Is it possible to apply liquid wallpaper on drywall without putty

Liquid Coating is a flat surface finish suitable for drywall applications. It is flexible, durable, and provides additional protection for the HA surface. Since wallpaper is sold as a dry mix, it is diluted to a certain consistency. The mixture has the following qualities:

Liquid Coating is a flat surface finish suitable for drywall applications. It is flexible, durable, and provides additional protection for the HA surface. Since wallpaper is sold as a dry mix, it is diluted to a certain consistency. The mixture has the following qualities:

- The mixture applied to the surface has no seams.

- Does not contain any impurities harmful to health.

- Increase of sound and heat insulation.

- Liquid formulations do not tolerate moisture.

- Absorb odor, dust.

To apply a mixture of wallpaper to a plasterboard surface, carry out preparatory work:

| P / p No. | Material used | Application on HA surfaces |

| 1. | Primer | Covers drywall, especially the attachment points, as well as after filling |

| 2. | Reinforcing tape | Close all joints of the gypsum board using Knauf putty |

| 3. | Putty | Apply the finishing mixture to cover the plasterboard surface. |

After filling, the surface must dry. It is cleaned from the remaining pieces of solution with sandpaper. After they are primed.

Prepare the liquid coating according to the instructions on the package.

No need to pour water into the wallpaper mixture "by eye". There is a strict adherence to the technology of preparing wallpaper for application.

Working with a mixture of wallpaper on a GK-surface:

- Before direct application, the mixture is thoroughly mixed to achieve homogeneity.

- A part of the wallpaper is applied to the plastic tool and evenly distributed over the surface, starting from the corner.

- If irregularities appear during the distribution of wallpaper over the surface, it is possible to correct them within an hour.

- It takes 24 hours to dry.

Having studied the process of applying wallpaper to the prepared surface of the gypsum board, many home craftsmen avoid mistakes.

