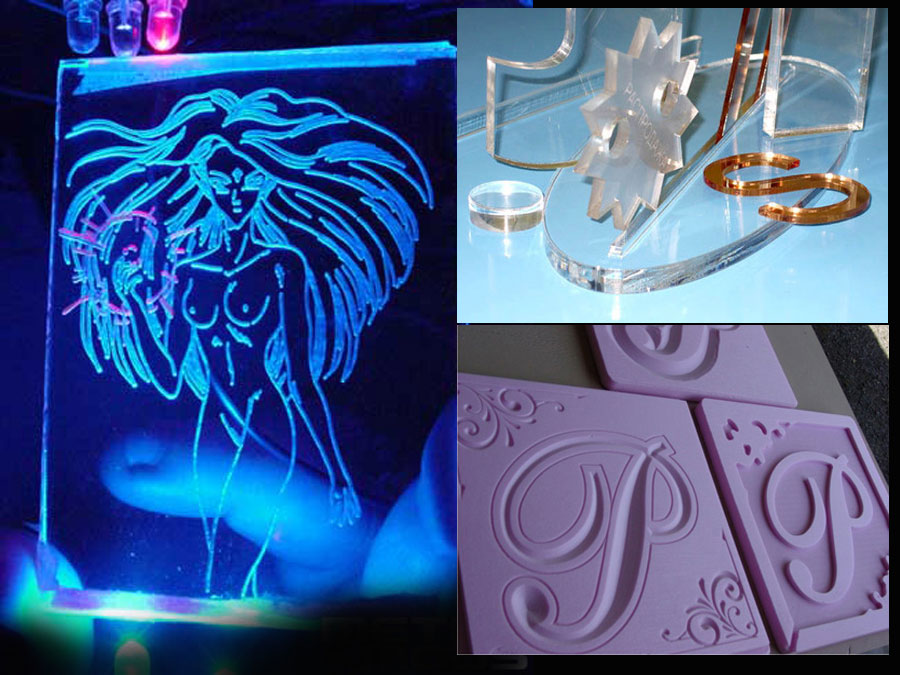

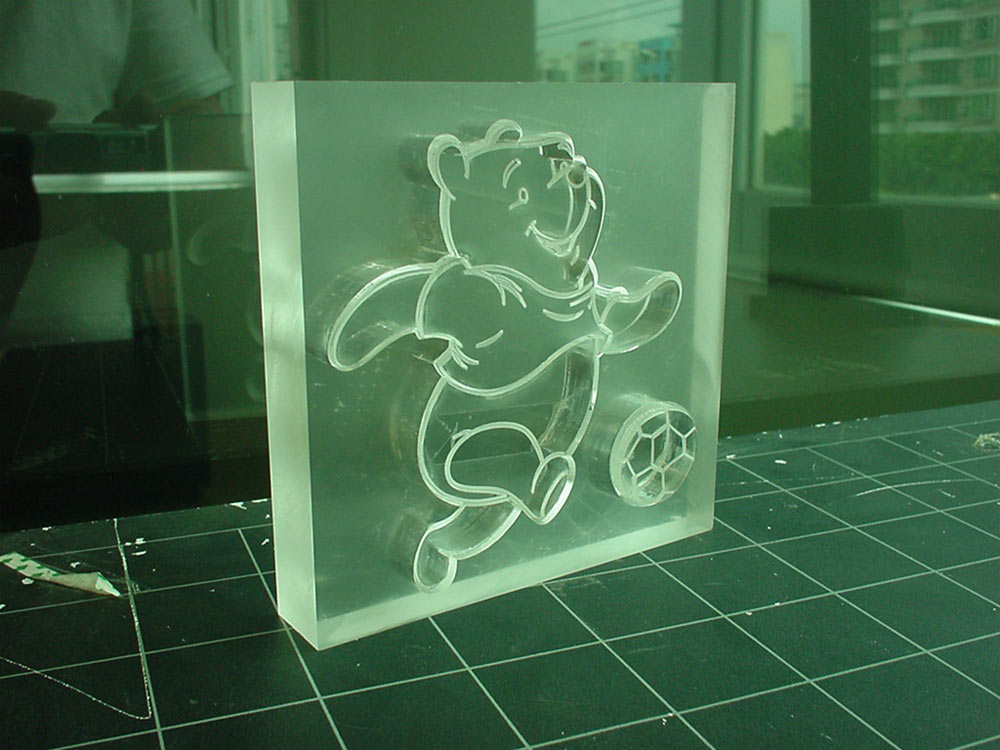

The nuances of the procedure with the addition of backlight

Engraving plexiglass tiles with backlighting is a more complex job, which is best left to professionals. However, if your training allows, you can do this work yourself.

To do this, you need to do the following:

- prepare the material of the required parameters, process the edges of the tiles;

- prepare an adhesive film, apply a sketch to it and glue it to the surface of the plexiglass;

- carefully cut out the contours of future engraving;

- use an engraving machine to apply a pattern to the glass;

- fix on the end side of the lamp or LED backlight, then fix the entire structure in the prepared case.

Plexiglass engraving is a multifunctional solution that is used in various fields of activity. You can engrave yourself by following clear instructions. You can also create a unique design by engraving with backlighting.

Applications

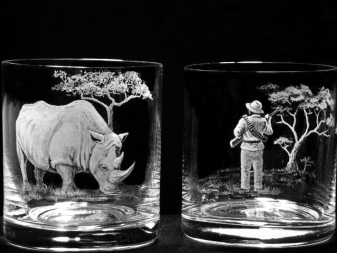

Due to the huge technological capabilities in the creation of various decorative patterns, engraving can be seen both on decor and household items, and on advertising structures. Most often, engraved patterns can be seen on the following items:

- automotive glass;

- lamps;

- interior items;

- glass parts of doors;

- glass cutlery;

- photo frames and glass paintings;

- decorative souvenirs;

- prize items, cups and medals.

