Welding with linoleum

Cold Welding or Fast Steel are allowed for. They consist of the following substances: tetrahydrofuran; plasticizers; polyvinyl chloride. The composition allows you to slightly straighten the edges of the linoleum to be glued using the prepared mass. The main feature of this type of welding is the difference in its behavior during work and in contact with different types and brands of linoleum. Manufacturers recommend three main types of adhesive components:

Glue type "A"

It is used when it is required to join the seams of a sufficiently hard material. The consistency of linoleum glue is characterized by significant fluidity. When working, a rather thin, neat seam is obtained.

Type "C"

This cold steel is suitable for linoleum, which has been in use for a relatively long time, has a strong degree of wear and is subject to cosmetic repair. The consistency of the adhesive mixture is thicker than "A". This determines the specifics and scope of its use. As a result of the work, the seam is filled. It fills in the gap between the old strips of linoleum. A visible new strip of adhesive forms at the bonding site.

Glue type "T"

This type designed for cold welding linoleum. The building material is PVC. Polyester is used. The composition of the T type glue for linoleum is specified in the product modification. It is used more often by professionals and builders.

Cold welding

Adhesive for joining metal parts is very popular primarily due to the fact that to work with it you do not need to have any welding skills and there is no need to purchase special equipment. Everyone can do this job. It is enough just to study the instructions in detail.

So, to work with metal glue you will need:

- welding glue;

- clamps (if necessary);

- degreaser (acetone);

- sandpaper.

Description of work with cold welding:

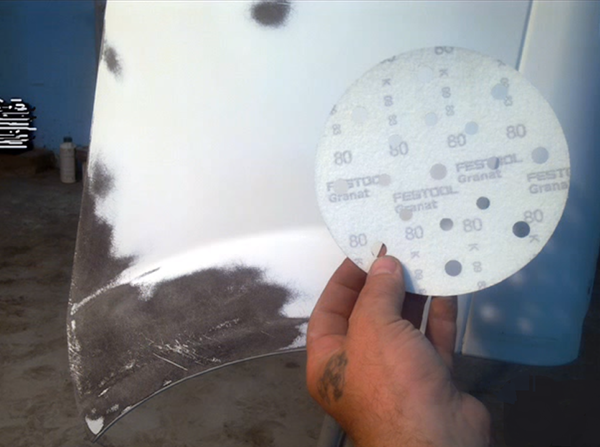

- First you need to prepare the surfaces of the parts to be bonded. They must be cleaned with sandpaper and degreased. The surfaces must be dry and roughened for better adhesion to the adhesive. The final result of the work depends on how well the preparation is performed. So take this step seriously.

- Many formulations easily stick to your hands, which, as a result, can disrupt the proportions of the glue components. To prevent this from happening, wet your hands with water.

- The two-component adhesive must be mixed with a hardener. If this is a hard plastic-like glue, then it should be thoroughly kneaded with your hands, liquid glue is mixed with a hardener in the proportion indicated in the instructions. When mixed, the composition tends to heat up.

- After mixing, you need to work with the glue quickly - no more than 3 minutes.

- When joining two flat surfaces, secure them with special clamps for a secure fit.

- Dry welding can take from 1 to 8 hours, depending on the type and manufacturer. After that, the repaired part can be putty and painted.

- Do not violate the instructions for using the glue, otherwise the strength of the weld will decrease.

There are many glue mixtures and glue sticks on the market under the general trade name Cold Welding or Fast Steel

... In fact, they have nothing to do with welding because:

Cold welding

pressure welding with significant plastic deformation without external heating of the parts to be joined

This is not cold welding

since there is no plastic deformation of the parts to be joined.

Welding

the process of obtaining permanent joints of parts by establishing interatomic bonds between the parts to be welded during their local (general) heating or plastic deformation, or the combined action of both

This is not welding

, since there is no heating or plastic deformation, and even less the establishment of interatomic bonds between the parts to be joined.

In this article, we will dwell in detail on the consideration of glue and rods "Cold welding".