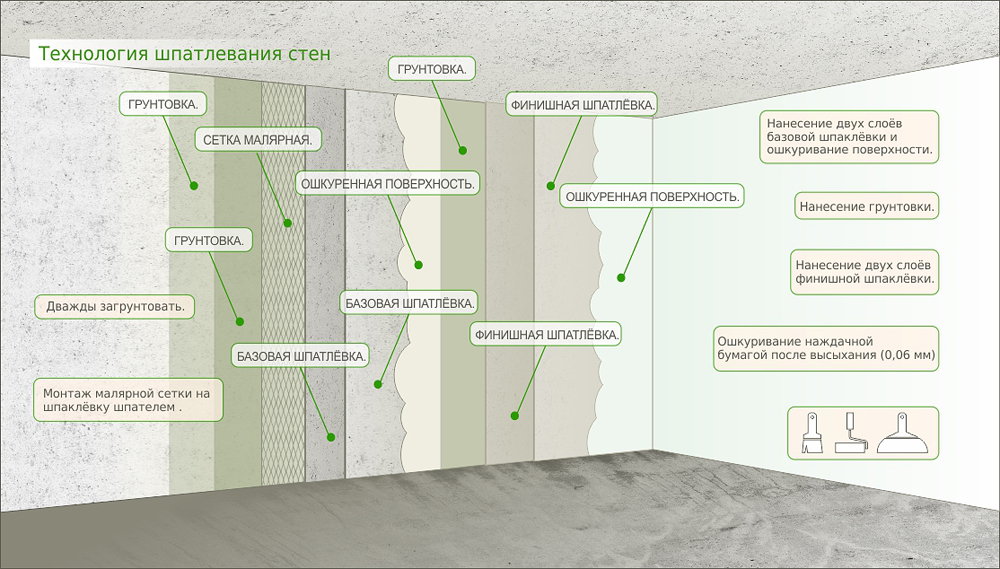

Do-it-yourself drywall putty

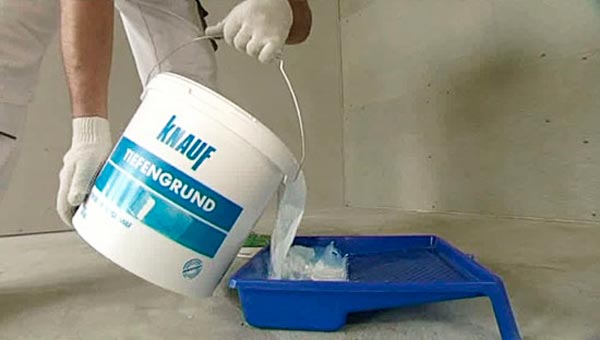

Before puttingty drywall, we prime the surface. Any primer is applied on a dry, clean surface. Therefore, we first remove the dirt from the surface, remove the dust (you can use a vacuum cleaner or a slightly damp cloth). After that, we prepare the soil according to the instructions (sometimes it is necessary to dilute with water, sometimes it is enough just to stir), pour it into a container and apply with a brush or roller.

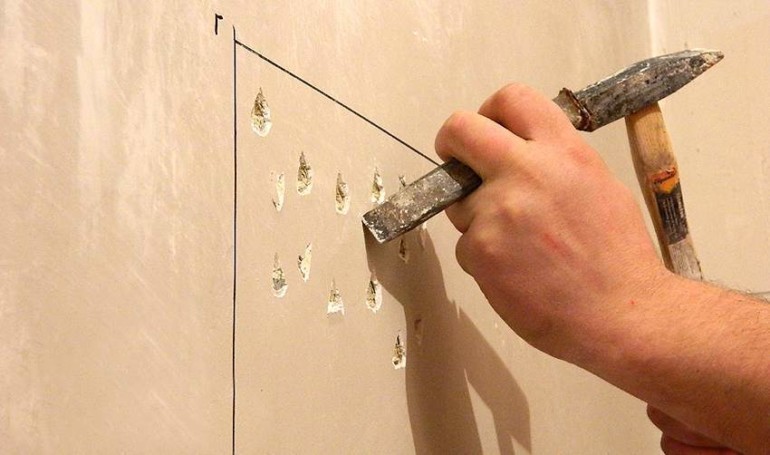

Once again we go through the seam, applying a fresh putty about 0.5 mm thick, take the soaked reinforcing tape and glue it to this compound.

We take a spatula 8 cm wide and press the tape well to the surface, squeezing out the excess putty from under it.

A few words about which putty is best to use for gypsum plasterboard. Any one is suitable - based on gypsum or polymers (latex).

Polymer putties are usually finishing - they give a very thin layer and an even surface. There are both starting and finishing gypsum. The difference is in the size of the particles. You can use any, as long as the quality is good. To putty surfaces, you need a large spatula - with a blade of 40 cm or more and a narrow one - 10 cm.

The first layer is applied with a starting putty. It is laid in a layer of about 5 mm (the maximum should be seen in the instructions for a particular putty) and hides all the irregularities. Dilute it with water to a thick sour cream, stir thoroughly so that there are no lumps. Perforated corners are used to design outer corners - slopes, ledges, etc. First, a piece of the required length is cut. The metal is very thin, it can be cut even with ordinary large scissors, but if there are scissors for metal, it is easier to work.

Edges are trimmed at 45C or less, not 90C. So, when puttingty drywall, the edge will not wrap.

- Environmental friendliness and resistance to chemical influences.

- Moisture resistance and the presence of antiseptic components.

- High level penetration.

Apply a layer of finishing mixture on the dried plasterboard wall primer under the putty.

After hardening, the surface should be cleaned

If the finishing will be completed by painting or wallpapering, then another application of the primer is performed.

When filling drywall, special attention is paid to the joints of two sheets and the grooves left after screwing in the screws. This coating will not be able to hide even small flaws, and in some cases even emphasize them.

Therefore, the correct plastering of drywall is the key to high-quality painting of the walls. The second method is simpler, and it takes much less time than the first, however, in terms of quality, such a coating will be decently inferior to the one that we did before. The manufacturer can be selected on such grounds as the ease of use of the solution.

For example, some companies tint mixtures yellowish or pinkish to make it easy to keep track of the evenness of the layers. Using a clean roller, the soil is spread evenly over the surface. If a composition with color indexing was chosen, then it becomes easy to control the areas of application of the solution during operation, as well as the completion of the drying period. The choice of material for the primer should be approached very carefully.

