Installation of gypsum vinyl

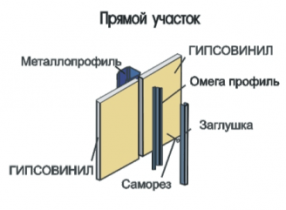

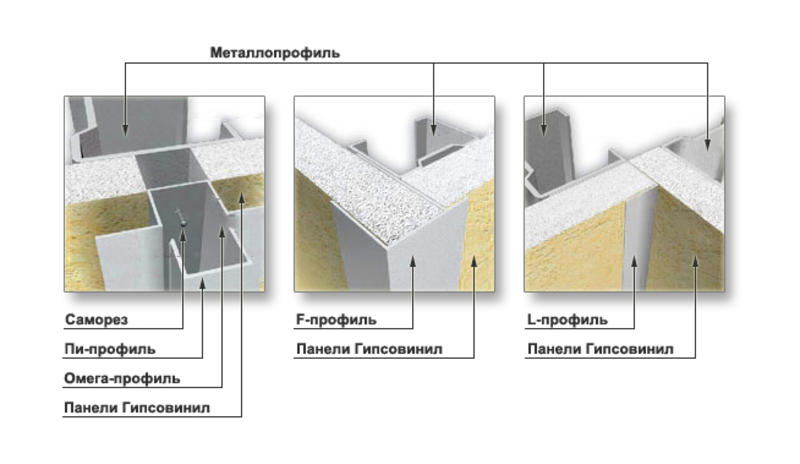

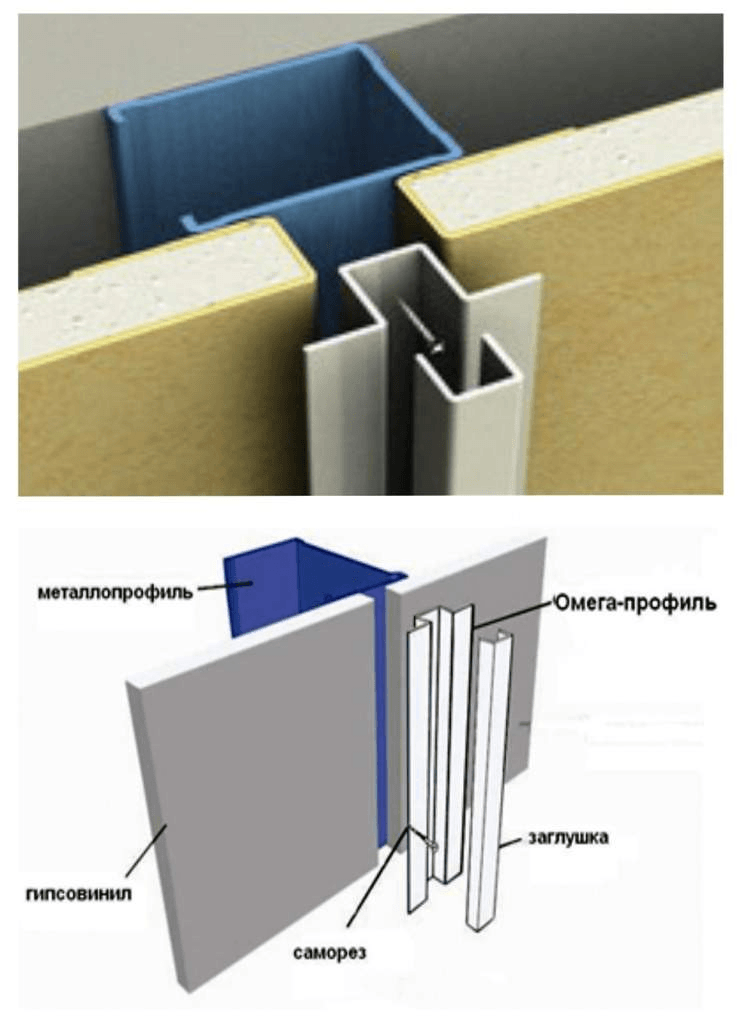

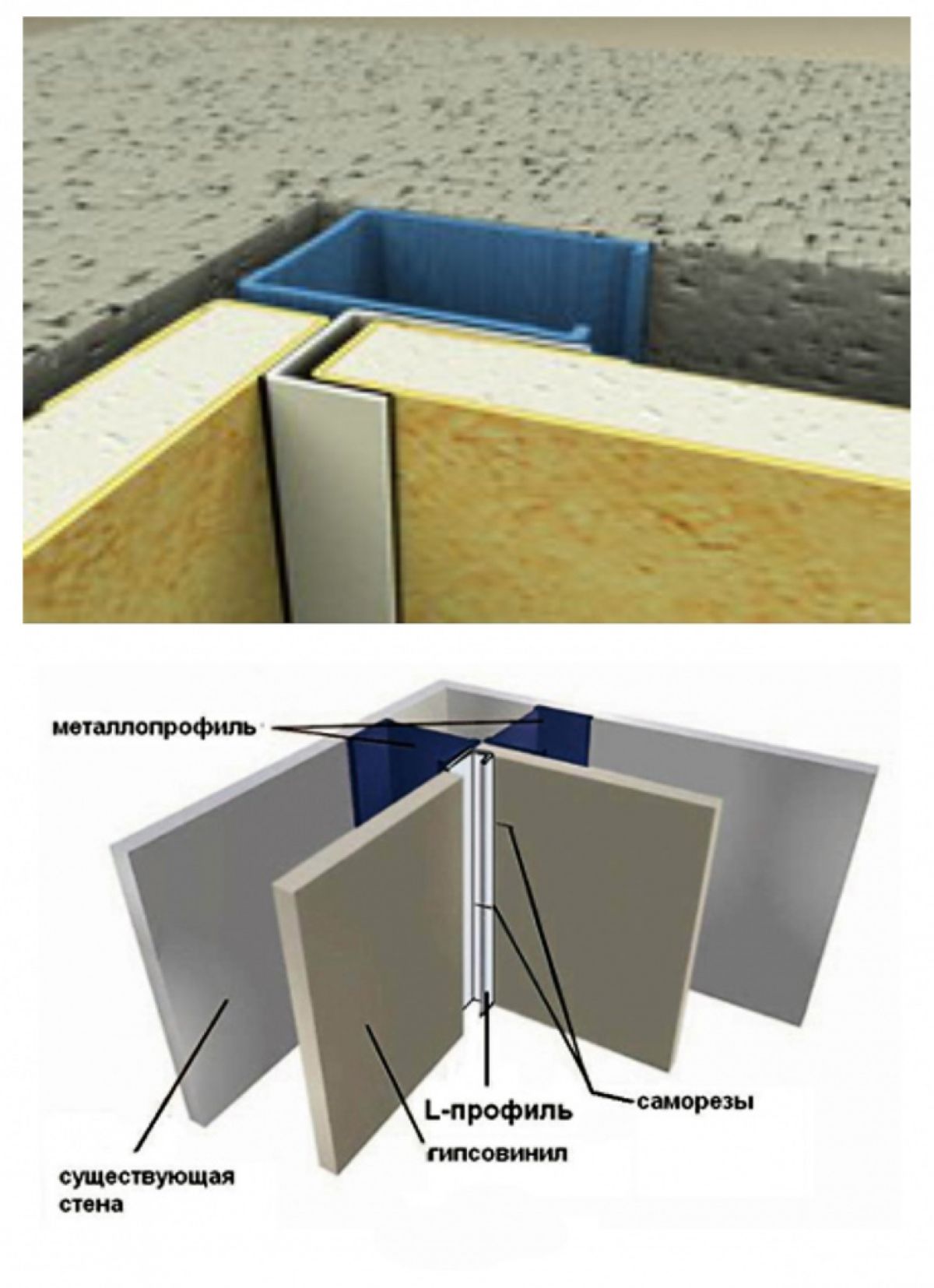

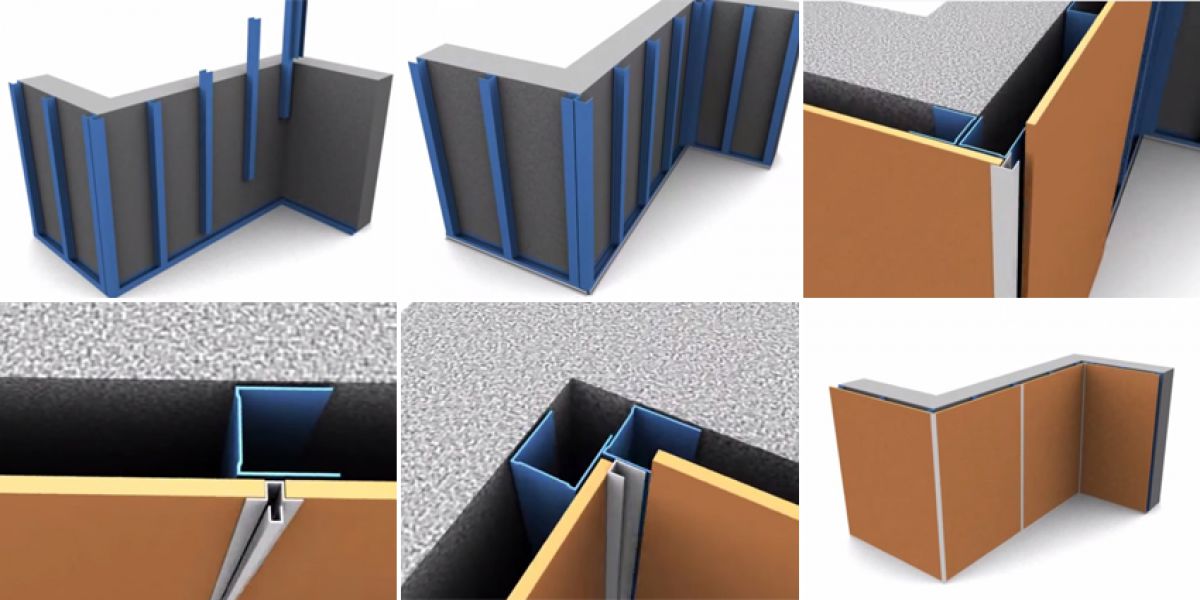

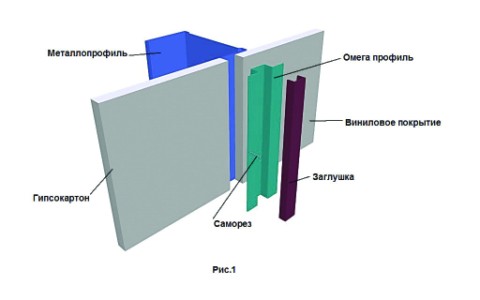

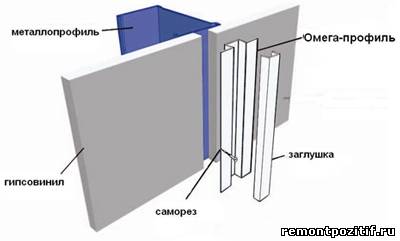

Installation of gypsum vinyl partitions is carried out using "dry" technology, which allows you to significantly save time and get rid of dirt in the room. Gypsum vinyl panels are attached to special guides, which, in turn, are attached to the walls. For the installation of finishing panels, you can use various types of profiles, which will allow, for example, to "bypass" the corner. As a rule, the profile for the installation of gypsum vinyl panels is made of aluminum, which is perfectly cut with a household power tool.

After the panels are installed, the aluminum profiles are closed with specialized plugs. There is a space between the surface of the finishing panels and the wall, in which various communications can be laid. Since gypsum vinyl panels can be easily removed from the guides, access to communications will not be limited. Thus, gypsum vinyl panels can be used for cosmetic renovation of premises without preliminary wall decoration.

Gypsum-nylon panels are perfectly cut with an ordinary tool, the frame for fixing gypsum-vinyl panels is attached to the walls using self-tapping screws. The installation technology allows you to insert glass, doors or various decorative elements into the partitions being erected.

