Varieties of primer for wood

Mastics and impregnations for wood include film-forming substances (resins, oils, bitumen or glue), as well as components in the form of plasticizers, pigments, etc. The assortment of primers for wood is quite wide. To obtain an optimal result of further finishing, you will need to select and buy a wood primer of the most suitable composition.

The following types of soil for wood are on sale:

- alkyd - this primer is used for painting wood with alkyd enamels like PF-115 and its imported analogues. In composition, such a primer resembles enamel, but includes a larger amount of organic solvents and cheaper pigments. Alkyd primer perfectly fits in one layer, while creating a water-repellent coating, dries within 10-15 hours, it can be applied by diluting with water;

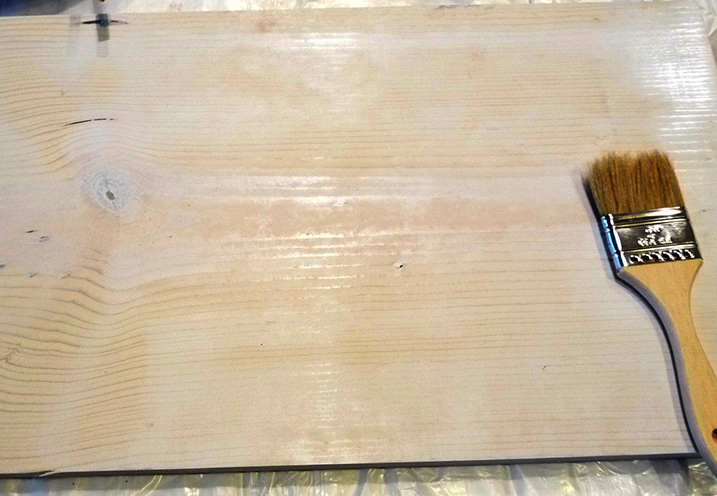

- acrylic - a penetrating water-soluble primer of this type (based on acrylic resins) is universal, since it is suitable for basic wood processing for various types of paints, it is almost completely absorbed into the depth of the processed material without the formation of a visible film on the wood surface. Acrylic wood primer is usually applied in 2-3 coats. This type of soil does not have a sharp specific smell, dries up in a few hours;

- silicone-acrylic primer fills the pores of the wood, strengthening it and creating a durable water-repellent (water-repellent) layer. Such a primer is suitable for preparing a base surface made of wood for painting with water-dispersion, alkyd, latex paints;

- polyurethane and epoxy primers based on polyurethane or epoxy resins can be used as a base for finishing with various paints and varnishes. These types of primer are similar in composition to varnish, but unlike it, they include more special solvents and do not contain tinting additives. When buying such a primer, it is recommended to carefully read the list of its components indicated on the package, since variations in the primer from different manufacturers can differ significantly in composition and consistency;

- shellac - this type of soil is intended for reliable isolation of knots on cuts of coniferous wood. Such a primer neutralizes the effect of resins released by the treated material, which can disturb the appearance and structure of the topcoat. Shellac primer can also be used as an insulator for waterborne stains;

- antiseptic - due to its composition, this type of soil has disinfecting (fungicidal, pesticidal) and other useful properties. Such priming is used to prevent and eliminate the processes of damage to wood by various types of fungus and mold, as well as to protect the tree from damage by various insect pests (in the form of shashel, various woodworm beetles);

- oil - such a primer is used for previously painted surfaces or as a base for subsequent painting (for this it is enough to apply one layer of primer);

- drying oil - traditionally used as a primer for coating with oil paints for exterior and interior work. This impregnation penetrates several millimeters deep into the wood, providing reliable protection against the effects of high humidity and decay, as well as strong adhesion of the oil paint to the base surface;

- styrene primer is used to create a film on the wood surface that protects the wood material from decay and destruction. Such a primer, which increases the adhesion of finishing materials to the base surface, is used for painting wood with oil-phthalic and alkyd enamels.