First of all, you should pay attention to the price. If the price of the mixture is half the price of the same primer from well-known manufacturers, then you should not rejoice and choose cheapness.

In a business like construction, the miser pays twice for sure.

It is better to choose a trusted manufacturer than a cheap one. Before you start directly priming, you need to choose the right tool for the job. Typically a soft roller, hard-to-reach brush and paint tray

When choosing a primer, pay attention to the manufacturer. You should not try to buy soil from an unknown company, even if it is cheaper - the quality of construction work is more important

The following primers are recommended: Knauf, Kaparol, Tikkurila, Ceresit.

Additional information on the topic:

- Plasterboard ceiling in a room with two windows

- Indoor aerated concrete wall decoration with plasterboard video

- Wall decoration in an apartment with plasterboard pros and cons

- Pvc panel for ceiling in bathroom or drywall

- Materials for working with drywall and profile

Types of primers: which one to choose under the wallpaper

Before choosing a primer, it must be remembered that the correct choice depends on the material of the wall surface (wood, concrete, putty, metal, etc.), the type of wallpaper (non-woven, vinyl, paper or washable) and other factors related to the operating conditions of the room (temperature, humidity, illumination).

Do I need to process the walls under non-woven wallpaper

Decorating the walls with non-woven wallpaper gives the room a special elegance of execution. Priming the walls will facilitate the sticker process itself, neutralize and prevent the appearance of mold and mildew, and also prevent the appearance of yellowness on the wallpaper.

Decorating the walls with non-woven wallpaper gives the room a special elegance of execution. Priming the walls will facilitate the sticker process itself, neutralize and prevent the appearance of mold and mildew, and also prevent the appearance of yellowness on the wallpaper.

For priming the walls before gluing non-woven wallpaper, the following types of materials are used:

- Acrylic primer. The most common and inexpensive material. Method of preparation: dilute the soil with water. After application, it dries quickly, about 2-3 hours at average room temperature. In the case of an uneven color of the wall, there are varieties of primers with a color scheme that will allow you to even out the tone.

- Non-woven alkyd primer. A specific solvent is required for dilution.This type is intended for priming walls made of wood material: chipboard, fiberboard, SIP panels, plywood, wood board, etc. This material covers the work surface with a moisture-resistant coating.

Latex primer is used for all types of coatings and materials from which the walls are made. In addition, this primer is easy to apply and maintain.

Experts recommend using wallpaper glue for priming. Method of preparation: dilute the dry glue mixture twice with warm water. Such material is applied exclusively with a roller with a thick pile. It is enough to cover the surface with two layers of material.

The disadvantage of this option is that each layer of soil dries from 4 to 10 hours, depending on the brand of glue.

It is recommended that when choosing a primer for non-woven wallpaper, it is prudent not to take on the basis of PVA, since this type of material will lead to premature yellowing of the wallpaper.

Which is better for vinyl wallpaper on a non-woven base

In the case of vinyl wallpaper, remember that this type of decor is made of synthetic PVC (decorative layer), and as a result, this will be the reason for moisture resistance.

In the case of vinyl wallpaper, remember that this type of decor is made of synthetic PVC (decorative layer), and as a result, this will be the reason for moisture resistance.

Vinyl wallpaper is applied exclusively to dry surfaces.

Suitable for vinyl wallpaper: acrylic, alkyd and latex primer. The choice of primer depends on the material of the wall surface on which the decal will be made.

Acrylic and latex primers are applicable for plastered and putty walls, since, according to their characteristics, they can penetrate into the top layer, sealing microcracks and pores.

If the application of a water-based primer to walls can lead to deformation and corrosion of the material, it is recommended to use an alkyd and glyphthalic primer.

Alkyd primer is intended for the treatment of walls made of wood-based materials. In this case, the solvent will prevent the wood from swelling from moisture.

Glyphthal primer is a pigment suspension based on acrylic lacquer. This variety is ideal for wood walls and will increase surface adhesion.

