Description and scope

The rivet nut is an important element of the connection, which is used at different stages of the production of many products and structures.

It is difficult to do without such an important constituent element. Thanks to this fastener, you can get a permanent connection in a place where it is not so easy to reach, or it is impossible to disassemble the product.

For working in a small space, it is recommended to use such elements.

The use of this fastener allows you to carry out installation in a short time without much effort. Nut rivets can be installed as single parts or as a finished product. You can rivet the product on one side.

Of course, it is useful to have the appropriate equipment for installation. If you have a special riveter at your disposal, the job will be completed in a few seconds. Another advantage of using such a tool is that the materials to be bonded will not deform. However, it is necessary to correctly select rivets in size, taking into account the type and thickness of the surface that will be joined. Conventional nut elements are not suitable for fastening thin steel sheets, as they are not as durable. Internal thread makes it possible to connect efficiently, firmly and for a long time. The diameter of the hardware affects the reliability of the nut rivets.

This element is often used in the automotive industry when a vehicle needs to be repaired. Disassembling the interior is inconvenient and time-consuming, so the use of rivet nuts is the best solution. However, the operation of such fasteners is wide, since it has a lot of advantages, excellent characteristics and its own characteristics.

Types of rivets

For each type of riveting tool, only the same types of rivet fasteners are suitable.

Exhaust

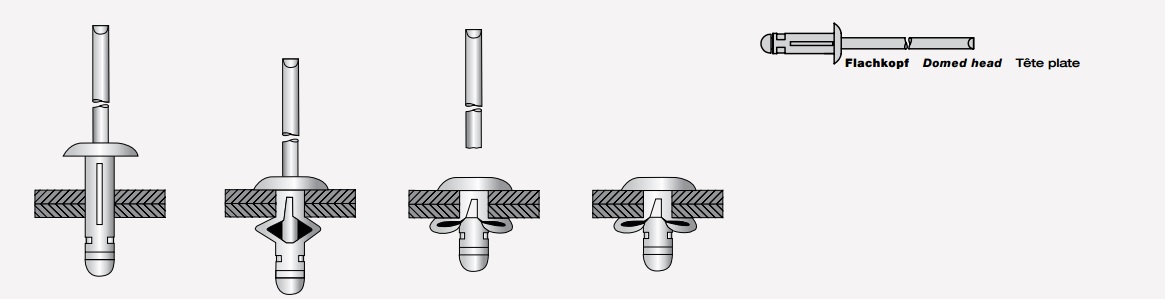

A fastener that consists of two main parts. The first part is a hollow cylinder (rivet body) with through holes on both sides, and a collar (rivet head) on one side.

The body of the rivet is made of metal that is easily deformable. The diameter of the cylinder is the size of the fastening material. The second part is the rod (rivet core), twice as long as the rivet body itself. Made of high strength steel. The core passes through the entire body of the rivet and has a seal at one end, which is called the head of the shank. The diameter of the rod head is slightly larger than the diameter of the rivet body. In appearance, the rivet shank resembles a nail.

Blind rivet fasteners, depending on their purpose, are of the following types:

- Secret - the junction has a flat surface;

- Regular with collar - standard and most commonly used;

- Conventional ones with a large shoulder are used when joining two materials of different softness.

- The increased collar allows a more even distribution of the pressing force on the joint surface and does not cause deformation of the material;

- Hermetically sealed rivets with a gas-tight body. The name speaks for itself - used for airtight and waterproof connections.