Panels from this type of finishing material are practically not subject to mechanical damage, if necessary, the gypsum vinyl panel can be removed and replaced with a new one. Another advantage of gypsum vinyl partitions is that it is not susceptible to "movement" of the building, which is typical for new office buildings, which can shrink significantly during the first years.

An experienced team within 24 hours can mount gypsum vinyl partitions with an area of up to 20 square meters. The cost of this type of material is from 250 rubles per square meter, installation of gypsum vinyl panels will cost the owner of an office or apartment approximately 25% of the cost of materials.

As a rule, gypsum vinyl panels are of a standard size, which greatly simplifies both the calculation of the required quantity and the transportation of the panels. All types of gypsum vinyl panels that are sold in our country have the necessary hygienic certificates and meet the requirements of Russian quality standards.

Gypsum vinyl panels are very easy to clean, if necessary, they can be washed with soapy water.

Advantages

Gypsum vinyl wall panels are in demand not only for their attractive and restrained appearance, but also for a set of operational parameters, thanks to which the material is able to serve faithfully for at least seven years.

The most significant advantage is strength, which makes it possible to install gypsum vinyl panels on the most difficult to access and configurationally complex parts of the surface.

Gypsum vinyl, like gypsum plasterboard, bends well - they can easily get off convex or concave arched openings, columns, etc.