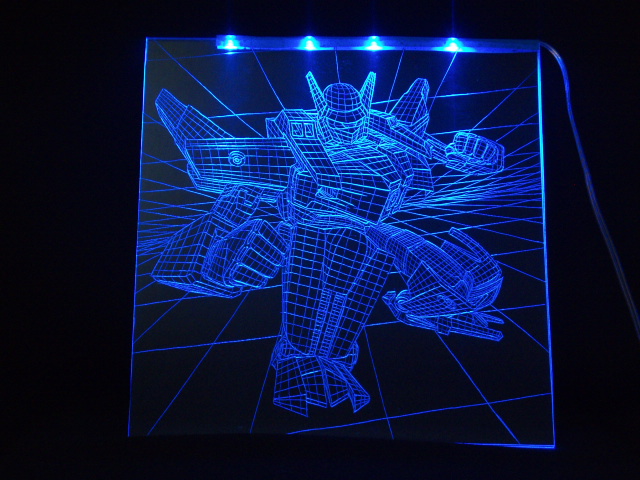

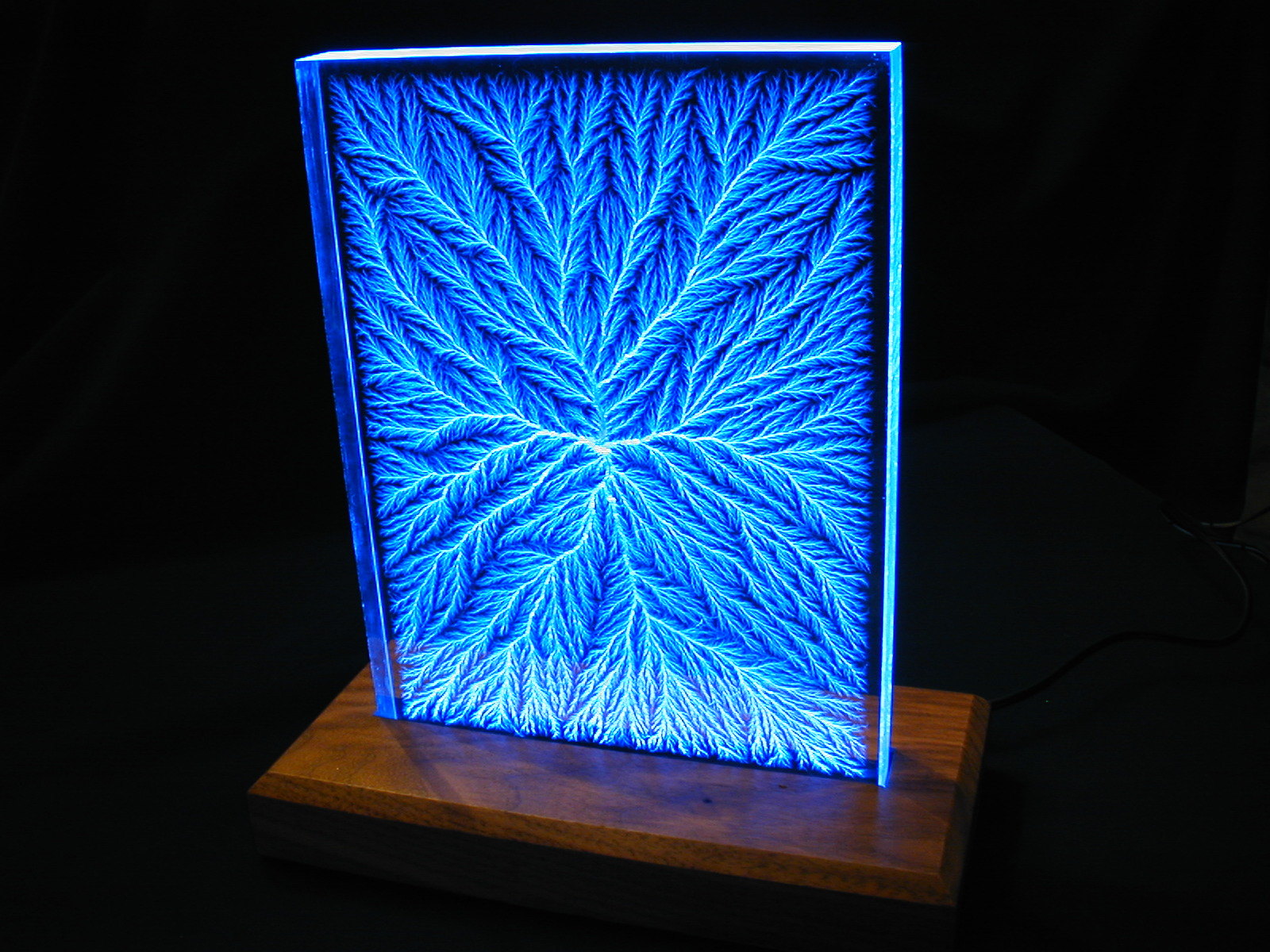

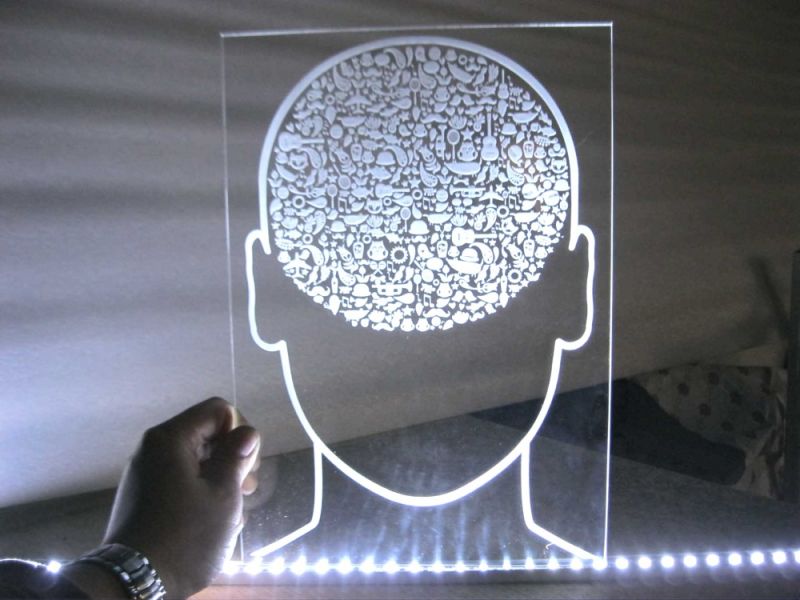

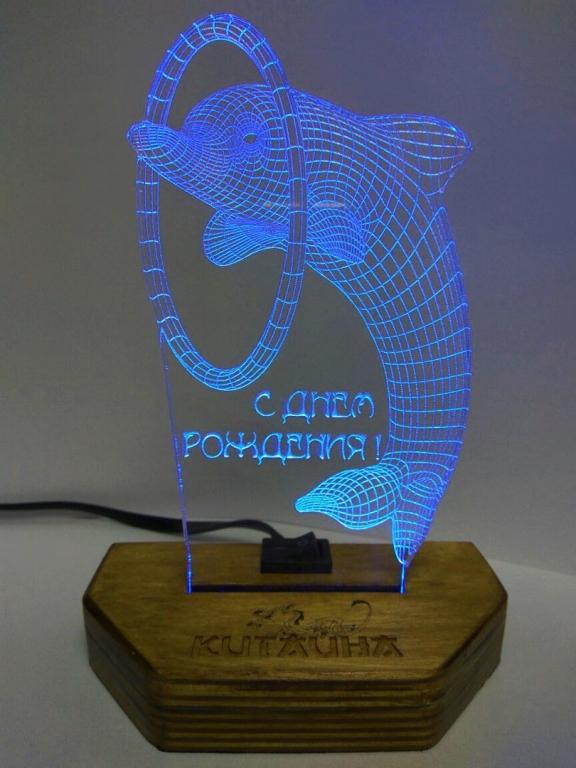

Recently, more and more orders for specialists have been received for decorating signboards, name plates and advertising items, the effect of which can be enhanced by installing additional lighting. Beams of light striking the engraved lines are refracted at different angles to create a dramatic glow.

Engraving technology

Images on plexiglass will look different on artificial glass, it all depends on the technology