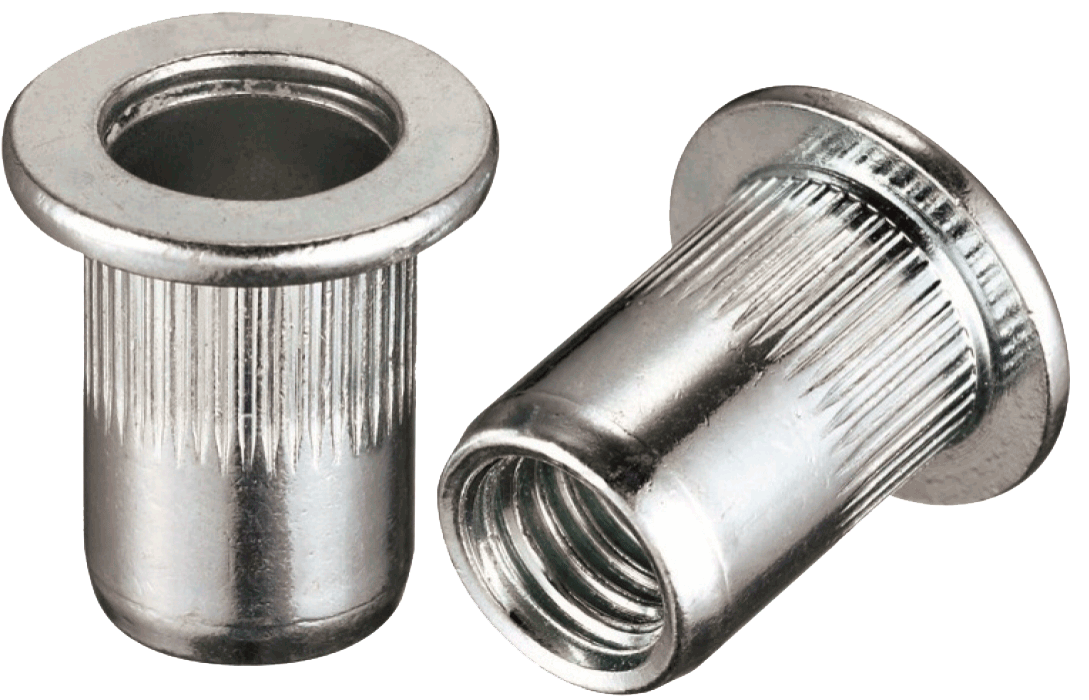

Threaded

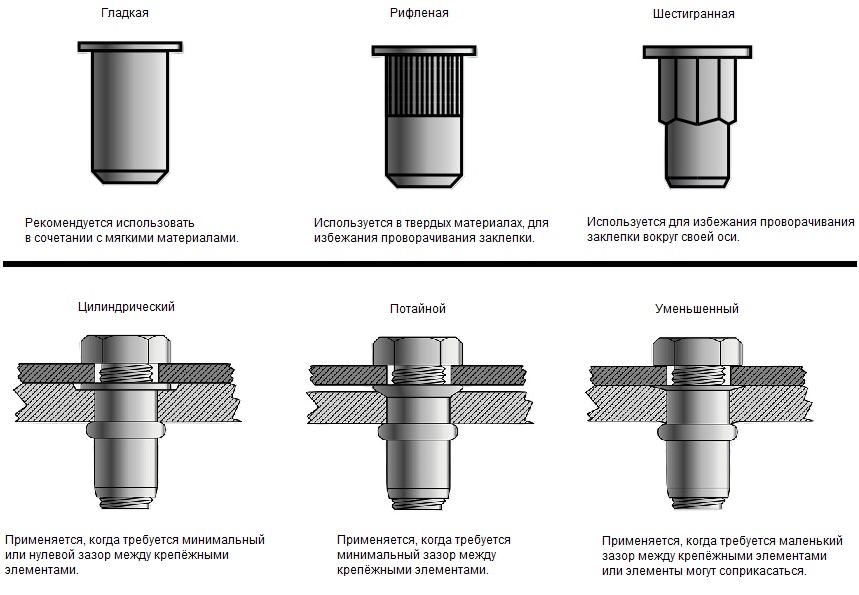

However, like the exhaust, it consists of a hollow cylinder made of soft metal. There is a metric thread inside the body. Some species have a grooved surface on the outside and on the shoulder. According to the shape of the body, rivet fasteners are divided into: round, hexagonal, grooved.

The threaded rivet connects very thin materials where the pull fastening material will not provide a strong connection and vibration resistance. This type of riveting is also used in places that are hard to connect to - ventilation and air conditioning systems, medical furniture, car parts and racks.

The body of pull-out and threaded rivets is made of soft metals - copper, aluminum, aluminum-silicon alloy. The rods of the pull-out fastening material are made only of steel. The rivets are coated with zinc as corrosion protection. If the parts are supposed to be used in an aggressive environment, then the rivets are made of stainless steel.

