Types of anchors

Anchor fasteners for hollow bricks differ not only in their dimensions, but also in technical and structural characteristics. Based on this, there are also areas of application of the anchor, which are aimed at solving certain installation problems. In this regard, anchor bolts are divided into several types.

Driven type

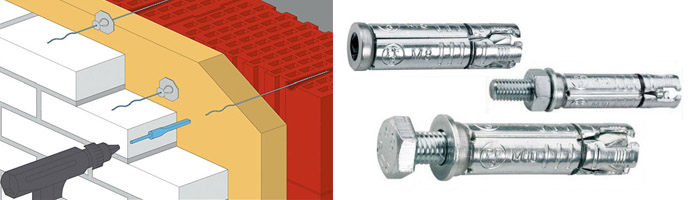

This is the simplest type of anchoring system. They are used mainly to perform fasteners on structures erected from solid bricks. Its principle of operation is that an anchor is installed in a previously prepared hole in the wall, after which a special spacer element is activated in it, thanks to which reliable fixation of all fasteners is ensured. At the end of the installation of the main part, a threaded element is screwed into the bolt.

Wedge type

This design of the anchor bolt has a special element that wedges during installation. Actually because of this feature, this fastener got its name. The wedge element, falling into the brickwork, expands and reliably fixes the fastening system to the building structure.

MSA type products

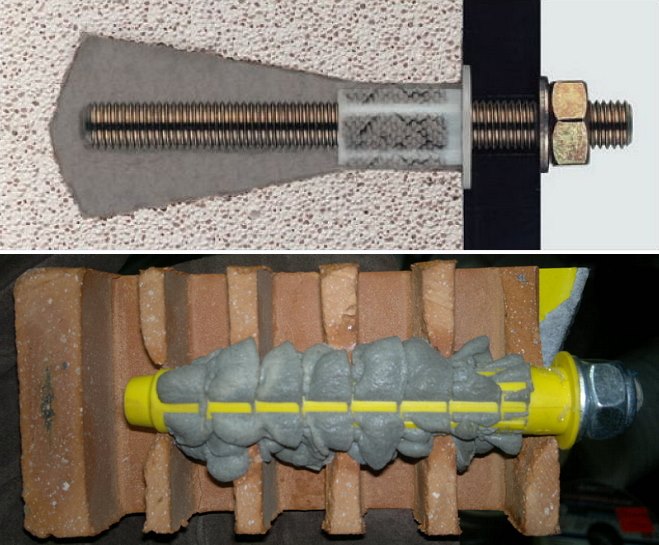

Their main feature is the presence of a brass sleeve in their design. On its lateral part, longitudinal cuts are made, due to which the sleeve is divided into peculiar petals, which expand during installation. And in order for the expansion of the expansion sleeve to be as large as possible, the inner hole in it has a tapered shape.

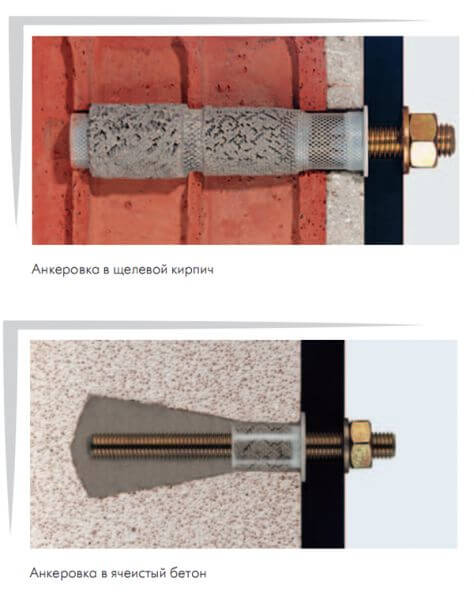

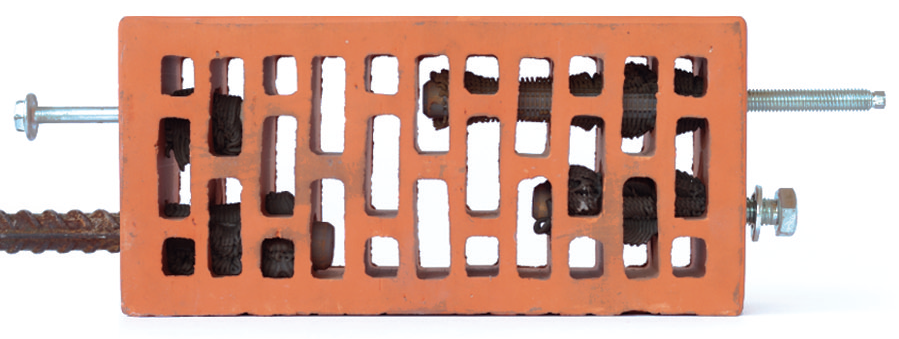

Chemical type

An anchor bolt into a brick wall, working according to the chemical principle, is fixed in a previously prepared hole using a special glue. This type is most suitable for use on hollow brick walls and other porous building materials. This is due to the fact that the adhesive, which is used with this type of anchor fasteners, fills all internal cavities, thereby reliably fixing the bolt.

