How to remove excess sealant from the surface?

In the process of work, there are times when the material was applied in large quantities or dripped onto the surface. There are several options for how to remove the sealant moment:

- If the surface is not susceptible to white spirit, soak a cotton pad in the liquid and thoroughly wipe off excess adhesive. This method is acceptable if the material has not yet had time to harden.

- You can buy Penta-840 silicone remover at a hardware store. Under the influence of this agent, the dried moment of the sealant will simply dissolve.

- To remove excess adhesive, dampen a cloth with soapy water and sweep over the surface.

- If the sealant has cured, it can be removed with a knife or spatula. But this can scratch the coating.

The field of application of silicone sealant is wide and varied. It will perfectly cope with any task, and most importantly, it provides a high-quality waterproof connection.

Manufacturers

Today there are many manufacturers producing high-quality and reliable polyurethane-based sealants. Let's take a closer look at some of them.

"Moment"

This manufacturer is one of the largest and most famous. The assortment of the company is very rich. Moment offers not only sealants, but also adhesive tapes, different types of adhesives, chemical anchors, and tile products.

As for polyurethane sealants, among them it is worth highlighting the popular product "Moment Herment", which forms a hard and elastic adhesive seam, which is highly resistant to water, household chemicals, oils, petroleum products, acids and salts.

This popular product is used for insulation and bonding of materials in construction and industry. It adheres easily to wood, skirting boards and various decorative objects.

Izhora

The production facility is located in St. Petersburg and offers high-quality polyurethane-based adhesives to consumers.

Izhora produces both one- and two-component compounds that can be used to seal joints on facades and plinths, when processing seams and cracks on ceilings, as well as for external processing of door and window openings.

In addition, the company offers formulations in gray, blue, green, yellow, brick, pink and lilac colors.

Olin

It is a renowned French manufacturer of high quality polyurethane sealants. The brand's assortment includes the popular Isoseal P40 and P25 compounds, which easily adhere to concrete, ceramics, glass, aluminum, steel and wood.

These polyurethane formulations are sold in 600 ml tubes and 300 ml cartridges. Olin polyurethane sealants are also available in a variety of colors: gray, beige, dark beige, dark gray, terracotta, orange, black and teak.

Retel car

Retel Car is a popular Italian manufacturer of polyurethane joint sealants that are non-drip and perfect for vertical surfaces. They are used in the automotive industry, for sealing containers, for laying air ducts and air conditioning systems.

Sikaflex

The Swiss company Sika produces a range of high quality products based on polyurethane. So, Sikaflex sealants are multi-purpose - they are used for roofing work, when installing air conditioning systems, as well as when pouring deformations on concrete.

Also, Sikaflex polyurethane sealants can be used when gluing window sills, steps, skirting boards, and various facing elements. They have excellent adhesion and adhere easily even to plastic.

Dap

It is a well-known US brand offering silicone, polymer and polyurethane sealants. The company's products are distinguished by affordable cost and good performance characteristics. For example, the popular Dap Kwik Seal, which is ideal for sealing joints in the kitchen or bathroom, can cost from 177 to 199 rubles (depending on the volume).

Types of bathroom sealants

Sealants are air-curing gel composites that retain elasticity. They were originally used as liquid spacers, then as waterproof glue. In everyday life, only one-component (ready-to-use) products are used, packaged in foil bags ("sausage"), polymer tubes, cartridges or aluminum tubes.

With the help of sealants in the bathroom, several problems are solved:

- waterproofing of enclosing structures - sealing cracks, cracks;

- rough finish - sealing the gaps between the door block and the wall;

- facing walls, floors - grouting tile joints (usually only in the corners and around the perimeter of the inspection hatches);

- plumbing installation - sealing of threads and sealing of cracks between the side of the bathtub, sink and the wall;

- interior decoration - gluing mirrors, hooks, decorative elements.

On facings, visible areas, a sealant is used that does not turn black under the influence of solar ultraviolet radiation and aggressive environments. There is the following compositional classification of sealants:

Acrylic

The main performance characteristics of acrylic sealant are:

- high-quality adhesion to acrylic bathtubs, PVC panels, wood, plastic, concrete;

- the minimum cost in its category;

- average indicators of elasticity (7%);

- the possibility of staining after hardening;

- a large selection of colors;

- vibration resistance;

- operating temperature -20 ° С ... + 80 ° С;

- lack of toxic components.