Under paper wallpaper

Paper wallpapers are the most economical option for wall decor. They are susceptible to the moisture of the adhesive, in addition, if a mistake is made during the preparation of the walls and the gluing process, they can bubble, delaminate and tear. To prevent errors, it is necessary to take into account all these nuances.

Paper wallpapers are the most economical option for wall decor. They are susceptible to the moisture of the adhesive, in addition, if a mistake is made during the preparation of the walls and the gluing process, they can bubble, delaminate and tear. To prevent errors, it is necessary to take into account all these nuances.

First of all, it is necessary to take into account the material of the walls, as is the case with non-woven and vinyl wallpaper. However, experts recommend using the option of priming with wallpaper glue, since this material during the gluing process will provide an opportunity for accurate correction in case of air grooves or uneven joints.

What to process under washing wallpaper: how to prime

Washing wallpaper is used in rooms where it is expected to remove dirt or moisture from them, such as a bath, kitchen or hallway. They are similar in structure to vinyl wallpaper. Due to the similarity of these types of finishing materials, the choice of primer is determined according to the same principle. It should be remembered that wallpaper with a polymer synthetic coating is glued after the primer has completely dried.

How to putty drywall: align the planes

To putty surfaces, you need a large spatula - with a blade of 40 cm or more and a narrow one - by 10 cm. The first layer is applied with a starting putty. It is laid in a layer of about 5 mm (the maximum should be seen in the instructions for a particular putty) and hides all the irregularities. Dilute it with water to a thick sour cream, stir thoroughly so that there are no lumps.

Such spatulas are needed to putty drywall over the entire surface.

The technique of plastering the surface of drywall is simple: we take a large spatula, at its end with a small spatula, lay out the roller from the putty. We press the blade to the surface and stretch the composition. We repeat several times, filling in some piece of the wall or ceiling. Then we clean the blade and run it over the surface that has just been putty, leveling it. You need to align as carefully as possible - it will take less time for sanding.

When the plasterboard is finished, wait until it dries. Then you take the already familiar tool - a bar with a net and level out all the flaws. Sanding is completed, remove dust, pass the surface again with a deep penetration primer. After drying, proceed to the application of the second layer.

So hold the spatula

Next, you need to putty drywall with a finishing compound. As they wrote, it can also be based on gypsum, like the starting one, or maybe based on polymers. Both are suitable, but with some it is more difficult to work - they quickly begin to roll down and freeze.

The finishing putty is made more liquid and applied in a thinner layer. The application technique is the same, nothing changes. In addition to the fact that it is more difficult to work, it spreads worse, but you need to stretch it in a thin layer and quickly align. On the primer, everything is much better, and without it, the lower layer quickly draws moisture from the fresh plaster and it begins to roll. After applying the finishing putty, wait again until everything is dry, then begin to level. But this time, not a mesh is used - noticeable grooves remain from it, but sandpaper with a fine grain. It is not so convenient to work with it - it clogs up quickly, but the surface is smooth. If you prepare the surface for painting, we do the backlighting from below or from the side and you can use not an incandescent lamp, but an LED one - all the flaws are visible. Even very small ones.

It is difficult to tell in words how to putty drywall - the movements are difficult to describe. In the video you can see how to hold the spatula, how to move it, how to apply or remove the mortar. For details on the technology, see the video.

And further.

The choice of composition for different surfaces

Today, the market offers a lot of building materials, among which the main options can be distinguished:

- Acrylic primer. This is the most optimal and versatile option equally suitable for any surface. Dries up within two to four hours. Ideal for subsequent filler applications.

- Phenolic. It is most widely used in the processing of metal and wood surfaces. Can be used for putty.

- Alkyd. Applies to wood surfaces only. Cannot be used for putty.

- Perchlorovinyl. Suitable for exterior walls made of bricks and cement.

- Glyphthalic. Ideal primer for wood and metal. However, its use is limited due to the toxicity of the substance.

- Polyvinyl acetate. It is used only for surfaces where the polyvinyl acetate paint will be applied, respectively.

- Polystyrene. Also toxic, but quite balanced.

What is the best primer for wood putty

Wood is a natural and harmless material. In order to increase its durability and service life, it will require processing with a special material - a primer for wood.