When choosing a material for priming, it is necessary to be guided by the conditions of work, which include:

- location of the treated surface (indoors or outdoors);

- humidity and air temperature;

- if you have time to process the wood.

Primer types

A primer for paint on wood will fully fulfill its functions if it is correctly selected. It is not surprising, because if you ask for a primer in a hardware store, you will immediately be asked about the type of substance.

There are two large groups of materials that differ from each other:

- Classification of primers by composition.

- Types of primers for their intended purpose.

By composition

Primers, according to their composition, can be divided into the following groups:

Acrylic based. The peculiarity of acrylic products is their versatility. It is suitable for chipboard, wood, concrete, brick and plastered surfaces. Used for porous materials, dries quickly (about 5 hours) and does not emit any odor

Allows the material to breathe, which is very important for wood. Air passes through its structure, the room is ventilated, and the material itself gets rid of excess moisture

Acrylic compounds are not suitable only for metal surfaces.

An alkyd primer for wood is considered the best option for treating wood. After application, the structure of the material becomes slightly swollen, the adhesion to the surface is improved. It dries not as quickly as the previous version, about 15 hours. Ingredients may be added to prevent rust and mildew. Glyphthalic compounds. They are mostly used for the treatment of metal surfaces, however, the products are also suitable for wood. Drying up to 24 hours. There is a big disadvantage - it can only be used for dry rooms. With prolonged exposure to moisture, the substance loses its original properties. Perchlorovinyl materials. Another versatile compound used for wood, brick, plaster and metal surfaces. Such a primer for wood for painting dries very quickly, in summer the layer will dry in just 1-2 hours. True, you cannot use a primer for internal surfaces, it is toxic. Polyvinyl acetate. Made from latex and polyvinyl acetate dispersion (main component). Suitable for all surfaces. True, a primer for acrylic paint or any other will not work. This is a prepared substrate for polyvinyl acetate paint only. Drying - about 30 minutes. Phenolic. Base coat for painting, applied to metal and wood surfaces. Drying takes about 15 hours. Scope of use: outdoor work. Polystyrene. Scope of use - external work on wood and plastered surfaces.

Aluminum. It is applied to a wooden surface. Additionally, it protects the material from the negative influence of the fungus. Epoxy. It is used for processing only metal and concrete, protecting against corrosion and improving adhesion. Shellac. Primer for painting wood. Thanks to her, resins will not stand out from the structure of conifers. Mineral. Made from cement, plaster and lime. Applies to brick and concrete only. Drying lasts from 3 hours to a day. It all depends on the thickness of the layer and the material.

By appointment

Thanks to the addition of additional components, the primer acquires certain properties for better painting of the walls. Types of products:

- Deep penetration. If the surface is loose and not strong enough, then this is the best option.The substance strengthens the wall, reducing the consumption of paints and varnishes. Scope of use: impregnation of plaster, for bricks, aerated concrete, foam concrete, gypsum board. It is not worth using a composition for preparing a surface that does not absorb moisture poorly.

- Antiseptic, for wet rooms. These include the kitchen and bathroom. The composition is supplemented with special substances that prevent the defeat of the fungus. In addition, it is water-repellent and increases fire resistance. After the base has been primed, paint or other finishing is applied. The adhesion is so high that biological microorganisms cannot penetrate into the layers in any way. Excellent composition for wood.

- Anti-corrosion. Used for metal, prevents rust.

- Adhesive and non-contact. This primer can be applied to old paint as it provides maximum adhesion to smooth and non-absorbent surfaces. Adhesion is increased by adding acicular quartz or sand to the composition. Ideal base for heavy wallpaper.

Manufacturers indicate what kind of primer it is. Just look at the packaging. There is information about the consumption, as well as the scope of use.

How to use a concrete primer

Plaster and other finishing materials are applied to the prepared base. The primer is so important because it strengthens the concrete and fills in microscopic pores and cracks. After drying, the compositions have no color, they are applied in 2-3 layers. Wait until the previous one is completely dry before applying.

