How to make a primer with your own hands

Often, when wallpapering, a primer is not used at all, and if they remember about it, they do not buy it, but cook it at home, for example, from PVA glue.

Expert opinion

Sergey Shablovsky

Plasterer

I recommend that you only dilute primers yourself with professional materials such as a concentrated acrylic solution. It will be cheaper than buying a universal primer, and more reliable than the "old-fashioned" methods.

From concentrate soil

To be sure of the quality of the material used, and most importantly, in compliance with the work technology, you need to know how much polymer is contained in the primer.

Expert opinion

Sergey Shablovsky

Plasterer

As mentioned above, the dry residue of acrylic / latex in the solution should be at least 7-10% for deep processing of walls and ceilings, and 12-15% for priming the floor before pouring leveling self-leveling mixtures. But manufacturers of universal primers almost always hide this information, i.e. sell highly diluted material.

It is easy to make a deep penetration primer from the concentrated one.

The way out of this situation is simple - to prepare the soil with your own hands from the concentrate. For example, a Weber MD 16 solution has a dry residue of 50% acrylic. Diluting it with water, you can be sure of the quality of the resulting product.

Proportions 50% -concentrate - water:

- for processing the floor under the levelers - 1: 3;

- for walls and ceilings before plastering, painting, wallpapering - 1: 5.

PVA glue

Perhaps this is the most famous recipe for homemade wall primer. It is used both under wallpaper and under tiles.

Recipe:

- PVA construction glue - 1 part.

- Water - 10 parts.

- Cement - 1 part, added to the solution if there is a priming under the tiles.

All components are mixed in a bucket, applied to the wall, soaking abundantly, but leaving no smudges, otherwise a film will form.

From wallpaper glue

Before gluing the wallpaper, the walls need to be prepared, but if there is no primer, it can be replaced with wallpaper glue. Prepare a weak solution as follows.

A pack of any dry glue (250 g) is diluted in 6 liters of cold water. Stir with a mixer, leave to swell for 5 minutes.

The glue primer is applied with a fur roller or a paint brush over the entire surface of the wall. After drying (after 4 hours), you can glue the wallpaper.

Consumption is 200 g / m2.

Previous

How to perform plastering according to SNiP: tolerances and requirements for simple, improved and high-quality plaster

Next

Rough finishing Mechanized plaster. It's fast, but not always expensive!

What types of primers are

Wall primers are specially designed for vertical surfaces, interior and exterior. They can be different in characteristics, method of application, on the basis, the level of protection against negative factors.

Acrylic

This remedy is one of the best options for home use. This is due to the fact that acrylic primers contain harmless polymers devoid of a specific odor. Additionally, you can highlight the fact that they are suitable for any type of surface and dry quickly after application.

Among the main advantages are the following:

- Hides small cracks and irregularities;

- Prolongs the life of the decorative coating;

- In case of excessive thickness, the composition is easily diluted with water;

- Allows to reduce the consumption of glue and paint.

It is noteworthy that a few hours after the application of the primer is enough to start further finishing the wall.

Deep penetration before plastering

The first class of primers is a deep penetration primer.

Visually resembles milk with a faint neutral odor. After application and drying, it leaves a resistant film on the surface, thereby strengthening and dedusting the layer.

The deep penetration primer is suitable for the treatment of loose surfaces, which helps to strengthen the wall and reduce paint consumption.

It works best for creating a reliable base for heavy types of wallpaper.

Mineral

A primer based on mineral components is used for the initial treatment of surfaces for the purpose of leveling.

The primer works on the basis of mineral components, respectively, with surfaces made of specialized mineral materials: concrete, brick, plaster, as well as gas silicate and expanded clay concrete blocks.

In such cases, cement is used as a binder.

Adhesive

Adhesive primer is a special solution, the purpose of which is to improve the adhesion of the treated surface with the finishing material. In addition to improving adhesion between materials, such a primer also performs other functions:

- protection of metal surfaces from corrosion;

- prevention of mold and mildew;

- increasing the strength of cracked or porous surfaces;

- decrease in the level of moisture absorption.

