Care

It's no secret that everything lasts longer if you provide timely care. So it is with a lawn created by means of a lawn mesh. In order for it to serve as long as possible and be distinguished by an attractive appearance, it is necessary to monitor its condition. In winter, snow should be removed from the lawn using a special shovel.

In addition, you must not forget about aerating the lawn, for which you can use a pitchfork.

It is also important to promptly get rid of debris that falls on the lawn and remove weeds that appear. If you notice that individual elements of the lawn began to deform over time, you need to replace them.

Among other nuances, it is worth noting the undesirability of using salt or other chemicals. If for the grid itself it is not so terrible, then the soil will definitely poison.

In winter, ice cannot be cracked using metal objects. Constant impacts on the surface of the grille will cause it to break. In order not to have the problem of ice, snow must be disposed of on time. If you haven't made it in time, you will have to wait for the snow and ice to melt.

Do not leave the car in one place for a long period. If for some reason a bunch of grass with earth falls out of the cell, you must immediately return it back and water it with water. Watering should be monitored constantly, moistening the lawn at least 2 times a week. From time to time it is necessary to fill up the soil in the cells and plant the grass. Throwing cigarette butts on the lawn is unacceptable.

Advantages and disadvantages

The use of lawn grids for arranging parking lots has its advantages.

- Installation of these systems is extremely simple and does not require complex calculations, as well as calling a specialist from outside.

- Doing it on your own allows you to save the family budget, and it takes relatively little time to work.

- During operation, the eco-parking does not deform and does not damage the root system of the growing grass.

- These systems are not traumatic for cars or people, children can play on such lawns.

- The materials used to create the gratings are not afraid of moisture and temperature extremes, they are strong and durable.

- The grates used to create the lawn are environmentally friendly, they do not interfere with the plants growing and developing properly.

- At the request of the owners of the house, the parking lot can be used not only as a parking lot, but also as an outdoor recreation area.

- The volumetric mesh for the parking area does not rust, does not grow moldy, does not emit toxic substances.

- Modular frameworks are not afraid of mechanical stress and rodent invasions, they allow you to grow a dense layer of grass.

- The use of a geomodular frame will prevent siltation of the adjacent territory.

- The lattice material used to create a parking lot is not afraid of chemicals, it is not destroyed by car fluids.

Thanks to this frame, slipping of cars is excluded. In addition, the structures reduce the level of dirt that usually occurs after rain.

However, along with the advantages, lawn grates used to create parking lots have several disadvantages.

- The weight load on the modular grids is different. For eco-parking to be durable and practical, you will not be able to save on modules. Individual modules are not sold in blocks of 1 sq. meter, and piece cells, which significantly increases the cost of the entire canvas.

- Building material options for parking areas are characterized by a greater thickness of modular walls. Individual varieties cannot at all create the appearance of a green lawn, since the frame itself is visible through the grass.

- Despite the simplicity of the laying technology, the technique is demanding on the preparation of the base. Otherwise, under the weight of the car, the soil will very soon begin to sink, holes will appear in the ground, the grate will begin to sink into the ground.

- One of the types of material, when the wheels are pressed on it, to some extent damages the grass against the ribs of the module. For this reason, the vegetation has to be trimmed.

- The machine should not be allowed to stand for a long time in one place of the made lawn. Lack of natural light will cause the grass to wither and become withered.

- Chemical fluids from the machine can enter the cells. They will not destroy the material, however, they cause significant damage to the soil and plants. Cleaning the cellular frame is a laborious task, because sometimes you have to remove some of the modules for this.