First, dust and dirt are removed from the concrete base, damage is restored. For repainting, it is sometimes necessary to completely remove the old coating. Grind the primer before applying. You can use any convenient tool:

- Brush;

- Roller;

- Spray.

It is advisable to use a sander to prepare the floors. It will remove the cement laitance from the new base, open the pores. For dedusting, it is best to have a construction vacuum cleaner, but you can do it with the tools at hand.

It is advisable to use a sander to prepare the floors.

Before carrying out work, you need to make sure that the manufacturer's instructions are followed: temperature, humidity, compatibility with other materials. The ripening period of freshly laid concrete structures is at least 28 days under normal conditions. At high humidity, the time increases.

Concrete primers can be prepared by the manufacturer, or the instructions will indicate the preparation method. Dry mixtures must be diluted with water, two-phase components are mixed in the required proportions, alkyd requires a solvent.

The required protective equipment depends on the toxicity. Gloves are required to use water-dispersion primers, and a respirator for polyurethane and epoxy primers.

The ripening period of freshly laid concrete structures is at least 28 days under normal conditions.

Tips and tricks for use

Applying a primer on concrete is one of the simplest stages of work, but even here you can make mistakes, which will then affect the quality of the repair. What should be foreseen?

Primers for concrete from different manufacturers are different, so mixing them is unacceptable. It is also impossible to process the walls in the same room with different primers, especially if you are going to paint or plaster. This is possible only under the wallpaper. It is best to calculate the approximate costs in advance and purchase all materials of the same brand.

In stores, you can find brush, roller and tray “primer kits”. In the open air, the soil quickly loses its quality, so small containers are used. Apply the solution with a brush in hard-to-reach places. A roller is best with a long telescopic handle: no need to step on a ladder. Materials:

- Foam: for solutions with a viscous consistency of the "concrete-contact" type;

- Fur: almost universal;

- Velor: if the surface is very smooth.

Professionals do not advise using a spray gun, but the manufacturer may indicate this method in the instructions. First, special thinners are often required, for example for adhesion primers. Secondly, a very thin layer is applied, and it will take more time for the necessary preparation. In addition, microparticles create a suspension in the air, you need to be in a mask and glasses when performing work.

The primers are colorless, but the room should be prepared in advance as for painting: cover the floors, apply masking tape, if required. Apply a primer from top to bottom or away from you. Long-handled rollers make it easy to handle floors and ceilings.

Primers for concrete from different manufacturers differ, so mixing them is unacceptable.

Primer before painting with water-based paint

Water-based coloring compositions are used for painting ceilings with increased requirements for strength and humidity. An example is the premises of kitchens and bathrooms. The main advantage of such a ceiling is the possibility of cleaning and normal operation in conditions of high humidity. Painting with water-based paint is considered a laborious and complex process, which is best left to professionals.

For self-priming, it is recommended to perform a number of preparatory work:

- Sand the finishing layer of the putty.

- Clean the surface from dust residues with a soft brush.

- In order to better adhere the soil to the base, degrease the base with white spirit or solvent.

- Using a paint roller, after rolling out the product in a special tray - "cuvette", apply the primer to the ceiling in one layer.

The time for complete drying of the primed ceiling surface is 4 to 6 hours. Then the surface is re-treated. When performing work on priming the ceiling, you must use protective goggles and gloves. The room temperature should be from +5 to +40 degrees with a humidity of no more than 75%.

Priming ceilings before painting with water-based paint is a mandatory procedure recommended for uniform staining and preventing paint overruns.

Do I need to prime the ceiling before painting with acrylic paint?

Acrylic paint is a water-dispersed suspension enriched with acrylic components. This mixture, although is a type of water-based paints, in fact, due to polymer components, it differs from other paints in its external silky appearance and excellent performance.

In order for the surface after painting with acrylics to be even and without streaks, it is necessary to apply a layer of primer liquid. The process of applying a primer is similar to painting with water-based compositions.