Silicone

By chemical composition, silicone sealants are divided into two broad categories:

- acidic - based on acetic acid, during operation they emit a characteristic odor;

- neutral - odorless, cost 50% more than vinegar modifications.

Main characteristics:

- resistance to aggressive environments, solar ultraviolet;

- operating temperature -60 ° С… + 300 ° С;

- high water resistance and elasticity;

- the color is white and transparent;

- high adhesion to concrete, brick, metals, wood, ceramics;

- low adhesion to plastics without an undercoat (primer);

- impossibility of staining the hardened layer.

There is a conditional classification of silicone compounds by purpose:

- low modulus - filling the seams of panel houses;

- electrical insulating - high dielectric properties;

- universal - can be used for various tasks;

- aquarium - transparent neutral compositions based on silicone with high adhesive power;

- sanitary - the composition contains antifungal additives;

- automotive - liquid gaskets with special properties (for high pressure and temperature).

To choose the right silicone for the bathroom, you need to take into account the factors:

- color - the joints with normal decorative value are filled with transparent material, they hide the uneven surface of the tile edge with white sealant or adjust the color to the wall / floor covering, decorative corner / profile;

- purpose - in the bathroom, compositions of the categories "sanitary", "aquarium" and "universal" are used.

Polyurethane

The performance characteristics of the polyurethane sealant are as follows:

- elasticity 250%, that is, the frozen composition stretches 2.5 times without breaking;

- biostability - the development of fungus, pathogenic bacteria, mold is impossible;

- chemical resistance - polyurethane glue can be used in mildly aggressive environments;

- high moisture resistance;

- mechanical strength - polyurethane does not collapse from vibrations, it is difficult to scratch, the elasticity of the composition prevents the formation of cracks

Polyurethane glue is more expensive than acrylic, acidic and neutral silicone.

MS-polymer

When mixing silicone and polyurethane composition, you can preserve all their useful qualities, while getting rid of the shortcomings. This was done by Japanese researchers back in the 70s of the last century. MS polymer sealant has the following characteristics:

- bonding of plastics - high adhesion to PVC, acrylic;

- UV resistance - the material will not turn yellow in the sun;

- shelf life - 2 years, operation - 10 years;

- coloring the seam after drying or using a colored compound.

The only drawback is the high cost of the product.

The agony of choice: which type of sealant is best for the bathroom?

The breadth of the assortment makes your head spin when you look at the shelves of a hardware store. In fact, the task is not that difficult, especially with a competent approach. First of all, you need to choose the appropriate type of sealant from those that are most often used in the repair of bathrooms.

Types of sealants for bathrooms

Silicone. It has a high degree of adhesion to most materials, which makes it the most popular sealant, but negatively affects the cost. Resistant to ultraviolet radiation, moisture, high and low temperatures, due to which it has a long service life. Slight shrinkage, which does not exceed 2%, makes it the best choice for sealing moving joints. Due to its high elasticity, the finished seam is easily deformed and is not able to hold the paint.

Acrylic. It is practically not inferior to silicone in terms of adhesion, immunity to ultraviolet light, temperature fluctuations and high humidity. At the same time, it has a more affordable cost if you compare the prices of one company. Its use is limited by the low elasticity of the seam, which is not suitable for surfaces that may be subject to deformation. Acrylic sealants can be painted, varnished or plastered.

Polyurethane. It is most often used to replace an old sealant layer, since it is not so critical to surface preparation, and fits well on difficult-to-clean silicone residues. As with acrylics, the finished seam can be opened with varnish or paint.

Silicone acrylic. It occupies an intermediate position between the two types, differing in good indicators of elasticity and strength. Another area of application of this group of sealants is the bonding of surfaces.

Choosing the best

If you have to seal the joints in the bathroom with a sealant, the best choice is a silicone sealant, which, in turn, is divided into two types:

Acid. They perfectly cope with their tasks, but the acetic acid included in the composition adversely affects metal, stone, marble, mirror and lime plaster surfaces. Due to their affordable cost, it is acidic silicones that are commonly used by employees. If your bathroom requires sealing the seams of acid-unstable materials, check this moment. You can find out if an acidic sealant is being used by the characteristic vinegar smell or the “A” mark on the package.

