What it is?

Adhesive anchor, liquid dowel, injection mass - all these definitions of a chemical anchor are used in the simple language of workers. A fastener consisting of a conventional or externally threaded reinforcing bar, a sleeve with a helical surface on the inside and a special adhesive (made of synthetic resin) is called a chemical anchor.

For the first time, this type of fastening system was used in the mining industry - with its help, it was possible to mount various fasteners to loose foundations. Later, anchors became popular in construction. Chemical materials provide reliable anchoring unlike traditional anchors.

Chemical anchors are a complete and sophisticated system that includes additional drilling tools, mixing guns, precision dispensers, scrapers and brushes for surface cleaning and others. The adhesive composition is selected individually, taking into account the installation conditions and the base material. Most often, a chemical anchor is used for plain or porous concrete, for brick structures, for sandstone or limestone. The mass penetrates into the base, into its pores and cracks, the synthetic components harden - and a reliable monolith is formed, which holds the part.

Liquid dowels are indispensable for very high and pulling loads, they can be used for the construction of balconies, bridges, canopies at the entrances to buildings.

What is a chemical anchor?

Often, builders are faced with the problem of how to install the product in a loose base. Some have heard about new materials and want to know a chemical anchor - what is it? This material, unlike conventional metal bolts, requires the use of a special glue. This mixture is in addition to the main metal part of the fastener (reinforcing bar, steel sleeve, threaded nut) and allows the part to be securely attached to any base.

Complete with a liquid anchor, they often sell a drilling device, a glue mixture dispenser, a brush for cleaning drilled holes. Externally, a chemical anchor looks like a tube with a sealant. Many manufacturers do not disclose the exact composition of the glue, but it is known that synthetic and natural resins, a hardener, quartz sand are necessarily present in it, and cement is a binder.

How does a chemical anchor work?

To mount such a massive object, such as a gate, stair railings, plumbing fixtures, a satellite dish, you need a special fastener called a chemical or liquid anchor. Installation takes place in this order: glue is fed into the drilled hole and a metal bolt is inserted, as a result of a chemical reaction that occurs between the constituent components of the glue solution, the mass gradually polymerizes and hardens.

1 Principle of operation - the advantages of a liquid composition over metal

A chemical anchor is an adhesive liquid mass that reliably fixes metal fasteners and a mounting base to each other. The European organization of technical standards calls it a gluing anchor, and among amateurs and professionals you can hear the concepts of "injection mass", "system of glued in anchors", "liquid anchor", "chemical dowel". However, the most common name among the inhabitants of the CIS countries is “chemical anchor”.

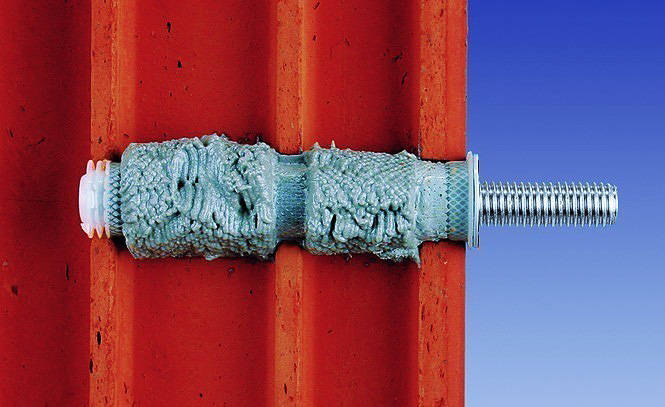

The principle of fastening with it is simple.The prepared hole in the base is filled with a binder liquid composition, after which a metal rod is inserted into it. After some time, the mixture begins to harden, firmly fixing the rod in the base. Thus, a solid monolithic fastening is created, which, depending on the quality of the manufacturer, the correct installation and the type of construction, can withstand significant loads of several tens of tons. The use of a chemical anchor is quite extensive. It is used to anchor fasteners in concrete, brick, stone, metal, timber, and other complex structural structures such as bridges, balconies and canopy buildings.