Among the large assortment of primers for acrylic paint, the primer ST-17 is best suited, which belongs to the group of deep-penetrating impregnations of the popular brand, the flagship in the field of building materials - the firm "Cerrazit". If it is necessary to additionally strengthen the surface to be treated and increase its adhesion capacity, use an adhesive paint - CT 16 primer produced by Ceresit.

Wood floor painting

Wood is such a natural material that without special protection it can quickly deteriorate. It follows from this that the main function of a floor covering is to protect it from rot, high humidity, mildew and mildew. But even this may not be enough. The décor of the house, including the flooring, should please the owners so that they enjoy spending time in it.

There are many reasons for using paint:

- paint prevents the wood from absorbing moisture or drying out;

- painted floors are not exposed to mold or mildew, and this increases their service life;

- painted floors do not require additional maintenance - they are often just enough to wash;

- paint protects the material from temperature fluctuations;

- thanks to paints and varnishes, you can easily make a beautiful and unique pattern.

Benefits of a primed ceiling

The quality of the ceiling finish depends on many factors: here is the skill of the finishers, and the correct finishing materials, and most importantly, the correct production technology. There are no trifles in construction, and if at least one technological operation is missed, or an unreasonable saving on building materials required by technology is allowed, then you can forget about the quality and durability of the repair performed.

The main evidence in favor of the advisability of a primer during repairs are the clear and undeniable advantages of primed ceilings:

- Filling the porous surface of the substrate and binding the remaining dust particles after cleaning.

- Improving adhesion (adhesion) of finishing materials. A slight roughness of the treated surface has a positive effect on the connection of layers of putty, plaster, paint.

- Creation of an antibacterial coating. If the primer contains antimicrobial components, in this case the applied primer will serve as a kind of shield against the penetration of fungal diseases, exclude the appearance of mold and unpleasant corrosion phenomena.

- Increasing the fire resistance of the final finish. The use of special types of primers with additives of fire retardants contributes to the non-flammability of the final finish.

- Reducing the actual consumption by 1.5 times, in general, expensive ceiling paint, which leads to a reduction in the cost of the ceiling repair budget. The thinnest transparent film of the base primer envelops the porous structure of the base and the subsequent surface treatment requires much less putty or paint.

A primed ceiling increases such an important indicator as paint coverage, and after painting, the surface will be perfectly flat and smooth.

Ceiling priming is an extremely important technological process that improves the technical and operational characteristics of the topcoat.

What is a primer and why is it needed

The need for a primer before painting is primarily due to the fact that, despite numerous attempts, it was not possible to develop completely universal coloring compositions that would simultaneously be a persistent decorative coating and at the same time possess the necessary adhesion to the base.

In view of this, in the overwhelming majority of cases, the painting process consists of three basic stages:

- preparation of the painted surface;

- filling small pores and creating the required adhesion coefficient for painting ("priming");

- applying a layer of paint.

When painting porous materials - and this is exactly what wood is - another problem arises - uneven absorption of paint, which increases its consumption, and difficulties arise with the creation of a uniform texture over the entire painted surface.

As a result, we get several answers at once to the question of why a primer is needed:

- To enhance adhesion between the surface to be painted and the paint layer.

- To eliminate the smallest irregularities.

- For clogging up pores that can absorb paint.

- To stabilize the moisture level in the wood.

- And also to prevent the processes of decay and protect against wood-boring beetles.

As you can see, even with the division of "responsibilities" between paint and primer, the latter is assigned too many diverse tasks, therefore, in practice, a separate version of the protective coating is selected for each type of processing.

Why does wood need a primer

Despite the large number of advantages, natural wood also has disadvantages. First of all, it is vulnerability to rot, mold and fungus, as well as insect attacks. To eliminate such problems, deep processing with a primer is carried out. In addition, such a procedure reduces paint consumption, because it makes the wood surface even and smooth.