Antifungal penetrating primer

Antifungal primer is an affordable and simple solution for protecting surfaces from the harmful effects of harmful microorganisms.

Such a primer is applied at the final stage immediately before finishing.

The actual issue of the use of antifungal treatment is for external walls that are under the influence of precipitation.

Insulating for color equalization

Such a substance makes it possible to align the colors of the final paint. In addition, during operation, it will allow you to maintain the brightness and saturation of the applied color for a longer time. It is used for both internal and external surfaces exposed to painting or plastering.

Universal for plastering and painting

The universal deep penetrating primer is intended for indoor and outdoor use, as well as in places where a strong adhesion effect is expected. A universal option is used for walls before painting or plastering, as well as gluing wallpaper. Additionally, it can be used for processing facades and floors.

Famous manufacturers

Prospectors

The domestic brand "Prospectors" is popular. For bases that are not afraid of deformation. Not suitable for metal.

Optimist

The competitor is "Optimist". Primer for mineral surfaces only. Drying time is 120 minutes versus 1 hour for the first brand.

Its consumption is slightly higher, about 50 grams per meter, but the penetration level is also higher, therefore there is a difference in drying time.

Ceresit

Among foreign impregnations, "Ceresit" should be distinguished. It is versatile, strengthens surfaces, improves paint penetration.

Ideal for porous substrates. The composition can penetrate into them to a depth of 10 centimeters, guaranteeing maximum strengthening. Dries on average 4-6 hours. After processing gypsum or wooden slabs, it will take a day to wait for drying.

Knauf

Knauf impregnation is also well known to builders. Good for outdoor use, allow walls to breathe without allowing moisture to pass through. Penetration level - up to 6 centimeters.

Features of surface preparation and application

Since the prospector's universal primer is available as a ready-to-use mixture, this greatly simplifies the application process.Before processing the base with this soil, it is necessary to perform preparatory work:

- the surface is thoroughly cleaned of any contamination, including construction debris, dirt, dust, old finishing materials, paint, plaster, or other flaking materials. This cleaning can be done with a knife, metal spatula or power tool;

- if there are stains of grease, oil or bitumen on the substrate, they must be removed with alcohol, acetone or solvent;

- if the finishing material crumbles or falls off heavily, then it must be removed. As a result, the base should be firm, dry and clean.

In addition, it is important to protect nearby products and surfaces from the ingress of primer. It is necessary to close windows, doors, and other objects with cellophane film or cardboard

If they are not protected, it will be quite difficult to remove the dried Prospector primer mixture from the surface.

Upon completion of the preparatory work, a sufficient amount of primer is poured into a small container. It is best to use a special drawer with a ribbed squeeze grid. To apply the primer, Prospectors can use a coarsely fluffy roller or brush of the required size. To speed up the application process, you can use a spray gun or a spray gun, but for this method of application, the primer must be diluted to the required consistency.

It can be primed in a temperature range of 5-30 degrees. It is not allowed to apply Prospectors primer at subzero temperatures, in frost. It is advisable to apply the mixture not in one, but in two layers, for maximum protection. The second coat should only be applied after the first coat has dried.

Surface priming rules

Facade preparation

Despite the adhesive properties, primer mixtures do not fit well on surfaces covered with dust, soot from exhaust gases, and oil stains. Exfoliated and crumbling areas are also not subject to priming, since they will begin to crumble during the application of the composition. In addition, the primer does not mask irregularities and cracks, and therefore all defects will be visible under the finish.

The surface is prepared according to SNiP 3.04.01-87. To begin with, they clean the facade of old plaster or paint, fill up cracks, if any.

Removing old plaster

Areas that are blackened from mold must be cleaned with a metal brush and treated with a chlorine-containing preparation (you can take the usual "whiteness"). Remove oil stains with any solvent. Metal elements are also degreased and cleaned from corrosion. Small areas of rust can be sanded with coarse sandpaper, but if a large area is affected, it is better to use a wire brush or drill with a grinding attachment. Finally, the base should be cleaned of dust in any convenient way.