The strength of fixation with a chemical anchor is much higher than with a spacer. The liquid dowel is capable of withstanding 2.5 times the breaking load. So, what are the main advantages of a chemical anchor:

- increased fastening strength in comparison with a metal anchor several times;

- widespread use of a liquid composition, the possibility of creating a strong attachment in less durable bases (foam and aerated concrete, porous brick);

- resistance to aggressive environments (alkali, water), the use of a fixing compound in wet conditions and even under water;

- does not cause stress on the walls of the hole, unlike spacer fasteners, it is suitable for mounting railings and parapets;

- creates a complete sealing of the seams;

- has a durability, the operation of the mount exceeds 50 years.

2 Clamp in ampoules and tubes - we disassemble the composition and sequence of work

Manufacturers carefully hide the proportions of all components of the chemical anchor. However, so that you have at least a rough idea of the composition of this adhesive mixture, here is a list of components: artificial resins based on polyurethane, acrylic and polyester, quartz sand and binders (cement), hardener. Only one thing is known for sure, that a chemical anchor is a mixture of two components. The first is an adhesive composition, and the second is a hardener. The liquid anchor is produced in two versions - in ampoules and tubes, cartridges of different volumes. Ampoules are designed for single use for a specific hole, and cartridges and tubes can be reused to work with a large number of fasteners.

Chemical anchor in ampoules

Also, chemical anchors are separated depending on the application temperature. There are summer, winter and spring-summer-autumn products. Summer anchor is used at temperatures from 5 to 40 ° C, spring-summer-autumn - from -10 to 40 ° C, and winter is able to solidify at -26-20 ° C. Due to the fact that the shelf life of a chemical anchor is short, it should be selected, focusing on the weather conditions during the period of work.

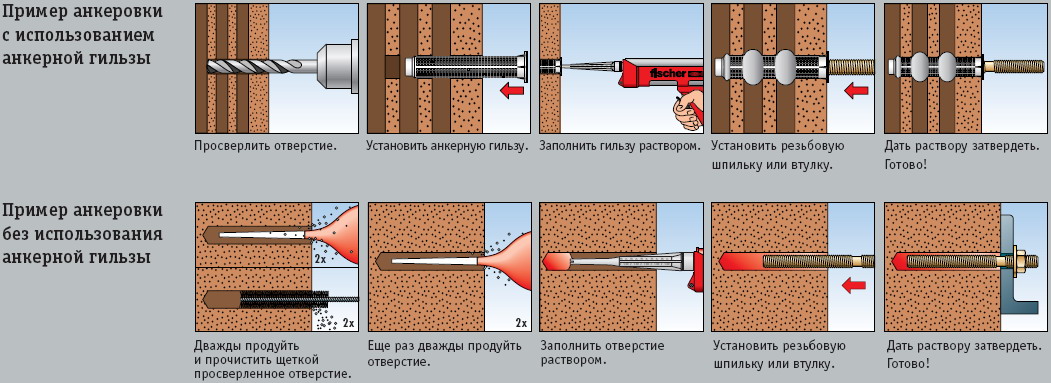

Regardless of the form in which you will use the liquid anchor, you need to make a hole and prepare it carefully. To make a hole in the supporting base, we use a punch. The diameter of the future hole should be 2 mm larger than the thickness of the steel bar. Next, we proceed to cleaning from dust, dirt and moisture in order to create the best adhesion of the surface to the adhesive. In this case, you will be helped by a pump for blowing out holes and a special metal brush, the tip of which is selected for the diameter of the rod. Experts recommend going through these tools twice, alternating them with each other.

