Bendable plywood: unique properties, scope

With a huge variety of modern building materials used in design and construction, it is natural materials that continue to enjoy deserved popularity. If at the same time they are of exotic origin and have unique properties, their value increases significantly. This can be easily seen on the example of flexible plywood, products from which have always attracted interest.

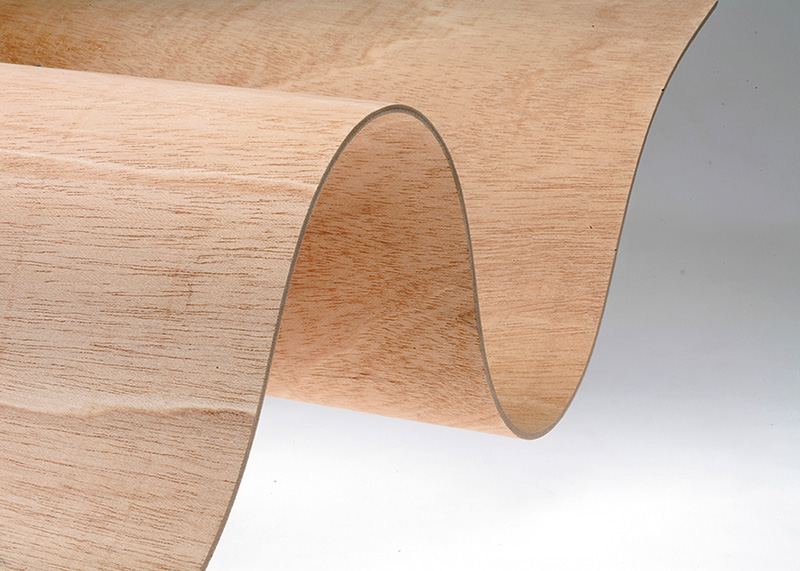

Such material can be bent, like a sheet of cardboard or plastic, within a certain radius, due to the thickness and properties of a particular type of plywood. At the same time, it retains the strength parameters, as well as the integrity of all layers and the outer coating. This is achieved through the use of certain types of wood and manufacturing technology, in which all plywood layers have the same fiber orientation.

Elite breeds: flexible Ceiba and Keruing plywood

Foldable plywood is of several types (Ceiba, Sumuma, Wig and Keruing), the names of which are due to the tree species. You can buy flexible Ceiba and Keruing plywood from us. These types of flexible plywood are most in demand in Moscow, as they have the greatest differences among themselves.

- In the tropical forests of the Middle East and Africa, the ceiba tree grows, possessing a strong but unusually light wood of a light cream color. The veneer obtained from it has an even and fine texture, which is preserved when bent and under the influence of various methods of decorative processing or staining. Ceiba flexible plywood has several analogues from other species, but is more popular due to its natural and pleasant shade.

- Keruing's homeland is the humid jungles of Indonesia and the few forests of Asia Minor. Such specific conditions led to the unique properties of flexible Keruing plywood: high moisture resistance and hardness not inferior to oak. Due to the increased resin content, Keruing plywood products need an additional varnish coating, which, in combination with the natural red-brown tint, gives them additional chic and nobility.

Buy flexible plywood in Moscow in the company

Before you buy bendable plywood, you should familiarize yourself with its parameters, which determine the scope and purpose of the application. Depending on the location of the fibers in relation to the rectangular shape of the sheet, there are longitudinally and transversely flexible plywood. This, as well as the density of a particular grade, is important for large cabinet or front parts in the manufacture of furniture and interior decoration. The thickness of flexible plywood varies from 3 mm and more. It affects the bending radius and strength properties. All of the above factors and the type of wood determine the price of flexible plywood, which you can check with our specialists.

Ordinary plywood can also be bent using moisture and heat treatment. But it is the special flexible plywood that allows you to do this without additional effort and cost. This is true even taking into account the fact that the price of Ceiba plywood is higher than that of ordinary plywood. For creative designers and constructors, bending plywood is of particular interest, as it allows you to create real masterpieces. We offer everyone who wants to realize their creative ideas to buy flexible plywood in Moscow at retail from 5 sheets.

