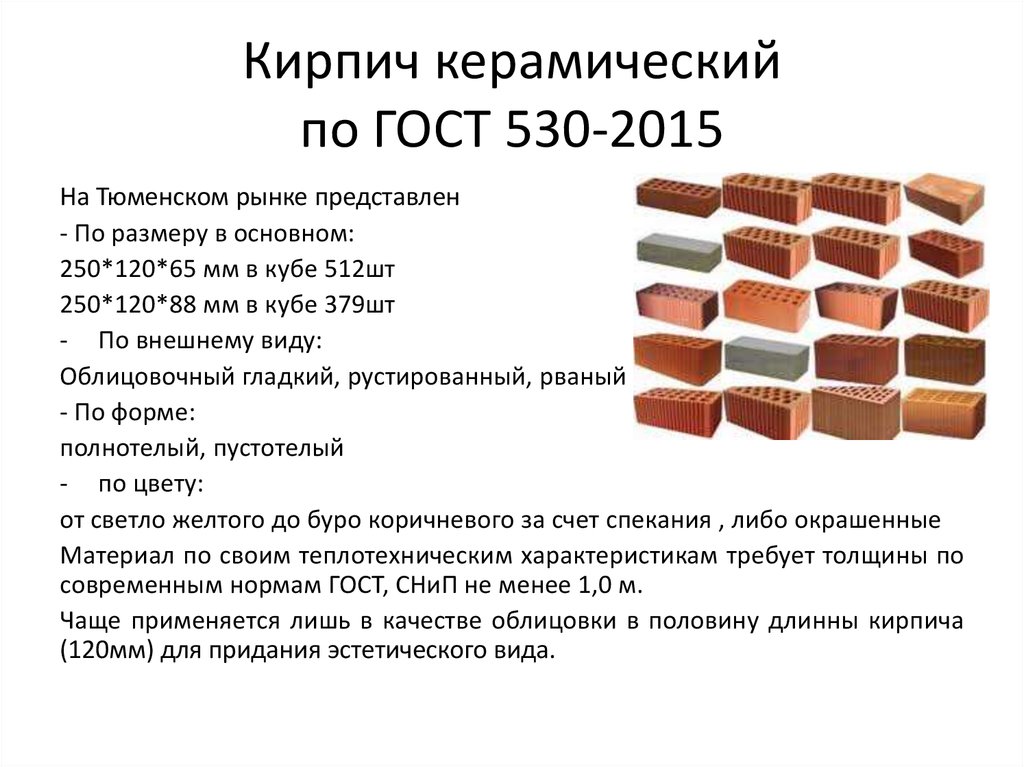

Required documents for ceramic bricks

When choosing a building material, the buyer must make sure that the bricks comply with generally accepted technical standards. For this, there are special documents in which all the necessary information is spelled out in detail:

- certificate of technical conditions or TU;

- Gost certificate.

If the manufacturer has all the documents that the buyer can familiarize himself with, you can be sure of the quality of the building material being purchased.

What should be included in the content of the document? Any manufacturer draws up a technical certificate based on the following points:

- technological process of brick production. It should indicate what is included in the mixture, as well as the scheme for making the material;

- product safety, that no radioactive substances were used in its manufacture and the brick is safe and environmentally friendly;

- environmental friendliness of the material guarantees environmental protection and will not harm it;

- production quality control of products and instilled reception. It describes how only manufactured bricks are tested in order to assess their quality;

- technical data on how the material should be transported and stored;

- in what areas it can be applied;

- manufacturer's warranty.

Taking into account the general rules for drawing up that, the manufacturer has the right to independently draw up this document and, at his discretion, indicate the characteristics of the brick. Therefore, there is no guarantee that the manufactured ceramic bricks meet the standards. To be on the safe side, the buyer is obliged to make sure that the manufacturer has a gost certificate.

Therefore, there is no guarantee that the manufactured ceramic bricks meet the standards. To be on the safe side, the buyer is obliged to make sure that the manufacturer has a gost certificate.

Carefully studying the GOST certificate, make sure that it is issued specifically for the products you need. The first three digits indicate the name of the product, the rest indicate the year in which the document was issued.

Certificate

GOST 530 for ceramic stone and brick meets the requirements that were adopted in 2012. And it looks like this.

- document number and its validity period;

- the name of the body that certified the products;

- a complete listing of the products that have been studied with a full description and technical specification;

- what exactly does the ceramic brick meet according to GOST;

- full name of the manufacturer of the product;

- to whom this document is issued;

- description of the documents on the basis of which the certificate was issued, research protocols;

- stamp and signature of the person in charge.

Recommendations

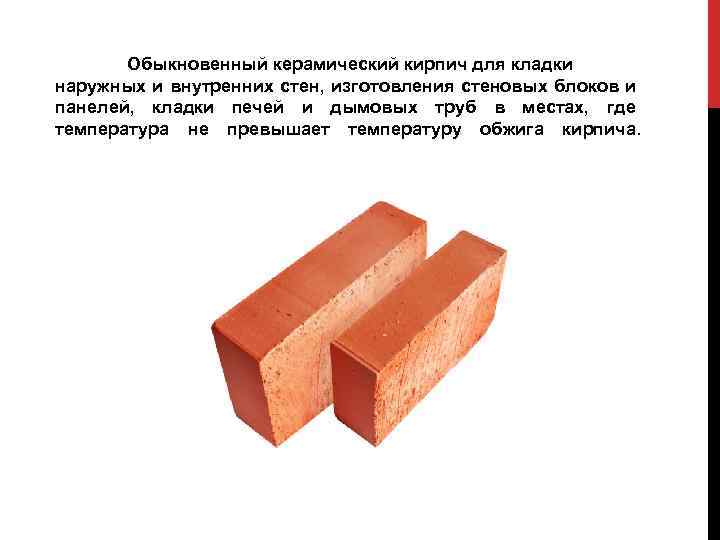

No matter how our life changes, solid red brick is of great value in the construction business. And today it is practically irreplaceable, being a universal building stone, which has the following advantages:

- traditional application - for many years it has remained unchanged in the construction of houses all over the world;

- environmental friendliness - its production is based on pure clay and sand and no more impurities;

- strength - according to this indicator, it is equated to natural stone, therefore, buildings of a kilometer height can be built from its full-bodied appearance;

- long-term stability - the service life of brick houses is quite long - 100-150 years, which we can see for ourselves on buildings that have come down to us from past centuries;

- fire resistance - ceramic bricks are non-flammable;

- low water absorption - it does not exceed 6%, moreover, it dries quickly, providing a favorable environment;

- comfort - the structure of red brick creates natural air conditioning in the room, which has a positive effect on the microclimate in it;

- high operational capabilities - brick houses stand for a long time without major repairs.

This is how it is, a red (ceramic) brick. And in order not to miscalculate when buying this building material, along the way, use a few tips:

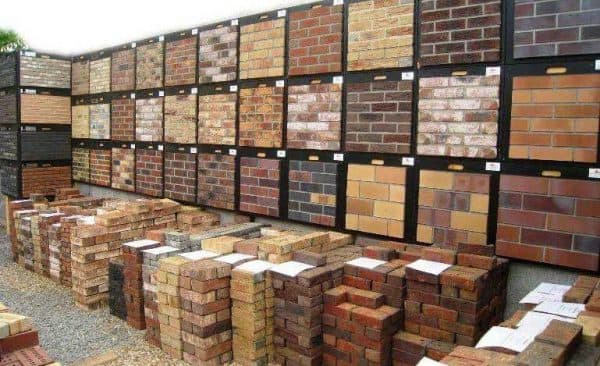

- buy a brick in early spring, before it starts to rise in price, but in winter this should not be done;

- never forget about the certificate or quality certificate for this batch of the product;

- do not buy in a hurry, but make sure that you take exactly the brick that you need;

- if you need an ordinary and facing stone, purchase it of the same brand, this will ensure the uniform strength of the wall being erected;

- try to calculate in advance the required amount of facing bricks in order to buy it from one batch, in order to avoid the difference in color shades.

Basic standards GOST 530 2012

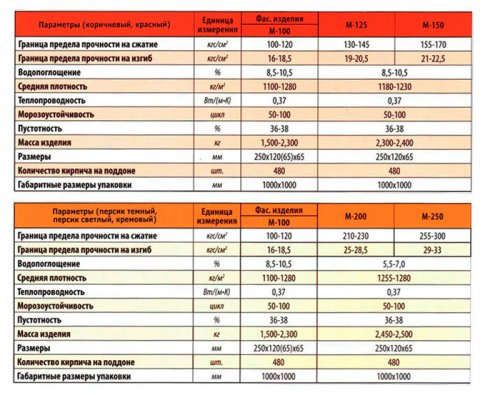

Here are the main provisions of the GOST characteristics for bricks.

The density of the stone largely depends on the density of the class to which the building material belongs.

- 0.7 - up to 700kg / m3;

- 0.8 - up to 800kg / m3;

- 1.0 - up to 1000k / hm3;

- 1.2 - up to 1200 kg / m3;

- 1.4 - up to 1400kg / m3;

- 2.0 - up to 2000kg / m3;

- 2.4 - up to 2400kg / m3.

Permissible deviations in product density for the class: 0.7, 0.8, 1.0 no more than 50 kg / m3. For other classes, no more than 100k / m3. As for the characteristics of thermal conductivity, they are estimated by the coefficients of masonry in dry mode. The strength grade of the brick depends on the possible compression and bending of the product.

Specifications

The moisture absorption of ceramic bricks can only be within the appropriate limits - no more than 6%. The initial water absorption of the product should be between 0.10 kg (m2 * min) - 3.00 kg (m2 * min). As for the facing bricks for the facade of the building, there are no restrictions.

There should be no damage such as cracking, crumbling, flaking and chips.

The coefficient depends on the values indicated by the manufacturer from 25 to 300. Ceramics is recognized as a non-combustible material, therefore, it must comply with this. The value of the specific radionuclide activity should not exceed 370 Bkkg

With regard to the methods of testing the quality of ceramic bricks, they are also spelled out in the Gost standards, and take into account a number of requirements that the test specimen must withstand in order to meet the quality.

All test results are indicated in the relevant documents, which are submitted for making an opinion on the quality of the brick under study.

Here are some points:

- compliance with the declared size: length, thickness, height;

- if the product is hollow, then the conformity of the dimensions of the voids is acceptable during production. To determine the size of the voids, at least three cavities are measured and the largest value is recorded.