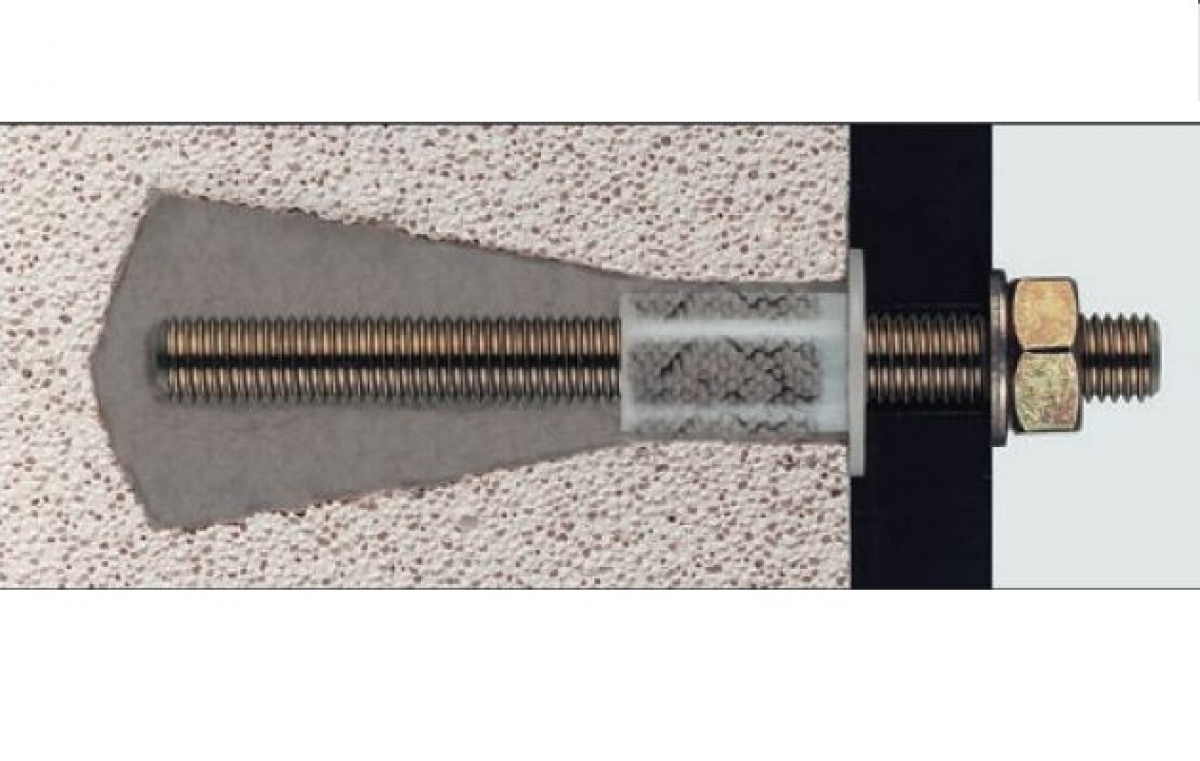

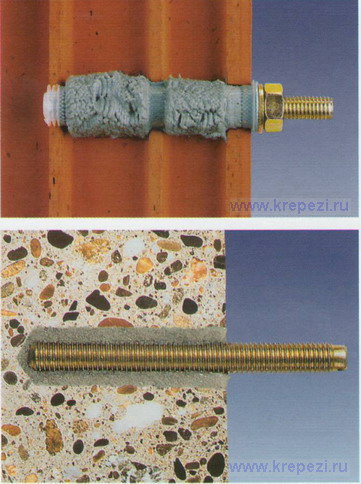

If you fill hollow structures with a chemical anchor, after preparing the hole, you must additionally insert a perforating sleeve into it, which allows you to prevent excessive leakage of the adhesive mass into the voids. Further steps will depend on the type of liquid anchor you are using. Using a chemical anchor in ampoules, insert it into the hole made, and then fix the rod. After some time, the adhesive will harden, creating a strong connection.

Chemical anchor in a tube

To use a liquid fixative in tubes, you will need a special manual dispenser. You can, of course, use a regular construction gun for silicone sealant, but it will be much more difficult to work with it, and more effort will have to be made. In a set with a tube, manufacturers often include replaceable mixers (nozzles) for filling the holes with a liquid mass. With each subsequent use, the previously used mixer must be replaced with a new one. Therefore, if you do not plan to use up liquid anchor in one go, purchase an additional replacement set of mixer attachments.