Materials and colors

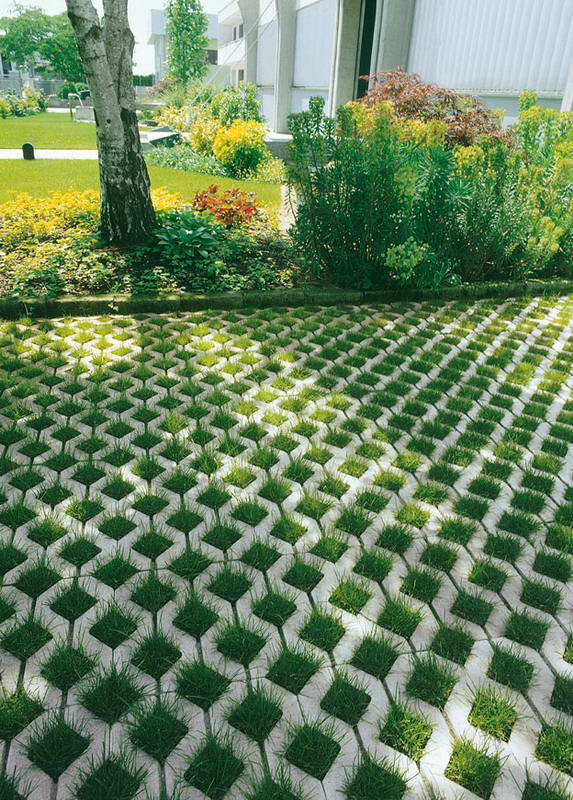

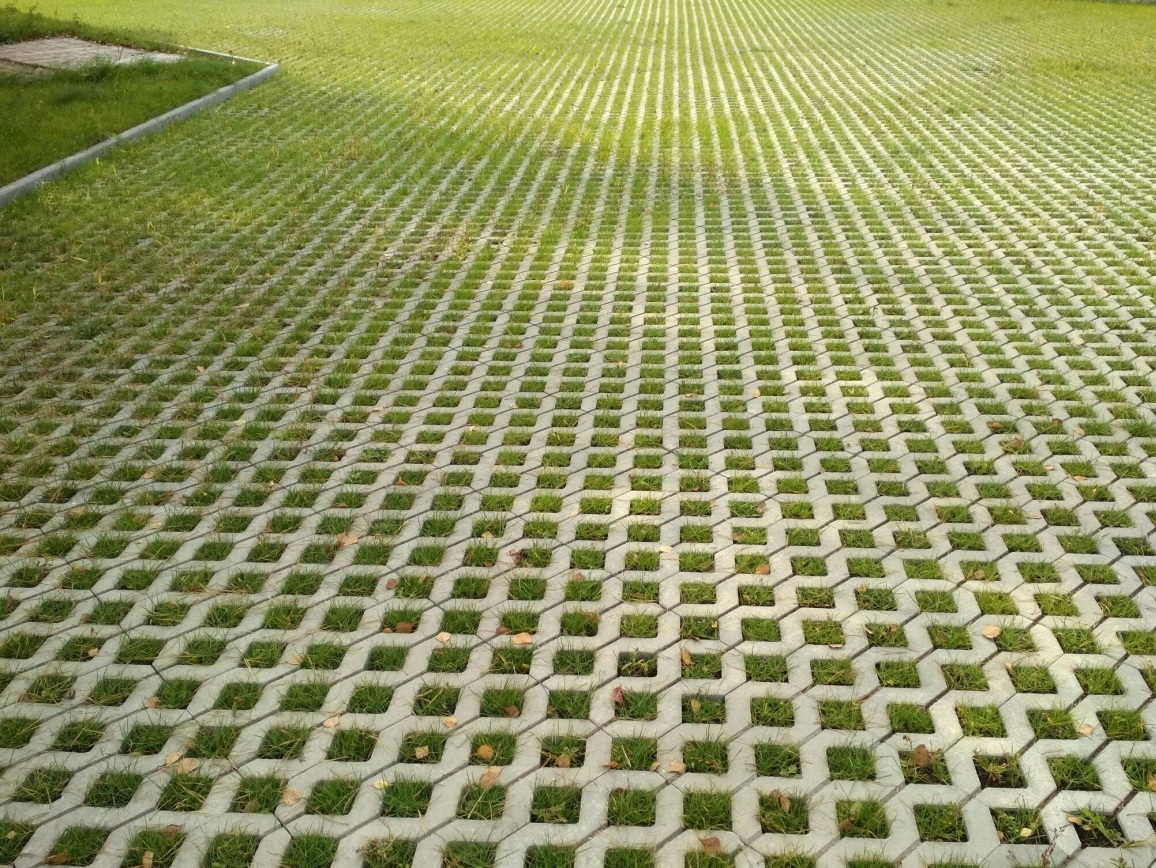

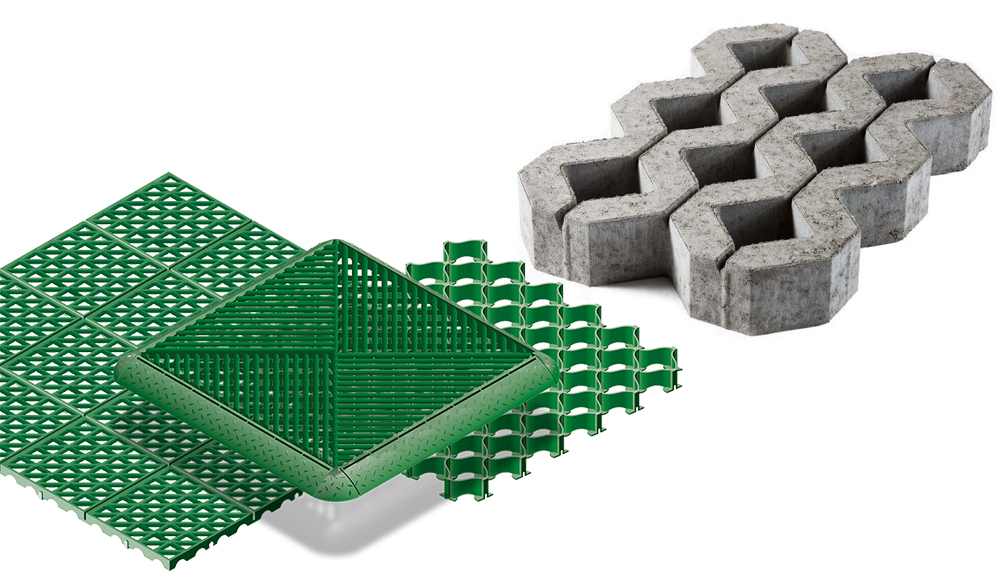

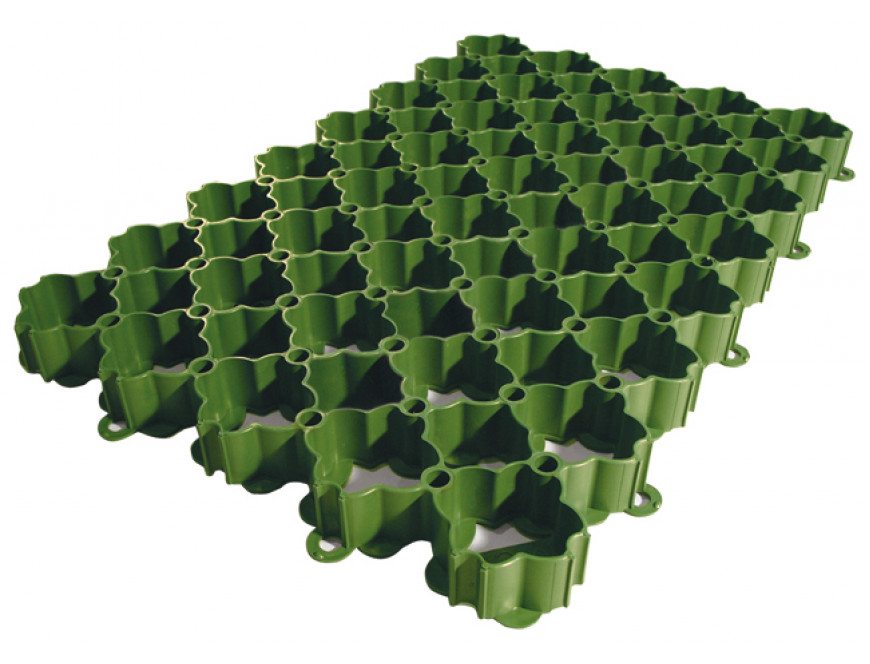

Plastics and concrete are used in the production of lawn gratings. At the same time, not only concrete materials are used for parking lots, but also a high-strength polymer obtained from polyethylene. Plastic products have additional reinforcements along the ribs; they are made for parking lots of cars. The height of a cellular module of this type usually does not exceed 5 cm.

Plastic grates protect the grass from damage, and the material itself, as a rule, serves as a reliable frame for more than 10-15 years. The durability of the frame is determined by the weight load for which the purchased grille is designed. This mesh promotes natural water filtration and high density grass growth. In addition to its practical function, it ennobles the entire territory, not only the parking space.

