Features of operation

Self-Locking Nuts are advanced mechanisms that hold units together, which are subjected to high vibration loads and shock manipulation. If ordinary fasteners can crack after several blows, then self-locking does not. The finished hardware should be characterized by the reliability of locking, the ease of tightening the thread. In this case, the master should know that the thread of such a nut can be unscrewed and tightened more than once. In the principle of operation of self-locking hardware, there is a frictional locking, due to which a high level of friction in the threaded turns is ensured. Ideally, such a nut should be tightened on the correct side and then heat treated.

To prevent the fasteners from unwinding, the following recommendations should be followed:

- use lock nuts;

- to carry out installation with a spring washer;

- fix the thread with a special type of glue;

- use nuts with nylon or polyamide ring.

Difficulties in using self-locking nuts include the following:

- the need for special surface treatments;

- creating additional stress in the case;

- danger of crushing the conical bearing surface;

- impossibility of full tightening in some cases.

Self-locking fasteners do not unwind, so their reliability is especially important in the manufacture of aircraft and missiles. They replaced standard nuts with less efficiency and difficulty in tightening. These mechanisms are not afraid of vibrations and vibrations, therefore, if there is a choice, experts advise buying self-locking fasteners.

For self-locking nuts, see the video below.

Species overview

The most common type of Erickson furniture nut is zinc coated. This coating provides an excellent aesthetic appearance, not just corrosion protection. The additional metal is applied using an electroplating bath. Its layer is relatively thin, but this is already enough to impart the necessary qualities. There are also Erickson nuts on sale, galvanized with brass.

This metal also successfully protects against corrosion. Experts point out that the brass-plated type of fastener has an attractive yellowish color. In some cases, nickel plating is used.

It is also worth noting that some Erickson nuts are made without a special coating. But in this case, despite the more favorable price, they are not durable enough.

At the option of the user, the product is equipped with a flat head or a cylindrical head.

The flat head is very popular. This solution ensures low visibility of the installed fasteners

Therefore, the connection turns out to be extremely aesthetically pleasing (this is important not only for furniture, but also for various stairs, partitions, interior designs). Regardless of the design of the head part, excellent safety of the connected structures is guaranteed

Typically, for the production of Erickson nuts, stainless steel with a high carbon content is taken; technical characteristics of the alloy should be specified additionally.

What it is?

The fastening element in the form of a self-locking nut is recommended as a connecting piece between elements of various structures. Standard hardware can only be screwed onto products that have threads. To make the connection stronger in this case, it can be strengthened with a grover, cotter pin, washer. The self-locking nut has a nylon retaining ring, so it can be used on its own without any additional fasteners.The advantage of hardware made in accordance with GOST is that it works with high quality and reliably connects the elements to each other. If the consumer prefers a self-locking nut, this means that he can be sure that this hardware is made of high quality steel and at the same time has a zinc anti-corrosion coating.