Neutral. Due to the fact that the components of these compositions do not enter into chemical reactions with alkalis and metals, they are used for any surfaces. Such versatility negatively affects the cost of sealants, but for the sake of the safety of finishing materials or plumbing, it makes sense to pay more. An indication that a neutral sealant has been used is the absence of a strong odor and the “N” marking on the tube.

Prevent mold

The warmth and humidity in the bathroom are favorable conditions for the development of fungi. To keep black mold-resistant mold from spreading around the bathroom, choose a sealant marked “sanitary”.It contains antifungal agents that will prevent mold spores from developing.

For plumbing fixtures made of acrylic, it is better to choose the sealant of the same name. Due to the similarity of the compositions, the connection will be stronger and more durable

Additional properties

All sealing mixtures on the market contain various additives that give them certain qualities:

Extenders - provide a significant expansion of the material, indispensable for filling wide joints, for example, around sewer pipes.

Fillers (quartz dust or chalk) - improve adhesion and reduce the cost of production.

Fungicides and antibacterial components - prevent the development of pathogenic microflora.

Organic solvents, mineral oils - serve as a tribute to environmental friendliness and safety of vapors for humans.

Pigments - Provides an extensive color palette that makes it easy to match a sealant to colored plumbing fixtures or tiles.

Tips & Tricks

The sealant is selected based on the type of material that will be fixed. Plastic, wood and metal have different properties and operating characteristics. To increase adhesion, craftsmen are advised to additionally purchase a primer. A layer of this composition is applied to the rough surface before using the sealant. The intermediate primer increases the adhesion of the adhesive to the material, the bond becomes more reliable and durable.

When using a sealant in an aggressive environment, preference should be given to samples with the presence of fungicides in the composition. Such a sealant withstands high humidity and is resistant to temperature extremes. Experts use it to equip a bathroom or balcony. The material can be toxic, so its use in kitchen decoration is unacceptable. In contact with food, the composition can negatively affect the well-being of residents.

When installing the aquarium, you should pay attention to the composition of the sealant. The material must be resistant to water

However, there should be no toxic substances in the composition - the sealant should be safe for animals. This material has increased tensile strength. It cannot be dissolved in water. Modern acrylic compositions are able to satisfy all the requirements of buyers, but the choice of composition should be taken seriously.

The permissible operating heating of such a composition should reach +300 degrees. Otherwise, there is a great risk of ignition of the material. Under the influence of critical temperatures, a simple acrylic sealant quickly loses its elasticity and collapses. In stores, you can find compounds that retain their properties when heated to +1500 degrees.

An important criterion for choosing a material is fire resistance. For work in warm rooms, it is necessary to choose a fire protection composition. Very often additional protection is required for wood panels. The place of the felling and the connection of the beams must be processed and protected. When assembling a bath or heated floors on logs with a wooden finish, all joints are coated with a sealant that protects the structure from overheating.

Do not apply sealant in direct sunlight. Light accelerates the formation of a dry film on the surface of the coating and the curing process. The coating does not harden evenly, so the sealant may become bubbled and cracked. The working surface must be covered with a screen. It is necessary to shade the wall within the first five days.

When buying a material, you must ask for a quality certificate. There are prescribed rules and regulations for each room. The documents indicate the requirements for materials and construction in each room. The sealant should be selected with this data in mind. It is better to purchase material under the guidance of a master. In the modern market, you can easily purchase material of inappropriate quality.

For information on how to use acrylic sealant, see the next video.