The area of use of wood material, which can be bent without additional effort, is constantly expanding. This is the manufacture of furniture, musical instruments, construction, construction of vehicles, body elements and decorations.Ultimately, unique art objects are created that are of great aesthetic and practical value. All that is needed for this is to buy Ceiba or Keruing plywood on our website.

* All prices indicated are for informational purposes only and in no case are an offer.

Features of plywood

Plywood consists of several (from 3 to 23) layers of wood veneer glued together in the perpendicular direction. This solution allows plywood sheets to remain flexible with high strength.

Plywood production requires not only special knowledge and skills, but also high-tech equipment. To obtain high quality material, the raw material is first subjected to hydrothermal treatment, peeled from the bark, divided into thin sheets and thoroughly dried. After that, the sheets are glued into one panel. Only a company with extensive experience and the necessary technical equipment can complete all stages of production correctly and end up with a really high-quality product.

Types of flexible plywood

The highly flexible wood material is available in various types. Their main difference is the raw material base - wood species.

• Ceiba - lightweight wood, has high strength, color - light cream, texture - fine and even (the tree grows in the Middle East and African tropics).

• Wig, Sumumu, Faveira - technical characteristics are not much different from Ceiba. But the color is more intense: creamy, light brown and pinkish. The tree is native to South American and African countries.

• Keruing grows in Indochina, as well as in Asia Minor. The hardness index of the material exceeds the well-known oak. The color of the wood is reddish, brown with a pink tint. The resin included in the composition makes the wood resistant to moisture. To prevent the release of resin, plywood undergoes a special treatment - it is covered with a protective varnish.

Furniture production using plywood

Furniture plywood has good flexibility. It is this feature of this material that often pushes craftsmen to make some kind of furniture with their own hands. In fact, there is nothing complicated about this, if you follow certain instructions.

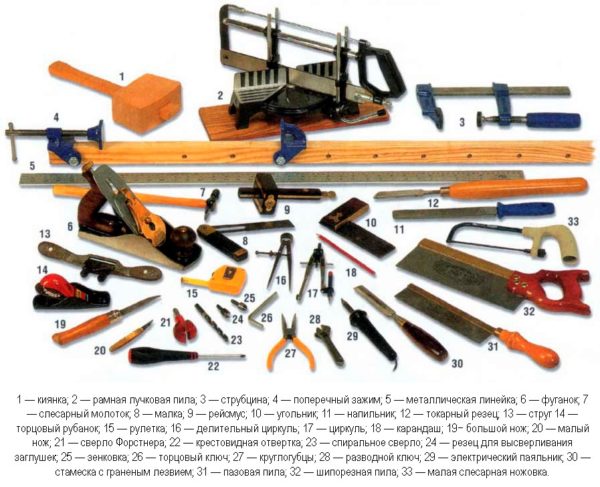

Regarding the thickness of the material, it should be noted that with different sheet thicknesses, a different sawing method is used. So, if the thickness of the plywood is not more than 1.5 mm, then you need to cut it only with a knife, if more than 1.5 mm, up to 6 mm, then a jigsaw is required for work. If the thickness of the product is over 6 mm, you will need to use a circular saw to cut the plywood.

|

It is not recommended to cut the plywood sheet across the veneer grain, otherwise the material will start to crack. To avoid this, small cuts should be made with the knife parallel to the cutting strip.

Before fixing the sheets with screws or nails, you must first make holes in the plate so that the canvas does not crack.

In places where furniture plywood is bent, it must be moistened with water, only then mounted.

There is a special sequence for gluing plywood sheets. The surface on which the plywood board is supposed to be glued should be cleaned with sandpaper. The glue must be applied in a thin layer. After that, the material is compressed until it solidifies completely.

Furniture plywood is considered a good material for making furniture. Despite the fact that plywood products are not as good in quality, they often outperform natural wood due to their technical characteristics. With the right choice of material, you can get good furniture at a low cost, which will last a long time and will have a pleasant appearance.