Make sure the adhesive is well mixed before using the chemistry in the tubes. Squeeze the slurry onto a separate cardboard backing or sheet of paper until the color is uniform - gray. This means that both components are well mixed and you can start working. Now we fill the prepared hole with a liquid dowel and insert a metal rod into it. As long as the mass is not frozen, the direction and depth of the rod can be easily changed. Remove excess composition after hardening.

The polymerization (hardening) of the glue takes from 1 to 5 hours. It all depends on the components that make up the adhesive, as well as the temperature. On average, at 20 ° C, hardening occurs after 20-40 minutes, and when the temperature drops to -5 ° C - after 5-6 hours. If the temperature readings are even lower, polymerization practically does not occur, with the exception of special winter formulations. Among the manufacturers of chemical anchors that already have their target audience and reputation in the market are HILTI, R-KER, SORMAT, KOELNER, TECH-KREP, INKA, KEW, MKT, Tecseal TECFIX. The cost of a tube, depending on the volume and manufacturer, varies in from 1800 to 2,400 rubles, and ampoules - from 200 to 600 rubles.

Main types and areas of use

The liquid fixative is available in single-use ampoules or tubes for up to 500 connections.

The ampoule device is a cylindrical capsule filled with adhesive and inserted into a pre-drilled hole. The hairpin or reinforcement is screwed into the cavity, the shell of the chemical anchor is destroyed.

A two-component mixture of resin and hardener, mixed with the threaded protrusions of the metal part, flows out, fills the hole and pores of the base. During the hardening of the mass, a reliable connection is formed that is able to withstand high tensile and shear forces.

For a liquid anchor in tubes, a construction gun is used, where a cartridge with a mixture and a mixer nozzle is placed. When it rotates, the chemical elements are mixed, the polymerization reaction begins. The hole is filled with glue and metal fasteners are inserted. After the solution has solidified, the compound is loaded.

The cartridge with the remaining solution can be reused. For this, a new mixer attachment is screwed on. The shelf life of chemical anchors for concrete is up to 12 months.

The composition of the mixture for concrete includes additives and deoxidizers to slow down the corrosion of reinforcement. Such glue is usually of a thick consistency, it is used in conjunction with smooth rods or pins.

Threaded anchors require high fluidity, accelerated hardening time. In these cases, the parts are glued in with a semi-liquid solution.

Injection anchors are widely used in construction and repair work, where the base is made of loose materials - slag and foam blocks, hollow bricks, slotted or cellular concrete, and the load on the fasteners is quite high. It:

- outdoor structures - wall lights, fences, metal or reinforced concrete flights of stairs, supports, canopies;

- internal - plumbing equipment, ceiling lamps, storage water heaters, suspended air conditioners.

Liquid anchors are indispensable in the construction of frame buildings, fastening blocks to the support system, heavy ceilings, equipment and scaffolding.

Chemical fasteners allow to withstand dynamic loads of advertising banners, antennas, radio masts, road billboards. Resistance to the action of water is a valuable quality when used in underwater and hydraulic structures - pools, dams, sea or river berths, water parks, collectors.

Old brick walls with many pores and cavities are being restored using liquid chemical mixtures for fasteners.

3 Homemade chemical anchor - is it possible?

Despite its advantages, the use of a chemical anchor has its drawbacks. The first one is short shelf life. After opening the package, the contents must be consumed within 2 weeks, and the total shelf life of the unopened package does not exceed 12 months. The hardening rate is rather slow and largely depends on weather conditions and temperature indicators. To work with a chemical anchor, you will need to additionally purchase a blower pump, a metal brush for cleaning, replaceable nozzles, as well as a special manual dispenser. All this entails material costs. And the liquid fixative itself costs money, and it must be consumed as soon as possible.

An analogue of a chemical anchor at home can be a mixture based on epoxy resin. The characteristic of the substance provides good adhesion (adhesion) to concrete, brick and other building materials, allows the use of the compound for fastening the anchor. To prepare such a mixture you will need: epoxy resin ED-20, hardener UP-583, filler made of cement, gypsum, plasticizers (DBF, DEG-1).