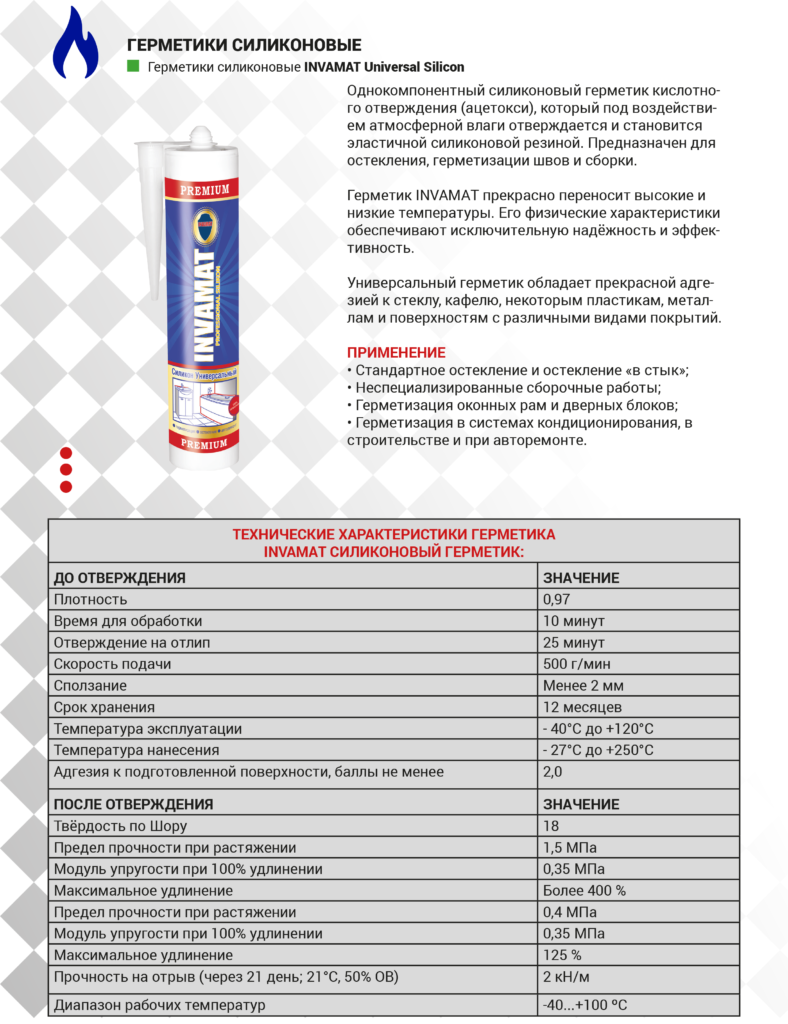

Silicone sealants - popular brands

When buying a silicone sealant, give preference to well-known brands that have long proven themselves from the best side, thereby distinguishing themselves from many similar materials.

Give preference to brands:

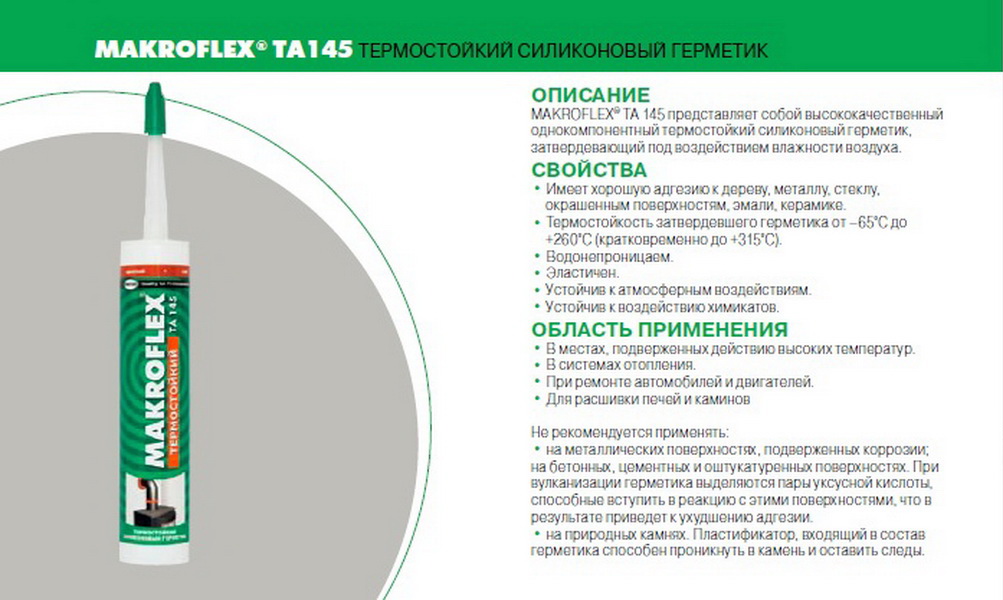

- Macroflex. Finnish brand with over 35 years of experience in the production of sealants and adhesives. Macroflex silicone sealant is famous for its high quality material, excellent performance, ease of use at home and the optimal solution for use by professionals.