Plywood as a versatile material

Plywood is a multi-layer building material that is made by gluing several layers of veneer.Veneer is very thin layers of wood, which are represented in a plywood sheet in an odd amount (3 or more). In order to increase the strength of the material, the veneer is applied in such a way that the wood fibers go strictly perpendicular to the fibers of the previous sheet.

Application of plywood sheets

Plywood is used in the following industries:

- In the aviation industry.

- In shipbuilding, including in the manufacture of boats with your own hands.

- In the furniture industry.

- In electrical engineering for the manufacture of various insulating products.

Advantages and disadvantages

Flexible wood sheets have a number of important advantages to consider when choosing materials.

- High level of flexural strength. The material can easily take a curved shape without losing its reliability and strength. If the sheet has a thickness of 1.5 mm, then it can be easily bent up to 180 degrees.

- High level of quality. The surface of such sheets is absolutely smooth and uniform, with the help of such materials it is easy to construct various structures.

- Light weight. As a rule, such plywood is produced in a lightweight version, which greatly simplifies the transportation and installation of this material.

- Decorative properties. Flexible plywood has a beautiful and neat appearance and often serves as a base for finishing. In addition, the surface of the plywood is processed using special grinding equipment, which also makes it more accurate and beautiful. Unusual design structures are often created from such material.

- Environmental friendliness. Constructions made of this wood are absolutely safe for humans and their health. During operation, the material will not emit harmful substances.

- Easy care. This flexible plywood is easy to clean. For this, you can use almost any detergent. It is best to use a cloth or soft sponge for cleaning.

- Long service life. Items made from flexible sheets retain their original appearance for a long time.

Despite the large number of important advantages, this type of plywood also has some disadvantages.

- Special storage technology. The sheets should not be left curled for a long time, they may deform.

- Special transportation rules. Flexible plywood should be transported only on a completely flat and solid surface.

Varieties

Flexible plywood can be produced in several versions. So, sheets can differ from each other depending on the size. The most popular are models with a thickness of 1.5, 3, 4 mm. They may also differ depending on the total weight. Special ultralight models are also produced today. But they can not be used for all construction work. Flexible plywood can be produced from a variety of materials. The most common domestic options are products made from a birch base. These materials have a relatively low cost. They can be found in almost any hardware store.

There is also plywood made from special ceiba wood. She belongs to the tropical species. Such plywood is often used in the construction of marine vessels. This wood has the highest level of strength and density. Ceiba practically does not deteriorate and does not deform when exposed to moisture.

Used to create flexible plywood and keruing wood. It has the most beautiful red or brownish pink color. This breed is distinguished by its special strength, which even exceeds the strength of oak. Keruing contains a large number of different natural resins. They allow you to make the material most resistant to high levels of moisture.But at the same time, its surface should be covered with special protective compounds that prevent excessive resin emissions.