Despite its strength, Viprok (viprok) is quite elastic, which is especially important in the case of natural shrinkage of new buildings. That is, with the "mobility" of the building, the probability of damage or breakage of the panel is minimal.

Gypsum vinyl wall panels are an excellent heat and sound insulator. Its use helps to properly reduce the level of incoming / outgoing noise and reduce the intensity of heat loss.

It should be noted that this property largely depends on the thickness of the outer layer, which can reach 1.5 mm. The thickened layer affects not only the insulation parameters, but also the overall strength.

Ease of installation is another advantage. As noted, gypsum vinyl panels can be installed using one of two techniques. Both allow you to finish the surface quickly and efficiently using a minimum number of tools.

If we are talking about self-installation, then it will not be possible to cope with the task alone, but together you can complete the finish quickly enough. A competent installation is a guarantee of a long operational life of up to 25 years.

The peculiarity of the installation work is that there is no need to use a putty for sealing joints due to the use of special connecting profiles, which make the installation process "dry" and fast.

Gypsum vinyl panels, the price of which is very affordable due to the cheapness of the components used for the production of the material, are also endowed with good moisture resistance. In addition, laminated plasterboard is fire resistant and environmentally friendly, so it can be installed in children's rooms as well.

Due to its practicality, viprock can be washed with a cloth soaked in water, soapy water or a weak solution of medical alcohol.