Epoxy resin can be the basis for creating an analogue of a chemical anchor

The cooking instructions are as follows. Add a plasticizer to the epoxy resin. The amount of plasticizer is 5-10% of the amount of epoxy that you use to prepare the composition. To thicken the mixture, we use cement, gypsum, mix everything thoroughly. At the end, add a hardener in a ratio of 1: 8 or 1:10, focusing on the thickness of the mixture, and to give elasticity - plasticizers. After mixing, you will get a liquid adhesive. Like the original, the homemade epoxy resin anchor has advantages and disadvantages. The advantages of using the mixture are the high strength of the substance after hardening, increased wear resistance and long-term operation.

Shrinkage of the composition after polymerization is minimal, and the temperature range at which installation can be carried out varies from -10 to 35 ° C. However, there are also disadvantages. Like a commercial liquid anchor, epoxy adhesive takes a long time to dry. The product hardens in 1–2 hours, and in some cases it can take up to 12 hours or even days. Before using the epoxy retainer, you must carefully prepare the hole, and especially take care of the absence of moisture, dry the mounting surface well. Later some time from such glue, phenol, harmful to health, can be released in small quantities. This must be taken into account if you will use the compound for fastening inside a living or working space.

Design and types

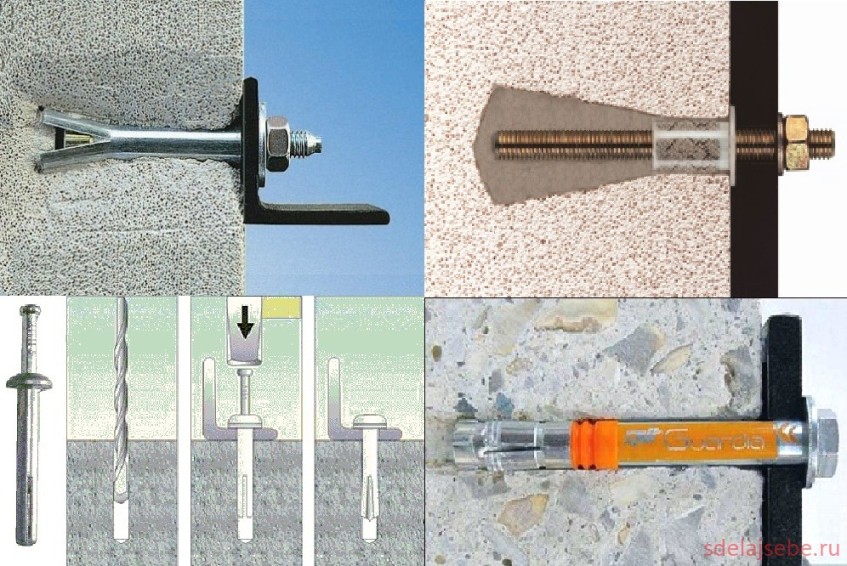

A chemical anchor is a fastening element containing:

- special adhesive composition;

- a metal sleeve with a thread inside;

- male threaded stud or regular reinforcing bar.

The adhesive composition in capsules is intended for the installation of one anchor. To install many products, it is better to purchase tubes or cartridges.

The metal elements of the chemical anchor can be made from galvanized or stainless steels of varying degrees of strength. The material of manufacture depends on the purpose of the fastener.