Metal brush with scraper

Grinding attachment for drill

Dilution of the primer

Alkyd compounds are usually ready-to-use, and you do not need to dilute them, moreover, not every solvent is suitable for them. But acrylic-based primers can be diluted with plain water. In what cases is this done?

If the primer is sold in a concentrated form, the instructions for use must indicate the proportions for diluting the solution with water. They may differ from manufacturer to manufacturer, so carefully study the information on the packaging. It is impractical to apply undiluted composition, since this will significantly increase the cost of repairs.

We dilute the soil

Experienced plasterers dilute the usual primer with water to save money when treating large facades. But only if the walls are concrete or brick, and the base is prepared for plastering or painting.Surfaces prone to shedding should not be treated with diluted primer, especially for putty and decorative plaster, since a low content of binders will cause the materials to peel off. When diluting, the mass fraction of water should not exceed 10% of the amount of soil.

We dilute two-component compositions according to the manufacturer's instructions

Applying primer to the surface

For priming the facade, a roller with a telescopic handle and a medium-width paint brush are most often used, which are used to treat hard-to-reach areas. Additionally, you will need a wide plastic pallet where the primer will be poured.

Telescopic rod

Roller with pallet

Step 1. Before use, the soil in the container is thoroughly mixed to evenly distribute the components. Pour a small amount into a plastic tray.

Mix the primer

Pour the soil into the tray

Step 2. The facade is processed in squares or in wide strips, starting from the corner of the building. They take a roller, dip it into the solution, roll it out on a pallet for uniform impregnation and begin to prime the wall in a horizontal or vertical direction. It is necessary to apply the primer evenly so that there are no dry and semi-dry areas. At the same time, it is also not worth applying the solution too abundantly - the excess will drain to the ground, and you will only increase the material consumption.

Facade priming

Step 3. Areas around openings, in inner corners, at the joints with protruding elements of the roof are primed with a paint brush. Splashes on glass or other elements that cannot be painted are immediately wiped off with a damp cloth, since it is more difficult to get rid of them after drying.

Primer application

Step 4. After completing the work, leave the surface to dry. Depending on the composition and air temperature, this will take from 2 to 6 hours for an acrylic primer, and about 10-12 hours for an alkyd one.

Primed wall

The second coat of primer is applied in the same way after the first one has dried. The interval between priming the facade and finishing should not exceed 48 hours. When performing priming work, the air temperature should be in the range from +5 to +30 degrees, and the air humidity should not exceed 60%.

After priming is complete, the instruments should be rinsed immediately with water. Dried soil splashes from the surface can be removed with a solvent or with vinegar essence. To do this, you need to drip a little product onto the stain, wait a few minutes and wipe it off with a hard sponge.

Features of concrete

Many novice repairmen believe that it is not necessary to protect concrete, but this is not the case. Despite the fact that the material itself has a high strength indicator, it is still susceptible to aggressive media and mechanical factors.

Water that enters the pores of the material freezes and leads to delamination of the concrete base, resulting in cracks in the base. Also, the reinforcement, which is contained inside the coating, under the influence of various factors leads to destruction.

If the dwelling has a concrete floor, then the owners should know that the top layer of such a base is very fragile and gradually begins to deteriorate and collapse during use.

Principles of preparing concrete for priming

Applying a primer to a concrete surface has the following functions:

- the soil removes dust from concrete, binding dust particles;

- protects against mold and corrosion;

- increases adhesion;

- improves the quality of finishing;

- strengthens the base.

Prepare the concrete before applying the primer. To do this, the surface is cleaned of dust and dirt, all oil stains are removed, and it is polished. If there are metal parts on the base, then they must be cleaned from corrosion.

Tips and tricks for use

Working with such solutions is quite simple if you follow the following recommendations:

- Apply the mixture with a brush or roller.

- It is necessary to ensure that the layer is evenly distributed.

- For rooms with a large area, it is better to treat the base with soil from a spray gun.