Ring anchor

In this case, the ring replaces the standard hex head of the bolt and is designed for more convenient and easy mounting of various objects.

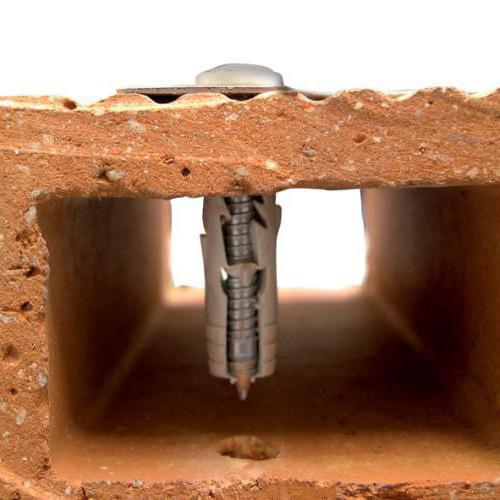

Double-expansion anchoring products

Their peculiarity lies in the presence of a spacer sleeve in the design, which expands during installation in several places simultaneously. Therefore, it is widely used when installing various products on hollow brick structures, since at least one of the spacers falls on the solid part, while the rest are in the empty one.

What are brickwork anchor bolts?

The brick anchor is a universal fastener that is equally successfully used both in the field of capital construction and in performing simple repairs and improvement of buildings and premises for various purposes. With the help of such a fastener, which is a bolt of a special design, objects and elements that differ even in significant weight can be reliably fixed on the surface of a brick wall. Such anchor bolts, in particular, can be used to fix furniture and interior items, lamps and chandeliers, suspended ceilings, hinged facades and much more.

The design features of a bolt of this type and the principle by which it operates are laid down in its name: anchor in translation from German means "anchor".An element that ensures reliable adhesion of such a fastener to the inner walls of a hole pre-drilled in the brick is a special sleeve. Placed in a hole in the wall, when the head of the anchor bolt is tightened, it begins to increase in diameter, expanding the inner walls of the hole and entering into reliable engagement with them.

To make the grip of the anchor bolt sleeve with the walls of the hole in the brick even more reliable, a special notch is applied to the lateral parts of its outer surface.

Installation rules for anchor systems

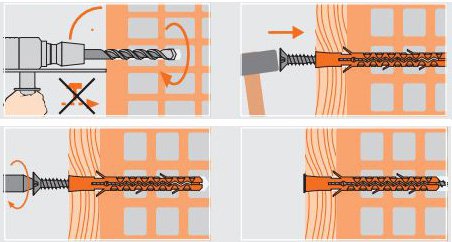

Make an anchor hole with a hammer drill in drilling mode

Make an anchor hole with a hammer drill in drilling mode

With the advent of household rock drills, the installation of fastening systems in the walls of buildings has become much easier. The older generation remembers how much pain it cost to install anchors.

A special metal tube (bolt) slowly punched a hole in the brickwork under the blows of the hammer. Now such an operation takes minutes.

To correctly and safely install anchors in a brick wall, you must adhere to the following rules:

- As far as possible, the hammer drill is used in the drilling mode. Brick is a rather fragile material and can crack and collapse under shock load. The resulting hole will not serve its purpose.

- The temptation to make it easier for yourself, holes are drilled in the cement joints of the masonry. However, this position of the anchors can lead to dire consequences. Under heavy load, the cement crumbles, and hanging objects can simply collapse to the floor.

- When drilling, you need to strictly control the horizontal position of the drill. At the slightest downward tilt of the cavity, there is a risk of the anchor falling out under the influence of the increased pull-out load.

- When driving with a hammer, a gasket (wooden board) is placed under the anchor. This saves the thread of the stud from damage.

- Before installing the anchoring system, it is necessary to check the cleanliness of the surfaces of the sleeve and the rod. For more information on working with an anchor bolt, see this video:

By following these fairly simple rules, you will always be sure of the strength and reliability of the attachment of hanging furniture and other items.

How to drill a hole in a brick wall

How to attach a sink to a wall

Installation of timber walls

Brick wall anchor

In modern construction, hollow ceramic stone is often used for the construction of load-bearing walls and partitions. During the arrangement of the premises, the question arises for the owners of the house: how can you securely fix heavy objects on the walls (hanging cabinets, air conditioning, etc.)? Today's article will help solve this problem.

In modern construction, hollow ceramic stone is often used for the construction of load-bearing walls and partitions. During the arrangement of the premises, the question arises for the owners of the house: how can you securely fix heavy objects on the walls (hanging cabinets, air conditioning, etc.)? Today's article will help solve this problem.