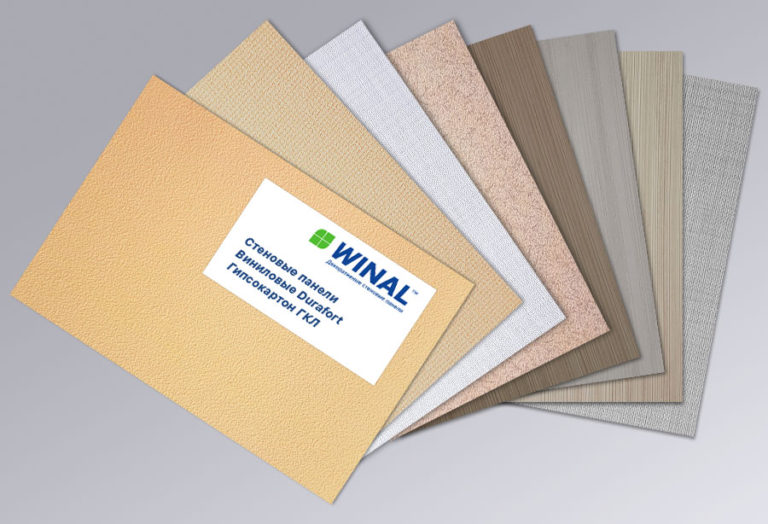

It should be noted the variety of different decors of the material, allowing you to choose options based on the preferences and the intended style of the room.

Production of panels GYPSOVINIL

Wall finishing panels GYPSOVINIL are manufactured industrially on the basis of Gyproc gypsum board (made in Finland), with the application of high-strength vinyl coating Durafort (made in Holland), contract wall covering Decorflex (made in Italy), using foreign high-quality adhesives and forced drying.

Most often they are used for cladding in shopping malls, hotels, cinemas, banks, restaurants, hospitals, beauty salons, sports complexes, kindergartens, schools, and airports.

Now with gypsum vinyl, they not only divide the space, but also use it to decorate walls and ceilings. And this is not surprising, because the price of gypsum vinyl is so affordable that it can be used to “sew up” elevator cabins, staircases, attics, halls, ventilation, and heating radiators. Builders and consumers love this material because it is fire resistant and provides sound insulation in the room. And during its use, the repair time is reduced by at least 3 times, since there is no need to specially prepare walls for gypsum vinyl, several types of repair work can be carried out in parallel, and the room should not have a strict temperature regime. They produce gypsum vinyl panels of completely different sizes, so that you can cut whatever your heart desires from them. Their height can start from 2.5 meters and reach 3.6 meters, width - 1.2 m. The thickness of the panels is 12.5 mm, and the weight is 9.5 kg per square meter.

You can choose from 48 base shades, pastels, and finishing with bright saturated colors to match the color of the panel. Color fastness guarantee - 8 years. The appearance of the panels can resemble the texture of fabric, stone chips, wood, plaster.

More than 300 additional color and texture solutions on request

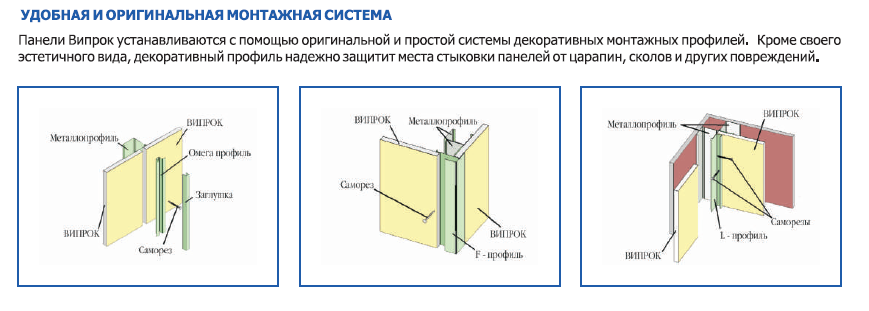

For decorative finishing of premises, together with gypsum vinyl panels, builders must use an aluminum decorative profile for wall cladding, the color of which can be selected from the catalog. Its main characteristics: length - 3000 mm, an omega profile is used at the joints, masked with a p-plug, the inner element is an l profile, outside - an f profile. The thickness of aluminum is 1.2 mm, the coating is a powder coating made of polymers.

All repairs that are carried out on gypsum vinyl panels are called dry. Before proceeding with the installation of the panels, it is necessary to mark the space where the gypsum vinyl will be attached. Then comes the installation of a metal frame, for example, a decorative profile made of aluminum and galvanized steel.Also, the necessary communications are being laid in the frame. And the last stage is plastering with gypsum vinyl itself.

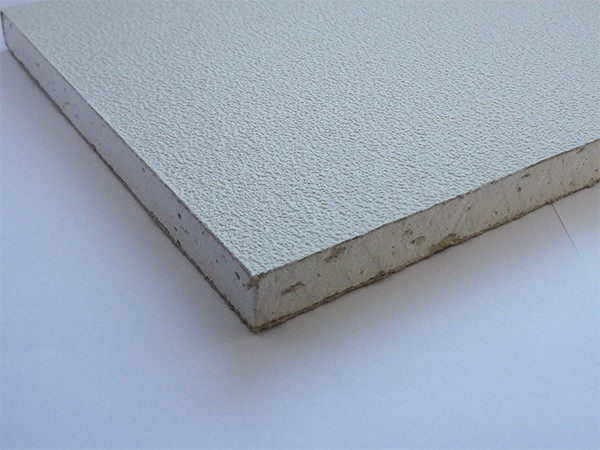

Characteristics of laminated drywall

The main feature of vinyl (laminated) coated drywall sheets is their front surface, which does not require final finishing. This allows you to speed up the pace of repairs and significantly save on materials. Consider what other advantages gypsum vinyl panels have:

- Like all types of gypsum board, it perfectly hides surface imperfections and evens out its plane.