- It is not recommended to apply the solution in frost, the permissible temperature for use is 5-30 degrees.

- If the base is porous, then the primer must be applied in three layers.

- The next layer is applied only after the previous ball has completely dried.

Peculiarities

A deep penetration primer has a number of features that distinguish it from a protective primer. Thus, it provides the smoothest and most even application of the finishing layer. Even the thinnest paint and varnish composition, including water-dispersion paint, as well as wallpaper and other materials, fits well on it.

This composition reduces the level of absorption of finishing materials. By filling all the pores on the surface-base, it significantly reduces the consumption of building and finishing mixtures. Thanks to him, paints and varnishes, as well as adhesives, will not be wasted. They will remain on the surface in the same amount as they were originally applied.

A feature of these compositions is their versatility. They are suitable for many surfaces. Manufacturers even present models that are called so - universal deep penetration primers. They can be used to treat any surface.

These compositions differ in some of their characteristics depending on the species. However, there are a number of properties that are characteristic of all types of deep penetration primers.

So, they mainly include water. She is a thinner. In the composition of these materials, a chemical diluent is practically not used. The maximum amount of non-volatile substances in deep penetration soil is no more than 20%.

The density of the deep penetration primer is similar to that of water and is 1 kg per 1 cubic meter. dm. That is why the peculiarity of this composition is that during the repair process it is possible to calculate its consumption. As a rule, for finishing 1 sq. m is spent from 100 to 200 g of this material, depending on the quality of the base. The absorbency of the substrate can greatly increase consumption, even though you will be using the same primer for different surfaces.

A special feature of the deep penetration primer is its short drying time. But, as a rule, the specific period of time for which it dries out depends on what percentage of the total mass is water.

Even the most well-impregnated surfaces dry in less than 3 hours. Particularly porous surfaces can dry in an hour. The compositions dry most quickly at an air temperature of +20 degrees and a humidity of 70%.

But this composition can also be used in rooms with high air humidity. From this, its properties will not deteriorate at all, only the drying time will increase.

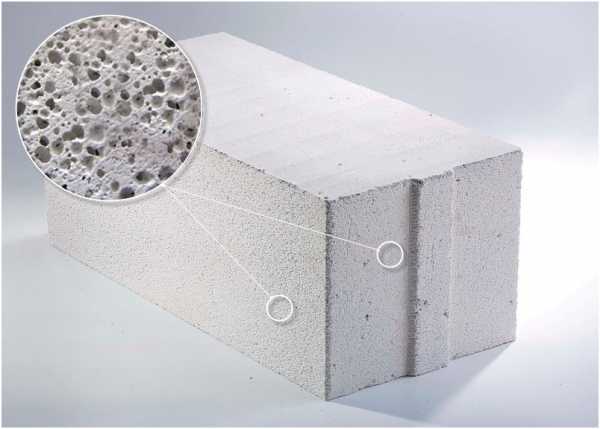

An important feature of using deeply penetrating primers is that they are used for certain finishing materials. As a rule, this is cement plaster or walls for painting, brick, lime whitewash before wallpapering, monolithic concrete, concrete screed, aerated concrete, OSB, chipboard

Deep penetrating soil can greatly affect the absorption rate of the material, regardless of its appearance. When finishing work, it is often used for concrete, aerated concrete and aerated concrete.

Deep penetration primer does not adhere well to the surface if there are dirty or oily stains on it. Therefore, the wall must always be prepared in advance. If you find stains after you have covered the wall with this compound, you must remove the contaminated area along with the primer. Otherwise, the properties of the material in this area will be greatly deteriorated. The absorption capacity is always lower in areas with oil stains.Therefore, the desired effect will not be, the primer simply will not be absorbed into them.

This primer is excellent for utility and industrial premises. In homes and apartments, it is often used to renovate kitchens and bathrooms. In these areas, it deeply penetrates walls, floors and ceilings and allows you to fight against mold and mildew. Thus, a durable and reliable layer is formed on the surface, which significantly reduces the level of water absorption. Thanks to this, the surfaces are not destroyed by moisture, and the possibility of the development of harmful microorganisms is also reduced.

