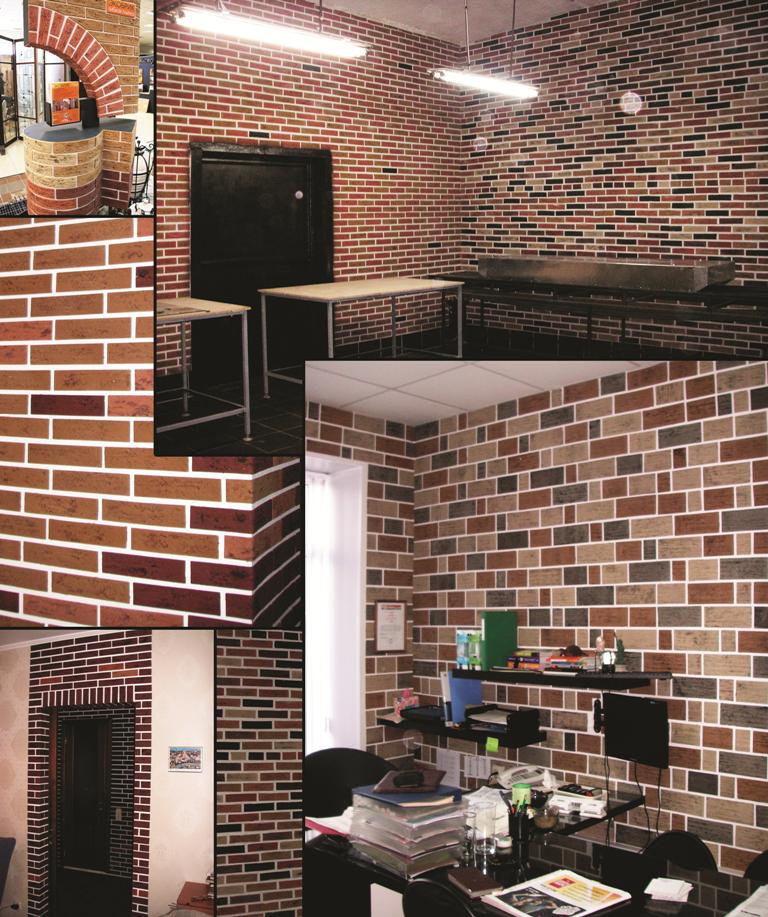

Gypsum tiles for interior decoration under a brick: advantages and disadvantages

Gypsum is a lightweight material that, if necessary, takes the required shape, structure, relief. The use of this material in the decoration of the interior space of a room is a simple, materially feasible and physically feasible task.

Advantages of plaster stone finishing inside the building:

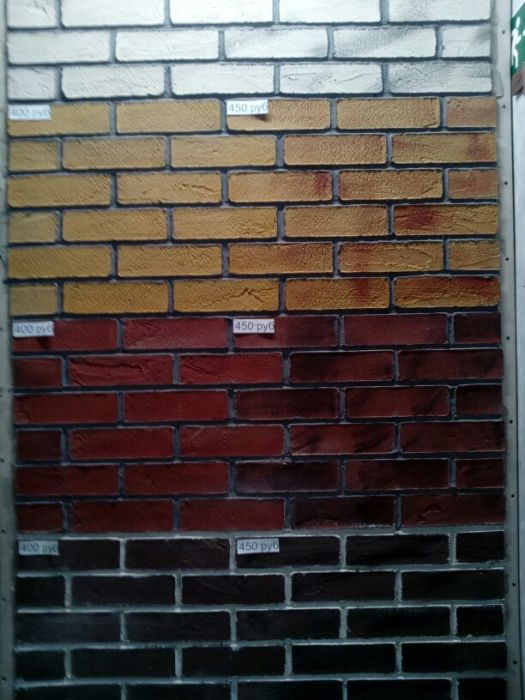

- A wide range of products that differ in texture, price, size and appearance.

- Relatively low pricing policy.

- Natural formulations.

- The ability to customize the finished tiles to the surface features.

- Simple design, wall mounting.

- Light weight of the finished product, which allows it to be used on any surfaces without the risk of wall deformation.

Among the disadvantages are such features as moisture absorption, lack of resistance to mechanical damage and crumbling. However, such disadvantages are insignificant, and during operation the material will not require labor-intensive maintenance. If necessary, you can replace damaged broken tiles with new ones without damaging the integrity of the wall.

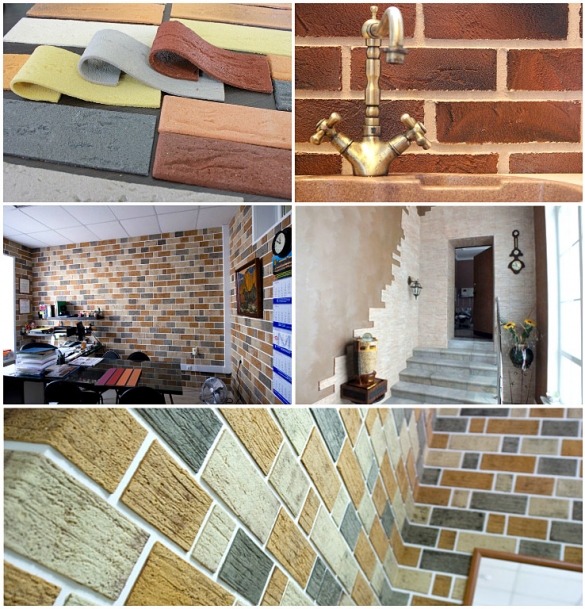

Types of decorative bricks

Brick-like finishes are made from various materials. Depending on the properties of the base and the characteristics of the production technology, each type of product is distinguished by its operational and decorative characteristics.

Clinker

Decorative bricks in the form of clinker tiles are characterized by high performance. The product is in demand in interior design as an interesting material for facing the stove and fireplace. Clinker is rarely used for solid wall cladding, most often the finish is used as an accent. This is due not only to the high cost of products, but also to the effect of the visual "heaviness" of the material.

Features of imitation from clinker:

- low coefficient of water absorption. The product is suitable for finishing rooms with a high level of humidity, it is also in demand in the decoration of the facade;

- environmental safety of the product;

- inertness to fluctuations in temperature of the environment;

- wear resistance;

- clinker false bricks do not react to chemicals.

The material is presented in a variety of shapes, sizes, colors and design options: there are models of matte finish, glazed or with a relief surface.