- Covering the sheets provides the material with the necessary care, it is not afraid of moisture and is easy to clean. The decorative design of the outer film (imitation wood, natural stone, fabric, etc.) itself becomes a finishing layer. The surface does not need to be sanded, putty, pasted over with wallpaper or painted.

- Like ordinary gypsum plasterboard, laminated drywall is able to increase the heat and sound insulation of floors. This ability depends on the thickness of the outer layer (it can be 1.5 mm), which also affects the quality of the strength of the material.

- Gypsum vinyl panels are easily assembled both by frameless method and by attaching to the details of the frame structure. The lathing can be made from steel profiles or varnished wooden beams.

- Vinyl coated drywall panels have excellent fire and water repellency properties. The material can be successfully used both for decorating a children's room and for repairing office premises.

- Installation of gypsum vinyl panels is accompanied by the formation of a minimum amount of construction waste, noise and dust. The sheets are covered with a special protective film, which peels off easily after all work is completed.

- A significant advantage of this drywall is also considered a high level of environmental friendliness.

Gypsum vinyl panels (gypsum vinyl, gypsum vinyl) - finishing panels based on gypsum (gyproc) with a high-strength vinyl coating.

Gypsum vinyl is characterized by increased wear resistance, strength and moisture resistance, sufficient for sanitization. As a result of the use of high-quality vinyl coating, the color range of tinting is practically unlimited.

Gypsum vinyl finishing panels are an excellent choice for finishing children's, medical and educational institutions. Its unique strength, lightfastness and mold resistance are highly commended by technicians and sanitary personnel.

The possibility of installation in unheated rooms and the absence of wet processes, along with low formation of debris during the preparation and installation of gypsum vinyl panels, contribute to the widespread use of this type of finishing panels, in the production of finishing and repair work both in personal and commercial construction.

The use of gyproc-based vinyl-coated panels in the production of finishing works in suburban and cottage construction is gaining popularity. Highly demanding customers appreciated the high speed of installation and the absence of cracks in the joints of gypsum vinyl panels.

At the same time, due to its unique appearance and amazing soundproofing characteristics, gypsum vinyl found its application not only in construction work, but also in interior solutions, as a finishing material in the manufacture of consoles, niches, office partitions, etc.

| Specifications of gypsum vinyl panels | |

|---|---|

| Width | 1200 mm |

| Length | 2500, 2700, 3000, 3300, 3600mm |

| Thickness | 13mm |

| The weight | 9.5 kg / m2 |

| Surface density of drywall | 820 kg / m3 |

| Drywall composition | 93% dihydrate gypsum, 6% - cardboard, 1% of the mass is formed by moisture, starch and organic surfactant |

| Vinyl surface density | 300 kg / m3 |

| Vinyl coating composition | Hard vinyl covering, weight - about 200 kg / m3, paper base (weight - 95 kg / m3). Thickness, depending on the embossing, from 0.40 to 0.47 mm. Dimensional stability - less than 0.5%, does not change after manual or mechanical application. |

| Lightfastness of the coating | 7 on an international scale. |

| Fire resistance of the coating | Class B-1 in Germany according to Din 4102 part 1, class 1 according to Dutch standard NEN 3883, class M1 on gypsum board in France. |

| Washing method | Resistant to abrasion, wet cleaning with non-abrasive detergents is allowed. Easy to wipe and wash with soapy water. The use of a brush is allowed when washing. |

| Mold resistant | Vinyl: good durability. Paper: good tenacity. |

| Fire hazard class (RF) | KM2 (g1, w2, t1, d1). G1 - fire-resistant panels. |

| Sound insulation of partitions made of panels | 38-51 dB, depending on the design of the partitions. |

What is it and where is it used?

Gypsum vinyl panels are ready-made sheets from which you can erect partitions and other structures inside buildings, structures for various purposes. At the heart of each such panel is gypsum board, on both sides of which a vinyl layer is applied. Such an outer covering not only serves as a replacement for the classic finish, but also provides increased moisture resistance to the created non-capital walls. The most popular types of film for the production of panels are produced by the brands Durafort, Newmor.

A distinctive characteristic of gypsum vinyl is its environmental safety. Even with strong heating, the material does not emit toxic substances. This makes the sheets suitable for residential use. The laminated coating of the panels allows you to give the material an original and stylish look. Among the ornaments used by manufacturers, the imitation of reptile skin, textile coverings, matting, and solid natural wood stands out.

The scope of application of gypsum vinyl panels is quite wide. They help to solve a number of problems.

- They create designer arches and other architectural elements in the interior. Flexible thin sheets are well suited for this kind of work. In addition, they are suitable for the construction of podiums, fireplace portals, as they have sufficient bearing capacity.