Optimist

The penetration depth of the primer is 5 mm. It belongs to the fourth safety class in terms of fire resistance, the spontaneous combustion temperature exceeds + 450C. The solution is odorless, dries up in 2-4 hours.

The penetrating emulsion fills the voids during application, creating a flexible coating that is resistant to deformation, chemicals and static attack.

Optimist

This primer perfectly protects the metal from the appearance of rust, and makes wood materials visually more structural and saturated, since the composition of the solution is completely transparent. The emulsion is packaged in containers of various capacities, which is convenient when calculating the amount.

The primer may require reapplication on highly absorbent surfaces. The two layers will be about 40 microns thick.

Works are carried out in a certain temperature range from 5 to 35 degrees Celsius. On top of the emulsion, after it has completely dried, you can apply any paints and varnishes, glue wallpaper, lay ceramic tiles. For this, tile adhesive with different characteristics is used.

Lacre

The manufacturer Lakra Sintez produces paints, primers and other paints and varnishes under the Lakra brand. This company produces deep penetration emulsions in three versions:

- universal deep penetration primer;

- interior penetrating against mold;

- interior deep penetration against mildew.

All of them are made on the basis of water-acrylic dispersion. And they are used to strengthen the bases before further finishing.

Lacre

Has the following technical characteristics:

- work temperature not lower than 12C;

- consumption on average 75 ml / m2;

- refers to frost-resistant;

- dries up in 180 minutes;

- penetrating power 6 mm;

- freezing during storage, only five cycles.

The primer is applied on concrete, brick, plaster surfaces outside and inside the premises using a roller, brush or spray gun. Also applied to floors before applying self-leveling compounds.

The second variety is a primer interior deep penetration - contains special additives that prevent the appearance of mold.

The third version of the penetrating primer is also intended for interior use and contains anti-mildew additives. Packing in 1; 3.5 and 9 kg, technical indicators will be identical to those described above. The primer reduces the consumption of subsequent paints and varnishes due to the formation of a strong and homogeneous structure on the surfaces.

Peculiarities

Acrylic primer is a liquid solution based on acrylic dispersion and special components. The peculiarity of this composition, first of all, lies in its protective qualities. The mixture is well absorbed into surfaces that have a porous structure, thereby strengthening the base. When the solution dries, a high-strength protective film forms on the surface, which, in turn, improves the adhesion properties and helps to reduce the consumption of paint and varnish or adhesive material.

Acrylic primers can vary in composition and some properties. However, all acrylic-based mixtures have common features and characteristics:

- the soil makes the treated surfaces more durable, especially if a deep-penetrating or strengthening mixture is used;

- reliable protection against moisture: the film created on the surface repels water;

- increases the level of adhesion: the topcoat will adhere well to the primed substrate;

- reduces the consumption of paint and varnish or glue mixtures during finishing;

- vapor permeability;

- good hiding power: dark-colored surfaces treated with acrylic primer will not show through under the finishing coat of light-colored paintwork.

The composition of acrylic-based mixtures can include a different set of components. However, acrylic primers also have common substances in the composition:

- water or organic solvent as a base;

- binding elements that provide the solution with a certain viscosity: drying oil, various resins, polymers;

- dyes;

- catalysts that accelerate the drying process of the primer mixture;

- special additives that give the solution certain qualities: antifoam agents, biocides.

Acrylic primer PRIMER C, penetrating, adhesive, LITOCOL

Description

PRIMER C-m is an aqueous dispersion of acrylic resins and is used only for indoor work. It is an environmentally friendly product, it does not contain toxic and allergenic substances. The composition is certified and has all the necessary sanitary and hygienic conclusions. The smallest polymer particles impregnate the top layer of the base, strengthen it and minimize dust formation. Deep penetration primer PRIMER C-m reduces the absorption of moisture by the surface material, which enhances the adhesion of the substrate and prevents cracking of the screed or leveling coating.