Some kind of brick, due to its unusual structure and a large number of cavities, is considered fragile by many craftsmen, but this is not so. Hollow bricks have the same strength as other types. You can make holes in it without fear

But, for greater fixation of the mounts, it is still better to pay attention to new and modern technologies.

Conventional mounts are already receding into the background. The chemical anchor is gaining more and more popularity, which is an alternative to all old methods and fastenings. It endures very heavy loads. And fixing it takes as much time as conventional fasteners require. The anchor is specially designed for the implementation of reliable fasteners in various types of ceramic stone, including hollow. In the case of such a brick, modern fasteners are used in conjunction with nipples, which have special holes that provide a strong fixation of the fasteners.

Types of anchors for working with masonry

Today there are many types of these fasteners. They have different purposes, therefore, the design of different anchors is different. For example, there are so-called frame anchors, which are only used to fasten windows and door strips to the wall.There are foundation anchors. With their help, for example, metal columns are installed.

Different sizes of anchors are also designed for different tasks.

Chemical anchor for hollow bricks and ordinary.

In the future, the strength of the structure that we create will depend on the correct choice of the fastening system.

Consider the anchor systems used for brickwork.

The drop-in anchor consists of a spacer part (sleeve), a bolt and a nut. The spacer part is hammered into the prepared hole. The bolt is screwed into the spacer part together with the nut, then the nut is removed. Such a mounting fastener is used for subsequent screwing with a hinge nut or corner nut. Shelves, cornices, etc. can be hung on them.

There are such types of drop-in anchors as bolt-hook, bolt-angle, bolt-ring. Their purpose is different than that of conventional bolted anchors. For example, a bolt angle is usually used to hang heavy kitchen cupboards or bathroom water heaters. The ring can be hung, for example, wickets or gates in a brick fence.

Diagram of screwing a dowel into a brick wall.

Wedge fasteners are used more often for through fastenings. The wedge holds the attached element firmly against the wall surface.

The so-called MSA. This hardware is made of brass. Like all anchoring systems, it has a notch on the outer surface of the sleeve for better adhesion to the inner surface of the hole in the wall material. The maximum inner section of the sleeve is 8 mm. It is intended for fixing not very heavy products and materials on a brick wall.

Double expansion anchor consists of a stud with two spacers and sleeves with cuts in the middle and at the end. Thanks to the two spacers, the mount is more durable. It is used when mounting on a wall of hollow bricks when greater resistance to pull-out is needed.

They also make double-spaced fasteners with a nut and a pressed-in washer. This type is used for fastening metal. Such systems are made of galvanized steel.

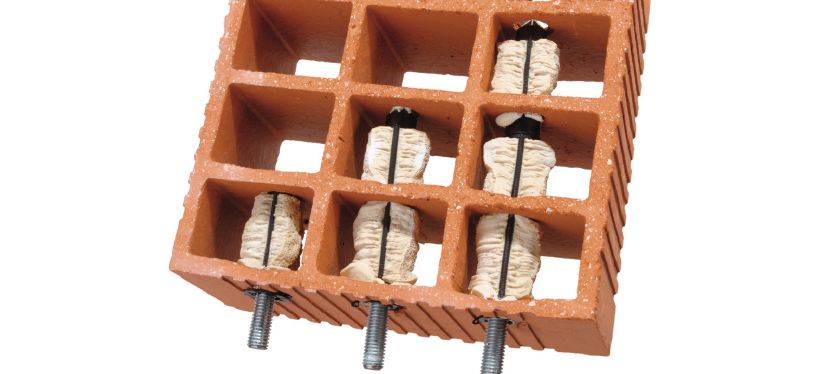

Not so long ago, a new type of anchor systems appeared - adhesive, or chemical. After all, fixing something to a wall made of hollow bricks is very problematic. For this purpose, this type of fastener is used. Instead of a sleeve, an ampoule with a special polyester glue is used in it, into which a hairpin is screwed. After a short time, the glue hardens and the secure attachment is ready.