- Ceilings and walls are covered. The finished finish significantly speeds up and facilitates this process, allowing you to immediately get an even decorative coating. Due to its quick installation, the material is popular in the decoration of offices and shopping centers, it meets the standards of medical institutions, it is approved for use in banking organizations, airport buildings, in hotels and hostels, at military-industrial facilities.

- Forms protrusions and fences for various purposes. With gypsum vinyl panels, functional or decorative elements can be quickly erected or completed. For example, they are well suited for creating check-in counters and temporary barriers, creating stands for performances in classrooms.

- Openings are faced at the locations of the slopes in door and window structures. If the same finish is on the walls, in addition to the general aesthetic solution, you can get an additional increase in sound insulation in the building.

- They create the details of the built-in furniture. The backs and sides of its body look much more attractive with this finish.

Plates made of gypsum vinyl are more expensive than classic gypsum plasterboard sheets, but the presence of a finished finish makes them a more functional and convenient solution. This is the best option for quickly changing commercial interiors with temporary or permanent partitions. Among the distinctive features of the material, it is also possible to highlight the economy of up to 27% in comparison with ordinary drywall, a long service life of up to 10 years.The panels are easily cut to size, since they have a flat edge and are suitable for cladding large rooms.

Gypsum Vinyl Panels

Gypsum vinyl panels can be covered on one side - for use as cladding or for the device of multilayer partitions for zoning a room and at the same time with the aim of hiding partitions of pipes, wiring or ventilation, and other engineering communications in the cavity. It is also possible to create a sound and heat insulating light wall, when filling the cavity between the panels with non-combustible mineral wool - stone or basalt. Such a wall will immediately have a finishing decorative finish.

The double-sided vinyl covering assumes the use of the panel as a thin and light decorative partition or, alternatively, as a mobile partition-screen. The disadvantage of this design is serious - significant fragility.

Pros of gypsum vinyl panels

The main advantages of vinyl flooring:

- Antibacterial, mildew and mildew do not live on PVC;

- Shades and colors, textures, both embossed and smooth, and a wide variety of imitations - leather, wood and stone, textiles and even glass of such elite types as Venetian - is not a complete list of the range of vinyl-coated panels;

- The durability declared by the manufacturer of one of the recognized brands - the leading European manufacturer of vinyl wall coverings Durafort - ten years.

Cons of gypsum vinyl panels

The disadvantages of gypsum vinyl panels include

- High cost;

- Fragility. Transportation and installation in violation of the manufacturer's recommendations may lead to panel breakage;

- Only one thickness - 12.5 mm with one-sided coating and 13 mm with double-sided. Dimensions also without options - 2.5 * 1.2 m 3 * 1.2 m.;

- Vinyl-coated gypsum panels are not recommended for permanently damp areas such as showers, bathrooms, baths and possibly basements. The properties of gypsum to quickly absorb moisture do not allow the use of this sheet material in a humid environment.

Installation of hypovinyl panels

During installation, it is important to protect the ends of the panels from moisture, to seal them with silicone or other waterproof compounds, since it is impossible to do without trimming to the desired size. When decorating the slopes of windows and doors with gypsum vinyl plates, they are also attached to adhesives

The glue should be moisture resistant and transparent.

Drywall color options

Blue

Blue

Blue

Blue

Gray beige

Gray beige

Peach

Peach

White

White

Red

Red

Dark grey

Dark grey

Green

Green

Sand

Sand

Gray

Gray

Light gray check

Light gray check

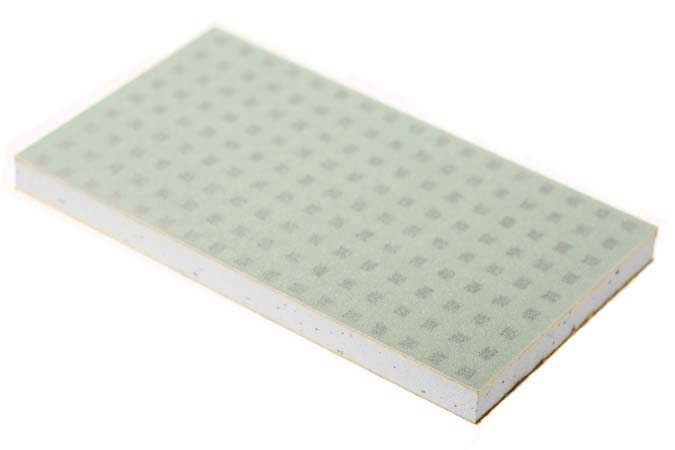

Light green checkered

Light green checkered

Brown check

Brown check

Beige Checked

Beige Checked

Light beige check

Light beige check

Decorative trim panels (gypsum vinyl) are specialty plasterboard panels with factory applied vinyl. The connection of the panels to each other and their fastening to the load-bearing elements of the building structure is carried out by a system of special aluminum or steel profiles. These profiles are in themselves an element of interior design due to the different color combinations with the vinyl covering.