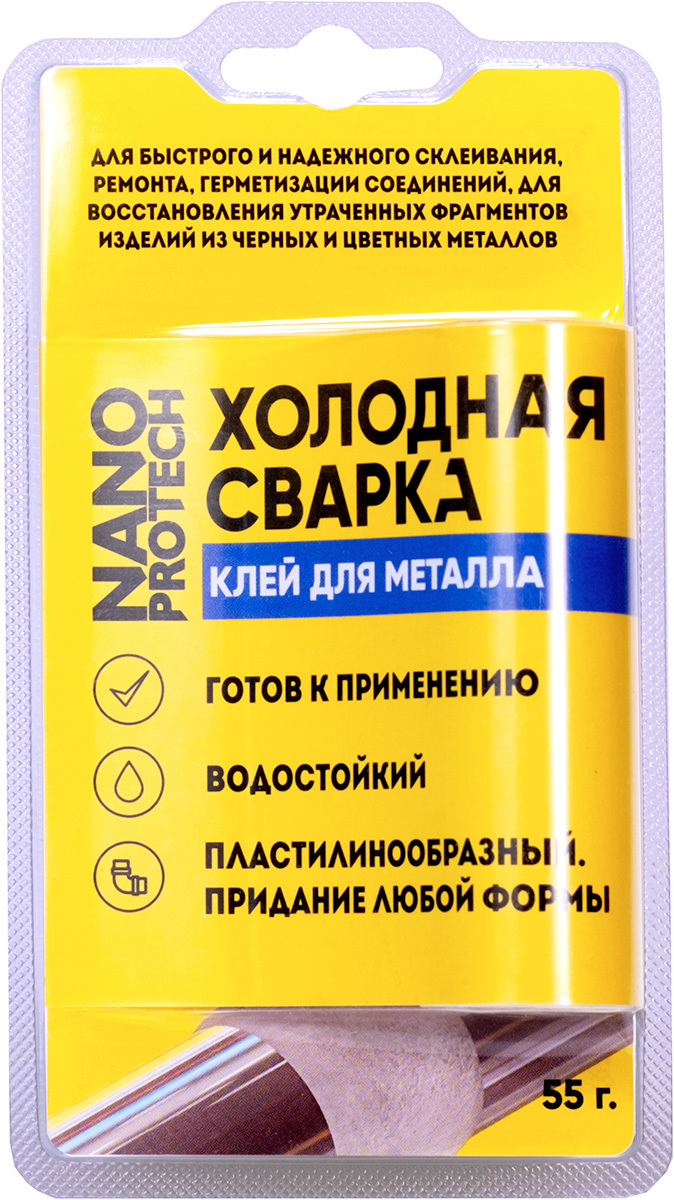

"Cold welding"

are called composite polymer materials used both for the repair of metals (steel, cast iron, aluminum, copper, titanium, etc.) and for the repair of wood, plastic and ceramic products.

Cold welding glue

two-component and comes in two tubes:

- epoxy resin with plasticizer and filler

- hardener

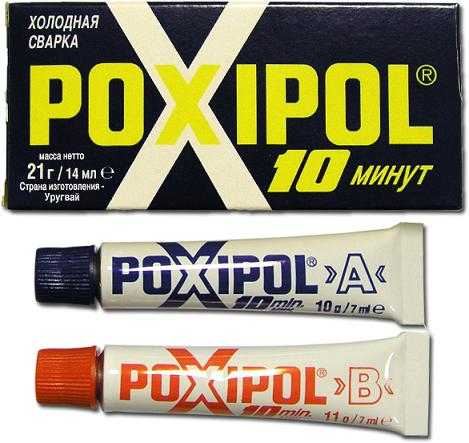

Figure 1 - Two-component adhesive

Epoxy resins in their pure form are fragile and poorly withstand vibrations and shock loads, which is why it is necessary plasticizer

(component for increasing the elasticity of epoxy resin). Filler

It is necessary to impart special properties to epoxy resins: thermal conductivity, heat resistance, abrasion resistance, etc. Depending on the required properties of "cold welding", powders of metals (aluminum, steel, cast iron, etc.) as well as mineral and artificial fillers are used as fillers.