Application area

It is recommended to use the primer PRIMER C together with cement-based adhesive mixtures, self-leveling compounds.

Used for surface treatment such as:

- screeds and plasters from cement-sand and gypsum compositions;

- dense concrete;

- load-bearing walls and partitions made of bricks, foam and aerated concrete, cinder blocks;

- anhydrite screeds;

- facing from tiles, mosaics, porcelain stoneware, natural stone.

PRIMER C is recommended for the following type of work:

-

Preparation of surfaces for laying tile, mosaic and porcelain stoneware cladding, natural stone tiles

The use of a primer before tiling reduces the consumption of glue and improves its adhesion to the surface. The primer layer serves as a reliable barrier to direct contact and chemical reaction between the gypsum surface and cement mixtures.

-

Hardening and dedusting of substrates before applying self-leveling compounds

The treatment of the floor with PRIMER C-m helps to increase the adhesion and better flow of the self-leveling compound. By reducing the absorbency, premature drying and cracking of the mixture is prevented. For best results, it is recommended to apply the primer in two coats.

Properties

- strengthens the base, binds dust;

- reduces water absorption of porous substrates;

- increases the adhesion of adhesive mixtures and decorative and protective plasters to the base;

- promotes the spreading of self-leveling mixtures;

- the primer is highly absorbent and provides deep penetration into the depth of the base;

- water-based, solvent-free, environmentally friendly;

- frost-resistant during transportation; differs in an affordable price among other deeply penetrating primers.

Instructions for use

Before applying the primer, the surface to be treated must be carefully prepared. It is cleaned of dust and dirt, paint residues, oils and grease, and all fragile areas are removed. All cracks and irregularities are repaired using appropriate compounds.

Apply PRIMER C-m in an even layer over the entire surface using a roller, brush or brush without puddles. The composition is thoroughly mixed before use. For highly absorbent substrates, the primer is applied twice, the first time using a primer diluted with water in a 1: 1 ratio.

Freezing is allowed during transportation of the product. It is prohibited to use PRIMER C-m together with adhesives and other LITOKOL products based on epoxy and epoxy-polyurethane base.

Specifications

| Indicator name | Meaning |

| Appearance | liquid |

| Colour | White |

| Dry residue | 11% |

| Viscosity | 10–20 mPa • s |

| Ph | 7-8 |

| Application temperature | from +5 ° С to +35 ° С |

| Penetration rate | deep |

| Drying time | 4 hours at a temperature of +23 ° С, when the temperature changes, the time may change |

| Elasticity | excellent |

| Moisture resistance | satisfactory |

| Resistant to solvents, acids and oils |

satisfactory |

| Operating temperature | from -5 ° С to +90 ° С |

| Storage term and conditions | 12 months in original packaging in a dry place at a temperature not lower than + 5 ° С. Short-term transportation is allowed at a temperature not lower than –15 ° С. No more than 5 freeze / thaw cycles are allowed |

Application technique and consumption per 1 m2

You can apply the primer to the walls with a wide paint brush or roller. With a roller, you can process the entire area quite quickly and evenly. When preparing the ceiling, again, it is better to choose a roller (foam or fur) with a long handle. It is convenient to work with a brush in the corners of a room and in hard-to-reach places, as well as when it is necessary to abundantly saturate the surface with a primer solution.

Sprayer / spray / spray gun accelerates priming and gives an even coat. For the home, you can use a hand held garden sprayer, and for professional work, you can use equipment with a compressor.

A penetrating primer is poured into the spray tank and the entire working surface is sprayed evenly. This method is not suitable for concrete contact, because the primer will have to be heavily thinned, and this will lead to sand settling. Adhesive quartz primer is best applied by hand.

Depending on the strength and porosity of the base, choose how much of the primer solution to apply to the walls. For example, lime plasters need to be deeply impregnated because they have low strength. At the same time, porous aerated concrete does not need to be impregnated, but it is enough to create a film on its surface that prevents the absorption of moisture from other finishing materials.