The best option is an alkyd primer. It should highlight its advantages and disadvantages, which determine its significant prevalence.

Pros: increased strength; high performance properties; the ability to work in subzero temperatures.

Cons: long drying time; the need to use the harmful substance "White Spirit" as a thinner and cleaner.

What primer to use before puttingty concrete walls

A concrete primer is important in cases where a high-quality coating is required. It is known that concrete surfaces are prone to destruction, as well as destructive effects of mechanical, chemical and natural factors.

A properly selected concrete primer should provide the ability to:

- Create a smooth surface.

- Ensure even distribution of the coating.

- Provide sufficient strength.

- Create protection against destructive factors.

- Reduce material consumption to create the next layer.

Among the most appropriate primer options for concrete are: alkyd primer, polystyrene, polyvinyl acetate.

Is it necessary to process before plasterboard putty

If the drywall surface is not contaminated with debris and dust, then a primer may not be needed, since the putty can get sufficient adhesion.

Nevertheless, the seams formed at the time of installation of drywall sheets require attention, and they must be primed without fail. It is recommended to use the material only for interior work and quality products from leading manufacturers.

How to paste wallpaper on drywall

The first step is to prepare the drywall for the putty. This is a mandatory procedure, it will help you avoid the neighborhood with small harmful insects and prevent the formation of wall fungus. Wallpaper pasting technology has a lot of nuances that cannot be considered in one work. Therefore, once again we suggest that you familiarize yourself with the material “How to glue the wallpaper yourself, quickly and efficiently”, in which you can find answers to almost all the questions that arise during the pasting of drywall with wallpaper.

- ladder;

- plastic buckets - 2 pcs.;

- bath;

- roller and paint brush;

- metal spatula;

- plastic spatula;

- plumb line;

- ruler;

- pencil;

- a knife with a replaceable blade (scissors);

- roulette;

- wallpaper roller;

- narrow, tapered rubber roller;

- foam sponge;

- napkins.

The situation when the walls shine through the wallpaper, among inexperienced finishers, is quite common. Here there is only one way out - to redo all the work done: remove the wallpaper, prepare the drywall for a new pasting (putty the wall), glue the tapestries in a new way.

- antibacterial composition;

- sanding mesh and sandpaper;

- paint brushes, rollers and maklovyts for applying antiseptic and primer;

- spatulas with narrow and wide blades;

- primer;

- gypsum or polymer putty;

- sealant or plaster for sealing joints;

- fiberglass or lavsan mesh tape (serpyanka).

Putty work, priming

After preparing the joints, the drywall should be primed before gluing the wallpaper before the putty. This will improve adhesion. Failure to apply a finishing layer leads to some problems:

- the elevation of the seams above the surface creates irregularities on the canvases after gluing;

- it will not be easy to remove the wallpaper when replacing: it will come off along with pieces of cardboard and plaster;

- the lines of the joints of the drywall sheets are visible through the thin wallpaper.

Puttying is performed in the following sequence:

- a solution is made from the finishing mixture with the expectation of 45 minutes of work, so as not to grab;

- using a wide spatula, apply it evenly to the wall;

- after drying, the applied layer is sanded with emery paper (float) until a smooth surface is obtained.

When the sanded surface is ready, some craftsmen may have a question: is it necessary to prime the drywall before gluing the wallpaper directly? Practice shows that this is necessary, since it prevents the rapid absorption of glue, provides better adhesion of materials (wallpaper to the wall). For information on how to finish the plasterboard base, see this video:

When processing walls, the floor should be covered with polyethylene

To prime a prepared plasterboard surface, it is enough to purchase the composition in a ready-made (cans from 5 to 10 liters) or concentrated (containers of 1-3 liters in volume) state.

The first can be used to immediately process the work surface, and the second - after dilution according to the specified recipe. The floor should be covered with plastic wrap to avoid stains.

The fewer defects on the treated surface, the better the wallpaper looks. We must strive for this.

The considered technology of carrying out preparatory work allows you to obtain a decorative coating from wallpaper for many years without repair. A beginner in decoration is also able to cope with all the work.