As hardener

predominantly polyethylene polyamine or amine hardener is used, which, by reacting chemically with epoxy resin, produces a hardening process.

The mechanical properties, setting time, operating temperature and field of application of the cold-weld adhesive depend on its constituent components.

Below is a summary of instructions for cold weld glue and putty, which may vary depending on the brand and manufacturer:

Cold welding classification "Almaz"

Cold welding of the Almaz-press series has high adhesion rates with various materials (wood, metals, ceramics, plastic, etc.). The manufacturer produces the following types within the series:

- "Universal". Suitable for joining metallic and non-metallic parts and products. It can be used for repair work in hard-to-reach places.

- "For woodwork." The composition allows you to firmly connect and fix various types of wood, plywood, veneer, bars and other wooden materials. It can be used when carrying out repair and restoration work on furniture. Has a natural wood shade.

- "For the repair of plumbing." It is used to restore ceramics, faience, porcelain and other materials from which plumbing fixtures and decorative items are made. Has a white tint, which allows you to hide the location of the repair work.

- "For car repair." It is used for sealing cracks, removing chips, restoring threads, sealing various surfaces, fixing decorative elements on vehicle surfaces.

- "With steel filler." This type of cold welding "Almaz" contains steel filler. The substance is used for bonding metal products (cast iron, steel, copper, aluminum and other types of ferrous and non-ferrous metals).

general information

Cold welding "Almaz" is produced in polymer cylindrical tubes. The glue is additionally protected with cellophane. The manufacturer produces tubes of different sizes for the convenience of the consumer.

Application area

Cold welding "Almaz" according to the instructions has the following scope of use:

- Joining of wooden, ceramic, plastic, concrete, glass, metal parts.

- Connection of products, parts and surfaces made of different materials.

- Elimination of leaks in pipelines, containers, tanks.

- Repair of garden, sports equipment.

- Repair in hard-to-reach areas or when it is impossible to dismantle or disassemble equipment, structures.

Advantages and disadvantages of Poxipol

The popularity of this brand of glue is due to its excellent adhesive properties. The seam is durable, does not collapse over time. The advantages of Poxipol are as follows:

- preservation of the joint volume after drying, the possibility of applying an adhesive layer of any thickness;

- the use of glue on any materials (even on those of different structure, density), no damage and corrosion when applied to most types of plastic;

- water resistance, oil resistance, scratch resistance;

- the ability to apply on vertical, horizontal bases using a continuous and dotted method;

- ease of mixing and ease of application;

- fast setting and short time to full hardening;

- the ability to use for indoor and outdoor work;

- lack of solvents in the composition, the possibility of using in residential premises, children's institutions;

- lack of traces, stains, streaks after drying;

- availability for sale in almost all hardware, hardware stores;

- simplicity and clarity of instructions for use.

The disadvantages of Poxipol glue include its low tensile strength. Therefore, you should not use the glue in conditions where parts are exposed to vibration, other movement, deformation, and high mechanical stress. The quality of adhesion decreases if the surface is not properly prepared, which can also be attributed to the disadvantages of the glue. Another disadvantage is the risk of damage to some materials (teflon, polypropylene, polyethylene), this glue cannot be used on them. Other disadvantages:

- higher price compared to domestic adhesives;

- low melting point;

- short pot life after dilution;

- the need for mixing components;

- too small packaging (if there is a large amount of work).

Description of welding

Cold welding is understood as processing with a polymer adhesive that helps to create reliable seams between the same or different materials without the use of heat. As a result, a permanent connection of elements is achieved, this is facilitated by a special composition of the chemical mass. The plastic agent penetrates into the parts to be welded, then solidifies, forming a monolithic joint.

Cold welding includes the following main components:

- epoxy resin;

- amine resins;

- steel fillers;

- minerals.