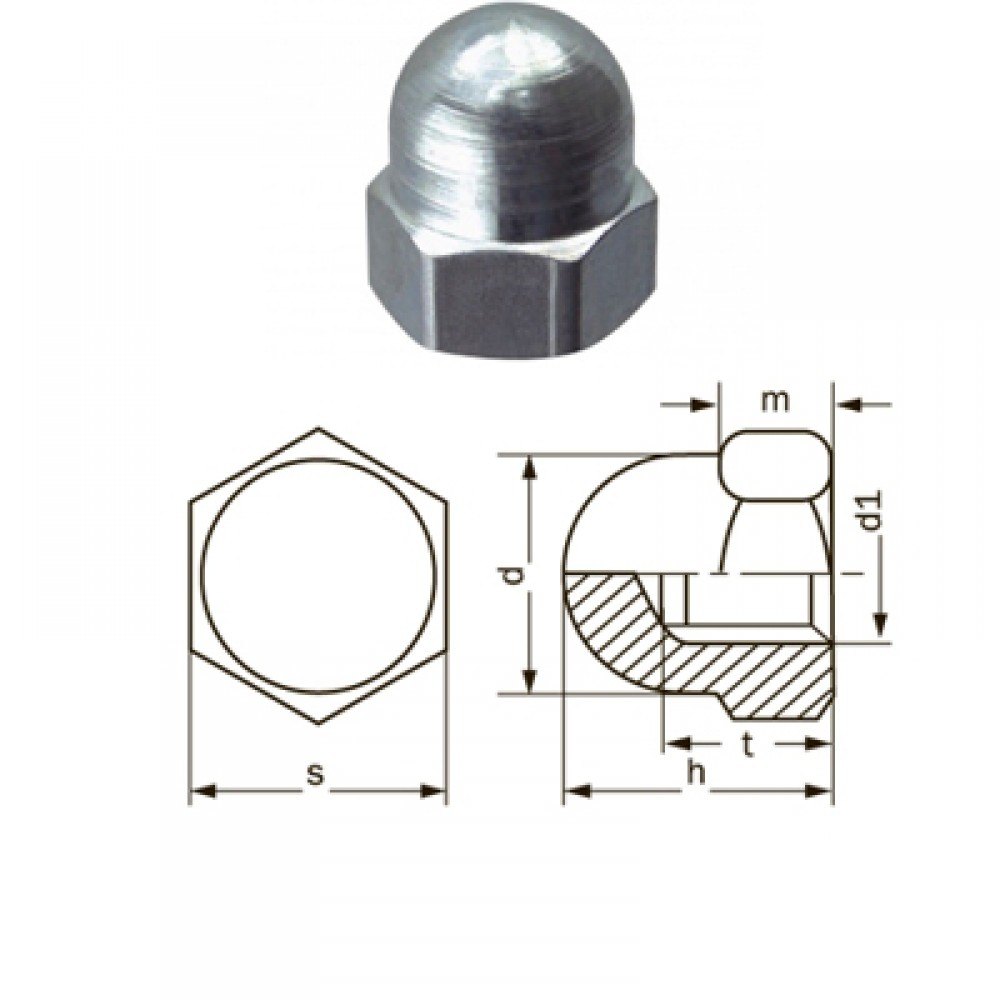

The construction of this type of hardware has the following components:

- an ordinary nut with six faces;

- side with one-sided increase;

- nylon spacer.

Species overview

Like any other hardware, the self-locking nut is available in several varieties.

- With nylon ring. This device looks like an ordinary nut, in the upper part of which a nylon ring is hidden. Hardware with insert can be made in strong and high strength class. This nut is usually used in conjunction with a bolt or screw.

- With a puck. Nuts of this type are considered a modern type of fastener, which is quite functional. The presence of a washer in the fastener prevents the connection from untwisting.

- Flanged is a nut that has a hexagonal shape. Such hardware is made of solid metal and can have a diameter from M5 to M16. It can be used in conjunction with fasteners that have a similar thread. Due to its high strength, the hardware is able to ensure the reliability of fastening.

- The self-locking cap nut is equipped with a nylon ring and is available in thread sizes from M4 to M16. An analogue of this hardware is considered to be a device without a non-metallic ring. These nuts are used to protect threaded fasteners from oil leakage. Self-locking fasteners have found their way into the assembly of vehicles and specialized types of equipment.

It is worth highlighting a few of the most common self-locking nut models.

- DIN 982. The galvanized product is equipped with a nylon ring. When using this hardware, you can get high locking parameters, as well as the reliability and durability of the fasteners. Consumers often give preference to this product, as it is able to fix details with high quality, while it does not need additional equipment.

- DIN 985 A2 and A4 are made of stainless steel. This type of fastener does not rust and protects the connection from the negative effects of environmental factors. During the manufacture of A4 nuts, manufacturers add molybdenum, so the product is reliably protected from chlorine and alkali.

- Nut DIN 6927 8.0 and 8.8. This nut model is equipped with a flange, so it can be used in various industries. This hardware does not have a non-metallic retaining element. It has found its use in harsh conditions. In this case, the use of a washer or a grover is not required.