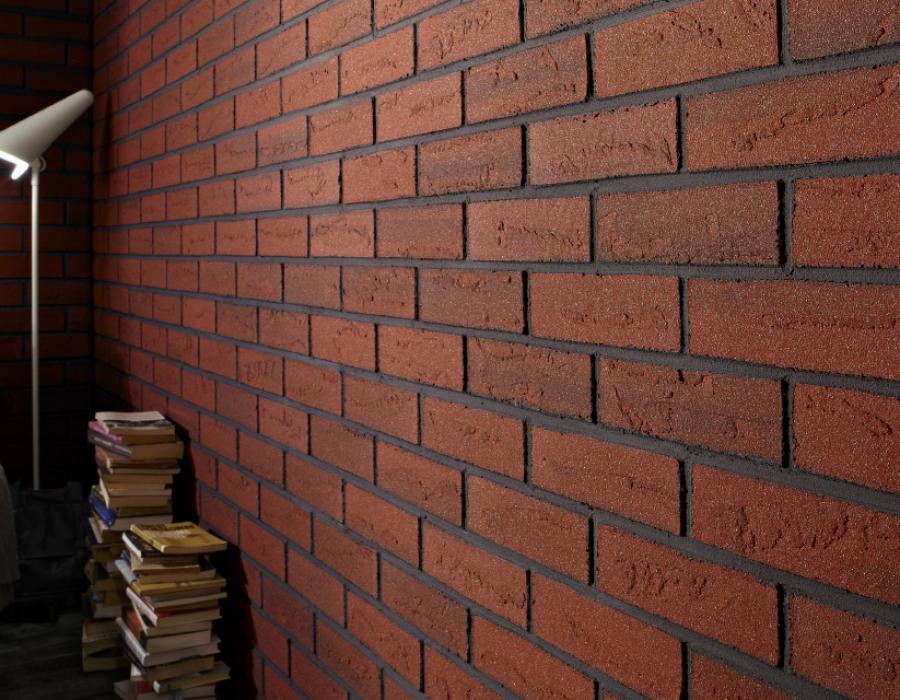

Decorative plaster brick

Decorative plaster brick

Gypsum

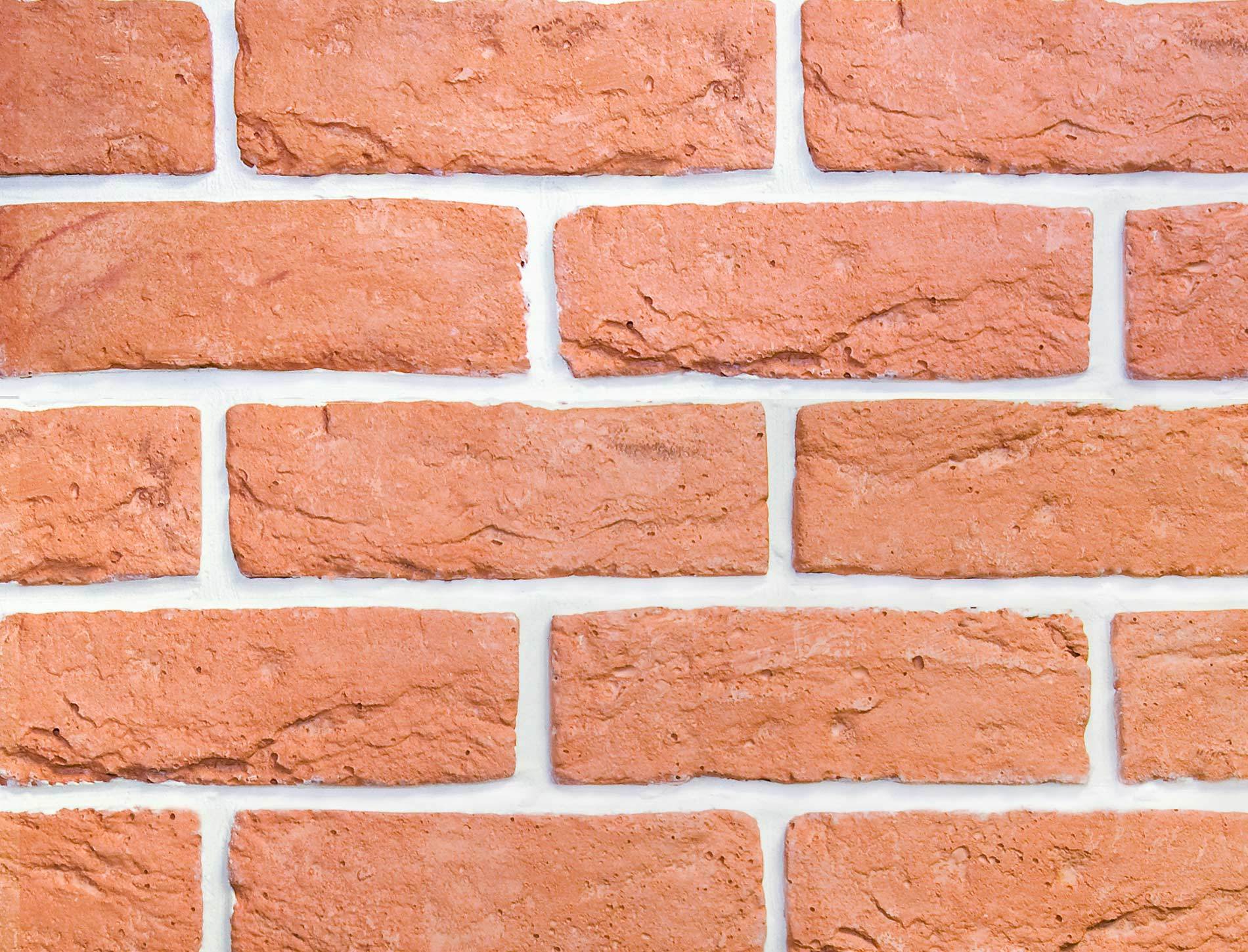

Imitation brick plaster is popular as an affordable and lightweight cladding option. Features of gypsum tiles:

- ecological impeccability;

- low cost of products;

- due to the hygroscopicity of the material, gypsum models without a protective coating cannot be used in the arrangement of premises with a high humidity coefficient;

- special curly elements for finishing corners are provided;

- for high adhesion, it is necessary to use a gypsum-based adhesive;

- it is necessary to use a grout for the joints between the tiles to create a single sealed layer.

There is also a false brick made of gypsum, which is made with the use of special additives and a moisture-proof layer on both surfaces. Tile adhesive marked "for complex substrates" is used to mount the material.

Polyurethane

Facing panels made of polyurethane with brick relief help to transform the interior without much financial and time efforts. The 3D finish imitating masonry is not susceptible to high humidity and temperature extremes.Polyurethane material allows you to create additional heat and sound insulation of premises, the products are in demand when arranging balconies, verandas, a bathroom and a kitchen group. Liquid nails or acrylic glue are used to fix the decor.