Decoding of marking

The strength and density of red and silicate bricks is determined in accordance with GOST. Quality control and determination of strength is carried out by a special method using the example of a selected 1 stone from a batch. It is designated as a brick marking. Red brick marks are written using an alphanumeric system:

| Designation | Peculiarities |

|---|---|

| M75 | Weak strength |

| Low price | |

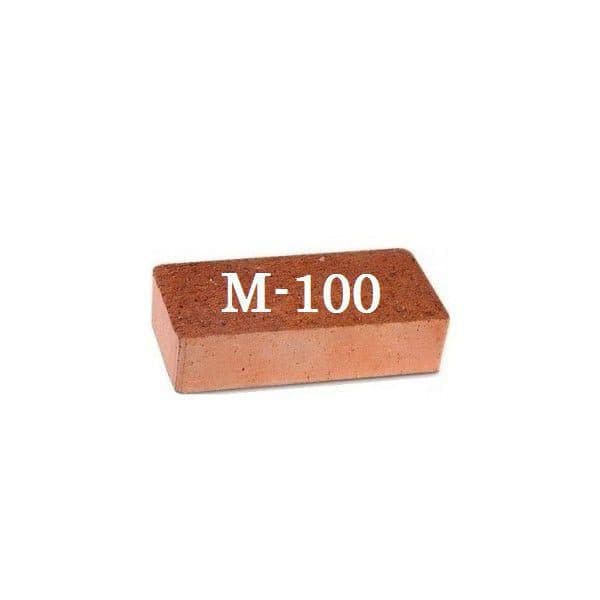

| M 100 | Durability allows building up to 3 floors and uncomplicated construction |

| Low cost | |

| M125 | Ordinary clay brick |

| High strength of bricks, construction of buildings up to 3 floors is allowed | |

| Construction of partition columns |

The M150 marking is more durable and is represented by the following types of building stone:

- Private 1nf 150. It is used in the creation of foundations, plinths, walls for high-rise buildings.

- Double. It is used for masonry of load-bearing walls, as it is distinguished by its high strength.

M200 and M250 brands of ceramic bricks are similar in characteristics, the difference is small in the ability to withstand the load. The first takes out 200 kg, and the second 250.And also have high water resistance. The following types are used in construction:

- Brick cr. It is used for load-bearing walls of multi-storey buildings, strength foundations.

- Facing. It is used for decorative paths.

M300 brick strength grade is considered the most expensive. Differs in durability and strength, it is also called non-destructive. Often used only in the form of solid bricks, less often hollow bricks. Sometimes builders use it instead of refractory for laying stoves, baths, fireplaces. Also suitable for exterior walls and basement construction.

Production and properties of technical bricks

In many ways, the technical indicators of product quality depend on production methods, so it is worth paying attention to this point as well. Each manufacturer uses its own method of producing ceramic bricks

There are two popular production methods:

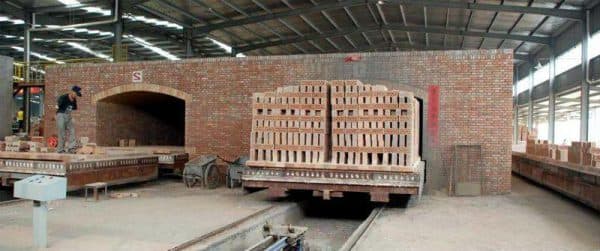

- plastic. When using this method, a plastic method of forming a brick is used. In production, clay is used, the moisture content of which should be no more than 30%. The bricks are formed on special equipment, and then they are sent under the belt press;

- when the pressing process is completed, the product is sent to a special furnace for subsequent firing. This is how ceramic bricks are made;

Kiln firing

semi-dry method. Here, a press is used to shape the future brick. Clay is used as a raw material, its moisture content should not be higher than 10%.

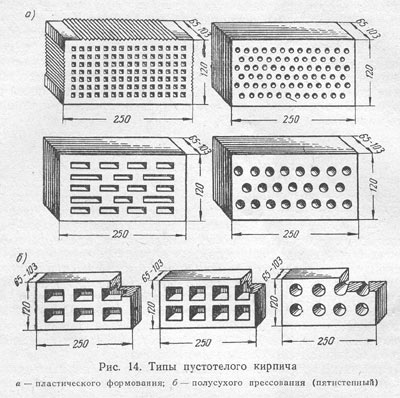

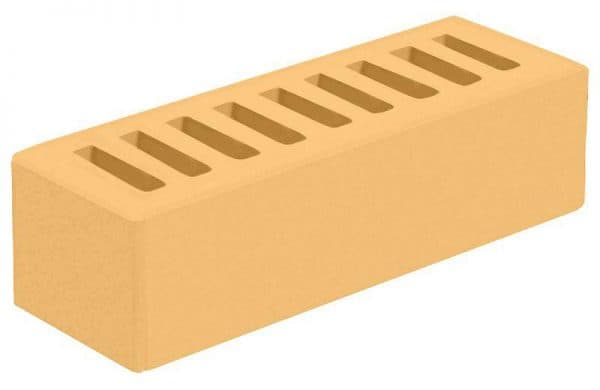

Classification - hollow and corpulent

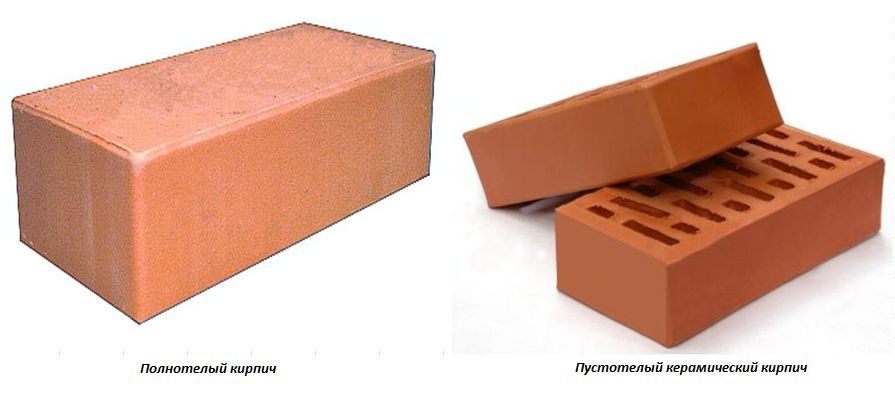

When choosing a ceramic brick, you should decide which type you need. The buyer can choose from a number of possible options:

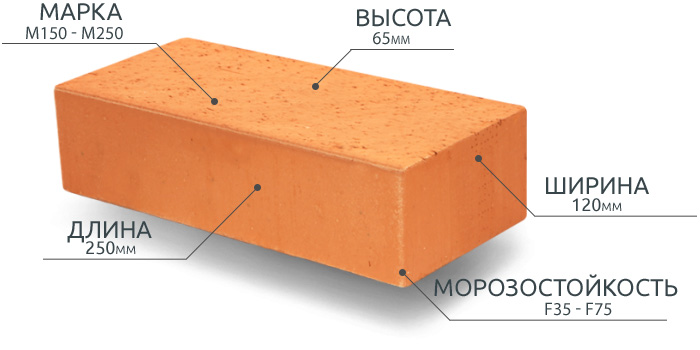

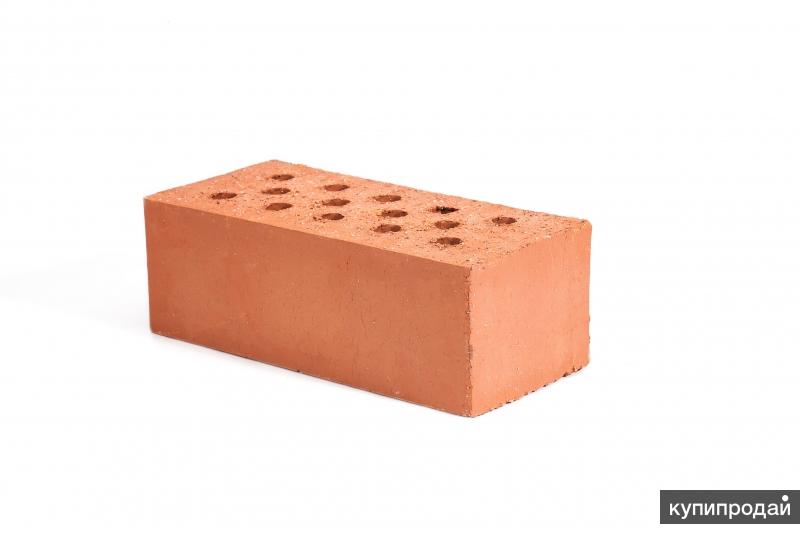

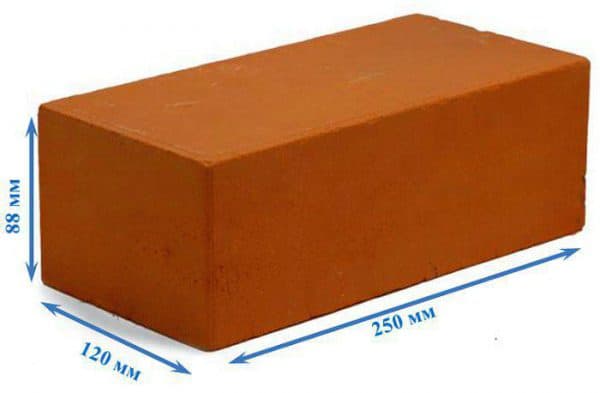

solid brick GOST 530 2012. Here is its size;

Corpulent

hollow brick GOST 530 2012.

Hollow

The weight characteristic is of great importance during construction. Therefore, more and more construction companies are using a variant of hollow ceramic bricks in building, with the same characteristics as those of a corpulent one.

Varieties and application

Depending on the purpose and characteristics, the following types are distinguished, which are presented here:

| Type of stone | Brick characteristics | Application |

|---|---|---|

| Corpulent | Small void volume, less than 13% | Foundation |

| Conducts heat well | Column erection | |

| Product weight 3.5 kg | Ground floor | |

| Hollow (poo) | Holds voids up to 50% of the volume | Strength buildings |

| Less durable than corpulent, but warmer and lighter | Wall masonry | |

| Has good sound insulation | Multi-storey buildings | |

| Facing | Has no bundles | For walls with ideal surfaces |

| Cracks excluded | Indoor finishing work | |

| Smooth shape | ||

| Glossy finish | Buildings of internal structures | |

| High price | ||

| Figured | Custom form | Round column construction |

| Various colors | Arches | |

| Interesting relief | Ornamental decorative elements | |

| Clinker | High frost resistance from F100 to F 300 | Pavement of roads |

| Large selection of colors | Construction of sidewalks | |

| Chamotny | Withstands temperatures up to 1800 degrees | For buildings that will interact with fire |

| Strength building |

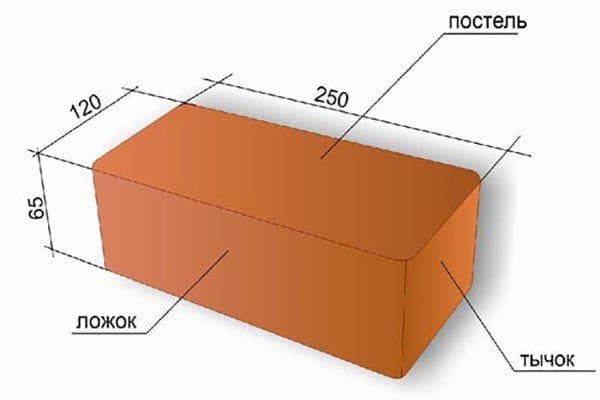

Brick dimensions according to GOST - height, length and width

Modern construction does not stand still. With the growth of requirements for the construction of houses, the range of brick sizes has also expanded:

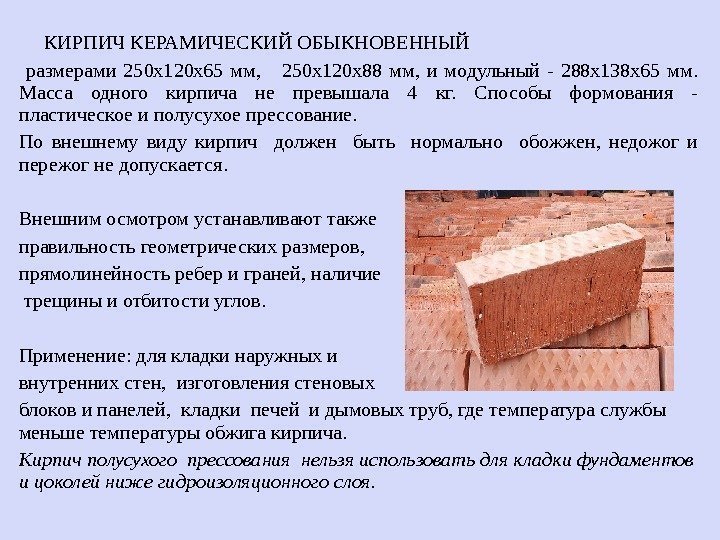

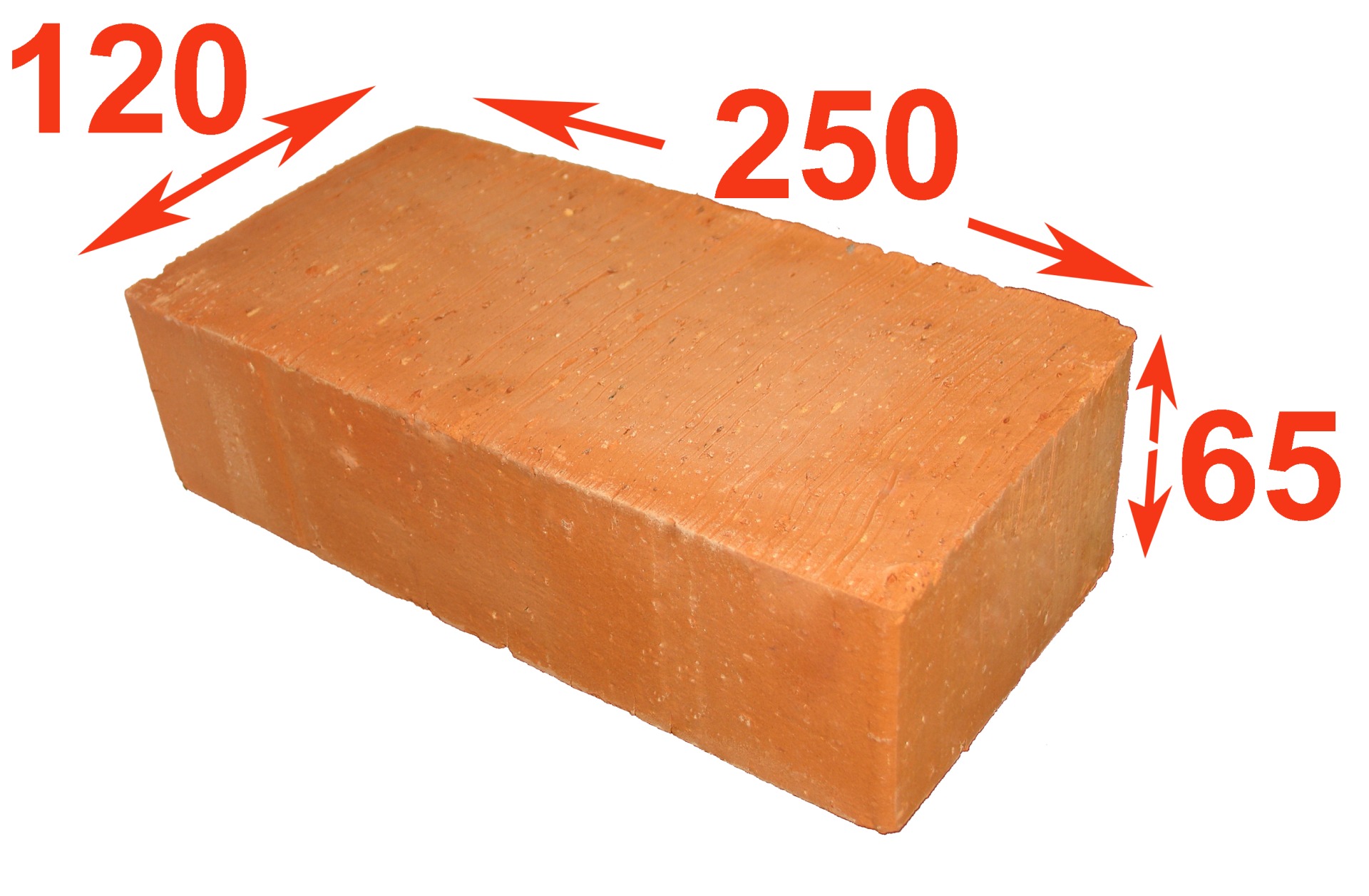

- Single - 250x120x65 mm (fixed by GOST 530-2007). According to the European marking, they have the RF designation.

- Double - 250x120x138 mm.

- One and a half - 250x120x88 mm.

- Modular - 280x130x80 mm.

- Euro bricks h - 250x85x65 mm.

The most popular in Europe are bricks NF (normal) - 240x115x71 and DF (thin) - 240x115x52, less common sizes - 250x85x65 mm and 200x100x50 (65). Today you can buy material up to 500 mm long. The choice of standard sizes is growing every year.