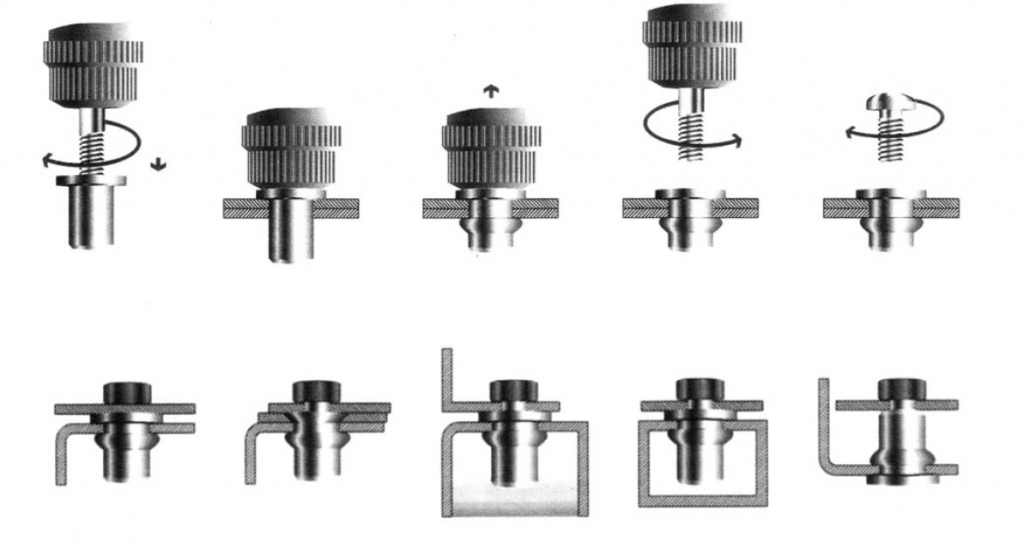

To install a threaded rivet nut:

- Find the right tool.

- Prepare your work surface by drilling a hole of a suitable diameter.

- Screw the rivet (A) onto the threaded rod (B). If you are installing an open rivet, the threaded rod should protrude 1 mm from the rivet body. If you are working with a closed rivet, screw the threaded rod of the tool into the rivet body until it stops.

- Adjust the tool head (C) so that it is firmly against the rivet screwed onto the threaded rod. Secure the head with the locknut (D).

- Insert the rivet into the hole and install it. In the process of installing the rivet, a reverse head is formed.

- After completing the installation process, unscrew the threaded tool stem from the rivet body.

- The rivet is installed. The resulting threaded hole is ready to use.

In the case of installing a blind rivet, the hole must be pre-machined with a 90 ° countersink. Countersinking must be done in such a way that after installation the rivet head protrudes above the working surface by about 0.1 mm - this will ensure direct contact between the parts after assembly. If the material into which the rivet is installed is too thin for countersinking, use a rivet with a small shoulder.

Rivet nuts

In the ProfKrepezh company you can wholesale nut rivets (rivet nuts, threaded rivets, rivet nuts).

The nut rivet is one of the new fastener elements that gained popularity and became widespread for the ease of installation, for its convenience and reliability during operation in steel structures.

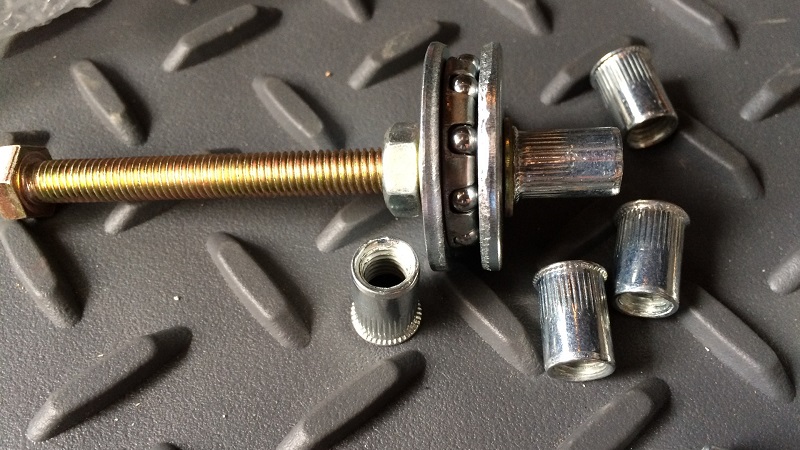

The nut rivet is a cylindrical, semi-hexagonal or hexagonal body with an internal metric thread.

The purpose of the rivet nut

- to create a threaded detachable connection, one that can be easily disassembled and assembled without disturbing the structure or component parts of the structure (detachable connections include, for example, bolt, screw, stud, screw, keyway);

- for operation in units of steel structures, products for construction and general machine-building purposes, the automotive industry, the food industry, the electrical industry.

Normative documents

The nut rivet is a cylindrical, semi-hexagonal or hexagonal body with an internal thread for metric dimensions.