Epoxy glue is great for plastic, metal, wood, but you need to study the instructions in detail. Universal compounds can really be used on any material, highly specialized ones are allowed to glue only one type of elements, otherwise the work efficiency will decrease.

Advantages of cold welding "Almaz"

What is the reason for the popularity of Almaz glue is, of course, its ease of use, in order to apply cold welding no additional knowledge and tools are needed. Almaz glue is universal, so it can be used in almost all household conditions, from gluing metal and wood to joining glass and plastic.

A distinctive feature of cold welding is the ability to bond non-homogeneous materials. "Almaz" will be able to connect without any problems, for example, metal with wood or glass with rubber. This glue is available in packages of different sizes and is sold at a democratic price. The shelf life of the substance is very long and does not require any special storage conditions. It is also a good advantage that it can be used over a relatively wide temperature range. It is very easy to maintain the required mode for glue hardening.

disadvantages

The main and most important disadvantage of the Almaz glue is its low quality compared to analogues produced abroad. The material in a dried state has a very high fragility.Cold welding "Almaz" cannot be used in critical joints, because their tensile strength will be very low. This glue is mainly used for repairing small household items and decorating items. Lumps are also a major problem.

During the mixing of the material, lumps form in consistency, which negatively affect the properties of the glue, respectively, and the quality of the connection. The outer layer does not have a very good property; during contact with dry surfaces of various kinds, it begins to stick to them. When repaired products are used in adverse conditions, the service life of the connection is rather short.

Application area

"Almaz" cold welding is an epoxy-based glue. Most often it is used when it is necessary to connect any objects for which there is no alternative means for gluing. It can also be used to repair broken ceramic items. If any shard has been lost, cold welding will be able to replace it without any problems.

Glue "Almaz" can join parts made of metal, plastic, glass, wood (parts do not have to be of the same material). However, in order for the bonding of the above materials to be good, it is necessary to carry out a number of preliminary works before the bonding process. Namely, it is necessary to thoroughly clean both surfaces to be glued from various kinds of contamination (traces of fat, oils, etc.). A solvent can help with this without any problems.

One of the main "tricks" of the glue is its ability to repair holes. That is, if an object breaks and a hole appears in it, cold welding will be able to seal the hole and provide a sufficiently strong connection. In order to seal a hole, it is necessary to apply a thin layer of the substance to the surface of the hole, after the mass has hardened, a strong layer is formed. After hardening, the area can be processed (sanded, painted, polished, etc.).

In a similar way, using cold welding, you can restore small lost parts, for this you need to give the mass the shape of the necessary part, as if using plasticine. After the resulting part has dried, it must not be subjected to high loads. Therefore, cold welding is very rarely used in various industries. Almaz universal glue can be used only in normal temperature conditions. It is unable to perform its functions in extremely high and low temperatures and in extreme climates.

In order for cold welding to perform its functions, you must strictly follow the instructions for use.

It is important to know: after connecting the parts to be glued, it is imperative to withstand the time indicated in the instructions, since only after this period has expired, the process of complete drying of the joint takes place