Purpose of formulations

To make sure whether it is necessary to prime the tree before painting and why it is necessary, you should familiarize yourself with the purpose of the primer compounds. They are used for the following purposes:

- Disinfection. Available types of wood are afraid of moisture and rot. This process impairs the aesthetics of the product and shortens its service life. Prolonged contact with water causes bacteria and harmful microorganisms to appear. It also leads to the formation of mold and mildew. To prevent such consequences, you need to treat the tree with an antiseptic agent. The substance protects the appearance of the material from negative factors for many years.

- Increased reliability. Deep Penetration Primer is a useful substance for strengthening the outer layer of the material. It is used to restore old furniture, staircases, flooring or decorative items. The composition contains special resins that penetrate deeply into the fibers and prevent their delamination.

- Absorption protection. Depending on the varietal characteristics, wood differs in different degrees of absorption of various substances. If you cover it with enamel without first applying a primer, a large amount of paint will be trapped between the pores. The task of the primer is to close micropores and create a smooth surface for subsequent application of paints and varnishes.

- Increased service life. Wood primer forms a reliable protective layer and prolongs the life of wood products. It provides protection against corrosive processes, the negative effects of moisture, mold and other problems.

- Maintaining visual appeal. The tree contains a special substance - tannin. It is a natural colorant that can be released from wood fibers and cause stains that impair the aesthetic appearance.

- Texture and color. A primer for wood for outdoor use is able to give the surface a beautiful texture and roughness. It also emphasizes the richness of paint and varnish compositions, especially if white paint is used for finishing.

Primer benefits

There are many advantages that a paintable primer has. Among them:

- Deep penetration into the pores, due to which the material acquires additional density.

- Reduced vulnerability to moisture absorption.

- Prevention of fungal growth and mold.

- Improving the performance of wood.

Types of decorative coatings

How to paint a wooden porch to get a reliable covering? Paints and varnishes can have not only a decorative function, but also protective components can be used in the composition.

Before buying, it is important to study their properties, color, texture.

Paints and varnishes can have not only a decorative function, but also protective components can be used in the composition.

Paints and varnishes can have not only a decorative function, but also protective components can be used in the composition.

Paints

Various colorful substances are produced, they can have hiding power, or, on the contrary, preserve the wood pattern, creating only a tint effect:

- So outdoor wood preservative paint that creates a new color is better suited to an old building. It will help to hide defects, I will forgive it to close the places where the finish has peeled off;

- The 2nd option is applicable only for the 1st painting of new structures.

Colorful substances are produced in different ways, they can have hiding power, or, on the contrary, preserve the wood pattern.

Colorful substances are produced in different ways, they can have hiding power, or, on the contrary, preserve the wood pattern.

Varnishes and impregnations

Transparent varnishes emphasize the natural grain of the wood, creating a reliable protective film on the surface. But they are not suitable for a single staircase coating. They can be applied to the steps only on top of the paint. A great option than you can paint the railings on the street.

If the house itself in the country house is not painted or covered with facing material, then in order not to create a contrasting porch that will look inappropriate, you can resort to impregnation. They, depending on the type, give a glossy or matte finish. Retaining the natural grain of the wood, making dark areas even darker.

Transparent varnishes emphasize the natural grain of the wood, creating a reliable protective film on the surface.

Transparent varnishes emphasize the natural grain of the wood, creating a reliable protective film on the surface.

Comparative characteristics of dyes for external work

The choice of composition is influenced by cost, service life, consumption. According to these criteria, the varnish has the highest cost, with the lowest consumption. It can last up to 8 years.

Enamels are cheaper than varnishes, about 2 times, but their consumption is much higher, with a service life of 6 years. Oil paints are even cheaper, consumption is about the same as enamels, this coating will be used for 5-7 years. Acrylic products are distinguished by the lowest price, with an average consumption, and the longest service life of up to ten years.

Acrylic products are distinguished by the lowest price, with an average consumption, and the longest service life of up to ten years.

Acrylic products are distinguished by the lowest price, with an average consumption, and the longest service life of up to ten years.