Advantages and disadvantages

In order to avoid unpleasant surprises during the installation of wall panels or their operation, it is recommended that you familiarize yourself with the advantages and disadvantages of the material.

Pros:

• strength, the ability to use in hard-to-reach places with a complex surface configuration;

• the sheet can be bent, giving it the desired shape;

• elasticity of the material prevents deformation during the shrinkage of the new building;

• moisture resistance;

• simple installation;

• additional sound and heat insulation;

• a wide selection of colors and shades, patterns imitating natural materials;

• simple care;

• long service life (over 25 years);

• affordable price.

With the help of gypsum vinyl wall panels, it becomes possible to arrange an exclusive design in the room, to zone the space, and to place beneficial accents in the interior.

Minuses:

• the indicator of moisture resistance is insufficient for the use of panels in rooms with a high level of humidity (kitchens, bathrooms);

• when cutting open edges need to be sealed (processing with a sealant, tape or other method);

• low resistance to abrasives excludes the use of aggressive agents and solvents for cleaning.

Application area

• design of arches and other decorative elements of the interior;

• for facing walls and ceilings;

• for the design of various ledges, protective structures that have a functional and decorative purpose;

• when installing slopes on openings;

• when constructing built-in furniture;

• for the installation of non-standard objects (podiums, fireplace portals, decorative fences, etc.).

Laminate coating not only protects drywall from external influences, but also provides decoration. The surface skillfully imitates matting, wood cut, animal and reptile skin. Newmor and Durafort films are used as decorative material.

The cost per square meter of panels varies from 350 to 800 rubles.

Installation rules

Installation of gypsum vinyl panels is possible in several ways. As in the case of conventional gypsum boards, they are installed in frame and frameless methods. The process of mounting on a profile and to a solid wall has quite large differences. That is why it is customary to consider them separately.

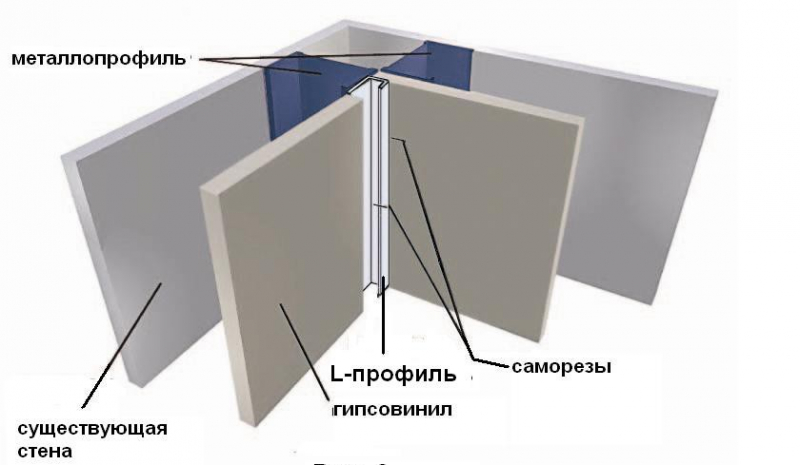

Fastening to a frame from a profile

This method is used when independent structures are created using gypsum vinyl panels: internal partitions, arched openings, other architectural elements (niches, ledges, podiums). Let's consider the procedure in more detail.

Markup. It is performed taking into account the thickness of the material and the dimensions of the profile.

Fastening of horizontal guides. The profile of the upper and lower rows is mounted to the ceiling and floor using dowels.

Installation of vertical battens. Rack profiles are fixed with a pitch of 400 mm. Their installation begins from the corner of the room, gradually moving towards the central part. Fastening is carried out on self-tapping screws.

Preparing the racks. They are degreased, covered with double-sided adhesive tape with a strip length of 650 mm and an interval of not more than 250 mm.

Installation of gypsum vinyl panels. They are attached to the second side of the adhesive tape starting from the bottom.

It is important to leave a technological gap of about 10-20 mm above the floor surface. The inner corner is secured by an L-shaped metal profile, securely fixed to the frame.

Joining sheets together

In the area of inter-slab joints, a W-shaped profile is attached. In the future, a decorative strip is inserted into it, covering the technological gaps. F-shaped plugs are placed on the outer corners of the panels.

Having mounted the covering over the entire plane of the prepared lathing, you can install decorative elements, cut in sockets or equip slopes in the opening. After that, the partition or other structure will be completely ready for use.

Solid base mount

This method of installing gypsum vinyl panels is used only if the base - the surface of the rough wall - is perfectly leveled. Any curvature will lead to the fact that the finished coating will not look aesthetically pleasing enough; discrepancies in the joints may appear. Beforehand, the surface is thoroughly degreased, cleaned of any contamination. Installation is also carried out using a special industrial-type adhesive tape: double-sided, with increased adhesive characteristics.

The main fastening elements are applied to the frame in the form of a solid wall in strips - perpendicularly, with a pitch of 1200 mm.Then, with a vertical and horizontal step of 200 mm, separate pieces of tape of 100 mm should be applied to the wall. During installation, the sheet is positioned so that its edges fall on solid strips, then it is strongly pressed against the surface. If everything is done correctly, the mount will be strong and reliable.