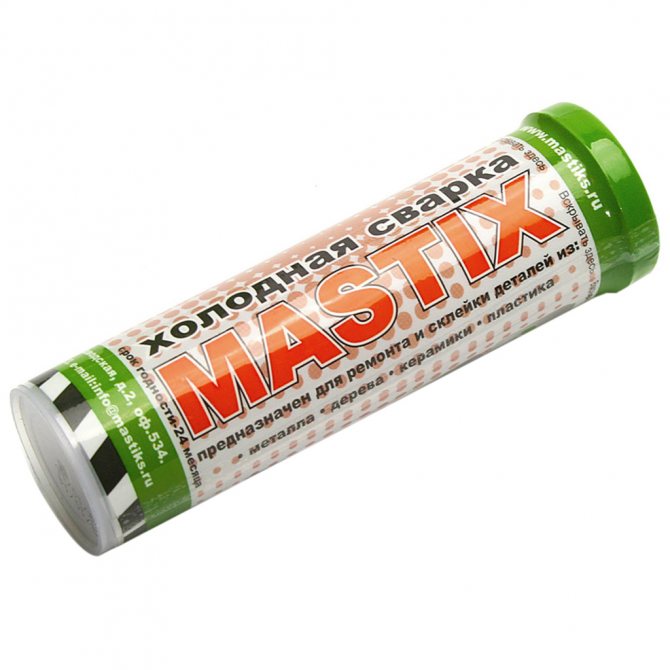

Roller cold welding

This is one of the varieties of cold welding. A technique that assumes a monolithic connection of blanks due to the impact of rollers on them. Since there are rollers on both sides, the metal is completely immersed in the working protrusion.

The rollers are constantly moving, and the product is moving. Working lips provide uniform deformation and bonding of the material. As a result of such actions, a monolithic seam is formed.

A great way if needed:

- produce a large number of identical metal parts;

- use in various branches of electrical engineering.

For work, hand-held machines or milling machines are used. What exactly - a machine or a milling cutter - depends on the metal being processed and the rules for working with it.

Disadvantages of Mastix

- The drying time here is slightly higher than in other brands, therefore, some problems may arise when working with it at different temperatures;

- During preparation, clumps can form, which lowers the quality of the joint and can lead to the need for rework.

Application area

Cold welding Mastix for metal is used both at home and in various repair procedures of professionals, depending on the type of material. Basically, it is used as an ordinary glue, which should connect metal, wood, plastic, stone and other things that are difficult to glue.

An equally important function is the repair of pipelines, various containers, car parts and other things. Cracks can be repaired by applying a plastic mass, and with penetration into the internal parts

Cold welding Mastix for metal

If the product is not operated at temperatures above 150 degrees Celsius, then chips can be repaired, parts restored and other repair procedures performed. The main thing is to withstand the time that cold welding dries, after which the part can be put into operation. The properties of the fortress here are not strong enough to withstand strong shocks, but vibration loads, which are often found in moving mechanisms, are tolerated quite normally.

Composition:

- Mineral fillers;

- Metallic fillers;

- Amine resin;

- Epoxy resin.

Views

For metal - it has a metal filler in its composition, which improves the quality of the connection with metal surfaces. It tolerates contact with moisture well, so it can be used in plumbing repairs. It is not highly sensitive to surface cleanliness, so it can be used with wet and oily parts.

Cold welding Mastix for metal welding

Universal - the mixture is used for quick repair of any surfaces. Has a wide range of operating temperatures. This is the most popular and frequently used option that may be needed in every home.

Universal cold welding Mastix

Heat Resistant - This cold weld has the highest burst temperature, which is 250 degrees Celsius. It is used to join metals, both ferrous and non-ferrous, used in thermally active spheres.

Heat Resistant Cold Welding Mastix

For plumbing - glue is used for work in wet conditions. Most often, this is the repair of plumbing, where high moisture resistance is needed and the ability to withstand work under pressure. Connects metal, porcelain, can be used to restore carvings, and so on.

Cold Welding Mastix for Plumbing Welding

Cold welding Mastix fast steel - contains a steel filler in the composition, which improves the quality of the connection and the restoration of lost elements with steel.

Cold welding fast Mastix steel

Cold Welding Mastix for Aluminum - Contains an aluminum filler that makes the bond to this metal stronger.

Cold Welding Mastix for Aluminum Welding

Properties and characteristics of Mastix

Before using Mastix cold welding, you should study its characteristics:

|

Parameter |

Parameter value |

| Package weight |

55 gram |

| Minimum working temperature |

-60 degrees Celsius |

| Maximum working temperature |

+ 150-250 degrees Celsius |

| Storage temperature |

up to +30 degrees Celsius |

| Drying start time |

from 7 minutes |

Features of use

Instructions for the use of cold welding Mastix assumes overexposure of all the rules. At the initial stage, you need to clean the surface from which the work will be carried out.