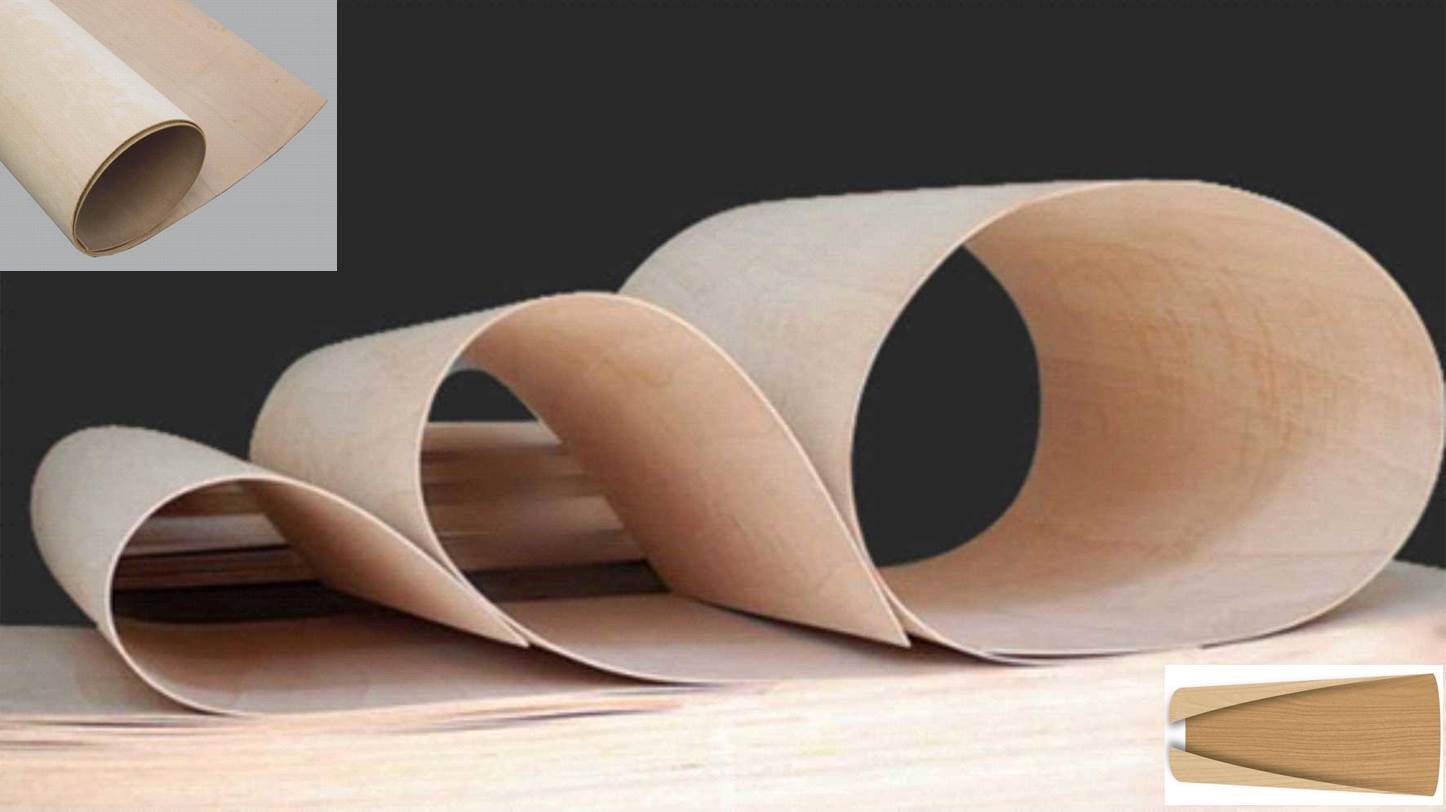

Foldable plywood can also be subdivided into separate groups depending on the direction of bending (longitudinal and transverse). Different sheets can have different degrees of density, as a rule, it varies in the range of 340-350 kg / m3. The bending radius of products can be from 5 to 90 centimeters.

Application of flexible plywood

Flexible plywood can be used to make various columns, arches, products with curved surfaces, and so on. Some craftsmen make exclusive things from flexible plywood that look unusually beautiful and original. Also, the use of flexible plywood involves the creation of kitchen cabinets, external mirrors, screens, partitions, pieces of furniture, soundproof gratings with its help.

In addition, souvenirs, toys, business cards, musical instruments, ice hockey sticks, sleds and the like are now produced from flexible plywood. Most often, flexible plywood is used to create original furniture facades, for the production of frameless furniture and curved doors.

Often, in the interior of modern rooms, designers create sheathing for rounded walls or partitions from flexible plywood. To obtain original forms in the decor, the property of flexible plywood is used to roll it into cylinders. It is interesting that such plywood is used in construction and flexible formwork: for casting concrete elements of non-repeating curved shapes, for example, when creating backyard ponds.

How to choose plywood for making furniture with your own hands

For the independent manufacture of furniture and other interior elements, plywood is most often used. This material has gained such popularity due to its functionality. Plywood does not require complex processing, it is characterized by a low weight, combined with strength and flexibility. In addition, the cost of glued wood panels is much lower than that of natural wood.

However, the plywood on the market varies greatly. To get really high quality, reliable and beautiful furniture, you need to use the appropriate material. In addition, different types of plywood are suitable for different purposes. For example, if you are planning to make garden furniture, you will need a waterproof FSF. Typical home furnishings are best made from 15mm birch plywood boards. For all sorts of interior designs - for example, podiums - more solid slabs will be required.