By shape, bricks are divided into:

However, in addition to basic dimensions such as height, length and width, permissions for deviations from the norm (defects) are also used. Their size depends on the type of building material - building or facing. The latter is subject to more stringent requirements, since the aesthetics of the building depend on its characteristics.

For building solid bricks, it is allowed:

- The presence of dullness and chips of ribs and corners no more than 2 and no more than 1.5 cm along the length of the rib;

- Curvature of edges and edges up to 0.3 cm;

- On the lateral longitudinal (spoon) edges, a crack up to 3 cm long across the width of the brick is allowed.

For a construction hollow version, it is allowed:

- No more than 2 bumps on corners or edges 1-1.5 cm long, provided that they do not reach the voids;

- Full thickness cracks in the bed. In width, they can reach the first row of voids;

- One crack on the butt and spoon (transverse lateral) faces.

For facing bricks it is not allowed:

- Chipped corners, the depth of which exceeds 1.5 cm;

- The presence of cracks;

- Broken ribs, the width of which is more than 0.3 cm, and the length exceeds 1.5 cm.

In this case, a facing material that has:

- No more than 1 bit of corners up to 1.5 cm deep;

- Separation of handwriting, which in total does not exceed 4 cm in length;

- No more than 1 broken ribs, in depth - not exceeding 3 cm, and in length - no more than 1.5 cm.

The architectural concept often involves the use of different textures and colors. The modern choice of building materials is almost limitless. If desired, you can combine artificially aged, variegated and textured options in the masonry without compromising the durability of the house.

One-and-a-half and double bricks are mainly produced as hollow bricks. This helps to reduce the weight of the structure.

The most popular in modern construction are large-sized porous blocks. Ceramic bricks are lighter and warmer than conventional construction options. Its use allows you to simplify and speed up construction, while reducing the consumption of masonry composition.

For laying 1 m 3, 512 single-type bricks are required, and one-and-a-half 26% more - 378 pieces.

The main differences

The standard distinguishes between two types of this product (brick and stone), several grades (in terms of compressive strength and frost resistance) and classes (in terms of density and heat resistance). These numbers, as they increase, indicate better product quality compared to a lower brand or class.

So, for example, the number in the frost resistance marking means the number of freezing procedures followed by thawing, which a brick of this type soaked in water must withstand without signs of destruction. Accordingly, the higher the class and brand of ordinary clay brick, the higher the price for it.

The division of products into bricks and stones depends on their size. The former are rectangular parallelepipeds in shape with a size denomination in a single version of 250x120x65 mm, and the latter are products of a larger format with a thickness of 140 mm and higher. At the same time, clay brick is produced corpulent or hollow, and the stone is only hollow.

The voids in them can be both vertical and horizontal. The production of stones is possible with a polished or unpolished bed (support face), with flat vertical surfaces or with projections on them for tongue-and-groove joints.

Based on the purpose of this building material, it can be ordinary, it is he who is most often called construction, or front. The latter type includes facade brick and stone, as well as those intended for cladding or decoration. A special variety is considered to be material for the construction of furnaces.

Features of choice

To prevent unnecessary waste of money and make a profitable purchase, it is necessary to pay attention to the following points when choosing a brick

- Product appearance.The brick should have a uniform color, which indicates that it is not overdried.

- Products should not have mechanical damage on the surface. No more than 2-3 percent of such bricks in a batch are allowed.

- All goods must be packed and certified.

- It is worth refusing to purchase products from unverified manufacturers.

As you can see, GOSTs are important not only for manufacturers, but also for buyers. If the latter have the necessary information regarding a particular product, this will allow them to avoid purchasing low-quality material.

You will learn how to choose a brick in the next video.

Let’s block ads! (Why?)

Classification of bricks by frost resistance

Frost resistance of a brick determines its ability to withstand the effects of temperature changes. In the water-saturated state, the brick is subjected to sequential freezing and thawing tests. The frost resistance index Мрз is measured in cycles. This indicator is measured by alternately immersing the brick in water for 8 hours, and then in the freezer for 8 hours. When the brick starts to break down, the cycles stop.

For regions with harsh winters, bricks with a frost resistance of at least 35 cycles are used. The higher this indicator, the better. Such a brick has a correspondingly higher price, but during operation it will not bring surprises.

Varieties

Brick today is presented in several forms.

- Private. Ordinary brick with standard dimensions, which does not have voids inside. Its cost is affordable, it is used for the construction of various structures.

- Corpulent. There are a small number of voids, the total volume of which does not exceed 13% of the volume of the product itself.

- Hollow. It has voids of various configurations in the body, which can be through and non-through.

- Facade. Presented in different forms, it is used for facades.

- Clinker. Differs in high strength, does not absorb water. It is used as a decorative material in landscape design. Dimensions are the same as for a standard product, but if necessary, it can be made in other parameters.

- Facial. Refers to decorative materials, but its characteristics are not inferior to ordinary brick. Meets all requirements for strength and other indicators.

- Ceramic stone. A ceramic product that has many voids inside and differs from ordinary brick in its large size.

Manufacturing features

Production methods are divided into such as:

- semi-dry pressing;

- incomplete firing or only heat drying;

- baking of clays and their mixtures.

Clay without impurities is rarely found in nature. Products made from too oily or, conversely, skinny clay will be fragile. Correct proportions are very important to obtain a quality building material. The manufacturing process has the following algorithm: the prepared clay mixture is placed in molds, then the brick is dried (from 6 to 15 days). At this stage, the production of raw materials ends. Firing bricks in special ovens at a temperature of 900–1000 ° C will turn clay into ceramics. The melting time and temperature depend on the brand and class.