There is a large assortment of false bricks on the market, which is in demand when decorating premises for various purposes:

- imitation of acrylic. The product is valued for its excellent strength and lightness characteristics; it is available in a wide variety of colors, textures and shapes;

- ceramic false brick. The characteristics of the material are similar to those of classic ceramic tiles; the product is often used in the arrangement of a kitchen group and a bathroom.

Perhaps the most expensive solution is the porcelain stoneware version of the product. The composition includes natural stone chips, which provide high strength characteristics.

Decorative brick made of porcelain stoneware

Decorative brick made of porcelain stoneware

Styrofoam

To reduce the cost of finishing work, craftsmen independently make imitation bricks from extruded material. It is not recommended to use ordinary white foam, but polystyrene foam, which has higher performance characteristics. A clerical knife is used to cut out elements of brickwork. Styrofoam is laid on liquid nails, after which it is painted with water-soluble paint.

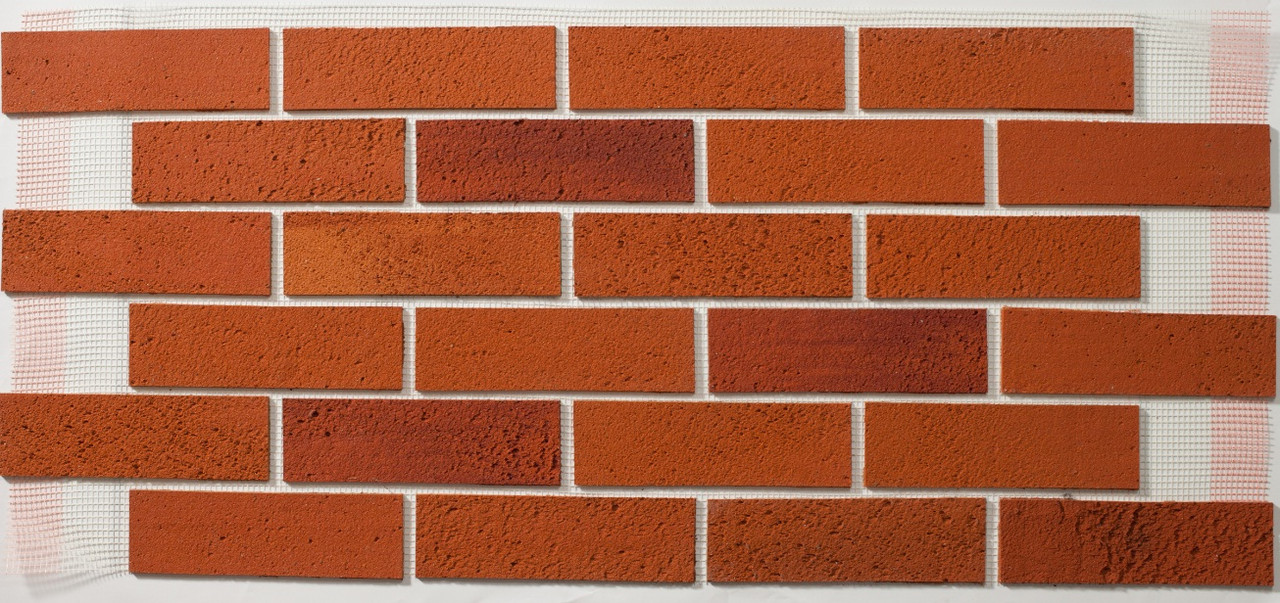

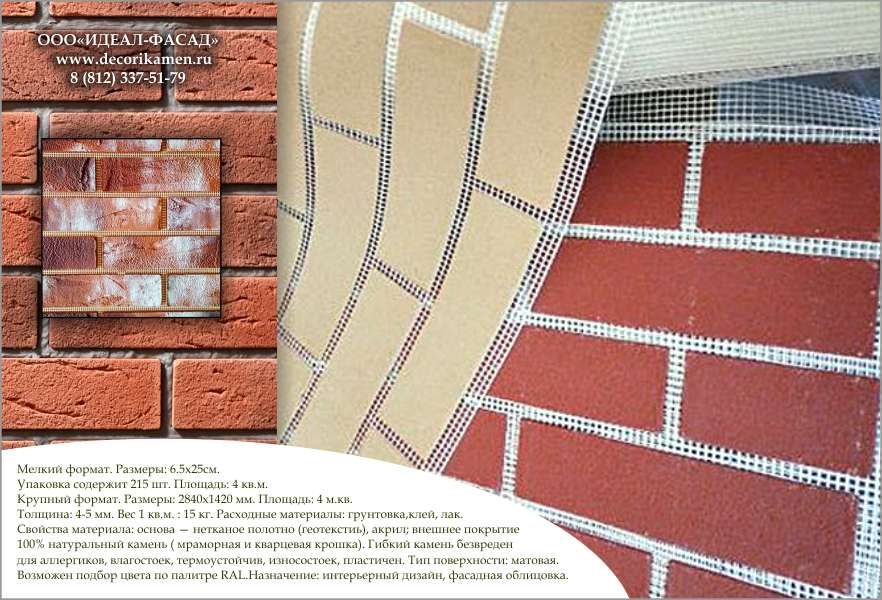

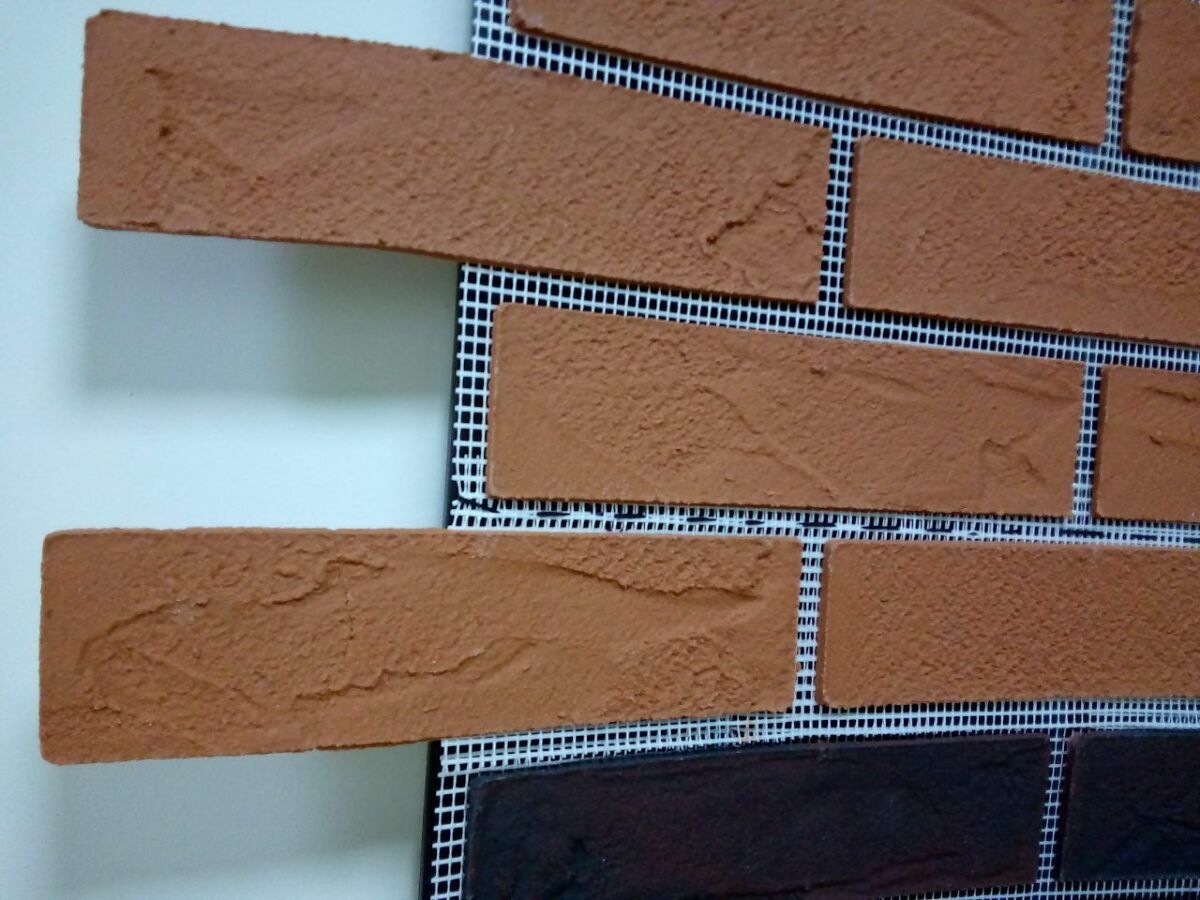

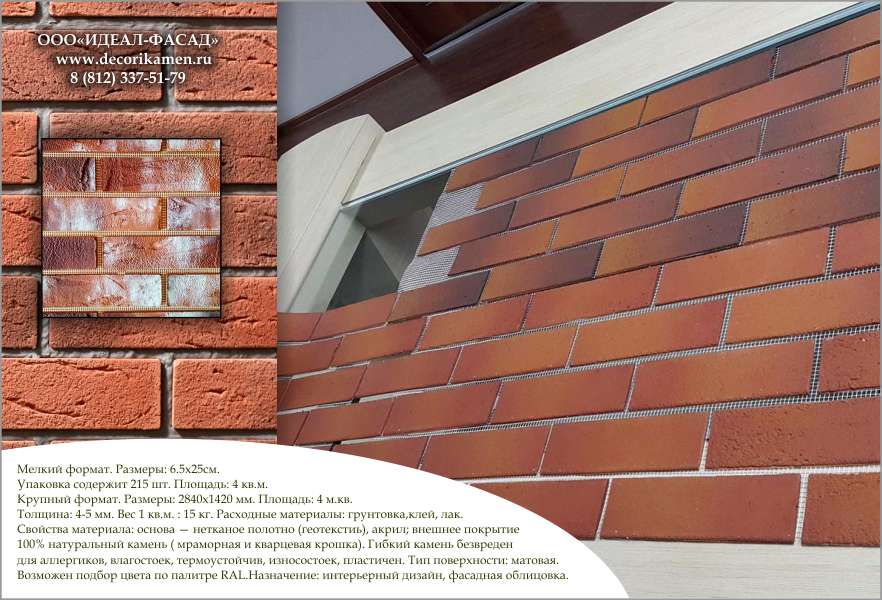

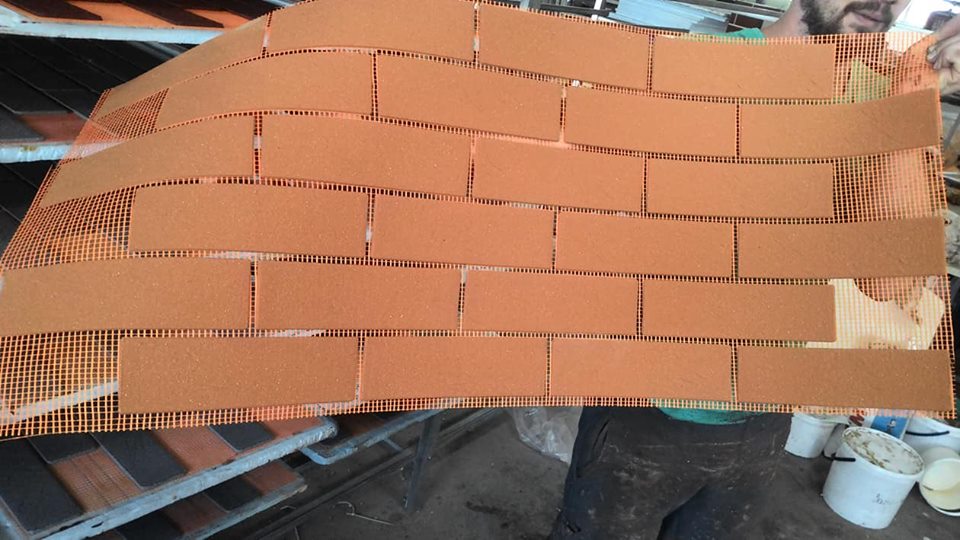

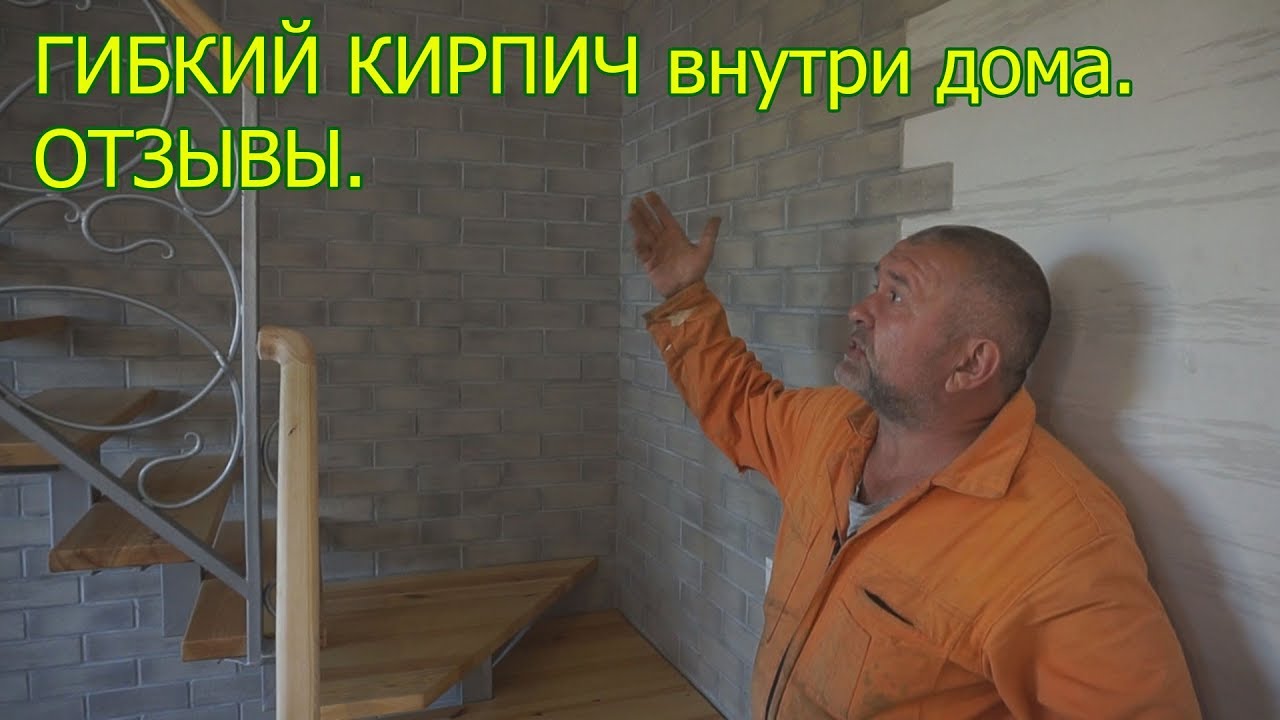

Types of flexible bricks

Flexible bricks are produced in four types:

- In the form of separate bricks-tiles;

- On a fiberglass mesh;

- Finished flexible sheet;

- On foam.

Using flexible bricks, you will get a beautiful facade, easily create an original interior decoration of the room.

Tile-brick

Flexible bricks in the form of individual tiles are used for finishing small sections of walls. Most often used in interior design.

Although, this tile can also be used to decorate the external facades of buildings. The tile tolerates temperature fluctuations well. Not afraid of moisture, has high air permeability.

Tiles are glued to a previously prepared, primed wall using any decorative glue.

After that, the same glue or any building masonry mixture is applied with a brush between the rows of tiles.