Variants of the second type are made of concrete, they look quite powerful, in practice they prove their ability to withstand large weight loads. They can be used, including for freight transport, their walls are thick and will not break from contact with trucks.

The advantage of concrete gratings is the low cost of the material itself. However, this nuance is covered by the need to order for the transportation of special vehicles, because the weight of such a grid is quite significant. In addition, it will take up a lot of space in the truck. The concrete frame does not retain moisture, such a lawn is never waterlogged.

However, unlike plastic counterparts, under this frame, you can carry out communications and lay a water supply. The root system of the grass will not be damaged by any contact between the concrete mesh and the machine, it will remain intact. The shape of the cells can be very diverse, as well as their size. For example, they are round, square, hexagonal, made in the form of honeycombs.

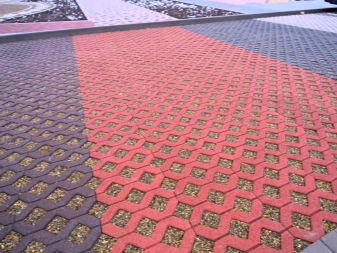

The color solutions of this material cannot be called diverse. Concrete lawn grates are produced in a natural grayish color. The degree of saturation of the solution may differ slightly. Sometimes the material gives off yellowness, sometimes its color is close to the tone of asphalt. Most often, the color is light, less often it can have a reddish or reddish-brown tint.

Plastic counterparts are available in two colors: black and green. In this case, the green tone can be different, depending on the color used in the production of the dye, its saturation and tone. Therefore, on sale there is a marsh, bright green, green-grayish, green-turquoise tones. In general, the green range is considered a good color scheme, because it is a color akin to the tone of the grown lawn. In fact, it allows you to disguise the trellis frame, thus giving the parking lot a more attractive aesthetic appearance.

Application area

Today, the lawn grating has found wide application not only among individuals, but also large enterprises. It is used to create green eco-parks, as well as sports fields and golf courses. This material is used in the design of garden paths, lawns and playgrounds are created with it.

These frame systems are used for arranging adjoining territories in the private sector (for example, in a country house, the territory of a country house), and it is also used to create massive parking spaces for light vehicles (parking lots). The use of this material in crowded places is relevant. For example, it becomes a lifesaver in the arrangement of bicycle and pedestrian paths.