Application features

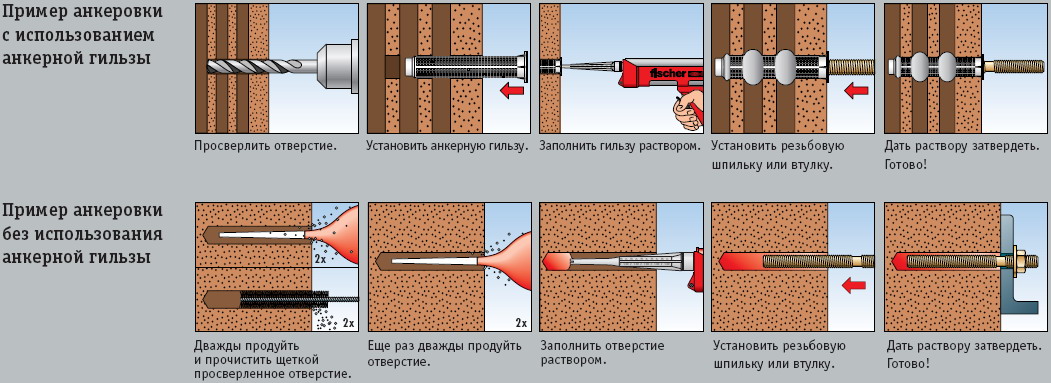

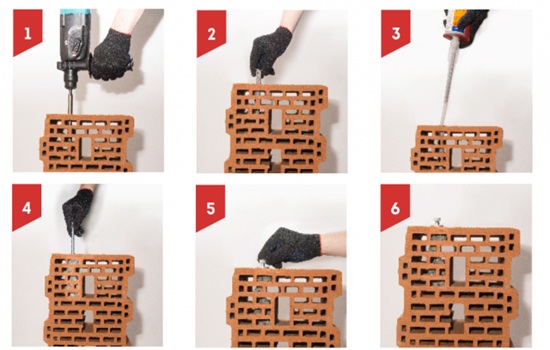

The installation process is carried out in several stages. The main ones are:

- Hole preparation.

- Composition room.

- Installation of the anchor into the uncured polymer mass.

- Tightening the nut.

Each of these stages is associated with its own characteristics.

To install you will need:

- chemical anchor;

- injection gun;

- threaded stud or fittings;

- hammer drill or drill;

- Boer;

- torque wrench;

- metal brush;

- manual or industrial vacuum cleaner;

- Remedies.

With the tools in hand, you can start installing the chemical anchor.

Cooking the hole

When working with brickwork, it is important to avoid splits and cracks in the brick. This requires refraining from using the hammer function on the equipment and drilling perpendicular to the plane.

To successfully install a hollow brick chemical anchor, a hole 2 millimeters larger than the diameter of the stud is required. It is necessary to mark in advance on the drill corresponding to the length of the anchor, or use the depth gauge.

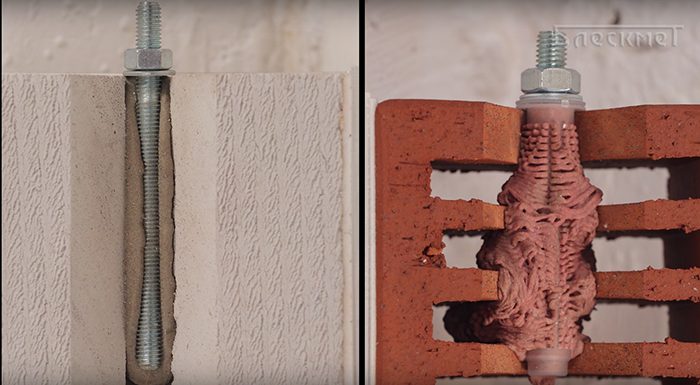

To improve adhesion, it is required to thoroughly clean the hole from dust and crumbs. This is done using a metal brush and a hand pump, with which the hole is blown several times until there are no visible dust residues.

Introducing the composition

The polymer mass is introduced into the hole using an injection gun.If the mixture has a uniform gray color, then it can be applied. It often happens that initially it is not possible to achieve good mixing - such a mixture should not be used. To use the gun, you need to place the nozzle in the drilled cavity and fill it with the compound. After each dose of glue is placed in the hole, it is required to remove the instrument slightly until more than 65% of the cavity volume is filled.