Ceiba Flexible Plywood

flexible plywood

Plywood, or rather hot compression rotary cut veneer, can bend and take a radius shape due to its unusual structure and low density. All veneer layers have the same fiber orientation, and in the production of seiba-lumber is additionally treated with thermosetting plastic glue. All this makes the plywood very docile. At the same time, unlike other building materials, Ceiba plywood does not need to be hydrated or heated. In a curved form, the material will also not lose its strength. Neither drywall nor ordinary plywood is capable of this. Therefore, the non-standard building material quickly found wide application in the production of furniture and interior parts.

Ceiba plywood is used to make:

- Original frameless furniture of bizarre shape;

- Interior details in the "modern" style (as in the photo of fashion magazines);

- Columns, bar counters and other design structures;

- Exhibition equipment such as counters and counters;

- Curved facades and furniture doors;

Preparation for the manufacture of plywood furniture

You can start making furniture from plywood after you have purchased all the necessary tools and materials. In the process of work, you will need the following:

- Plywood sheets.The thickness of the plywood sheets used depends on the impending load on the part and its purpose. For the manufacture of a strong frame and shelves, a material with a thickness of 18 mm is used. For the facade, a thickness of no more than 12 mm is enough. Wall cabinet doors, which are fixed with stiffeners, can be made of 6 mm plywood.

- Fasteners. To ensure reliable and effective fastening of individual structural parts to each other, special fasteners are used - visible and hidden. Screws are used to fasten individual parts. With the help of glue or silicone sealant, individual structural elements can be additionally fixed.

- An important element of furniture is fittings, which are used to ensure the functionality of the structure and form its decorative appearance. These include: handles, awnings, door closers, wheels, limiters.

- Decorative finishing material: varnish, stain, film, putty.

- Of the tools you will need: jigsaw, measuring tools (tape measure, square), clamp and cross clamp, sandpaper, screwdriver.

Installation features

The production uses a special technique and equipment, due to which beautiful curved shapes of furniture or decor are obtained. You can get a high-quality result at home, but for this you need to take into account some of the nuances.