Do not confuse threaded rivets with blind rivets. Blind rivets are used to create a permanent connection !!!

The reason for such a variety of names can be explained by the lack of GOST, ISO or DIN standard for nut rivets.

TU 1680-001-10702513-2019

Installation

It is made with a special tool - a rivet, with the help of which the rivet is mounted into a hole in the structure pre-drilled or punched with special equipment

For reliable fastening, it is important to correctly make a mounting hole for the required type and size of rivets in accordance with the manufacturer's recommendations

Particular attention should be paid to the thickness of the structural part into which the installation is made. This is necessary for the correct spreading of the rivet (the formation of a "skirt" on the back side)

There are 2 rivet lengths: first and second length. The difference is in the range of thicknesses - smaller and larger.

The resulting deformed part ("skirt") should be tightly pressed against the part, without gaps and distortions.

Next, a threaded rod or an ordinary bolt with a metric thread is screwed into the installed rivet with the required tightening torque, which directly holds the fastened structural parts together.

Advantages

Some of the main advantages of nut rivets are:

no need to further use: traditional bolts with a nut (especially inconvenient option if there is difficulty with access to the back side of the supporting structure - "blind" installation) or the use of welding, requiring the skills of a highly qualified specialist.

the installation does not damage the pre-treated surface of the part, if it is coated or painted.

The result is a neat, aesthetic attachment point that provides a secure connection, convenient and quick assembly and disassembly of the attached structural element.

Nut rivets materials

Galvanized zinc-plated carbon structural steel for use in non-corrosive and mildly corrosive environments.

Corrosion-resistant (stainless) steel - alloy steel with a high chromium content (not less than 12%) and nickel for operation in non-aggressive, slightly aggressive, moderately aggressive and highly aggressive environments.

Peculiarities

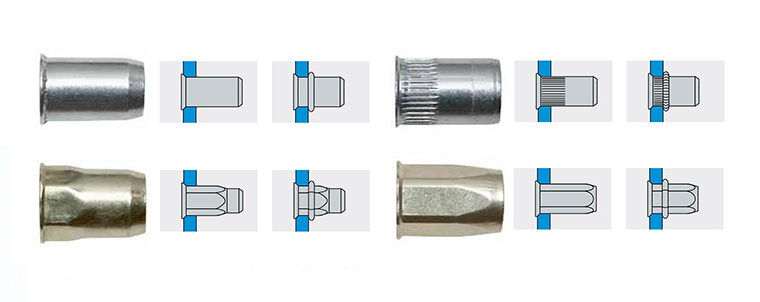

Rivets are fasteners in the form of a sleeve or a rod with a embedded head at one end and a head that closes in the process of riveting at the other. Threaded rivets differ from blind rivets by the presence of a thread. That is, they are hexagonal or cylindrical bushings with a support flange in the upper part and a thread in the lower one. The upper part is made in the form of a thin-walled tube without threads and often has a longitudinal outer notch. During the installation process, it is deformed. The vertical notch on the top ensures uniform deformation and prevents material tearing.

The advantages of threaded rivets include:

- ease of use;

- strong fastening of elements made of fragile and thin materials like sheet metal without deformation;

- the possibility of one-sided fixation in the event that the total thickness of the parts to be joined exceeds the length of the fastening element without loss of strength;

- maintaining the strength of the connection over time;

- mechanical and chemical non-aggressiveness;

- maintaining the integrity of the surface and paintwork;

- the ability to connect elements from different materials;

- lack of mechanical stress in the structure;

- possibility of dismantling and re-installation.

Despite the fact that at present, in most cases, instead of rivets, welded or glued joints are used, the fasteners under consideration have a number of advantages in comparison with them, which determine their indispensability in some nodes. First, threaded rivets are thermally stable. Secondly, they do not cause structural changes in elements during installation, unlike welding, which is especially important when joining parts made of different materials, the behavior of which can be unpredictable. Thirdly, threaded rivets ensure movement retention.

However, these fasteners have several disadvantages:

- installation is complicated by the need for pre-making holes;

- most threaded rivets do not seal the seams;

- installation is associated with high noise levels.

Pros of using threaded rivet nuts:

- Possibility of creating a reliable threaded connection in thin sheet material.

- Simple installation that does not require much time and effort (one-sided access to the work surface is sufficient).

- No deformation of the working surface or damage to the paintwork after installing the rivet.

- The strength of the established connection does not lose its properties over time.

- The ability to remove and re-establish the connection if necessary.