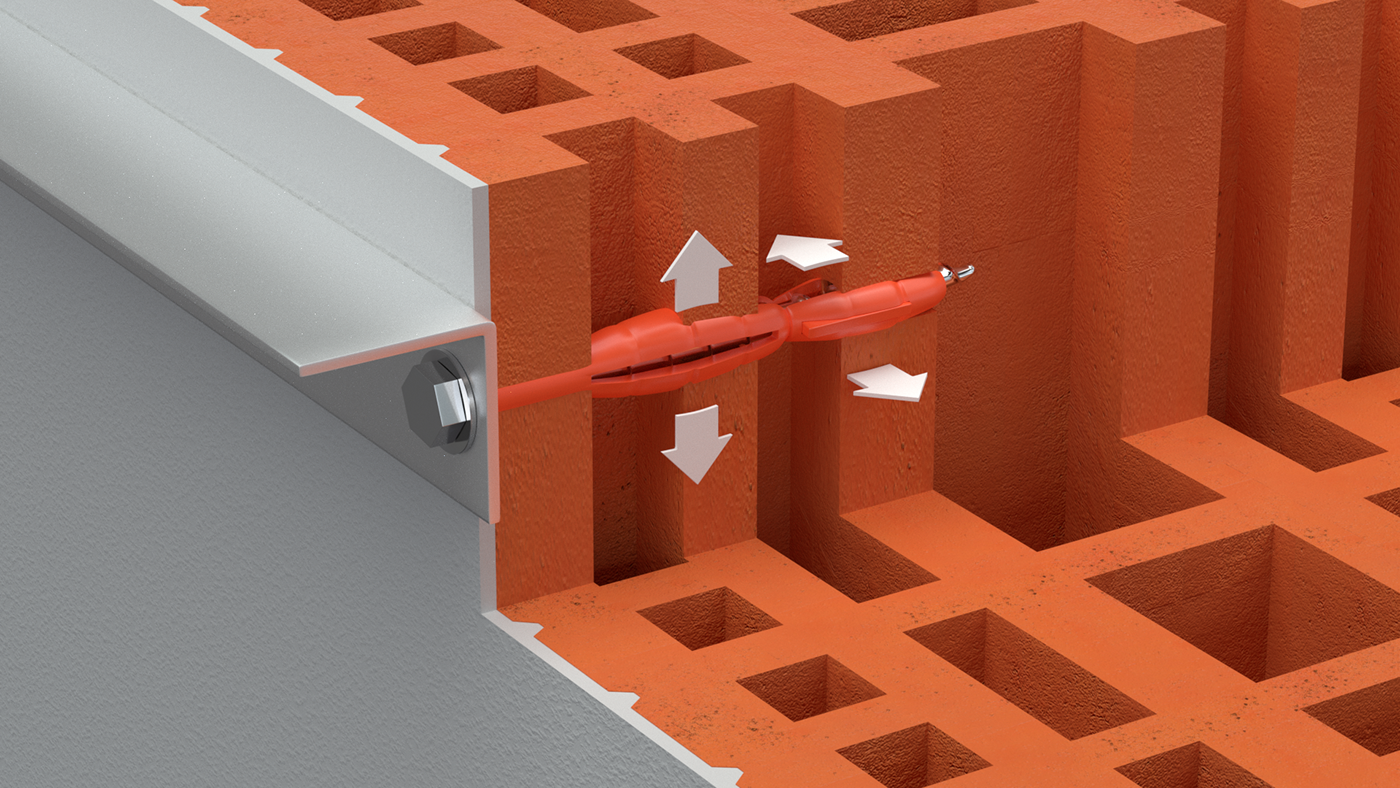

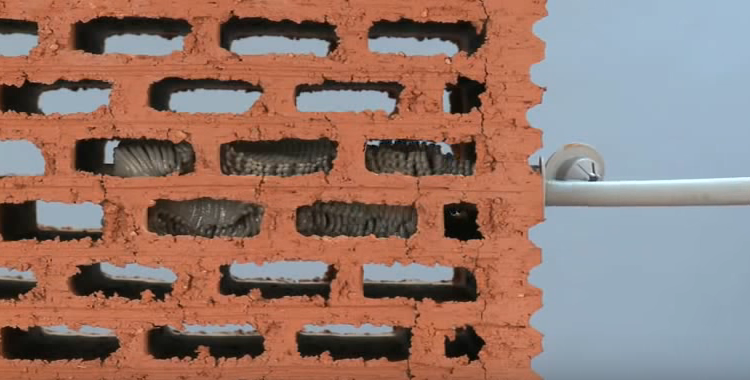

The procedure for placing a chemical dowel in a hollow brick is characterized by a number of features. They are related to the fact that the presence of a large number of voids does not allow the formation of a natural hole. To achieve the goal, a special plastic sleeve is inserted, which is filled with glue. When the pin is immersed in a hollow brick, part of the chemical composition comes out through the mesh walls of the sleeve into the cavity. This promotes more grip.

There are also special ampoules. They are placed in the hole, the composition is mixed with a hairpin. The second option is more suitable for piece work, when there is no need to buy cartridges with a chemical composition.

Installing a metal anchor

We place the metal structure in the hole using rotational movements

It is important to distribute the solution evenly. To do this, it is recommended to periodically pull the fasteners towards you and only then tighten it

While the glue dries, you can correct the position of the anchor.

Tighten the nut

After waiting for the complete solidification of the polymer mass, you can proceed to the installation of equipment and structures. The manufacturer's instructions indicate the maximum force applied to tighten the nut. It is recommended to use a torque wrench in order to control the applied forces.

Chemical anchors are suitable for fasteners made of steel. Due to its positive properties, the anchor can be installed in high humidity or even under water. When used correctly, it is possible to avoid the destruction of the brick, which allows installation at the very edge of the surface.

Chemical anchor is a new direction in construction, thanks to which complex work is simplified. The offer market is becoming more extensive, there are more anchors with various new fastener characteristics.

Features of lightweight brick walls

The walls are hollow for two reasons:

- The first: when slotted bricks are used for masonry.

- The second: when the walls of the building are lightened due to the device inside the masonry of cavity-wells, then filled with heat-insulating material. When performing well masonry, both hollow brick and solid brick can be used, so a variety of anchors may be needed in the work.