with which the glass was produced. If glass is made of plastic by casting, then the engraving surface is soft, similar to velvet, but on the surface of extruded acrylic the image will be rough and grainy in structure. By using the engraving depth and beam tilt, you can get quite different and delightful effects in your decoration. For example, images appear with shadows or images with a mirrored image. All this is successfully used when creating signage with volumetric letters or backlit signs.

How to do it?

Modern technological progress provides for both an industrial method of engraving, and the possibility of doing it yourself at home.

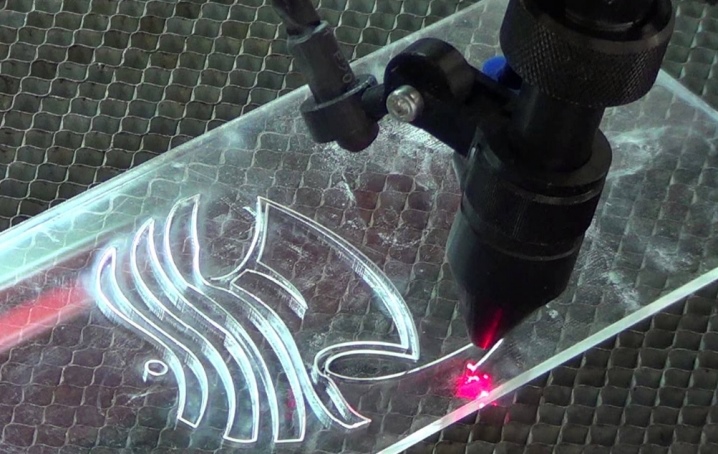

To decorate products, large enterprises use special machines, which, according to a set program, use a CNC laser to burn out a given pattern. Due to the high temperature conditions and software accuracy, all lines have clear and even outlines. The laser engraving method can also be used at home, however, the purchase of a special machine requires large financial investments and professional skills of the master, who must undergo both theoretical and practical training.