- Moment. A leading manufacturer of construction chemicals of the highest quality, supplying goods to the market for over 130 years. At the moment, silicone sealant is being produced at a plant in Russia, observing the latest technologies. This material ideally combines a relatively low price, reliability and quality.

- Soudal. World-class Polish manufacturer of sealants, adhesives, roofing seals. Manufacturing of products is carried out taking into account the requirements of the ISO 9001 quality certification system. The modern technological base ensures excellent performance and safety of products.

- Econ. The product line was launched on the building materials market in 2008 by Henkel. Econ brand products are distinguished by an ideal combination of quality and price. Ease of use, easy handling and modern looking packaging will make construction and renovation a pleasure.

- Titanium. The titanium silicone sealant is produced by the Polish company Selena, which is the world leader in the sale of household and construction chemicals. Titanium-branded sealants are professional joint sealers and are used in a variety of applications. The company also produces sealants based on acrylic, polyurethane and modified bitumen.

- Ceresite. The leader of sales in the field of building dry mixes and chemicals, which has been popular for over a century. The wide varied range of materials and the ease of use set the German Ceresit apart from other similar brands.

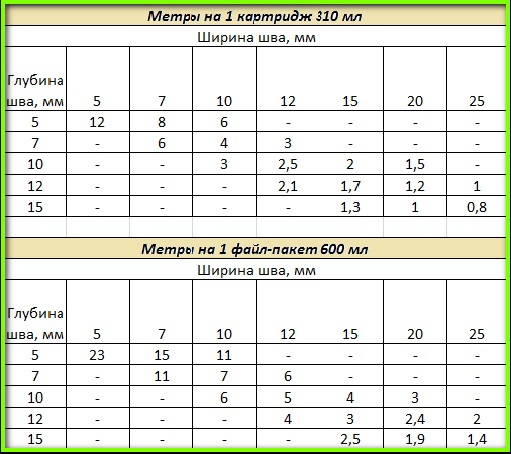

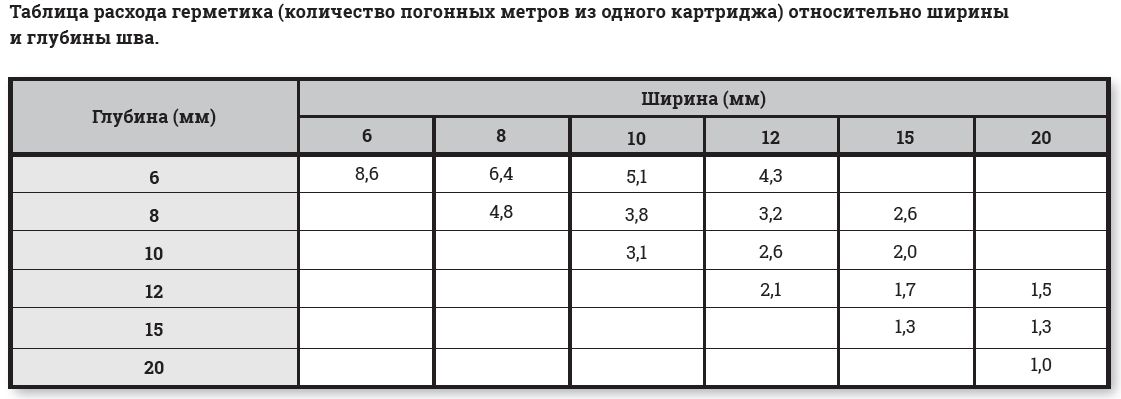

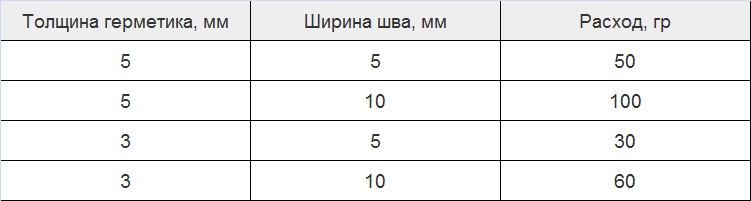

Consumption

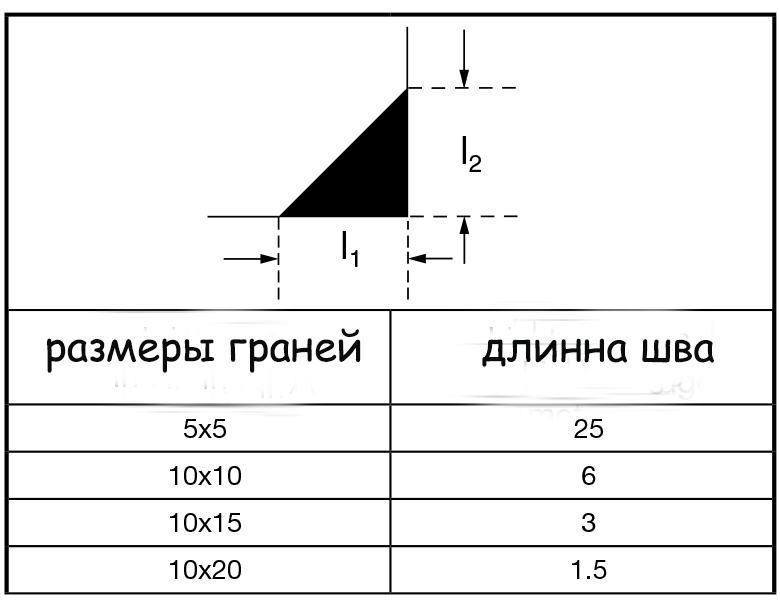

To calculate the amount of material required for sealing joints or other work, you need to know some of the features of the work, then it will become clear how much material you need to purchase per 1 m² of surface. This is an approximate value for the width and depth of the gap. The sealant consumption is calculated using a fairly simple formula: the width of the joint must be multiplied by the depth, as a result, we get the calculated meter. For triangular seams, the resulting value must be further divided by two. As practice shows, a tube of silicone sealant with a volume of 0.3 kg can fill 10 m of a working area with a composition of 5x5 mm.

Colors

Colored silicone sealants are very popular today. They are widespread in finishing works, not only indoors, but also outside. Colored silicone is able to isolate various connections to prevent leakage. It can help you get rid of cracks in your kitchen countertop. It is also possible to close the joints between plumbing devices with the base of the connection (for example, the seam between the kitchen faucet and the sink).