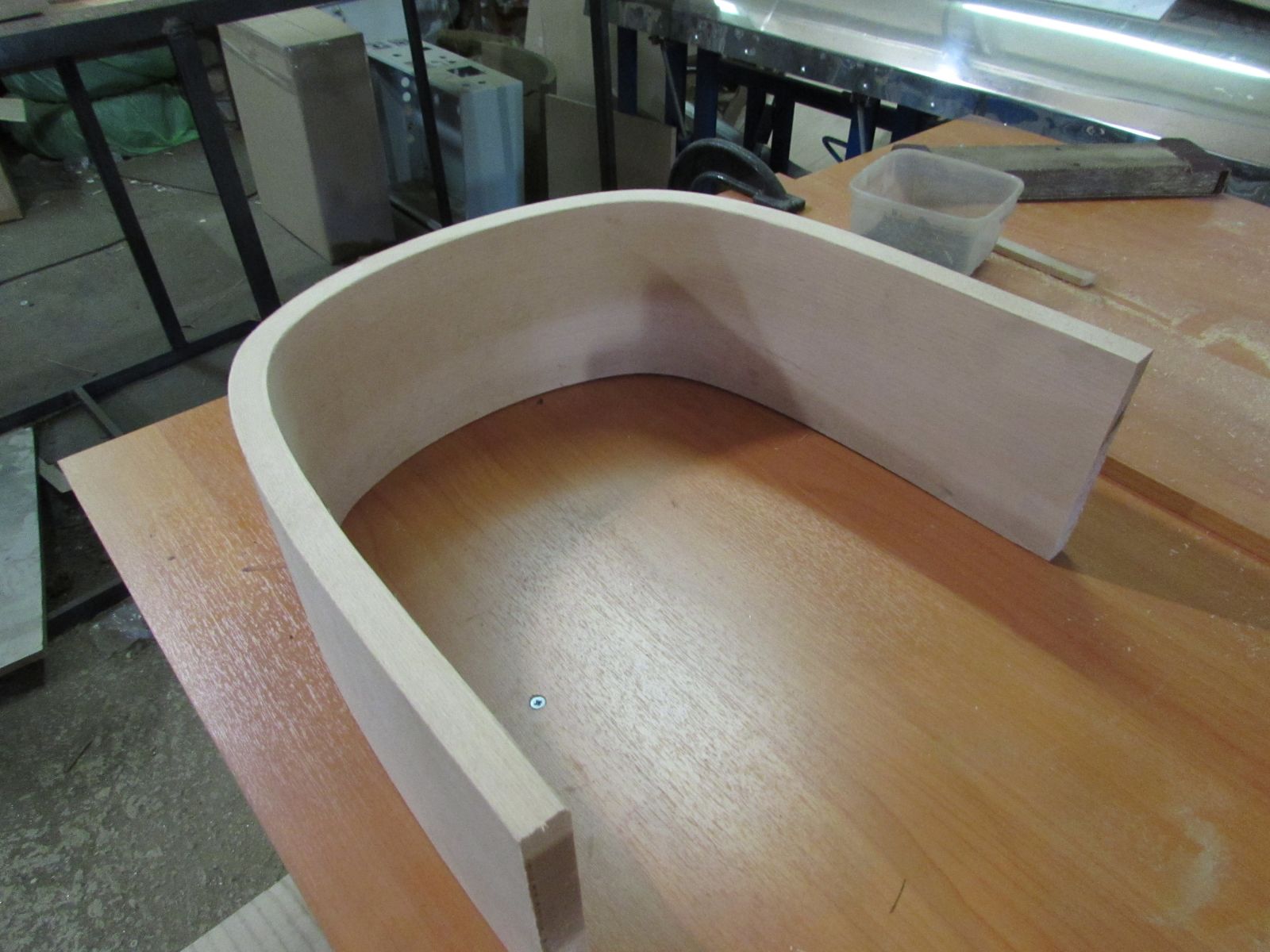

For furniture or shelves, it is best to purchase a few thin sheets of flexible plywood. First, you need to glue them together, and then give the desired shape, softening the material with steam. When designing small items, you can get by with an electric kettle or steam ironing machine.

If it is necessary to give concavity to a thick plywood sheet, it is pre-immersed in hot water for 20-30 minutes.

It is important here to prevent delamination of the material. Softened wood is more pliable, takes almost any shape

After forming the line, the workpiece is placed in a rigid holding frame and allowed to dry. Thus, the resulting shape of the part is fixed.

It is not recommended to use a building hair dryer or an oven to dry the damp plywood, there is a high probability of cracking of the material.

Features of making furniture from plywood

Knowing about the flexibility of plywood in work, many home craftsmen probably thought about making furniture with their own hands. And in reality, there is nothing particularly complicated here - you just have to adhere to simple recommendations in the work.

The instructions for working with plywood provide several tips:

- This rule applies to working with sheets of various thicknesses:

Cutting the sheet with a clerical knife.

Cutting the sheet with a clerical knife.

-

- If the thickness is more than one and a half millimeters, but less than six, then you should use a jigsaw.

- In the event that the sheet has a thickness of more than 6 mm, you will have to cut it with a circular saw.

- Never cut the plywood board across the grain, as this will cause the material to crack. To prevent this, weakening incisions should be made. They are made with a knife, parallel to the cutting line.

- Before joining the sheets with screws or nails, it is necessary to pre-drill the holes, otherwise cracks will form in the material.

Advice!

If you are connecting soft wood building materials with screws, then small washers should be placed under their caps.

- To bend the panel, first moisten it with water and then fix it. In this position, you should keep the sheet for about 12 hours.

Bend the panel using the cover to shape it.

Bend the panel using the cover to shape it.

- In order to glue plywood, there is a simple instruction:

- First, it is necessary to clean with sandpaper at the gluing point.

- Apply the adhesive in a uniform thin layer.

- We squeeze the material until it dries completely.

Advice!