Dimensions (edit)

Products of category M6 have a standardized length of 1.2 cm. The size for the hexagon is 0.5 or 0.4 cm. The length of the created thread will be 0.7 cm. Its pitch is strictly standardized - 0.1 cm.

Separately, it should be said about the nut of the M3 format. This product is only available in accuracy category A. Height ranges from 0.215 to 0.4 cm. The smallest grip height when using a key is 0.172 cm. Diameter ranges from 0.3 to 0.345 cm. The default thread pitch is 0.05 cm.

It should be borne in mind that the diameter of the circumscribed circle differs depending on the standard used. According to DIN 934, it is 0.601 cm. According to GOST 5915-70, it is slightly less - 0.59 cm. But the turnkey dimension in both standards is the same and is 0.55 cm. In some cases, Erickson knurled nuts are used.

This is the typical M4 product. The diameter is 0.57 cm. The semicircular head is 0.8 cm in size. By default, most of these nuts are coated with white zinc. The standard packaging includes up to 10 thousand copies. True, such large orders are mainly made only by furniture factories.

The Erickson M5 nut is slightly different. The "body" of such fasteners has a size of 0.65 cm. The size of semicircular head parts can already reach 1.2 cm. Oxidation of structural metal is often practiced.In general, as already mentioned, this is one of the most "popular" options.

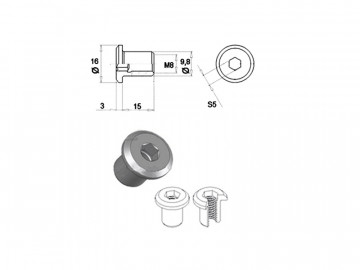

Products of the M12 format are practically not produced anywhere, and do not appear in catalogs (they are made only in isolated cases to order). The Erickson nut of category M8 has a total section size of 1 cm.At the same time, the size of a flat head can reach 1.5 cm.And the total length of the structure is 1.35 cm.In M10, the corresponding parameters are:

-

1.4 cm;

-

3 cm (in a semicircular version);

-

1.6 cm.

The following video shows you how to select and install a nut.

Features and purpose

Outwardly, Erickson's nut looks most like an old-fashioned "cylinder" hat. She even has special "fields". A special thread is applied inside the fastening hardware (in its cylindrical part). The head is equipped with a slot with 6 edges. The key use of Erickson nuts is in the furniture industry.

Cabinet manufacturers all over the world use this product very widely. Such fasteners do not just connect different structural parts, they tightly press them together. This solves the problem that was created for decades by the use of traditional collapsible joints, which did not provide such a clamping force. In the vast majority of cases, people buy nuts of the size range from M5 to M10 (which will be discussed later). The design of Erickson's fasteners makes it possible to use a socket wrench with 6 faces.

It provides a convenient installation of fasteners in the working position, regardless of the plane. Therefore, the duration of the installation work is reduced several times, and you do not even need auxiliary units and devices.

Therefore, you will have to be guided by the provisions of the general standard for hex nuts. And this is GOST 5927-70, adopted back in 1970. The standard introduces the following requirements:

-

thread section not less than 1.6 and not more than 48 mm;

-

the ability to use a one-sided chamfer (in one of the modifications);

-

restrictions on the weight of nuts (attached);

-

standard for the diameter of the circumscribed circle;

-

a certain turnkey dimension;

-

norms governing coarse and fine thread pitches;

-

the specified height of the product.

The length of Erickson nuts varies from 1.45 to 2.3 cm. Their turnkey size can be 0.4-0.6 cm. In this case, the outer section of the head is 1.5-2.2 cm, and the outer section of the sleeve is from 0.89 to 1.2 cm. Furniture screws with a hexagon inside or with a press washer and a straight slot can be used with this fastener. The exact analogs of Erickson's nut will be products with assortment designations:

-

563 A0;

-

563 C3;

-

593 A0;

-

594 A0;

-

594 A5;

-

596 A0;

-

596 C3.

Most often, such fasteners are not used in "pure form", but in conjunction with profile washers. The main task of the washer is to further reduce the mechanical stress on all surfaces to be joined.