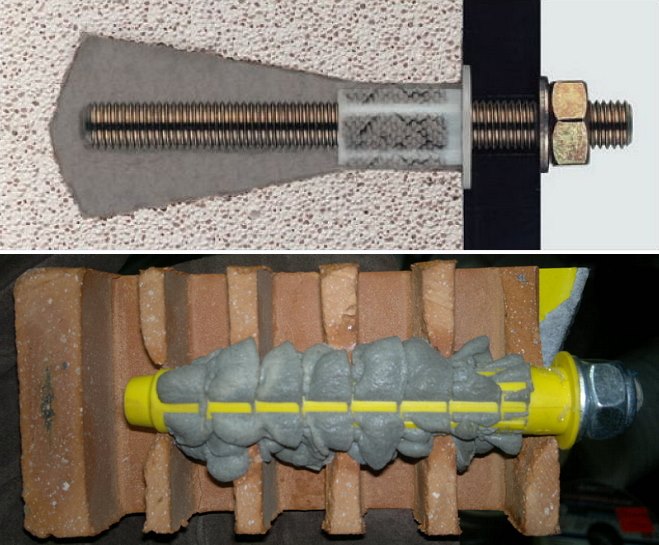

The peculiarity of using a chemical anchor is that an adhesive composition is injected into a hole in concrete, aerated concrete, masonry or any other material, which, after polymerization, ensures the exceptional reliability of the resulting joint.

Advantages of a chemical anchor versus an expansion anchor in hollow building materials (click to enlarge)

The adhesive composition of the chemical anchor fills all free pores, providing rigid anchorage even in “problematic” materials

The composition of the glue is kept secret by the manufacturer, but it is assumed that it includes the following components:

- artificial resin based on polyester, polyurethane and acrylic;

- fillers that provide good strength characteristics of the joint being formed (such fillers are quartz sand and cement);

- hardener, which is responsible for the speed and quality of polymerization of the adhesive.

HILTI chemical anchor complete with mixer and extension

As is clear from the above composition, all the components of such an adhesive are mixed immediately before the installation of the anchor bolt. Modern manufacturers produce an adhesive composition for chemical anchors:

- in special capsules, the diameter and height of which correspond to the dimensions of the hole for the bolt;

- in cartridges and tubes (the internal volume of such containers is divided into two compartments, one of which contains an adhesive composition, and the other contains a hardener).

The approximate consumption of the adhesive can be determined in advance.

When using capsules, as stated in the detailed instructions for such elements, they are the first to be inserted into the hole. The mixing of the components of the adhesive and its further polymerization occurs due to the fact that a metal pin is inserted into the hole, which destroys the capsule shell and the internal partition between its compartments.

The technology of using cartridges and tubes, the inner compartments of which contain glue and hardener, looks a little different. To use such elements, a special pistol is required, with the help of which the components of the mixture are squeezed out, simultaneously mixing, into the cavity of the previously made hole.

How to install an anchor bolt in concrete

The whole process is quite simple, the main thing is to correctly measure and implement everything as accurately as possible. But there are several nuances that need to be considered.

Practical tips for installing anchors in concrete:

- The strength indicator of fasteners is influenced not only by the anchor, but also by the quality of the base material (concrete in this case), proper preparation for installation, taking into account the material of the attached structure and the structure of the bolt itself.

- If a layer of finish is applied to the wall, the hole must be deeper, as the finish is usually less durable than concrete.

- It is advisable to take the drill 0.5 mm thinner than the diameter of the future hole.

- When working with a hammer drill, it is best to use a special carbide tip.

- Carefully read the instructions - the permissible force and the maximum number of revolutions must be indicated on the packaging with anchors.

- When screwing the anchor in, in no case should it be twisted until it stops, as the material may collapse.

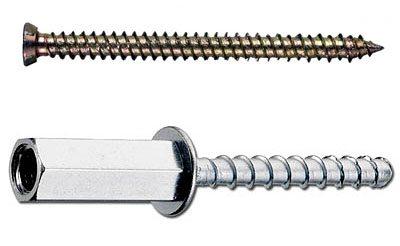

Permanent fixture: concrete dowel

The dowel is a spacer made of polypropylene or nylon, which is similar in function and operation to an anchor. Not used independently, fixed in concrete with special nails or screws... To strengthen the fixation, it is often performed with spikes or tendrils.

This type of fastening is used where there are no too heavy loads on concrete - fastening shelves, hooks for TVs, lighting fixtures. The dowels are hammered into the dowels, the screws are screwed in with a screwdriver or screwdriver. You will also need a regular hammer to drive in nails.