In artisanal conditions, you can also do kiln from an iron barrel, which is installed over a pit with firewood for a furnace. Place the raw brick in the barrel, leaving gaps between them for better baking. It should be heated with a fire made under it for 20-22 hours, then about 6 hours the barrel should cool down on its own. Extract finished products.

Equipment for the organization of a mini-brick workshop

The machine for making bricks at home can be safely called the technical base of the enterprise. The use of such a device automates the workflow, simplifies it for the master and saves time.

You can buy a new machine for an average of 45-150 thousand rubles. (Bricks, Titan 80-450 PPSH, SK-1, SP20 Hammer 1, SpetsRemZavod, etc.). Prices for used devices start at $ 8,000.There are machines of different sizes and functionalities for creating different types of bricks: lego (by the method of semi-dry pressing without firing), facing, raw bricks. They have high performance, are compact, do not require electricity and quickly pay off. It takes about 5-10 seconds to make one product; in an 8-hour shift, it is really possible to make more than 1,000 units. The cost of 1 brick with dimensions 250 × 125 × 65 is 5-8 rubles. a piece. If you have an investment, it is advisable to purchase a brick machine with electronic sensors. The pressure should not be less than 130 kg / cm², and the thickness of the matrix walls - 2 cm. Many models of such devices are multifunctional and, in addition to bricks, can produce other products: tiles, cinder blocks.

There are many types of bricks, you can find out about this and see each of the types by writing on our website at. In this article, we will acquaint you with the most famous and popular types among builders, these are:

- is the most common and is made from lime and sand. Because it does not retain heat well and does not withstand moisture at all, it is used when erecting partitions and walls inside a room. After pressing, this type of brick is subjected to autoclaving (supply of hot steam under pressure).

- obtained by firing various clay mixtures in kilns at high temperatures. It is used everywhere, from foundations to wall cladding in construction, when laying stoves, indoors and outdoors.

- used for decorative purposes and as paving slabs.

- Refractory, capable of accumulating and slowly giving off heat, therefore it is used in the construction of furnaces.

- There are also e and hollow, double and clinker (they are the most durable because they are fired at higher temperatures than ceramic).

In the manufacture of pressed bricks, a brick press is used. If someone is interested in seeing or getting acquainted with the press device, you can watch a video on working with a brick press.

In the distant past, a brick production technology was developed. You can buy it today in different types, shapes and colors. But, many builders were interested in the question: “How to make a homemade pressed brick with your own hands?

". Everyone would like to have a unique material of their own design and cladding. Not every brick made in factories can be made at home. High cost and complex technological processes are a hindrance.

But, there are craftsmen who have developed a technology for making even silicate with their own hands at home.

Specifications

The aforementioned GOST has been applied since 2013 and includes the following building materials:

ceramic stones and bricks used for building walls and facades;

Ceramic

clinker bricks are used in the construction of the foundation and reinforcement of walls, on which a significant load is planned. Here is the size of the red brick for the foundation;

Clinker

oven brick. Here is its size.

Stove

Also, the established standards divide bricks into characteristics:

the purpose of the material. There are ordinary and facing bricks. The first is used when erecting walls with subsequent cladding with another material;

Private

facing brick is used only for finishing the external facade of the walls. Here about this brick. The color and texture of the brick building material does not matter;

Facing

- the new GOST contains separate standards for solid and hollow characteristics;

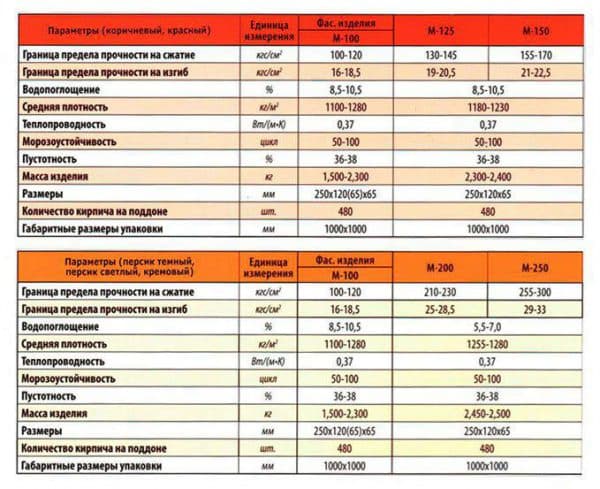

- technical characteristics of ceramic bricks GOST 530 2012 also include differences in compressive strength from M100-M300. This characteristic indicates the ability of a brick to withstand heavy loads;

M-100

- The F number indicated in the document indicates resistance to sudden changes in temperature and the number of cycles that a material can withstand from 25 to 300.But these figures are not always limiting, some manufacturers, thanks especially to technology, can achieve frost resistance up to 1000 cycles;

- the standard also indicates the density that each product must comply with. All bricks are divided into a number of heat engineering groups. Their characteristics start from highly efficient ones, the density of which is 0.7-0.8, to low-efficient ones, with a density of 2.0-2.4;

- must comply with the dimensions of the brick. Only minimal derogation is allowed.

Here are some of the types:

dimensions of a single brick - 250 * 120 * 65;

Single

euro brick - 250 * 85 * 65;

Euro

the size of one and a half thickened - 250 * 120 * 88;

One and a half

modular single - 250 * 138 * 65.

The names of each side of the brick and its purpose with characteristics (spoons, poke, bed) are also described.

Names of the parties

As for the weight of the product, there are no restrictions or standards here, everything is left to the discretion of the manufacturer, and depends on the materials used in production.

Here are its pros and cons. As for defects, there should be a minimum number of them, for example, the presence of cracks in the facing brick indicates a marriage.