Styling

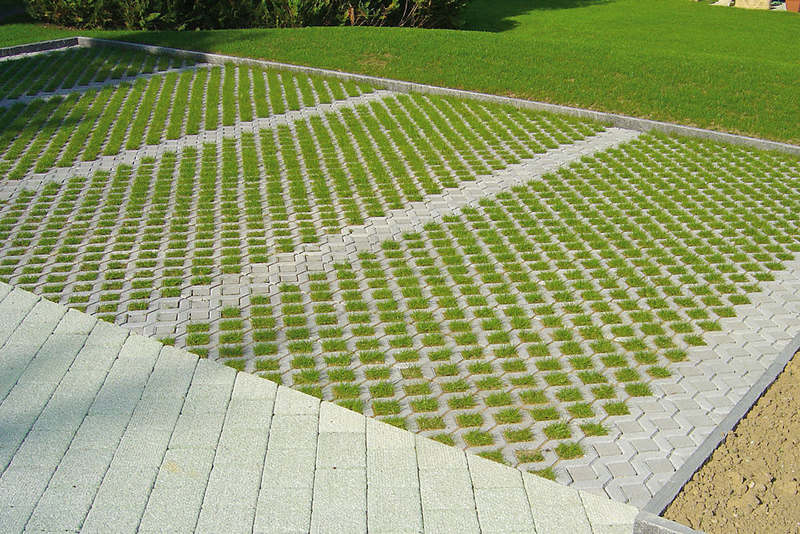

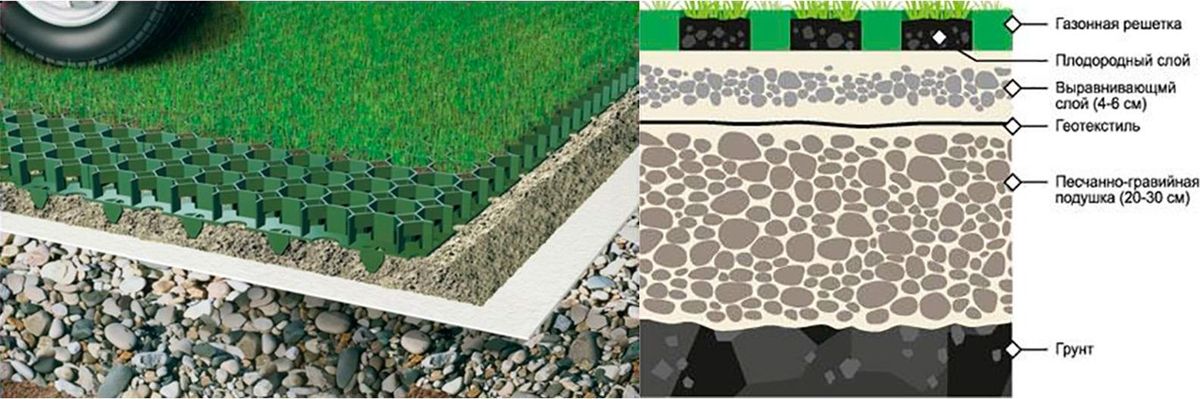

The technology of creating a frame lawn using a lawn lattice is extremely simple, and therefore everyone can master it. To properly lay the grill with your own hands, you must adhere to the step-by-step installation scheme presented below.

- They buy material based on calculations of the required amount, taking into account a given weight load.

- Using pegs and a construction cord, they mark the future lawn area.

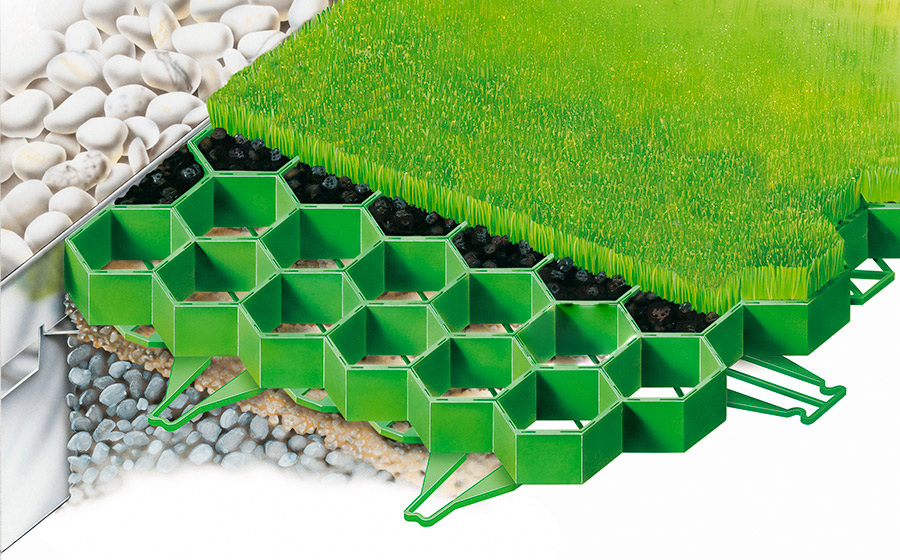

- Soil is removed from the entire area of the marked area, while the thickness of the removed layer to create parking lots is usually from 25 to 35 cm.

- The surface is leveled, tamped, strengthening the boundaries of the dug area.

- A so-called sand and gravel cushion is placed on the bottom of the dug "pit", the thickness of which should be at least 25-40 cm (for pedestrian areas 25, entrance to garage 35, light car 40, cargo - 50 cm).

- The pillow is moistened with water, after which it is tamped and the surface is leveled.

- The walls and bottom can be reinforced with a small layer of concrete, sometimes the walls are reinforced with brickwork.

- Geotextiles are placed on top of the pillow, which will prevent the growth of weeds and the leaching of soil from the cellular frame under the influence of atmospheric precipitation, as well as when snow melts.

- A layer of sand with a thickness of at least 3-5 cm is poured on top of the geotextile. This layer is leveling, it will allow all the elements to be leveled when installing the lattice.

- Concrete modules are laid on top of the leveling layer. Using a rubber mallet, trim the heights of the protruding elements.

- During the laying of the concrete modules, the correctness of the laying is checked using the building level.

- Earth is poured into the cells of the laid frame, filling them about half, after which the soil is moistened for shrinkage.

- Further, the earth is poured and the seeds are sown with moistening of the soil.