In the event that the glued sheets will be used in conditions of high humidity, then waterproof glue should be used.

When gluing, it is necessary to observe strict parallelism of the fibers.

- In case of peeling of plywood, it is necessary to use paper spacers to glue its layers.

Types of plywood

To understand how to choose plywood that is best suited for solving your problems, you need to understand what this material is characterized by.

Plywood can be classified according to the type of wood used for its production:

- Deciduous. As a rule, birch is the starting material for it. Sometimes - poplar, alder, maple, aspen. High density gives birch plywood extra strength. It has a pleasant light shade and smooth texture. This has ensured her great popularity in the manufacture of furniture and interior decoration.

- Coniferous. Pine, larch, cedar are used as raw materials. Due to the saturation with resins, plywood made of coniferous wood has good moisture resistance. This makes it possible to manufacture furniture from it for rooms with a high level of humidity.

- Combined. The inner layers of such plywood are made of softwood, while the outside is covered with deciduous veneer. Thus, composite plywood combines both strength and moisture resistance. It has found wide application in various fields - construction, renovation, furniture production.

Also, plywood can be divided into 5 grades in accordance with the quality of the outer veneer:

- Elite (E / A). It is almost impossible to buy plywood of this type for self-production of furniture, because its entire volume is purchased by manufacturing enterprises. Elite plywood is almost free from knots, cracks, glue residues and other defects.

- First (I / B).

- Second (II / BB).

The first and second grades of plywood are distinguished by a minimum number of flaws, which makes them the best solution for home-made furniture. - Third (III / CP).

- Fourth (IV / C).

The third and fourth grades can be used for the embodiment of interior ideas that require a topcoat - for example, podiums.

Plywood is also subdivided depending on the degree of processing: - Unpolished (NSh).

- Sanded on one side (Ш1).

- Sanded on both sides (Ш2).

In the furniture industry, sanded plywood has found wider application. Unsanded material will have to be sanded with sandpaper.

There are also many types of plywood, depending on the water resistance of the glue impregnation. Materials such as FBA can be used to make home furniture. This brand is glued with natural glue, which makes it the most environmentally friendly type of plywood. However, it belongs to non-moisture resistant varieties. There is also a heavy-duty brand of non-moisture-resistant plywood - BV. It is impregnated with bakelite varnish. Grades FB, FBS and BS are also characterized by strength due to impregnation, however, in their production, an alcohol-soluble varnish was used, due to which they are distinguished by resistance to moisture.

For the production of home furniture from plywood with your own hands, you can use the FC brand. It is not suitable for outdoor furniture, since it has average water resistance. If you want to make garden furniture, you can choose the FSF grade. But for a home environment, it is not suitable. Moisture resistance is accompanied by a high content of chemicals, which is unacceptable for use inside buildings.

A universal option that is suitable for both indoor and outdoor use is film faced plywood. Such material is not afraid of mechanical stress, the effects of aggressive external factors, and does not need finishing.

Plywood is perfect for DIY furniture production. It combines economy with reliability, flexibility and ease of handling.The main thing is to choose the material in accordance with the tasks for which it is intended.

All-fanera sells plywood of various brands and grades at affordable prices. If you wish, you can arrange delivery with us in Moscow and abroad.

Features of furniture plywood

Advice!

For the production of kitchen furniture, only plywood with a high level of moisture resistance should be used.

The best option is FSF sheets.

Otherwise, such pieces of furniture will quickly lose their attractive appearance under the influence of moisture and frequent temperature changes.

Advantages and Disadvantages of Plywood Sheets Compared to Wood

Materials such as furniture board or plywood are successfully used in furniture production, and today, much more often than natural wood. As mentioned above, the main reason for this is the low price of plywood sheets.

However, in practice, this material has a significant number of advantages.

Let's consider some of them:

- It consists of wood, only of its thin layers (about 1 mm), while its price is an order of magnitude cheaper.

- Even large plywood sheets are dimensionally stable. This is achieved due to a special production technology - crossing the veneer fibers.

- Real freedom of choice in terms of size.

- High lateral strength when compared to a wooden panel of the same thickness.

Unfortunately, this material besides the advantages.