Advantages of laser engraving:

- the thickness of the pattern is not more than 0.01 mm;

- the ability to create patterns of any complexity;

- high quality of work;

- drawing a pattern both on flat surfaces and on convex ones;

- full automation of the process.

At home, most craftsmen use the following types of tools:

- electric dremel;

- engraver (drill).

Regardless of the method chosen, there are several techniques for applying the pattern.

- A graphics editor is a program that allows you to transfer an image to film. The resulting image just needs to be fixed on the working surface.

- A plotter is a device for precise construction of layouts.

- A marker is a device that leaves clear lines on the glass. You can apply a drawing either independently or by redrawing a sketch.

To prevent the appearance of defects and damage to raw materials, as well as breakdown of working equipment, novice craftsmen should carefully study the recommendations of specialists before starting work:

- work of the engraver only at low speeds, which will prevent excessive melting of the pattern and the appearance of uneven edges;

- regular cleaning of glass sawdust with special brushes;

- mandatory setting of the line depth limiter, which will help to get a clear and uniform pattern;

- creating a drawing only according to a pre-applied stencil;

- exact selection of the required nozzle;

- obligatory trial engraving on a small workpiece.

It is strictly forbidden to use rags to clean the glass during operation, contact with the glass of which may lead to dullness of the working surface.

For engraving on plexiglass, see the video.

Step-by-step instruction

You can engrave the glass yourself, but this requires following certain guidelines.

Preparatory stage

The first thing you need to do is draw up a sketch of the proposed work. You have three main options at this stage of work:

- Create a project in a vector graphics editor, CorelDraw will do well. Apply the finished layout to the film, which can be done in any advertising agency. After that, the film must be applied to the glass tile and, preferably, secured with mounting tape. You will receive a finished stencil. Before applying the film, spray the glass surface with water from a spray bottle, then apply it and expel any air bubbles.

- A plotter, that is, a device for accurate construction of layouts. You need to put a tile of glass on top of the sketch and translate the drawing. Place the drawing underneath the glass.

The plotter is used to sketch on plexiglass

Typically, engraving is done from the inside of the surface to keep the outside surface smooth.

Application technology

Before starting work, the first thing to do is to put on glasses. They cost less than 150 rubles, and the eyes are priceless. Flying debris can severely damage your eyes. Next, you need to lubricate the flexible shaft and attach it to the engraver. This will make it more convenient to work and reduce the likelihood that the engraver will lead and damage the drawing.

It is better to hold the engraver on a suspension - this is how vibration is smoothed out. Many tools come with brackets / stands for securing. Work with gloves to protect your hands and ensure a smooth glide on the glass surface. It is better to use a professional device - this will increase the quality of the result obtained, and the risk of damage or spoil the work will not be so high.

A special place is occupied by the choice of attachments for engraving work. This is an important point, when choosing, you must clearly understand what result and effect you want to achieve.

Engraver attachments should be selected depending on the type of sketch

There are nozzles that leave thinner lines, there are for coarse application of elements. In almost all works with the presence of several parts, several attachments must be combined in one job. So, for example, using a cylindrical nozzle, in which the working part is made in the form of a pointed cone, you will get a thin, neat line.The boron nozzle with a spherical tip is better suited for rough sketching.

It is recommended to apply the engraving at a minimum speed, because at a high speed, the material can melt and remain on the nozzle, creating additional inconveniences.