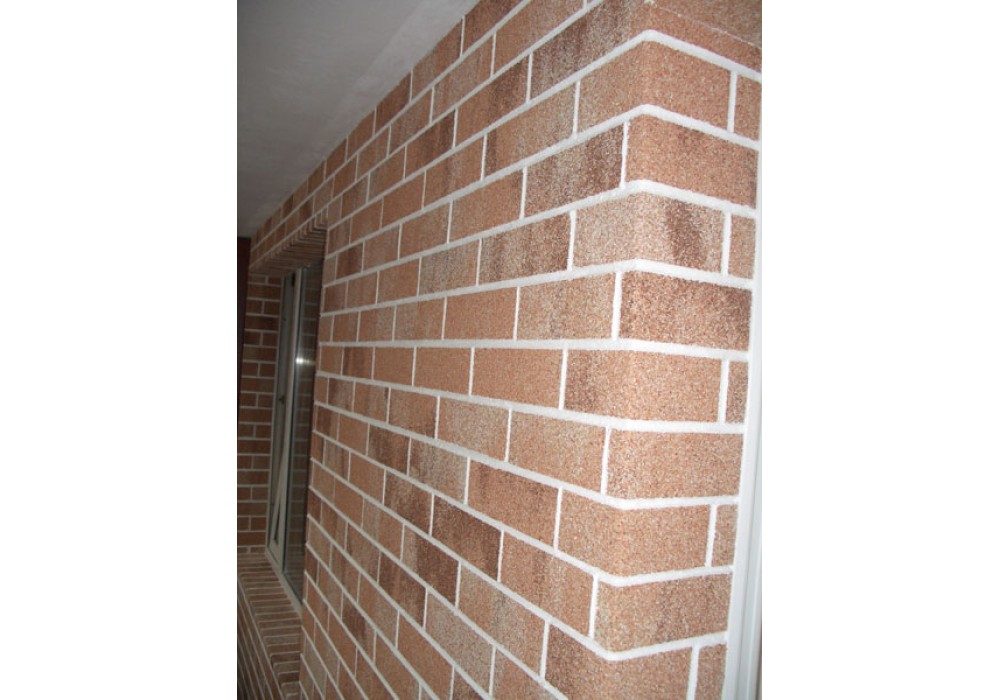

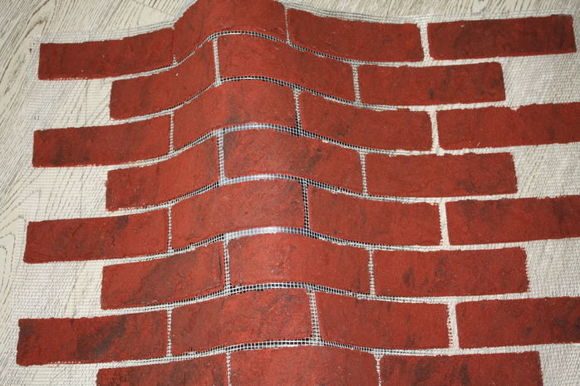

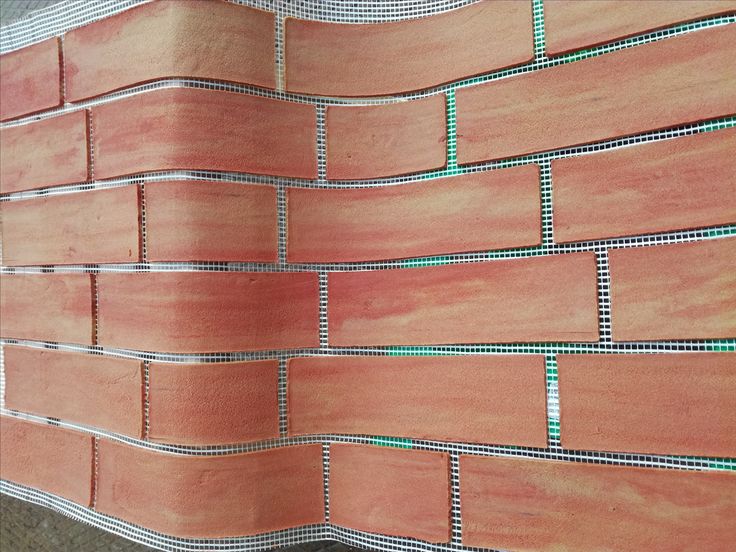

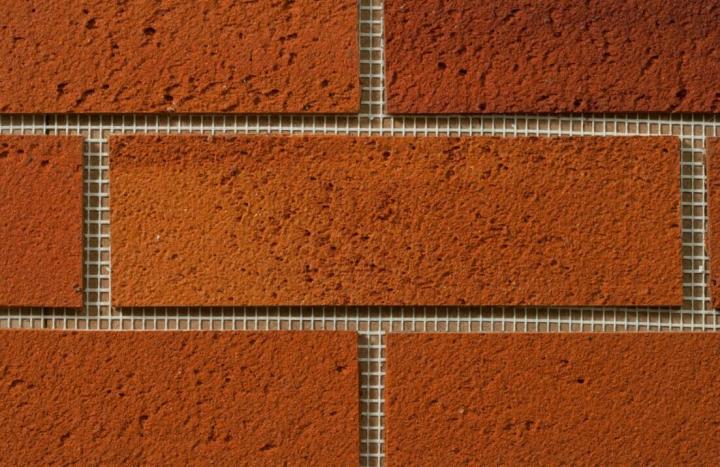

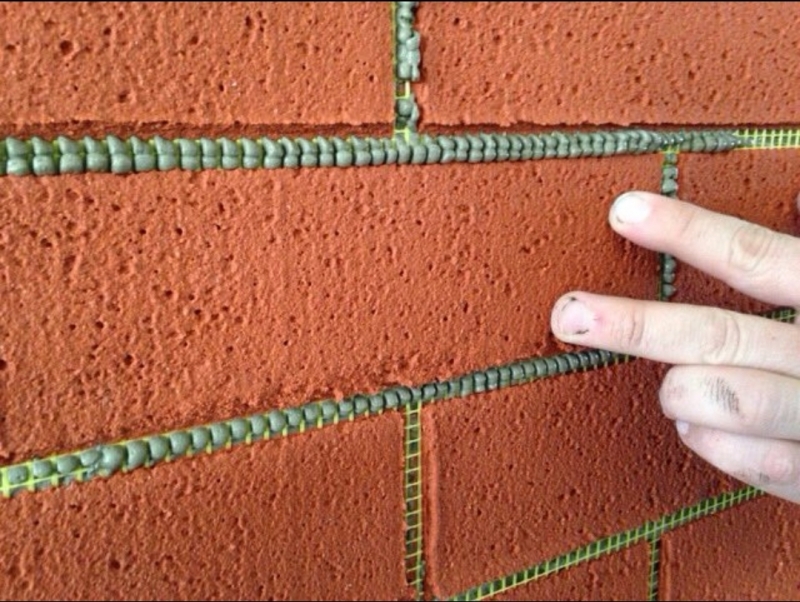

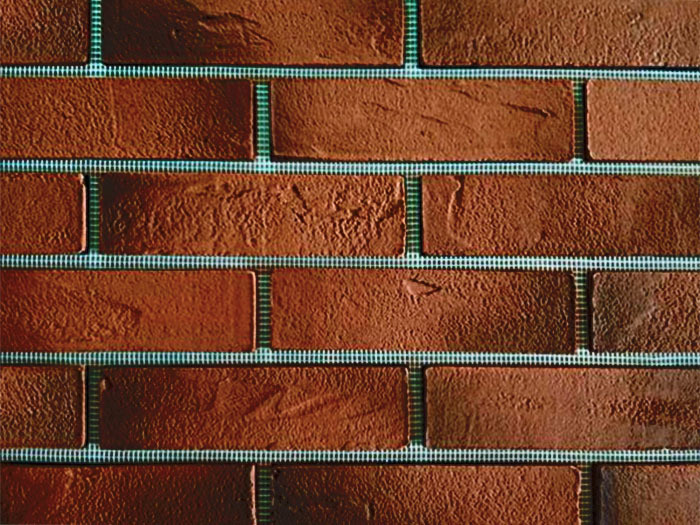

Flexible brick on fiberglass

Flexible bricks are placed on a fiberglass mesh, imitating brickwork. The mesh is glued to the wall. Then, the gaps between the brick blocks are filled with a special mixture.

It is most convenient to clad the facades of buildings with flexible bricks fixed to a fiberglass mesh. The size of the mesh is one meter long and half a meter high.

The mesh is elastic, flexible, conveniently attached to the wall, easy to cut. Flexible brick on fiberglass does not crack, it is assembled like a puzzle.

At the same time, it externally imitates 100% clinker brickwork. One square meter of mesh weighs only 5 kilograms.

After gluing, the mesh is pressed to the base, and the glue that has emerged between the tiles is rubbed with a spatula for jointing.

Finished sheet

Finished sheets are a base of quartz sand and acrylic binders, on which elements of flexible bricks are applied. A vapor-permeable membrane backing allows the walls to “breathe”.

The finished sheets are glued to the wall without grouting, like wallpaper. The material is easy to cut. It is used for interior and exterior decoration.

It is glued to the walls with general purpose assembly and construction glue.

Before gluing, it is recommended to prepare the walls in advance:

- Clean from dirt, dust, layers;

- Level the surface;

- Apply a suitable primer.

Finished sheets that mimic brickwork can be of various sizes. They are also produced in the form of rolls up to three meters long.

Thermal panels

Thermal panels are foam boards of various thicknesses. On the front side of the slab, elements of flexible bricks are applied, imitating masonry.

Of course, foam blocks, with brick tiles applied to them, are not at all flexible.

It is a lightweight, comfortable finishing material that serves both for insulation and for decorating the facade.

It is safe to say that today, this is one of the best solutions for home decoration.

They are very convenient and quick to stick to the wall using construction adhesive-foam in cylinders.

Positive sides of flexible bricks

Among the advantages are:

- Beauty, aesthetics;

- Durability;

- Convenience in work: easy to stack, cut and so on;

- Light weight, which does not load the foundation;

- It tolerates frost well;

- Easy to fold, make corners, circles, rolls and so on;

- Due to its elasticity, the tile does not crack, does not fall off.

disadvantages

There are almost no drawbacks to flexible tiles. Among the reviews of those who used this material, the only gripe is the accuracy of the dimensions.

That is, in comparison with clinker tiles, which have ideal dimensions, flexible bricks are slightly inferior.

But, again, due to the fact that the material is easy to cut, this drawback does not play a big role.