Well cavities in brick walls

Well-type masonry consists of two parallel walls connected by transverse diaphragms - which we see in the above photo. It is they who perform the role of anchors in this case. Thanks to them, vertical wells are formed, which are filled with either foam insulation or bulk to improve the thermal properties of the enclosing structure.

Alternatively, concrete-anchor laying can be performed. What is it?

In principle, this is a kind of well masonry, only here cellular or ash concrete is used as insulation. Since it solidifies, forms a solid monolith, the means for achieving maximum rigidity of the structure here is an anchor brick.

Anchoring of lightweight masonry with poke bricks

Under this intriguing name, the most ordinary bricks are hidden, which are laid in a spoon row with pokes. This is done so that the protruding faces form teeth in the inner cavity of the wall.

In the process of hardening of the concrete poured into the wells, the anchor bricks will be firmly fixed in it.In the above picture, and without words, it is perfectly visible how in this case the anchoring of the brickwork is carried out.

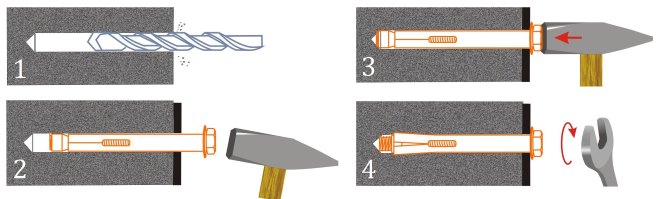

How to properly install the anchor in masonry

Anchoring products used for fastening various objects to brick structures are designed in such a way that their installation does not cause any difficulties. It is performed in the following sequence.

- A hole is drilled in the structure on which the fasteners are to be made. Its diameter should correspond to the diameter of the anchor product.

- After thorough cleaning of the hole, an anchor bolt is driven into the brick, inserted or screwed in.

- By tightening the bolt head, it is necessary to achieve maximum expansion of the spacer sleeve, which will be evidenced by the reliable fixation of the fastener in the brickwork.

Anchor installation principle

When choosing a place for drilling a hole, you should pay attention to the fact that it does not fall on the gap between the bricks filled with cement mortar. This hole should only be made in the body of the brick itself.

It is also necessary to pay attention to the state of the material from which the building structure is made, because cracks in it can significantly weaken the formed joint.

Hollow base anchors

The instructions given in the previous chapter were focused on anchoring the walls themselves during their construction and brick cladding. Now we will consider which anchor for masonry can be used in the case when you need to hang a cabinet, lamp, CCTV camera, etc. on the wall.

Types of fasteners

There are no problems with walls made of solid bricks: holes are simply drilled in them, and hammer-in dowel-nails are installed. But for walls built of slotted bricks or porous ceramic blocks, this technology is not suitable. Due to the hollow structure of the base, a regular dowel will not hold - this requires hollow brick anchors.

And this is what manufacturers are offering our attention today:

Product typeUseful information

Wedge type anchor with nut

This anchor bolt is used for bricks - and not only solid, but also hollow. And in general, it is suitable for almost any base, except for plasterboard sheathing. The wedge anchor has the highest degree of reliability, and therefore is used in cases where something very heavy needs to be hung on the wall. It is also suitable for through fastenings.

It is a steel rod with a diameter of 6 to 24 mm, various lengths, with a movable sleeve and a tapered shank. When tightening the nut, the cone opens and the anchor is firmly fixed in the base.

They are made of galvanized steel, the price starts from 3.5 rubles. a piece.

Drop-in anchor with spacer sleeve

This type of anchor is perfect for all types of hollow bases. It consists of a spacer, usually a brass cylinder sleeve, a fastener (bolt), and a fixing nut. First, they are screwed together, and then the nut is removed. Moreover, the bolt in such an anchor can have any shape: a hook, a ring, an angle, which makes it possible to use such anchors in a variety of situations - for example, hang a water heater on the wall.

The cost depends on the size and material of manufacture, and varies from 4 to 50 rubles... a piece.

Two-component chemical anchor

These anchors provide the best wall grip and can be used in a wide variety of situations. Among them, there are also options for monolithic and hollow bases. The chemical anchor is held in the brickwork due to the nylon sleeve, which increases in volume after the introduction of a special two-component composition. A long threaded pin is installed in it, and when the filling polymerizes, an almost monolithic connection is obtained.

The cost of a tube of adhesive composition with a hardener in a separate package is about 1350 rubles. Studs with nuts cost about 45 rubles, and are purchased separately.

What unites anchors for bases with a reduced load-bearing capacity is the presence of sleeves with which they are connected to the wall. The point is that when the sleeve is installed in the drilled hole, it expands and is firmly fixed, and then the anchor itself is inserted into it.

It can be anything - a pin, a screw, a long screw, or a smooth rod. But in everyday life, all these options are simply called: anchor bolts for bricks.