After that, you need to cut off the part that you will use from the total mass. Here it should be taken into account that both components are equally. This is followed by kneading and application to the surface. Next, you need to wait from 20 minutes to an hour for everything to grab securely.

Overview of foreign manufacturers

There is a large selection of completely different glue welds on the market, and not all of them are of good quality.In this regard, we have compiled a list of products from both foreign and domestic manufacturers. Selected the most practical options that customers love. Let's start with foreign ones.

Poxipol

Price ~ 400 rubles.

Excellent two-component product, time-tested. Available in two colors: transparent and regular. The price of this product varies by volume, small packages cost from 380 rubles, and large ones from 800.

Poxipol is intended for bonding metal, concrete, faience, wood, marble, plastic, glass, reinforced concrete, fiber cement, ceramics, granite and porcelain. After complete cooling, welding can be drilled, sanded and even threaded. By the way, it cools down very quickly, initial drying occurs after 10 minutes from the beginning of work. The seams are durable.

This glue is two-component, you need to mix it yourself. Manufacturers have taken care of the convenience of their customers by including self-cleaning mixing trays in the packaging. If there is any product left on the tray, it can be easily peeled off.

DONE DEAL

Price ~ 400 rubles.

DONE DEAL is a two-component adhesive designed for car repairs. Its heat resistance has an amplitude from -55 ° C to + 150 ° C, which allows it to weld heated parts. This adhesive also allows welding on cast iron, aluminum alloys and non-ferrous metals. The seams are very strong and durable. You need to work with this weld quickly because it dries up within the first five minutes.

Abro

Price ~ from 200 rubles.

Abro is a representative of dry cold welding. Bonds a range of materials such as metal, wood, glass, plastic, ceramics. Due to its ability to maintain its properties at a temperature of 260 ℃, it is suitable for repairing: gas tanks, radiators, mufflers, battery housings, oil pan, cylinder heads, body and body parts.

Abro has a peculiarity, when it hardens, it increases its volume, the effect of a cork is obtained. Due to this ability, this glue is suitable for the repair of barrels and plumbing. It can also work underwater.

Linocol linoleum adhesive

Price ~ 300 rubles.

Linocol welding is suitable for filling gaps in PVC floor and wall coverings. Allows you to bond materials at a distance of less than 1 mm to 4 mm. Usually sold in a volume of 50 ml, this is enough for 15-20 meters. Within one minute, it sets, and after 6 hours the seam will be completely ready. This welding is immediately ready for use, it is presented in the form of a homogeneous mass.

The kit does not include a metal nozzle in the form of a needle, therefore, to work with a narrow joint line, you must purchase it yourself.

Weicon

Price ~ 650 rubles.

An incredibly strong and durable adhesive. Produced in the form of a stick of welding paste. Its technical characteristics are good news. Works at temperatures from -50 ℃ to 300 ℃. The finished joint is resistant to esters, salt water, various oils, most acids and alkalis. It hardens and adheres to the material very quickly, initial drying takes place within 5 minutes.

It is not universal; a special stick is made for each material. The range includes cold welding for steel, copper, stainless steel, aluminum, plastic, concrete and for sealing leaks.

Werner muller

Price ~ 725 rubles.

The German company Werner Muller produces adhesives for the repair of PVC floor coverings. There are three types of welding to choose from (type A, type C, type T), depending on the width of the space between pieces of material and coating, how to choose a welding mixture is described above.

The tube of this product holds 44 grams of adhesive. Cold welding from Werner Muller evens out the edge heights, ensures optimal seam insertion and prevents strong absorption of the product, but do not forget to apply tape before welding.

Cold welding applications for metal

For the effectiveness of the product, it is not enough just to apply it to the surface. Follow certain rules. Details are shown below.

How to work with this glue:

- Prepare the surface for work. Take an emery plaster and remove layers of dirt and rust. The larger and deeper the scratches, the better. There is a high probability that the connection will come out reliable.

- Dry thoroughly. Use regular glue. A dry surface is needed.

- Degrease. Use acetone. It will eliminate even minor grease stains.