Defective

If we take into account an ordinary brick, then there can be only two of them, otherwise the quality of the future structure is significantly reduced.

Any organization accredited by Gosstandart can issue a certificate of conformity to the Gost standard.

For more information about the characteristics of ceramic bricks, see the video:

Application

In the construction of load-bearing walls and structures, single solid brick is mainly used. Its dimensions are standard - 25x12x6.5 cm. In these products, made according to accepted standards, the porosity of the material is only 12-13%.

Building walls

And this ensures excellent strength of all structures erected with its help.

Arrangement of a fireplace

By the type of manufacture, this type of building material is divided into red (ceramic) and white (silicate). The first is the product of firing pressed clay briquettes. Its application is universal:

arrangement of foundations;

Laying the foundation

- erection of walls, partitions;

- construction of fences;

Fence construction

laying of stoves, fireplaces.

This multipurpose use is ensured by the high strength of this material. It seems that there is no need to convince anyone of this once again.

It is subdivided into two types:

construction, or, as it is also called - wall, basement, masonry, clay or private;

Private

facing.

Facing

The size of the clay brick is indicated above, which corresponds to GOST 530-2007 "Bricks and ceramic stones". The stone that provides the operational characteristics of the masonry is an ordinary full-bodied brick. Its dimensions, quite understandably, are no different from the standard ones.

They are designed so that the material can be easily picked up by hand and does not create any difficulties for the bricklayer during masonry.

So cracks and small cracks on this building material do not yet indicate its poor quality. Everything, as they say, is fixable. Clinker bricks, which are mainly used for cladding work, have low water absorption and high strength.

Hollow clinker

It belongs to hollow stones and is used for decorative finishing. But with regards to the red solid brick, it is still more reliable. Therefore, it is used for more demanding work.

The red brick filled inside, in addition to everything, can be smooth and rough, which is good for decorative plaster (its reliable adhesion to the working surface is ensured).

And it got accustomed so well that it is not just used until now, but is gaining more and more momentum in application. Now you can find several varieties of one-and-a-half bricks, including hollow porous, perforated and others.

Dimensions and weight according to GOST

Standard sizes of single, one and a half and double products:

When designing buildings and structures, all characteristics are taken into account, including the overall dimensions and weight of red brick.

The manufacture of products according to uniform dimensions allows the designer to easily select elements of a certain format for construction or cladding, and knowing their approximate weight - correctly calculate the loads of the structure being erected on the foundation.

It will be possible to purchase the material from any manufacturer and at any time after the preparation of the project.

Standard sizes of red bricks normal (regular) 1NF format:

- length - 250 mm;

- width - 120 mm;

- height - 65 mm.

It is the dimensions of single elements provided for by GOST that are a kind of starting point - i.e. a material with other parameters will have a different marking instead of 1NF, where the number denotes its proportions of the ratio with a single one.

So, the size of one and a half red brick will already be 250 × 120 × 88 mm, and will be designated as 1.4 NF. Products of these formats are produced as ordinary and facing.

The list of sizes of facing red bricks can be supplemented with euro format products (0.7NF, 250 × 85 × 65 mm), and ordinary ones - with double elements (2.1 NF, 250 × 120 × 138 mm).

Dimensions of red brick euro format

Thin face material (euros) will help reduce the financial costs of facing, and a large stone (double) will significantly speed up the process of building a house.

Many are often interested in the question of how thick the red brick is. For materials of basic formats (single, one and a half and double) it is standard - 120 mm.

The exception is euro size elements, the width of which is reduced to 85 mm.

Deviations from standard dimensions

According to GOST, the maximum permissible deviations from standard sizes on one element (regardless of the format) are:

- in length ± 4 mm;

- in width ± 3;

- in thickness ± 2 mm for front and ± 3 for ordinary material.

Standard red brick weight

The GOST does not reflect information about how much a single or red brick of other dimensions weighs - the standard indicates only material classes in terms of average specific gravity.

Depending on the class of average density, the products are divided into several groups according to thermal characteristics:

- 2.0 and 2.4 - ineffective (normal);

- 1.4 - conditionally effective;

- 1.2 - effective; 1.0 - increased efficiency;

- 0.7 and 0.8 - high efficiency.

Before proceeding directly to the question of how much 1 standard red brick weighs, you need to consider its types depending on the structure.

The material is available in several options:

Hollow (slotted)

With the amount of voids up to 45%. It is much lighter than corpulent, but less durable.

Corpulent - the number of voids is no more than 13% of the total volume of red brick. It differs in a larger mass, but the strength characteristics of the elements are an order of magnitude higher.

Table 1. Weight (weight) of red bricks of single (250 × 120 × 65 mm), one and a half (250 × 120 × 88 mm), double (250 × 120 × 138 mm) and euro (250 × 85 × 65 mm) formats:

The weight of a red facing brick does not differ from the weight of an ordinary hollow brick. The only thing worth noting is that cladding products are produced only 0.7NF, 1NF and 1.4NF, and there are no double formats for finishing work.

How much does an oven red brick weigh?

Kiln brick

Interested in the weight of red oven bricks, many consumers do not know its main purpose - this is a brick with increased characteristics, but not refractory.

Note! A material made of ordinary clay is intended for laying the body of the stove and chimney. If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products made from special types of clay are used.

If you need elements for laying out the internal heated surfaces of the furnace, then for this, special refractory products are used, made of special types of clay.

Standard kiln material also has a fairly high heat resistance and increased density compared to traditional building or cladding products.

In this regard, to the question of how much a red brick weighs for a stove, one can unequivocally answer that it is heavier than the usual corpulent one and its mass is in the range of 3.7-4.2 kg.