It also has some disadvantages:

- The mass of the plywood sheet will be greater than the wood of the same thickness.

- The ends have stripes, which affects the aesthetic perception of the product, since many people negatively regard plywood as a material.

Facing the ends of plywood.

Facing the ends of plywood.

Advice!

If you do not want the veneer layers to be visible at the ends, they can be sealed or covered with several layers of dark varnish.

This material gives you less freedom in surface treatment, since the face layers are about 1 mm thick, so they can be "removed" with a tool if careless.

Some manufacturers save on adhesives by using adhesives that are harmful for human health... Thus, buying plywood from an irresponsible manufacturer can backfire, which cannot be the case with purchasing even the lowest quality natural wood.

DF brand products - composition, types, standard sizes and applications

Inexpensive rotary cut veneer (coniferous and birch) is used as the basis for decorative plywood. Just as in the case of ordinary plywood, several layers of veneer are glued together and then pressed on special equipment. Facing wood-laminated boards of various shades

The outer layer of DF, as a rule, is made of noble tree species: alder, linden, oak, beech, cherry and even exotic Aformsia (although the price for such a material is quite high). A cheaper version of the face layer is decorative paper impregnated with special resins, or colored polymer film.

Varieties of decorative plywood

From GOST 14614-79 it follows that decorative wood-laminated boards are divided into groups according to the following factors:

-

By the number of veneered sides:

- one-sided;

- double-sided.

Instructions on what defects should not be on the front side of the DFP Continuation of the previous table

-

By facing material:

- DF-1 - plywood sheets covered with a transparent polymer film, through which the natural veneer texture remains visible. The fixation of the protective and decorative layer is carried out with urea-melamine-formaldehyde resins;

- DF-2 - plywood faced with paper or film, completely hiding the natural pattern of veneer and imitating the texture of noble wood species.To fix the facing layer, again, urea-melamine-formaldehyde resins are used;

- DF-3 - here a transparent film with increased moisture resistance, glued to the base with melamine-formaldehyde resins, acts as a decorative layer;

- DF-4 - plywood sheets covered with a transparent film of increased moisture resistance + paper that hides the veneer and imitates the texture of valuable wood. The adhesive is melamine-formaldehyde resins.

In addition to the main varieties of this material, I would like to talk about two more interesting modifications of it:

- Flexible plywood (thickness - from 4 to 15 mm, maximum bending radius - from 5 to 15 cm). Very cost-effective and convenient sheets for making bent rounded structures with your own hands: arches, columns, furniture facades, doors, semicircular walls and much more. This plywood decor allows you to create truly exclusive interiors!

Flexible wood laminate

Flexible plywood sheets have a three-layer structure: a main layer of extra strong mahogany wood and two layers of rotary cut veneer. All elements are hot glued together using thermosetting plastic glue. In the photo - an exclusive rack, the trunk and shelves of which are made of flexible plywood

- Ultra lightweight plywood. This modification is made from tropical wood species, which have a rather low specific gravity. Seiba veneer is most often used as the basis (inner layers), and falcatta and other light tropical species are used for the outer cladding.

Ceiba tree

Standard sizes of facing plywood

Since the considered type of plywood is used exclusively indoors, there is no need to produce large-format DF sheets. As you can see in the table below, the largest standard dimensions for decorative plywood sheets are 2440x1525 mm. DF standard sizes

Applications

Where is the use of decorative plywood acceptable?

As a rule, this material is used in various indoor construction works:

Sheathing of surfaces - walls, ceilings, floors. If ordinary plywood has an unpresentable appearance and therefore is suitable only for rough work, then decorative sheets are a worthy alternative to panels made of natural wood.

Stunning plywood ceiling - mesmerizing!

Interior decoration of train carriages, ship cabins, passenger transport salons. DF qualities such as high wear resistance, resistance to mechanical damage and durability make it an exceptional material in this particular area.

Interior decoration of transport

- Manufacturing of furniture from plywood - in particular, kitchen facades, doors, countertops, counters and so on.

- Creation of all kinds of decor for the interior.

Here is such an unusual Christmas tree