- Prepare the adhesive. Take a knife and cut it across the cylinder. Be careful to keep the original proportions in the resulting piece. Knead the piece thoroughly so that it becomes soft and uniform in color. Moisten the product with water and then the mass will not remain on your hands.

- Apply the compound quickly to the work surface as it hardens quickly. Therefore, you need to do everything clearly and quickly the first time. If you need to glue the hole with this mass, try to let some of the mass go inside.

- Leave the repair surface overnight to dry. And only after the deadline has passed, you can perform the following actions - cleaning, putty, painting.

Application:

- With a high likelihood of high internal stresses;

- Products are large in size;

- There is a risk of hesitation.

To make cold welding, you need to have certain equipment with which a high-strength monolithic connection is made. This method can be used to connect any metals to each other. The particular advantage of working with this method is in joining materials that cannot be heated. Almost any metal can be welded, even low plastic ones.

Separately about specific cases

In some situations, when using liquid welding, additional steps are required.

PVC pipes

Damage to plastic elements of a water supply system or heating system is a common situation. To quickly eliminate the leak, a cold welding method is used.

The repair is performed as follows:

- Prepare the surface for processing. Remove particles of moisture, dust and dirt.

- Calculate the value of the deflection of the face. For a pipe with a diameter of 4 cm, this parameter should not exceed 2 mm.

- The defect is covered with dry composition. Apply a fixing tourniquet to the connection. If all actions are performed correctly, the leak will disappear.

This measure is temporary, it only postpones the procedure for replacing the damaged element with a new pipe.

Surface preparation for welding.

Surface preparation for welding.

Floor linoleum

To glue canvases of this material, perform the following steps:

- Lay the elements on the floor with an overlap. Using a metal ruler and a construction knife, both canvases are cut. If the overlap is 10 cm wide, the cut line should have been 5 cm away from the edge.

- Remove scraps of canvases. You should get an even joint.

- Bend back the canvases. If the material is not fixed, the joint is glued with double-sided tape. It is recommended that you work with a partner during these stages. First, the adhesive tape is glued to the floor, freed from the protective film. Linoleum is laid on top. The joint is rolled with a roller.

- Wipe and dry the areas of linoleum adjacent to the joint. Glue the joint with masking tape. It is also rolled over with a roller. If the preparatory steps are carried out correctly, liquid welding does not fall on the surface of the floor covering.

- Cut the masking tape along the joint line. This will allow you to accurately apply the liquid weld to the joint.

- Shake the bottle with the welding agent, clean the tip of contamination.

- Distribute the glue. For this, the tip is inserted into the gap between the canvases, pressed with a finger. The other hand squeezes the tube. Slowly lead the tube along the joint. The compound should not come into contact with unprotected areas of the floor covering. If this happens, wait until the product dries, and then clean it off with a knife.

- After 15-20 minutes, remove the masking tape. It is recommended to do this at an acute angle. After completing all the actions, a thin invisible seam is formed.

When using thick type C formulations, masking tape can be dispensed with.

conclusions

Before use, the surface must be prepared: clean and sand. When there is paintwork - it must be removed, when there is rust - treat it. After that, it is necessary to degrease the surface, perhaps, for example, use a solvent.

The welding kit itself involves 2 rods of a plasticine-like substance, which should be mixed directly before use. If you do not mix the composition in time, then after thirty minutes it will begin to turn to stone.

Mix the composition with your hands, kneading it like plasticine.

You can apply ready-made cold welding with your hands.

However, for convenience and the most careful look, spatulas can be used, soaked in water in advance.

The repaired part must be immobilized for approximately thirty minutes.

The final hardening occurs in a day. After that, the surface can be processed like ordinary metal.

Summing up, it should be noted that cold welding is a unique method of joining metals of different composition and strength. Its use implies compliance with some specific conditions, but this does not prevent users from using it everywhere, while responding positively to its characteristics.

- What gasoline should you use for your chainsaw? How to breed?

- Inverter welding machines. Model rating, how to choose