The main properties of colored sealants are strength, reliability and safety. One of the features is the absence of any odor. The composition of silicone contains substances that constantly fight against various fungi and mold.

And the main thing is a huge selection of colors, thanks to which the appearance of the rooms acquires integrity.Joints and seams are not visible, connections and fastenings are not visible. On the other hand, a colored sealant can serve as a contrast in separation. You just need to choose the right shade.

The colored pigment is incorporated into the adhesive mass of the silicone during the manufacturing process. But despite the added color, the sealant is also UV resistant. The original shade does not disappear after application and drying. Over the years, it does not fade and does not become cloudy. It can be assumed that the white color of the sealant is already a color, but this is a mistake. Just like transparent silicone, white is considered a classic. Colored shades - it can be beige, brown, gray, and even black - are a bright addition to the decoration of any room.

Antifungal bathroom sealants

You cannot do without a high-quality sealant against mold, if the old joint putty has turned black, spots, dark stripes have appeared on it. For the bathroom, sealants are produced based on silicone and acrylicas well as combined formulations.

Silicone sealants

Such products are the most popular for sealing joints in the bathroom. They are available in two varieties - neutral and acidic. Neutral sealants have chemical stability, do not participate in reactions with materials, the atmosphere of the room. They are distinguished by high elasticity, stretching due to the flexibility that the rubber in the composition gives them. Most neutral sealants contain fungicidal anti-mold additives.

The second type of silicone-based sealant is acidic. They are inexpensive, but some of their properties do not contribute to a long and effective service. Acids in the composition can react with materials, so such products are not suitable for all surfaces. The level of their adhesion to glass, metal, acrylic is also lower than that of neutral ones.

Another disadvantage of the funds is an unpleasant vinegar smell. On contact with metal bases, there is a risk of oxidation of the latter and damage to their appearance. That is why it is recommended to process only durable plastic, wood, ceramics with acid sealants. Neutral compounds are usually purchased for sealing metal substrates.

Acrylic sealants

Among the acrylic compounds there are moisture-resistant and non-moisture resistant. The latter are not used in the bathroom, since they are not able to withstand high humidity and direct contact with water. Any acrylic based sealants are quite resistant to static loads, temperature extremes, but they can react negatively to chemicals and aggressive detergents.