If you need to veneer the corner of the cladding with gypsum vinyl, it is not necessary to completely cut it. It is enough just to make an incision on the back of the sheet with a cutter, remove dust residues from it, apply a sealant and bend, fixing it to the surface. The corner will look solid. To obtain a bend when creating arched structures, gypsum vinyl sheet can be heated from the inside out with a building hairdryer, and then shaped on a template.

The following video explains how to install gypsum vinyl panels.

Properties and characteristics of gypsum vinyl

The gypsum vinyl panels are based on a drywall layer laminated with vinyl on both sides. The composition of drywall is not regulated, but most often 93% of gypsum dihydrate and cardboard with a content of not more than 6% are used.

In this case, the remaining 1% is formed due to moisture, starchy part and surface-active organic containing. Vinyl lamination consists of a paper backing with a weight of about 95 kg / m3 and a hard vinyl layer with a weight of approximately 200 kg / m3.

The thickness directly depends on the embossing and varies in the range of 0.40-0.47 mm. Vinyl cover can be of three main types:

- Newmor;

- Durafort;

- PVC film.

Laminated drywall is decorated with a variety of designs - the texture of decorative plaster, matting, wood, bamboo, etc. The most widely presented products are lamination from PVC film imitating the skin of reptiles or expensive wood species.

They also differ in color variety. The gypsum vinyl wall panels that have been industrially coated with Newmor and Durafort are produced in pastel colors with a few bold color accents in the collection.

Gypsum vinyl is a universal material in use, which indicates the possibility of its use for a variety of purposes, in particular:

- for wall cladding, ceiling structures;

- designer finishing of arches;

- construction of niches, partitions, consoles;

- decoration or construction of furniture;

- constructions of non-standard structures (fireplace portals, podiums, etc.);

- installation of slopes on windows and doorways, etc.

disadvantages

Has gypsum vinyl and several disadvantages:

- The moisture resistance of Viproka is insufficient to install them in extremely damp or cold rooms (bathrooms, kitchens, basements, etc.). The optimum humidity value should not exceed 25%.

- In direct mounting, the trimmed edges of the material need to be sealed. That is, the cut must be coated with sealant and insulated with adhesive tape or tape.

- the impossibility of using for cleaning agents with abrasives or solvents.

Gypsum vinyl wall panels are a great alternative to drywall or glass-magnesium sheets. It does not require putty, which affects the speed of work. At the same time, the material is endowed with many unconditional advantages, which determines the constant demand.

Application of gypsum vinyl panels

In addition to cladding walls and ceilings in various types of rooms, this material (gypsum vinyl panels) is often used for the following purposes:

- Office decoration (cladding, production of partitions).

- Decorative finishing of arched openings of various types.

- Installation of slopes on window and door openings.

- Niche device.

- Interior design of restaurants and hotel rooms.

- Execution of decorative elements in multi-level structures made of vinyl plasterboard.

- Manufacturing of cabinet furniture.

- Manufacturing of non-standard structures (decorative fireplaces, podiums, etc.).

Before proceeding with the design of the future structure, you need to familiarize yourself with some of the points that limit the use of this material:

- Attractive and versatile gypsum vinyl panels have limitations in their use in some types of premises. They cannot be used in the decoration of basements, bathrooms and other places with high humidity levels (above 25%).

- When working on the creation of slopes of window and door openings, it is necessary to use transparent and waterproof glue.

- If, during the installation of the material, it becomes necessary to cut a part of the sheet, then its edge will need to be treated with a sealant and closed with adhesive tape.

- The surface of gypsum vinyl panels can only be washed with products that do not contain abrasive particles. Do not use thinner or benzine to remove stains. Use a soft foam sponge to wash and clean the surface.

What are they?

Standard 12mm gypsum vinyl panels are available as regular flat-edged boards or tongue-and-groove products for quicker installation. Wall and ceiling slabs are blind and have no technological holes. For the walls of office buildings and other premises, both decorative and monochromatic versions of coatings without a pattern are produced. For the ceiling, you can choose pure white matte or glossy design solutions.

For the walls of buildings and structures that require spectacular design, stage and club decorations, original types of coatings are used. They can be golden or silver, have more than 200 options for colors, textures and ornaments. 3D panels with an immersive effect are in great demand - a three-dimensional image looks very realistic.

Characteristics of gypsum vinyl panels

- It is coated in a production way. For this, a standard gypsum sheet is covered with PVC film, which is a decorative finish of the layer, which does not require additional processing on the part of specialists who are realizing the cladding of the room with this material.

- Decorative gypsum boards of various colors and textures can be purchased at the appropriate retail outlets. The most popular are marble and wood imitation. The consumer can purchase both glossy and matte boards.

- The sheets are 12 mm thick and have overall dimensions of 3.0 m by 1.2 m. Smaller sheets can be ordered if desired.

- Fastening vinyl sheets to the frame is carried out using double-sided tape.

- The gaps between the cladding fragments are covered with decorative panels. They can be made of metal or plastic.

- Manufacturers produce conventional decorative plasterboards and a fire-resistant version.