- You can buy threaded rivets in a small volume, test the installation and then select the fasteners of the required length to be installed in it.

The use of threaded rivets eliminates the need for welding, threading, the use of additional fasteners and makes it possible to work with thin sheet material, as well as in places with limited access. This is why the rivet technique is widely used in a wide variety of industries, from furniture manufacturing to aerospace.

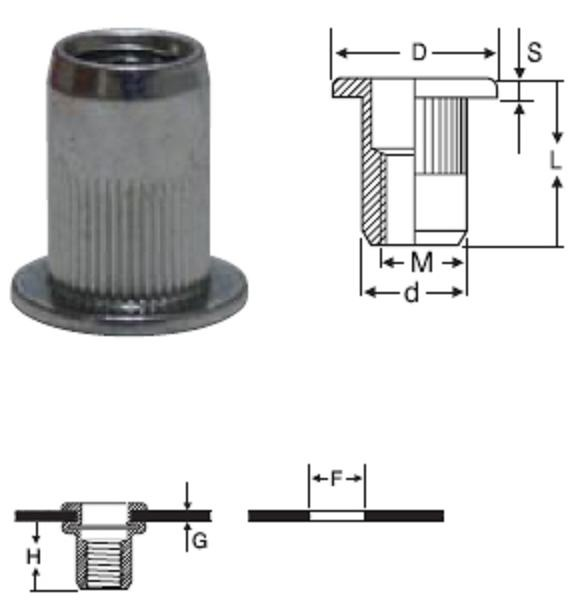

|

1. Bolt or screw for securing a structural member. 2. Structural element 3. Working surface (one or more materials to be joined). 4. Reverse head (formed during the rivet installation process). 5. Reliable internal rivet thread. 6. Closed (blind) or open end of the rivet. 7. Chamfer (makes it easier to insert the rivet into the hole). 8. Rivet barrel (smooth, hexagonal or grooved). 9. Thickness of bonded materials. 10. Rivet head (cylindrical, countersunk or small). |

Species overview

Nut or screw rivets are available on the market in a wide range. Each type of this product has its own characteristics and advantages, as well as the scope. Therefore, first you need to understand the characteristics in order to make the right choice. The rivets differ in their design, namely the internal thread, as it forms the locking belt during compression.

These products are distinguished by the type of head and the type of thread. The M4 - 8 nut rivet has a non-separable connection, therefore it is suitable only for conditions where movement is limited, if it is impossible to access the back of the part. The screw sample belongs to the category of collapsible rivets. The profile of the leg also differs from product to product - hexagonal and round. The type of collar can be open, closed, hidden, small and large, which should also be taken into account when choosing a fastening element.

Hexagonal rivet is used for fastening sheet profiles to each other. Such a nut has the form of a sleeve with an internal thread. This element is an excellent alternative to welded joints, so you can fasten products with thin-walled material. It is often used in the manufacture of furniture, electrical devices, air conditioning systems and the manufacture of metal cabinets. The blind nut is designed to create threads when using screws, studs and bolts. If tightness of the fastening is required, it is better to choose this option. Thanks to the standard collars, deformation of the base material is prevented, since the contact area is large. To install such a rivet, a hole must be drilled.

Cage nuts are used when there is no fastener. If there is a hole, but there is no thread, this product will help out. However, here you will need a special tool that is designed to work with blind nuts. The most common form of riveting nuts is cylindrical. It is sturdy and easy to work with.

Usage Tips

First you need to decide what exactly you will use the rivet nut for in order to take into account the characteristics of the tool. The thread size is of great importance and must be matched to the fastening parameters.When it comes to a new installation, it is necessary to remove the dimensions from the hole in order to avoid damage to its side parts.

As for the material, if you are going to use the nut in a damp room, it is better to choose a product with corrosion resistance. Elements made of stainless steel, steel coating or aluminum are suitable for such parameters.

A bolt and nut can be used to install a threaded rivet if the correct tool is not at hand. However, it will be much easier and faster if you use a pneumatic, battery or mechanical riveter. The product must be screwed onto the thread, after which the fastener is inserted into the hole, and the tool turns on. The rotation will be fast, so the threaded portion will stretch out and a bulge will form around the portion. The tabs need to be pressed against the back of the panel to get tightness.

When the nut is secured, it rotates in the opposite direction and releases from it, leaving the inside of the fastener intact. After such a simple work, it is not necessary to carry out additional finishing or painting the surface. The nuts can be installed at any time.

For information on how to install a rivet nut without a rivet, see the next video.