Other properties of acrylic sealants are as follows:

- can be operated at temperatures from -25 ... to +80 degrees;

- do not darken, do not fade from the influence of UV rays;

- the seam can, if necessary, whiten, paint, plaster.

Most often, such compositions are used to prevent the appearance of mold between the tiles on the floor, at the toilet, to seal all kinds of cracks and cracks. Due to the low elasticity, the seams will still have to be periodically renewed, since a network of microcracks will be visible on them. It is categorically not recommended to seal joints subject to deformation with acrylic, as well as joints of dissimilar materials.

Acrylic Silicone Sealants

In the composition of such sealants, both substances are present: acrylic and silicone. They are considered resistant to moisture, temperature extremes, solar radiation, while retaining elasticity throughout their entire service life. The products have a high degree of adhesion to most materials used for finishing the bathroom. They are white in color and are well suited to tile joints, plumbing fixtures, bathtub and sink-to-wall joints.

Polyurethane based sealants

You can also remove mold in the bathroom using polyurethane sealants.They adhere perfectly to all materials except plastic. When applied to plastic products, you will first have to use a special deep penetration primer. Most often, polyurethane compounds are used to seal joints between a wall and a cast-iron, acrylic bathtub, as well as in places where a significant seam thickness is required.

The advantages of such funds are:

- high elasticity, no cracking during operation;

- minimum time before the start of polymerization and final solidification;

- an increase in volume up to 5-10 times from the initial, therefore, low consumption;

- the ability to operate at -60 ... + 80 degrees, no negative reaction to temperature changes;

- non-shrinkage of the seam, elimination of loss of density over time.

The seam can be performed both on horizontal and vertical bases: it will not drain, it will immediately be securely fixed in place. The disadvantages include the sharp, unpleasant smell of the sealant upon application, which completely disappears after drying. Therefore, it is necessary to work with polyurethane compounds with strict adherence to safety measures, although then they become 100% harmless.

How to apply the sealant correctly. Step-by-step instruction

Silicone based sealants are available in 310 ml plastic tubes. Before using the sealant, it must be prepared:

- The tip of the tube is cut first.

- Next, the cap that comes with the kit is put on it.

- The valve is then cut at the desired angle.

- Then the prepared sealant is inserted into a special gun. Then it is fixed in the tool.

Starting work, insert the cap of the tube into the joint and, pressing the trigger of the gun, evenly distribute the seal on the base to be processed.

You should not save on the sealant. All cavities in the gap must be filled. Otherwise, when the sealant hardens, cracks may appear between the base and the seal.

Often, a filled joint does not turn out to be completely flat. In this case, there is no need to wait for the sealant to dry. It is necessary to remove its excess and smooth the seam with a moistened rubber spatula. You can also use a small plastic scraper for this. Professional builders often level the filled joint with a finger soaked in a solution of laundry soap.

How to remove from the surface

The silicone seal is flexible, but nevertheless durable. It adheres firmly to the base. Tearing off the seal from its surface is not easy. The material has to be cut by inserting a sharp knife between the interlocking surfaces. Therefore, it is necessary to work with the silicone sealant carefully.

But what if you still need to remove the hardened sealant from the base? When the silicone layer is quite thick, it is relatively easy to remove. It should be hooked with something and simply ripped off the base.

A different situation arises if you have to remove a thin layer or stains of inaccurately applied material. It is difficult to remove them, especially when it is necessary to maintain a sealed joint.

In this case, you should carefully separate the layer to be removed from the one that needs to be preserved. To do this, cut through the material in the problem area with a sharp knife, and wipe off unnecessary residues with your finger.

This method works well for a fresh seal that has not reached 100% strength.

Old material is removed only with the help of chemical compounds that soften it. There are many cleaners available from manufacturers to help remove old sealant. The best ones are:

- Silicone-Remover. It is a universal cleaner for all surfaces.

- Sili-kill from the Dutch manufacturer Den-Braven. After its application, the silicone is simply removed with a sanitary napkin.

- Permaloid-7799.This product is intended for removing silicone sealant from metal substrates and painted surfaces.

- Permaloid-7010. It serves to remove the sealant from plastic, including PVC, acrylic, polystyrene.