Below we will consider what materials and when to prime.

| Brick | Before plastering, moisten with plenty of water, a primer is needed if you want to bind dust particles. |

| Aerated concrete and other cellular blocks | To reduce water absorption before plastering, prime with a penetrating primer with a dry residue of 7-10% in two layers. Silicate formulations are well suited. |

| Concrete | To increase adhesion to gypsum plasters, concrete walls are treated with quartz-primer (concrete contact). An acrylic composition with a dry residue of 12-15% is applied to concrete floors before pouring the leveling agents. |

| Gypsum and Lime Plaster | They draw moisture well into themselves, so it is imperative to reduce their water absorption by priming with a deep-penetrating compound before the next layer of plaster, gluing wallpaper or liquid wallpaper. |

| Cement-sand plaster, tile adhesive | Before gluing the tiles, moisten with water, before puttingtying, cover with a universal primer. |

| Drywall | They are treated with concrete contact to increase adhesion before gluing the tiles. A deep penetration primer is sufficient under the wallpaper. |

| Fiberboard, chipboard | They are primed with concrete contact, quartz sand in the composition will increase adhesion with subsequent finishing. |

| Wood | Protect against mold, antifungal impregnation or alkyd paint-primer. |

| Metal | To prevent rust, the metal is coated with an alkyd (glyphtene) primer such as GF-021. |

After proper priming of aerated concrete, its water absorption is reduced by 50-70%

Consumption of priming material per 1 m2 of wall:

| Type of | Consumption, gr per sq.m. |

| Concrete contact | 200-400 |

| Deep penetration | 100-180 |

| Silicate | 150-200 |

| Alkyd | 100-120 |

| Perchlorovinyl | 60-100 |

Knowing these numbers and the area of the walls, you can calculate the amount of soil without a calculator.

The video below shows the process of applying primer from a spray gun to brick walls.

How to calculate the quantity?

Payment deep primer consumption penetration is a rather difficult task. This is because the absorbency of different surfaces varies greatly. As a rule, the compositions that are applied to concrete have a flow rate of about 100 to 200 ml per sq. m. But there are also economical types of primer for concrete, for example, a highly concentrated primer from the manufacturer Knauf, which per sq. m. m are consumed in a volume of 70 to 100 ml.

Acrylic impregnations are consumed in no more than 250 ml per sq. m. The consumption of antifungal compounds is higher and amounts to about 300 g per sq. m. m. The antiseptic has a fairly economical consumption, which averages 100 ml per sq. m. m. Facade compositions are consumed within 300 ml per sq. m. m depending on the complexity of the finishing work.

Many of those who decided to make repairs with their own hands are wondering about the compatibility of such impregnations with drywall. Since drywall is afraid of moisture, water-repellent impregnations are very often used to process it. Thus, this composition improves the technical characteristics of drywall, and also improves the adhesion of this material.

How to choose?

In order for the result of finishing work to be of high quality and meet your expectations, it is worth taking a responsible approach to the choice of a primer mixture.

It is imperative that you purchase a high quality mix. Cheap formulations will not provide adequate surface protection and good adhesion.

Before buying, you should familiarize yourself with the most popular manufacturers and the composition of primers. There are a number of significant factors to consider when choosing a primer. Let's highlight the main ones.

Type of finishing works

Initially, it is worth deciding what kind of work the primer is intended for. Varieties for preparing the substrate indoors or outdoors are different. For outdoor work, it is better to use special facade mixtures that are frost-resistant and moisture-resistant. For interior work, you need to select a more environmentally friendly primer that does not contain toxins. To prepare surfaces in rooms with high humidity levels, you need to choose a soil with an antiseptic.

Surface to be treated

It is worth carefully studying the marking: it should indicate for which specific types of base the composition is suitable (walls, floor, ceiling). The material on which the primer will be applied is different; you cannot use the first thing that you like on the shop window for processing.

Further type of finishing

The type of finishing works matters. Compositions for surface treatment for painting, tiling, decorative plaster and wallpaper are different.

Drying speed

For interior work, it is better to choose mixtures that dry quickly. This will reduce the time required to prepare the foundation.