Also at low rpms it is easier to control the depth of the lines. In practice, moreover, questions often arise about how to maintain the same track depth. If there is no proper experience in such work, then you can put a limiter, you can make it yourself from trimming the tube.

To engrave plexiglass, use the engraver at low rpm for better control of the engraving depth.

Another topical issue is shading sketch elements, if there are fillings in it. For these works, you can use a whetstone, but you need to work with it filigree so as not to damage the lines, or use a bur, but increase the speed by 60–70%.

The best option for engraving will be movement against the nozzle - from right to left, but here you need to proceed from your convenience, the main thing is that all shading lines are in the same direction.

Before embarking on a responsible project, you should definitely practice on pieces of glass.

Before engraving, you should practice on small pieces of plexiglass to get used to working with the engraver.

The cost of the services provided

The cost of the finished product consists of the costs of developing a layout or drawing, manufacturing and final processing of the product. The cost of the material used in the manufacture of the order. Cutting material: cutting meter from 30 rubles, cutting thick materials or extra strong materials - from 50 rubles for each meter of passage.

Completion of the customer's layout from 500 rubles, development of a model from 500 rubles, a finished model from our database - 50 rubles.

2D processing is calculated from the length of the model vector. The cost of a meter of a vector when milling is 140 rubles, a cut over 100 meters of a vector - a 5% discount.

3D processing of the model is formed as follows: a minute of machine operation is 30 rubles, t is the time spent on roughing and finishing the product. Price = t x 30 rubles.

The company's craftsmen will carry out high-quality grinding, polishing, painting, decoration. Price for 10 cm square: grinding - 2 rubles, painting 1 layer - 3 rubles. (taking into account the material), decoration - from complexity, not less than 30 rubles.

3D CNC milling in Moscow and Moscow region:

metal, wood, plastic, facades + 7 (915) 009-00-50

Laser engraving process

Plexiglas engraving is always applied from the back of the acrylic plate, since it is more convenient to view the entire front side, where the carved image is obtained.

The process begins with removing the protective layer from the side of the surface on which the image is planned to be applied. On the front side, the engraver leaves the protective layer intact so as not to accidentally damage the surface. The layer is removed from the workpiece material with a focused laser beam at the highest power. This process is the reason for the appearance of the planned image; it is based on raster technology, when the laser beam burns not lines, but points.

The image on the surface is obtained by correct control of all parameters of the laser radiation. The quality of the image depends on the properties of the substance in the material on which the drawing is applied.

Hand engraved organic glass

Not always engraving can be carried out on a machine, if there is a special tool, then engraving can be done at home. For do-it-yourself engraving, you need an "engraver" machine.

Before starting the DIY engraving process, watch the video about the engraving machine. The process itself will be easier if you follow it in stages according to the instructions:

- Prepare a sketch, if you do not have the talent of an artist, then look at the pictures in the photo, maybe this will help your imagination.

- The prepared drawing will need to be copied onto the plexiglass surface. With this, everything is simple: plexiglass is placed on the image and a picture is drawn using a felt-tip pen.

- Work on the device is carried out using a flexible shaft, it adjusts the cutting part of the mechanism.

- Engraving is carried out by the cutting part of the nozzle, which can be different, depending on the pattern.

- For the process to go well, you need to "rehearse" a little on the remnants of plexiglass. Thus, you can choose the right attachment for your drawing.

- Just as with machine engraving, you do not need to work at high power, you can damage the surface of the product.

- The whole process boils down to the fact that the nozzle is drowned to the planned depth.

- Of course, an experienced craftsman will be able to keep the nozzle at the same level, but a beginner will have to make a limiter using a plaster or electrical tape.

- During the process of engraving, dust will accumulate on the surface, you should not clean it with a rag, you can scratch the surface, so use a vacuum cleaner.

All decorative images obtained on the glass can be decorated with edge lighting. Plexiglas for backlighting should be of considerable thickness. The design with LEDs is easy to make, you just need to connect the wires to the crossbars of the bracket, and fix it all on the back of the plexiglass.