Interesting articles:

- Waterproofing agent for bricks. Understanding, choosing, applying

- Hyper-pressed bricks, production equipment

- Dutch brick, types, manufacturing methods

- Decorative brick

- History, application and perspectives of red brick

- What are the bricks

- Diy sawdust and cement brick

- Ceramic brick

The main advantages of plaster brick decor

Any finishes have their pros and cons.

Decorative plaster brickwork has its advantages:

- Low weight of the coating - in comparison with the natural brick version, it does not overload the load-bearing elements of the building structures;

- Imitation of bricks from plaster mortars is highly durable, resistant to various types of mechanical damage;

- Making a brick wall with your own labor is easy and simple. You can save on the services of specialists;

- Imitation brick looks great in the interior of premises of various styles (from loft to Gothic);

- Can be used for indoor use or for facades;

- During operation, no special maintenance is required;

- Changing the decor when changing the interior is done by painting in any color.

In the loft style, decorative plaster for concrete is found a little less often than imitation brick.

Brick finish also has disadvantages:

- The need for more frequent removal of dust accumulated by the relief;

- The ability to perform work only at temperatures above +10 C;

- The need to knock down the embossed coating when changing the surface texture.

The following is information on how to make an imitation of a brick wall with your own hands.

Original ways to create an imitation

Agree, the purchase of a quality product that will skillfully imitate a brick will cost the buyer a lot of money. Is there really no way to make such a solution for your interior more affordable? Of course have! Nothing is impossible for a person, and they came up with various original methods, which we will talk about in this chapter.

Let's consider several options in which we will use different mixtures. You can get the job done by mixing gypsum plaster with tile cement glue, using clean or decorative plaster, or thick paint.

Option 1

Step 1 - applying plaster to the wall surface.

The first option is very simple to implement, but the work itself is quite painstaking and time-consuming, but the texture is very expressive. So, we dilute the plaster mixture and apply it with a spatula on the wall with a layer of 1-2 cm - it depends on the depth of the relief that you want to get. You need to apply the mixture unevenly so that the result looks like a natural stone.

Plastering the wall surface

Plastering the wall surface

Step 2 - extruding the texture.

Then we take a deep rectangular shape, moisten it in water so that it does not stick to the plaster and start making prints, thereby creating the desired imitation.

Extruding a texture

Extruding a texture

Prices for popular types of plaster

Plaster

Step 3 - blending.

Take a wet paint brush and start smoothing out the edges. "Brick" will look like a natural stone.

The finished wall needs to be sanded and painted in the desired color. An excellent result for the most modest investment. If you use a mixture with tile adhesive, then it will turn out to be very strong.

Shading

Shading

Option 2

Step 1 - stencil sticker.

The base is processed and then painted white. Then a thin masking tape in the form of a checkerboard is glued to the wall. So we get a stencil that will help very quickly form the seams on the surface.

Stencil sticker

Stencil sticker

Step 2 - painting.

Now we can start painting the wall with a dark, thick paint. After passing a few squares, we partially remove the stencil, and the perfect brick texture will remain in its place.

Of course, the result is not very voluminous, but for interior decoration this is quite enough. And given the simplicity and speed of the method, it becomes a priority for many.

Painting

Painting

If you want a more realistic effect, then instead of paint, use a thin layer of plaster - the tape is removed when the mixture sets a little.

Option 3

Step 1 - Plastering

We start by applying gypsum plaster to the base. Its surface must be made as smooth and even as possible, therefore beacons are used without fail.

Plastering

Plastering

Step 2 - cutting the relief.

After the plaster grabs a little, we take the rule, apply it to the wall with a certain step and cut the seams with a wide screwdriver. It turns out very beautifully and effectively.

This work is very painstaking, but the appearance of the wall will be level, the treasure will have smooth edges.

Cutting relief

Cutting relief

As you can see, there are a lot of ways to decorate your home with brickwork. Choose the best option for yourself, and go ahead - you will definitely succeed.

8 installation rules everyone should know

Installation of decorative bricks is a very exciting experience in which you do not need any additional tools. But you should know some nuances:

You can glue a brick both from the floor and from the ceiling and no matter what material it is made of. Installation from the ceiling is done in cases where the final ceiling has already been mounted and it is more logical to start laying from it, because

if you start from the floor, it may turn out that only a narrow piece of brick will fit the ceiling, and this looks extremely ugly.

If there are corners on the wall, then the laying is always done from the corner.

If you plan to lay with jointing, then you need to immediately think about what color the seams will be. When I glued myself a stone, I took white glue and rubbed the tiles with it. If a different color is planned, then it is better to tint the glue.

If possible, then buy an angular form, this will greatly facilitate your installation. It is difficult to create a beautiful corner without corner pieces, especially when bricks are in different parts of different thicknesses.

To form the same seam, use a glazing bead of the same thickness from 5 to 10 mm.

It so happens that some bricks are of different lengths, so before laying, check the lengths and thickness of the vertical seams by eye so that the seam does not "run away" compared to other rows.

After installation, be sure to cover the brick and the seams with water-based acrylic varnish. It will protect the surface from damage and such a wall can be wiped with a damp cloth.

Gypsum is afraid of water and if you do it in wet rooms, then before varnishing it must be treated with a water repellent.

Materials (edit)

Decorative clinker bricks can be of any color.The material is characterized as strong and practical, durable in use. The option can be used both for finishing the premises inside and for finishing the facade of the building.

Everyone knows that gypsum is a crumbly and fragile material, although it is very lightweight and excellent for use during interior finishing work. The natural color of gypsum is white, it can be changed at the stage of dilution of the solution or during installation.

Polyurethane as a material for the manufacture of decorative bricks is widely used for interior decoration.

Polyurethane is widely used for interior decoration

One of the materials for finishing a brick-like wall is polystyrene, available commercially, easy to use and often used in practice.

The most convenient and popular type of indoor decor is gypsum brick. Its cost is cheaper than other analogues, while it is stronger than polymeric materials, and its visual combination with other interior items is more harmonious. If there is a desire to create on your own, then it will not be difficult to make gypsum tiles: mix water with gypsum in the correct proportions, add PVA glue, prepare molds for pouring the solution and wait for it to dry. To make colored gypsum, you just need to add a coloring pigment to the solution.

The most popular type of room decor is gypsum brick.

When laying decorative bricks, you should choose the right adhesive mixture. Ordinary cement glue is used for tiles. Silicone sealants provide fast adhesion to virtually any surface.

To decorate the facade of a building, the adhesive mixture must be resistant to frost and temperature changes, otherwise the solution will flake off along with the decorative coating

It is important to always monitor the storage conditions and shelf life of long-acquired adhesive mixtures so that their useful properties are suitable for use.