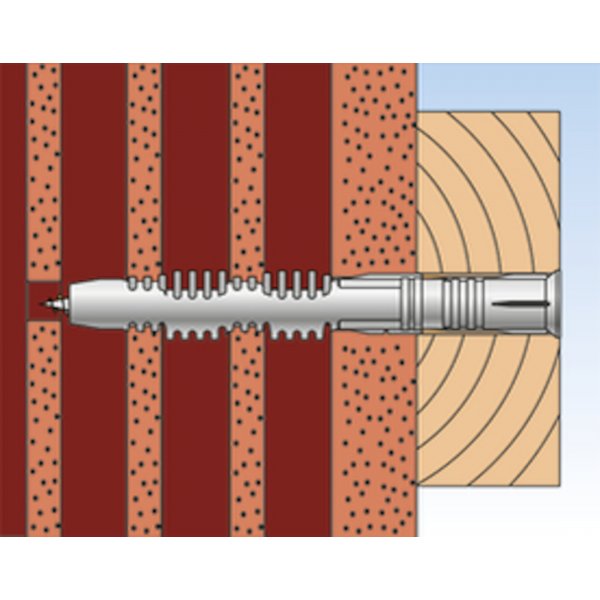

Dowel for aerated concrete - design features

The soft and loose materials from which the walls are built have always been problematic when it comes to attaching various household products to them. As a result, not a single manufacturer of fastening structures gave a guarantee that their anchor or self-tapping screw would adhere well to such a surface. In practice, this was very often confirmed, the soft base simply crumbled, and the fasteners lost their holding properties.

But a way out was found, namely dowel for aerated concrete and solved the problems of mounting in soft materials. The immediate solution to this issue was the specific design of such fasteners. Outwardly, this is a sleeve on which there are ribs made in the form of a spiral; when installing a self-tapping screw, it expands the sleeve, which, with spiral ribs, as it were, cuts into the soft surface of aerated concrete. As a result, we get a strong mount that holds a certain load.

Fasteners of this category are available in two versions, plastic and metal. As for the metal version, its design can also be of two types. The first design sample has the same wide spirals on its basis as the plastic one, and the method of its fastening is completely identical to its plastic counterpart.

The second type of such a dowel has a completely different design. It is designed as a bushing with teeth along the entire length, also the main feature is the tapered shape, increasing from the bottom edge to the bottom. On the working surface with teeth, the metal has technical slots, which expand at the moment of tightening a bolt or self-tapping screw, and the teeth also firmly dig into the soft material.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to mount equipment and fix massive objects and structures on the walls and floors of the building.

It is important to choose the right hardware for work

Fasteners for solid bricks will not provide the necessary adhesion to the hollow material

Therefore, it is important to preliminarily determine the basic raw material from which the enclosing structure was erected.

Sequence of work:

- The plane is being marked. The work is done very carefully. Hollow ceramic bricks are fragile. If you make two holes with a small gap between each other, the material is likely to deform.

- The hole in the brick is made with a specialized drill. The section of the anchor element and the depth of its insertion are taken into account. The perpendicularity of the hole produced is a guarantee of quality work.

- After creating the hole, it is cleaned of dust and debris. The depth accuracy is checked.

- In the process of inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product dangles, it is better to take the hardware larger. It should be selected according to the diameter of the resulting hole.

Miscellaneous stand-alone equipment

Fisher has many significant advantages that you should pay attention to. First, it works well with almost any building material.

First, it works well with almost any building material.

Secondly, the fastening system itself is quite simple and versatile for any construction project.

Thirdly, thanks to non-expansion anchoring, it is possible to reduce the dimensions of the edge and axial distances.

Fourthly, such fasteners are quite different and are used for all kinds of devices.

How much load can the Fischer anchor withstand? There are some requirements. As for the brickwork, you don't have to worry here, since such fasteners provide for any loads that can be placed on a hollow brick structure.

The same applies to aerated concrete structures. If we talk about working with compressed concrete, then here it all depends on which threaded rods you will use.

Since the Fischer fixture is a chemical fixture, it is divided into two separate chambers. The first chamber contains the chemical solution itself.

The other contains a hardener. They must be mixed before use and then squeezed out.

Brick anchor

Each major type of fastener has many small subspecies. However, this should not confuse you. The fact is that in any case, the principle of their application is very similar, and the differences are only small.

You can find out about the features of each subspecies of fasteners you are interested in from the consultants of the store in which you will purchase them.

Choosing the type of fastener to use it in your home, first of all, you need to decide exactly what you want to attach to the wall. Analyze which types of fasteners may be suitable for use with your materials, and then choose the most convenient one. an acceptable and cost-effective fastener option for you.

Have you noticed a mistake? Select it and press Ctrl + Enter. to let us know.