Which composition to choose

In order to make the right choice, you need to focus on the following criteria:

- Color, whether the hiding property is necessary, or whether the texture needs to be preserved;

- The climate of the area, what are the maximum temperature indicators (lowest and highest);

- Humidity. Total humidity, and rainfall frequency.

In order to make the right choice, you need to focus on certain criteria.

In order to make the right choice, you need to focus on certain criteria.

What wood should be protected from

It is known that a tree cannot withstand the influence of natural factors for a long time. And in order for the structure to last longer, it is necessary to provide protection against various types of lesions. These include:

- Various types of natural precipitation, they act on the tree itself, destroying, the wood swells. All this leads to a reduction in the service life of structures;

- Exposure to ultraviolet radiation, leads to a loss of color of the applied dye composition, as a result, the tree dries up. Cracks appear;

- Biological influence, mold and fungus form on the surface from moisture, various insects also like to settle in the tree.

All these negative factors can be avoided by painting the surface with special means, but what is better to paint a tree on the street in order to get protection that will not peel off, this will be discussed below.

The tree cannot withstand the influence of natural factors for a long time.

Soil types

The range of paintable wall primers is varied. By the type of basis, they can all be divided into several groups:

- Acrylic. Versatile, well suited for wood, concrete, chipboard, plaster, drywall, etc. Can be used for porous coatings, dries for about 5 hours, odorless. Does not apply to metals.

- Glyphthalic. The area of application is metal and wood. It dries for about a day, loses its properties in conditions of high humidity.

- Alkyd. A good option for any wood. After processing, the fibers slightly swell, which significantly improves adhesion. Dries about 15 hours.

- Perchlorovinyl. A universal product that is used for plaster, metal, plywood, wood, etc. Dries quickly, it takes about an hour. It is better to choose it for outdoor use due to its high toxicity.

- Epoxy. Two-component agent that significantly increases the adhesion of the substrate. Used for metal and concrete.

- Mineral with gypsum, cement or lime. Used for concrete or brick. Dries from three hours to a day.

- Aluminum.Used for wood. Additionally, it protects it from fungal infection.

The optimal and most popular option is universal primers that are suitable for almost any material. They improve the adhesion of the substrate and strengthen it, but have no special characteristics. However, in most cases, the latter is not required.

Instagram stroydecor777

The primer must be chosen correctly based on the type of substrate

Compositions for coloring wood

Wooden surfaces can be painted with several types of finishing materials. Each option differs in the composition and appearance of the resulting coating.

Paints

Wood paints are consistently popular. They allow the surface to be refreshed but hide the natural texture. If the technology is observed, a coating is obtained that is distinguished by individuality and excellent decorative effect.

The following compositions can be used in the work:

Oil. This variety is rarely used at the moment. This is due to the many negative qualities that the mixture possesses. Among them, a pungent and toxic odor is especially distinguished, as well as a long drying time. The composition is used for painting wooden bases and household products.

Of the advantages of oil paint, one can note good adhesion, high hiding power.

Alkyd enamels. This option, like the previous one, has become less popular, but the demand remains at a good level. This is because the mixture is great for outdoor woodworking. After application, a thin film is formed on the surface, thanks to which it is possible to emphasize the texture of the base. In addition, enamel has low vapor permeability, which reduces the risk of wood deformation when exposed to moisture. They are characterized by fragility.

Alkyd compounds are best used for outdoor use, as they have a toxic odor

-

Water-based (water-dispersed):

- Acrylic. The basis of such solutions is water and acrylic resins, there are also additional modifiers in the composition. Due to this, the mixture is completely environmentally friendly. The area of application is extensive: it can be internal and external surfaces and even furniture. Due to its elasticity, the material prevents the appearance of cracks and damage to the wood.

- Latex. They hide surface cracks up to 1 mm wide, a good option for protecting the coating from the harmful effects of moisture.

- Epoxy. Such mixtures are characterized by a narrow specialization. They can be used to paint coatings that are under heavy loads: floors, stairs, street paths made of boards.