Laying gypsum bricks with your own hands

Laying plaster bricks

If you listen to some of the recommendations of experienced finishers, the work will be quite simple:

- Before laying, do not forget about the preliminary preparation of the walls: the imposition of plaster, putty, primer.

- The range of gypsum tiles on the market is quite diverse. It remains only to calculate the required amount of material, select it and take it with a small margin.

- In order to lay the gypsum brick, you will need an ordinary white tile adhesive. The consistency of the glue must be brought to a thick and viscous mass.

- You can trim the tiles with a metal hacksaw or a file.

- Wall decoration is done from the bottom up, the glue is applied not to the wall, but to the tiles. It is recommended to remove excess glue immediately.

- The material needs to be firmly fixed and dry. This can take about 24 hours.

- It is best to varnish the coating with stone mortar. The choice of color or shade of varnish depends only on you. There should be at least two layers of solution application.

- The seams are necessarily processed, all defects are removed and masked.

Advantages and disadvantages

Flexible tiles have the following positive and negative parameters.

|

pros |

Minuses |

| Resistance to numerous mechanical influences | It is not allowed to use caustic agents or alkalis during the care process. |

| Ecological cleanliness | The process of cleaning the coating from contamination is complicated |

| Resistance to fire and steam | Since a material is chosen that imitates a brick, such a coating does not always fit into modern or unusual interior styles. |

| Attractive appearance | Some manufacturers set high prices for goods |

| Resistance to constant exposure to ultraviolet radiation or other environmental factors | If you purchase items from different lots, then they may differ slightly from each other, which will be clearly visible on the coating. |

| Long service life | Unscrupulous manufacturers who offer low-quality material work on the market |

| Resistant to high temperature | — |

| Ease of cutting | — |

| It is not required to use expensive and complex corner elements during the installation process | — |

| Ease and efficiency of installation | — |

| Affordable price | — |

| Details are highly elastic, so they can be used for different substrates |

— |

The material has a lot of advantages, but there are few disadvantages.

Therefore, it is considered an excellent choice for interior decoration of any room, however, it is important to make sure in advance that the coating imitating brick will fit well into the style of the room.

Styling features

Decorating with flexible tiles imitating brickwork is considered a fairly simple process that can be easily done by anyone. This does not require the use of specific or expensive tools.

The glue is available in the form of a dry mix or a ready-made composition. In the first case, the mixture will have to be mixed with the optimal amount of water in accordance with the existing instructions. In the second, you can proceed to the direct installation work immediately after opening the container with glue.

The laying process itself is divided into the following stages:

the wall is being prepared - it must be flat and perfectly clean. If there are transitions and unevenness, then they are eliminated with a standard leveling mortar. Further, the wall is covered with a special primer that contains antiseptics. This layer increases the adhesion between the brick tiles and the base;

Surface marking

Surface marking

- the room temperature should not be set below 5 degrees, as this will negatively affect the quality of gluing;

- markings are applied to the wall;

- the prepared adhesive solution is distributed on the base, and its thickness should be approximately 2 mm. It is applied with an ordinary spatula, but it is recommended to distribute over the surface with a notched spatula, which ensures the creation of a perfectly even layer;

Glue application

Glue application

gluing the tiles in successive rows begins. It is recommended to start the first row with a whole tile, and the next with half of it. This allows you to get an interesting and beautiful work result. Cutting flexible tiles is very easy using standard sharp scissors

During work, it is important to ensure that the rows are even and beautiful, and that exactly the same distance is left between all the tiles. The seams must be identical in thickness, otherwise the entire finish will not be attractive.

In the corners, the elements are easily bent, so an integral coating is formed. This process is performed for both external and internal corners;

Installation of tiles

Installation of tiles Tiles can be resized as needed

Tiles can be resized as needed

after creating the coating, the remaining adhesive solution is leveled in the seams, for which an ordinary thin brush is used, which is pre-moistened with water. There is no need to seal up the joints with grout, which is considered an advantage of the material, since there is no need to spend additional money for these purposes.

Remove excess glue with a brush

Remove excess glue with a brush

Thus, the process of laying tiles imitating brick is considered understandable, therefore, it is accessible to everyone.

How to glue decorative bricks

Laying of decorative stone should be carried out strictly according to the instructions. Otherwise, you may not like the result.

The glue solution is applied with a spatula to the surface to be coated, rubbing in order to fill in irregularities, microcracks and ensure full contact between the glue and the base.

After that, the glue is applied to the area to be veneered with a notched trowel. The spatula is held at an angle of 60 degrees to the base.Further, an adhesive solution is applied to the brick surface with a layer of 1-3 mm, rubbing it with a spatula over the entire surface of the facing material.

The decorative brick is neatly pressed against the wall, moving it slightly in different directions for the best grip. A significant squeezing out of the adhesive solution should not be allowed, it can subsequently create difficulties when laying the next row. If the stone slides, moves, the reason for this may be a liquid solution. It must be fairly plastic to prevent the brick from breaking.

Selection by size, brick color and installation is a creative process and there are no hard standards. But in the process of work, clearly defined places of crowding of small or large elements of the same height and color should not be created.

Decorative brick lends itself well to processing, it is easy to cut it, just give it the desired size using a regular hacksaw with fine teeth and a planer with a rasp blade. Fine adjustments can be made with coarse sandpaper.

During the laying process, there should be no concentration points with masonry fit or sawed elements. You need to alternate elements in thickness, size, texture and color. Installation is carried out using cladding from different boxes at the same time. It is necessary that the masonry has a harmonious and attractive appearance.

It is not necessary to use brick in the interior everywhere - since there is a high probability of a too rough appearance of the room. Brick, although decorative, is a rather heavy building material, and therefore it should be included in the design of the interior without fanaticism. Brick trim is common to emphasize any detail in the interior: window or doorways, space around the fireplace, bar counter, interroom lintel, columns in the middle of the room, etc. This preserves the brick style without intrusiveness.

Why is it better to make from plaster and buy forms, and not from drywall or putty?

Having made a stone in the form, you will receive a quality product, each tile will be even, it will have its own texture and after installation it will only need to be coated with acrylic varnish. When making a stone from drywall, there are a lot of problems and it is not a fact that it will last a long time.

Your brick is unstuck

Making drywall bricks is a more laborious process. First you need to cut the sheet into bricks, then peel off the cardboard from one side. Next, you need to apply texture to each brick, picking with a knife or other sharp objects will never achieve a good drawing. Of course, you can not do any texture, but personally I would not like a smooth brick. With putty, the same is not so simple, but the quality is many times better than with drywall.

There are also people who make bricks from egg carriages, soak them in water, mold bricks and glue them. Well, this is such masochism in general ..