You can also find dowel nails designed for use with a power gun. Fasteners in concrete are made of metal, outwardly it is somewhat reminiscent of a bullet. It is relevant where you need to hang a large number of small items.

Concrete dowel: fast but strong

Nagels are those that are most often used to equip fasteners near the edges of a concrete wall. The fasteners do not require additional fixation, they are screwed into the hole, where a little epoxy glue is poured in advance. It is not necessary to drill holes - the dowel can be screwed directly into the concrete wall. If you still need to make a hole in the concrete, then it is better to choose a drill (a hammer drill can damage the wall).

Screw it in with a screwdriver - and after that it is no longer possible to unscrew the pin back. Therefore, the preliminary marking must be done especially carefully.

Types of chemical-based anchors, installation

All chemical anchors are divided into two main types, depending on the form of delivery of the adhesive: capsule (supplied in tubes and cartridges) and ampoule (one-component and two-component). It is this difference that directly affects the installation, assuming a different technology for installing the anchor.

Installation of ampoule anchors

The adhesive is sealed in a glass cylinder, and in direct contact with air, the viscous mixture hardens. Installation is quite simple: first, mark the place of the fastener and drill a hole, then clean it of construction dust, insert an ampoule with an adhesive into the hole made with the required depth and size, screw a pin or reinforcement into it. At the moment of screwing in, the ampoule cracks and the glue comes out into the hole, hardens and provides a reliable connection (pieces of glass additionally reinforce the fasteners).

If the glue is from one component, then the ampoule is simple, if from two, then two ampoules are used, one of which contains styrene. The setting speed of the substance directly depends on the compliance with the instructions for the air temperature and the type of chemical anchor. Two-component chemical anchors are most often used where maximum strength is required (fastener strength class is 5.8) and in conditions of high humidity, in water.

The disadvantage of this type of fastener is that if the anchor is chosen incorrectly for a large hole, the resin may not completely fill it and the reliability of the connection will be low.

Installation of injection anchors

The cartridge is a small container with a spout through which the glue mixture is squeezed out. The tube is a small reservoir of 400-800 milliliters, which is used in conjunction with a construction gun. In terms of one fastening, the cost of such a chemical anchor is lower than that of an ampoule, a wider choice of filler is presented. The adhesive anchor can be made not only on the basis of synthetic resin, but also polyurethane, acrylate.

Installation is carried out as follows: on the surface of the concrete mark the place of attachment, drill a hole, clean it, squeeze out the glue and insert the dowel. The adhesive hardens and provides a secure, durable attachment, is used for walls made of materials with voids inside.

Often, before squeezing out the glue, a perforated sleeve of plastic or metal is inserted into the material, which does not allow the resin to spread too much over the inner surface of the monolith. There are currently no other methods of fastening in hollow materials. Depending on the depth and size of the hole, one charge of a cartridge or tube is enough to make many fastenings.

Dimensions and characteristics of anchor bolts

Before deciding which anchor is best for concrete in performing specific tasks, it is necessary to consider not only the variety of structures, but also the sizes, because fasteners can be of different lengths and diameters.

Classification of anchors by size:

- Small - section up to 8 mm / length up to 55

- Medium anchors - up to 12/120 mm

- Large - with a maximum diameter of 24 mm and a length of 220 mm

Anchor bolt for concrete sizes can be different: characteristics are determined by three indicators. So, if you decipher the marking M8 10 / 60-115, then it will be: thread diameter of the anchor M8, outer diameter 10 (it is with this diameter that the hole for fasteners is drilled, this is the diameter of the drill), the length of the anchor is 115 millimeters, the approximate thickness of the element, which it is planned to strengthen - 60 millimeters.

All technical characteristics of anchors are indicated in the table, these can be weight, maximum torque and permissible bending moment, minimum pulling out force, optimal loads, distance between axes and to the edge, etc. In accordance with all these parameters, suitable products are selected and high-quality fastening to concrete with anchors is performed.