Epoxy coatings are highly durable and resistant to abrasion, as well as to various chemicals and solvents

Thus, to the question: is it possible to paint a tree with water-based paint, the answer will be in the affirmative. It is these products that are considered the most preferable. She not only possesses excellent characteristics, but is also well tinted, which allows her to realize design imagination.

Lucky

When deciding how to paint a tree, be sure to take into account that paint is not the only option, varnish is an excellent alternative. It is a composition based on natural or synthetic resins. As a solvent, various substances can be used that determine the properties of the material. The resulting film can be transparent or change (emphasize) the texture of the wood.

Colored varnishes allow you to imitate a variety of wood species

Several composition options are suitable for work:

- Polyurethane. It is most in demand because it dries quickly and has excellent durability. But due to the presence of a solvent in the composition, it has a specific smell.

- Water. Suitable for outdoor and indoor work.Differs in environmental friendliness, but requires impregnation of the base with a primer. It may take up to 24 hours to dry.

- Acrylic. A modern composition with good decorative qualities. The disadvantage is the high price.

- Nitrolac. Has a low light fastness, suitable for work with inexpensive furniture.

Varnish can be a stand-alone coating or an auxiliary protective coating when applying paint to wood surfaces. In this case, it is necessary to choose the right base in order to achieve the best effect.

Other dye options

These can be the following substances:

- Stain. Allows you to give the wood a richer texture. For example, after treating cheap pine with the right stain, the appearance of a noble oak is created. It can act as a protective impregnation.

- Potassium permanganate. The solution is prepared in a proportion of 50 g of manganese per 1 liter of warm water. The base is well treated with the mixture, if necessary in several layers. If you paint the floors with this composition, they will look like a dark walnut.

Regardless of the material chosen, the surface is covered with a colorless varnish.

What primers are used to prepare wood

Before making an estimate for the purchase of construction "chemicals", we recommend that you pay attention that not all primers on sale are suitable for wood processing. Below are considered the main types of protective and preparatory primers, most often used during the construction of log and log houses.

Below are considered the main types of protective and preparatory primers, most often used during the construction of log and log houses.

Alkyd

They are used in cases where it is necessary to reduce the porosity of wood, reduce the absorption coefficient and prevent the swelling of fibers from excess moisture.

Relevant for untreated wood, ends of log cabins, as well as products from fiberboard and chipboard. They have a pronounced “finishing smoothing” effect. Drying time 12-16 hours.

There are modifications with a special additive that creates a matte surface after drying (used to enhance the color of decorative coatings).

Feature: they contain solvents, the presence of which in residential premises is undesirable.

Acrylic

Indications for use are the same as in the previous version, but unlike alkyd ones, they do not contain hazardous chemical compounds.

They are well diluted with water and have a high drying rate (2-4 hours).

They are used for surface preparation for painting with latex, water-based and alkyd paints.

Shellac

Primers of this type are used to neutralize the action of resins in conifers when preparing their surface for varnish and paints sensitive to the chemical composition of the base.

Often used alone for knot processing.

Antiseptic

Used for wood preservation and prevention of decay processes.

Independent application is allowed (without subsequent painting).

It is recommended to use this primer to treat all wooden products in contact with the external environment, as well as those used for the assembly of particularly critical units (cage, Mauerlat, roof frame, etc.).

The company "Master Srubov" accepts orders for any types of installation, repair and finishing work performed during the construction of houses from timber and logs, baths and utility structures. You can clarify the details of cooperation, as well as make a request for the development and evaluation of the work plan, by going to the "Contacts" section and contacting us at the coordinates published there.

Calculate the cost of painting and insulating your home right now

Do you have accurate measurements at home?

Measured by myself There is a project of the house The measurers came I want to call the measurer

By clicking on the button, you consent to the processing of personal data

How to equip an underfloor water heating system in a wooden house

PPU for thermal insulation of a wooden house

Characteristics and classification of oil impregnations for a wooden house

Domestic sealant Therma-Chink for thermal insulation of wooden houses