Make sure the area is well ventilated before starting work. Although acrylic primer is not a highly toxic material, it is still not recommended to breathe its vapors for several hours. If the home craftsman does not have experience in performing this kind of work, the question naturally arises: is it necessary to prime the drywall before puttingty. It will be useful to find out the opinion of professionals on when it is necessary to apply a primer, and in which cases, you can skip this procedure.

Of great importance is the color of the primer, which will show through from under the thin wallpaper. For light wallpaper, you need to choose a mixture of only white, for heavy, bright or dark materials with embossing, a composition of any shade is suitable. Drywall is one of the most popular and relatively inexpensive materials for leveling walls, it has many characteristics that are valuable for creating a comfortable environment, including lightness in installation, high speed of work, excellent sound and heat insulation, absence of extraneous odors, fire resistance, environmental friendliness. In the process of DIY repair, the question inevitably arises: is it necessary to prime the drywall before gluing the wallpaper and how to do it correctly.

Finishing the outside corners of the room is the most time consuming. This is primarily due to the low strength of these areas. Further processing of plasterboard walls for wallpaper begins with sealing the seams.

In this process, a reinforcing tape is used, and it boils down to a number of actions: As can be seen from the above technology, the preparation of gypsum plasterboard walls for wallpapering includes a number of procedures, including priming. In this case, the primer is applied before each new layer of finishing: puttying the seams, plastering the walls, between the layers of putty and before sticking the wallpaper.Finally, dust is swept from the walls and impregnated with acrylic primer of deep penetration. It is necessary for better adhesion of wallpaper and saving glue. Serpyanka is a lavs or fiberglass tape with an adhesive applied to its surface.

Outwardly, it looks like an ordinary medical bandage. Serpyanka should be glued as tightly as possible to the joints between the sheets, avoiding the appearance of air cushions. If the serpyanka does not adhere well, you can add a small amount of PVA glue. Preparing drywall for wallpapering begins with a preliminary examination of the walls. The joints of the slabs that require preliminary trimming are determined, the depths of the self-tapping heads are controlled so that they do not interfere with the surface finish.

If necessary, defects are eliminated.

Conclusion

When deciding whether it is necessary to prime drywall before puttingty, you should also pay attention to the financial issue. Due to the fact that the cost of the primer is not so high, and its consumption is low, the purchase will not significantly affect the cost of repair

When priming, a solution is first prepared. According to the instructions, it is diluted with water and poured into a separate container. With a clean roller, the primer is evenly applied to the surface. Sometimes materials with color indication are produced.Thanks to it, it is easier to track where the solution is applied, and also to notice the time it dries completely.

In some cases, # 8212, experts also recommend making a starting layer between grouting joints and finishing filler, but this step can be skipped to get a thinner surface. It is necessary, for example, to putty the seams between adjacent sheets, the places where the screws are screwed in, which fix the material, and so on. Possible future renovation.

In the absence of putty on the surface of the walls, it will be impossible to remove the already existing layer of wallpaper. The fact is that when they are removed, gypsum will separate, which will cause the need to re-install the panels. They differ mainly in grain size. The smaller the grain of the bonding element, the thinner the minimum applied layer, the less roughness. For example, on the popular universal plaster KNAUF Rotband, the largest grain size is 1.2 mm.

But in fact, the particles of gypsum are, of course, smaller. They are simply sifted less thoroughly than in putty. Therefore, after mixing with water, grains are visible in the solution.

The putty has the consistency of sour cream. A light trowel of the dried mixture is a good technique. In this case, the tops of the texture protrusions will be removed and the lower white layer will appear.

The gloss of the Venetian is given by a protective wax applied at the very end.

- Improves the adhesion of the finishing material to drywall;

- Strengthens the base;

- Reduces the consumption of finishing materials (putty, wallpaper glue, paint, etc.), which saves money;

- Promotes uniform distribution of paint on the surface;

- Protects the surface from mold, mildew and other pests.

If the quality of the acquired composition still raises suspicion, you should test it yourself. To do this, dip a brush into the liquid and apply it to a small section of the wall.