necessary, mixing with fillers is carried out, and the product is ready. The process is shown in more detail in the video.

The quality of cement largely depends on the raw materials from which it is produced, and the accuracy of adherence to all technological stages.

Considering that the characteristics of the building materials made from it are determined by the quality of the mixture, it is worth paying close attention to it.

Main characteristics

What properties of cement should you pay attention to in the first place:

the strength of cement, like concrete, is the most important indicator that is decisive when choosing raw materials for construction. This parameter is tested based on the maximum load that the cement beam can withstand;

Typically, you can find out about the strength by marking the block. Usually the following designations are used: M400 or M500. Astringent variations of cement are produced from M300 to M800.

Checking the cement block for strength

Checking the cement block for strength

steaming activity is another important characteristic that shows how actively the binder is tarred. The strength of the binder and the time of heat and moisture treatment directly depend on this indicator. There are 3 steaming groups. The first is the best and most effective;

Steaming samples

Steaming samples

These are the two most important characteristics of a binder used in any construction industry. Therefore, with each new batch, even if there is a quality certificate on hand, tests of such properties are carried out. Based on the data obtained, the composition is adjusted.

setting time - the time when the cement composition begins to set. Usually it is from 45 minutes to 10 hours. The higher the temperature, the faster the setting occurs;

Vic's device for determining the setting time

Vic's device for determining the setting time

- bulk density - in a loose state it is approximately 900-1100 kg / cm3, in a compacted one - 1400-1700 kg / cm3, this true value is 3000-3100 kg / cm3;

- water demand - the required amount of water to hydrate the cement and create the plasticity of the dough. Typically, approximately 17% of the cement mass required for hydration is taken. But it happens that such an indicator is increased due to the fact that the water demand of the cement itself is higher.

How high-quality the astringent property has turned out is tested even in factory laboratories and, on the basis of such tests, a quality passport is issued, from which we learn all the characteristics. But we receive it only after a month, since the passport is issued on the basis of sample tests at 28 days of age. Therefore, each new batch is independently tested in the laboratory to find out how high quality it is. The latter depends on the composition of the binder itself.

How to make cement at home

Despite the complex production process, you can make cement with your own hands. Of course, not according to the classical technology with fine crushing of clinker and firing at high temperatures. Consider one of the popular recipes:

- The resulting composition is used to seal cracks and other imperfections in floors and screeds.

- You will need water lime, stone ash and regular water. Everything in equal proportions.

- All ingredients are mixed until a sour cream consistency is obtained. In this form, a similar "cement" is used.

Just do not do too much of it - such a composition dries quickly.

Another popular glycerin-based recipe. It got widespread due to its good strength:

- Lead litter is ground to the finest possible state and dried in any type of oven at high temperatures.

- Glycerin is added to the resulting "clinker".

- Homemade cement made in this way most closely resembles a store-bought analogue.

How to prepare cement mortar from cottage cheese

Curd cement

Curd cement

Ever wondered how you get cement from cottage cheese? It turns out that there is such cement. How do you create such a mixture? Very simple:

- A thin layer of dried skim milk cottage cheese without whey. You get a kind of powder - 1 part.

- You will also need caustic lime - 10 parts.

- These ingredients are mixed and water is added to them. Everything is mixed and brought to a mushy state.

Cement by unconventional technology

An unconventional method of making cement is popular in China. Pork blood is used as one of the main ingredients. Despite the fact that the moral and ethical side of this issue raises a lot of controversy, from the point of view of strength and durability, such material does not raise questions.

So, the special ingredients of the Chinese masters:

- alum powder - 6 parts;

- fresh pork blood - 40 parts;

- slaked fluff lime - 54 parts.

All ingredients are mixed until smooth. The resulting composition has good strength and adhesion, so it has been quite popular lately.

Proportions for cement mortar, or How to properly dilute cement

We have learned how to make a cement mortar from alternative materials. And now we will consider the classic composition of cement mortar, which is used for filling joints, cracks, repairing concrete products, gluing blocks and bricks. In fact, this is an ordinary masonry mortar, where cement and sand are traditionally mixed in proportions: 1: 3. If desired, plasticizers are added to it.

For leveling small cracks, it is more suitable to prepare a cement paste from an ordinary binder of any brand and water. They are simply mixed in certain proportions to obtain a creamy consistency. Such a solution perfectly fills small gaps, dries quickly and lends itself well to sanding.

Cement is the foundation of any home. One way or another, this material is used at different stages. Even during the construction of a log house, a reinforced concrete foundation is the main frame element

For this reason, it is important to be attentive to its quality, to pay attention to all the points that we described in detail in the article.

If you have questions to the author of the material or want to share your experience of using various cement materials, write comments.

Previous Building materialsFinishing material of universal type - DSP boards: sizes, prices, methods of laying, characteristics

The next Building materialsSimply about the complex: a comparative table of thermal conductivity of building materials