Installation tips

In the modern construction industry, a large number of types of anchors are used for both hollow and porous materials. With rational selection, each of them will serve for more than a dozen years. It is enough just to follow some simple installation rules, namely:

In the modern construction industry, a large number of types of anchors are used for both hollow and porous materials. With rational selection, each of them will serve for more than a dozen years. It is enough just to follow some simple installation rules, namely:

- For hollow brick structures, it is strongly not recommended to use a hammer drill. Such an "aggressive" tool can easily damage the wall.

- Do not install anchors in masonry joints. These places are much "weaker" than bricks, so a mount installed in such a fragile place can lose its holding capacity over time.

- The hole in the vertical wall must be perfectly horizontal. Even a slight vertical deflection up or down will reduce the reliability of the fastening.

- When installing drop-in anchors, it is not necessary to knock with a hammer directly on the metal: this can lead to damage to the fastening. Better to put a wooden block.

- Before screwing in the bolt, the bore of the sleeve must be cleaned to avoid damaging the threads.

Compliance with the installation technology will ensure the reliability and long service life of the fastener.

Things to remember when installing anchor systems

Everything that used to be fastened to the walls with nails, screws, screws and bolts, today they are mounted using anchor systems. Anchors for brick walls are the most reliable way to hang, connect any elements or objects with brickwork. But in order for the fasteners to be durable, one must not forget about a number of rules.

You cannot use a puncher to make holes in the brick, since this material is quite fragile. Under the influence of impacts from a hammer drill, it can crumble and crack. In this case, you will need to make a new hole.

Anchor holes must not be drilled into brickwork seams. Cement mortar, due to the presence of sand in it, has a lower strength than brick.The mount, especially if the load on it is large, can fall out over time, and the consequences can be unpredictable.

The holes in the wall must be perfectly horizontal. Even a slight downward slope reduces the pull-out resistance of the fastener.

When installing a driven structure, do not hit the metal with a hammer, it is better to put a piece of wood so as not to damage the thread edge.

Before screwing in the bolt, clean the inner surface of the sleeve so as not to damage the threads.

Observing these rules, you can firmly and reliably mount a visor above the entrance, a sports wall for your son, shelves for flowers and books, or any other items needed in a house or apartment.

Types of anchors for hollow bricks

-

- Wedge (hairpin). This model is most often used for through fastening of heavy elements, such as sports equipment, advertising and information boards, lighting devices, etc. in the wall. They are made, as a rule, of high quality galvanized steel, since the fastening is subjected to heavy loads. Sometimes there are products made of stainless steel and non-ferrous metals, but the former are distinguished by a high price, and the latter are designed for light loads.

- Hammer. It consists of a brass spacer sleeve-cylinder, a fastening element - a bolt of any shape (ring, hook) - and a fixing nut. All parts are screwed together, and then the nut is removed. This is the most common, demanded and easy-to-install type of anchorage.

- Folding spring with a hairpin. Used in materials with sufficient voids. A folded spring anchor is inserted into the drilled hole, which opens in the void, being securely held there by its petals. For final fixing, just tighten the nut with a wrench. Such anchors are characterized by the fact that they do not require an exact drilling depth and preliminary hole cleaning.

- Double bursting. This model includes a double-spreader pin and a sleeve, notched in the middle and at the end. Such a structure allows you to reliably fix the necessary things on hollow walls and at the same time reduce the risk of pulling out several times.

-

Chemical, or glue. The chemical anchor for hollow bricks is relatively new. According to the builders, the hollow core material "gets along" best with anchors of this type.

The entire threaded metal stud is secured with a nylon sleeve and a special chemical composition. The composition hardens, after which the bearing capacity of the finished joint will be an order of magnitude higher than the traditional mechanical one. Chemical anchors are widely used in the installation of canopies, railings, balconies, bridges. This type of fastening is resistant to water, alkali and other adverse factors. Its service life reaches 50 years.

Conclusion

Hollow brick is a building material that helps trap heat in a room. It is inexpensive and effective to build from it, especially since there are so many different fasteners for it.

Fashion for Naked: the best images of the stars. We select a Naked cosmetic bag for your make-up It's nice when fashion pushes us not only to experiment, but also to accept ourselves and our beauty. Fashionable positive attitude to your own body.

Toxicosis: causes, consequences, treatment The assumption that nausea worries a woman only in the morning is incorrect. It can last all day, but is most pronounced in the morning. It comes from.

What does the shape of your nose say about your personality? Many experts believe that looking at the nose can tell a lot about a person's personality.

Therefore, when you first meet, pay attention to the nose of the unfamiliar

15 Cancer Symptoms Women Mostly Ignore Many of the signs of cancer are similar to those of other diseases or conditions and are often ignored.

Pay attention to your body. If you notice

Why are some babies born with the "kiss of an angel"? Angels, as we all know, are kind to people and their health. If your child has the so-called kiss of an angel, then you have nothing to do.

13 Signs You Have The Best Husband Husbands are truly great people. What a pity that good spouses don't grow on trees. If your significant other does these 13 things, then you can.