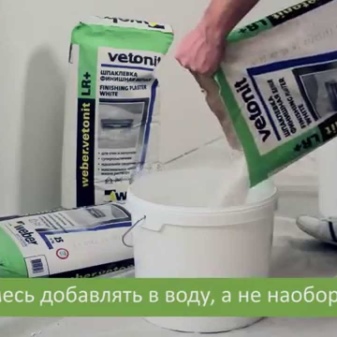

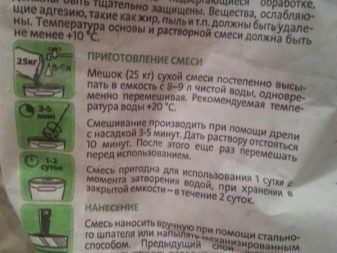

Preparation of the solution

Construction and repairs require flawless alignment of walls and ceilings, but if a powdery mixture is chosen, it must be diluted correctly.

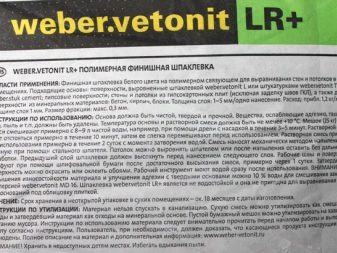

Instructions for use are usually found on paper packaging. It indicates the exact proportions of water and building product, as well as the conditions for the maturation of the solution and the time of its action.

Usually a package of 25 kg is taken for 9 liters of water at room temperature. The mixture is poured into water and stirred until a homogeneous thick consistency. After it is infused (within 15 minutes), it is mixed again using a construction mixer. The solution must be used no more than a day. The admissible layer of putty is 5 mm.

It is worth noting that the nuances of the dilution of different types of Vetonit putty may differ slightly. Storage should be carried out in a dry, dark and cool place.

Application nuances

Vetonit formulations, suitable for rooms with high humidity levels, have their own subtleties in application:

- the solutions best fit on gypsum and drywall, as well as on aggloporite, expanded clay and other mineral surfaces;

- despite the fact that due to the small fraction the leveling is carried out as much as possible, it is undesirable to lay tiles on Vetonit (except for certain types of product);

- do not apply the mixture on surfaces previously treated with self-leveling compounds;

- It is recommended to seal the joints and seams between the slabs made of gypsum plasterboard fragments with special putties of the JS category, they are also used if the finishing, interior decoration of bathrooms, pools and saunas with tiles is required.

Mixtures can be applied not only manually, but also by a mechanized method. By spraying, the compounds can be used even for difficult substrates. So they perfectly cover wood and materials that differ in porosity.

An important condition - application should take place on a thoroughly cleaned and degreased surface

Leveling steps

Putty is applied either by spraying with special equipment or manually with spatulas of different sizes. For construction work, you will need a plastic container, a grinding and planer machine, rags, and a set of spatulas.

Workflow order:

- surface preparation consists in removing old wall coverings, paint, removing greasy stains, rinsing and drying the surface;

- then all the irregularities are indicated - the bulges are cut off, and the depressions are marked with chalk or pencil;

- grooves and cracks are sealed with a medium and long spatula, and as much mortar is taken on it as is needed for one movement;

- drying should be done in a natural way with closed windows and doors (except for interior doors);

- the final putty is applied in the thinnest layer, then, when it dries, it is passed with an abrasive and polished, additionally leveling the corners with a suitable spatula.

The consumption of the product is very economical - about 20 kg of material is needed for 20 square meters of area.

Subtleties of application

Surface. Before applying any finishing putty Vetonit, the work surface must be pre-leveled. Any defects must be covered or sanded down, the finishing solution is not designed to eliminate them. All excess dirt, dust, old finishes, mold must be cleaned. After that, you need to degrease and prime.

Vetonit putty is intended to be applied by hand, although it is possible to apply it by spray

After the applied layer has hardened (24 hours), pay attention to the places where the joints and seams used to be.Irregularities are often formed in these areas.

After finishing the putty work, it is better to immediately rinse the tools with water, after the solution has hardened, it will be much more difficult to do this.

When working, it is better to use protective equipment: goggles, mask or respirator. Although the Vetonit putty mixtures produced in Russia are made from natural raw materials and do not have a toxic effect, the dust formed during work can mechanically harm health, for example, if it gets into the eyes or lungs. For brands "KR" and "LR" it is better to use water with a temperature of about +10 C. If necessary, to obtain a particularly durable surface, use a special mesh.

This putty mixture has only positive reviews and is suitable even for difficult substrates. If you decide to repair or other construction, then feel free to choose it.

In the next video, a professional shares secrets and tips for applying and choosing a putty.

Peculiarities

Putty from the manufacturer Weber Vetonit is a building mixture widely used for finishing works. The material is suitable for dry rooms with low humidity. However, there are varieties of moisture-resistant building materials on sale.

It is one of the best finishing solutions today. Various types of composition are successfully used for wood, concrete, stone, as well as drywall. The dry mixture has a gray-white color, a weak specific odor, a fine fraction (no more than 0.5 mm), which makes it possible for optimal adhesion.

With the help of this material, you can successfully eliminate various defects (cracks, potholes, crevices). The putty is the finishing one. This means that after processing and drying the surfaces, you can start painting or wallpapering.

Restrictions to use, depending on the composition, are high humidity, as well as temperature conditions (+ 10 degrees inside the building). This is because the performance of the material may deteriorate. Moreover, it may start to turn yellow.

The Vetonit mixture, which has become popular, is produced by Russia. There are more than 200 branches of this international construction company known abroad.

Views

"Vetonit" supplies the following options for finishing putty to the building materials market:

- "B" - cement plaster with high moisture resistance.

- "BX" is suitable for facade work, having powerful waterproofing qualities.

- "JS" and "LR" - putty for finishing and superfinishing with increased durability and excellent appearance.

- "T", "KR" - types intended for rooms with low humidity.

- "LR Fine", "LR +" are used for places with low and normal humidity levels.

- "VH" and "KR" - lime topcoat.

"Vetonit LR +"

Finishing putty made of high quality white limestone, finely ground marble and polymer additives. It is used for clean, pre-leveled surfaces; before application, the coating should be degreased and cleaned of small debris.

The main features include:

- particle size up to 3 millimeters;

- the thickness of the applied layer is from 1 to 5 millimeters, a thicker layer is recommended to be used on small surfaces and to thin out with an increase in the processed canvas;

- the speed of complete drying at a temperature of 20C - 24 hours;

- must be used in rooms with low humidity levels, otherwise the color will take on a yellow tint;

- consumption of putty with a layer thickness of 1 mm - 1.2 kg / sq. m;

- the shelf life of the mixed solution is a day in an open container, 48 hours in a closed container;

- sold in bags weighing 5.25 kg;

- dry, the mixture can be stored for 1.5 years.

"Vetonit JS"

A putty mixture on polymer glue with finely ground marble, used for finishing and superfinishing puttying for painting and wallpapering.

Other features include:

- intended for:

- filling drywall and grouting;

- application on a surface previously painted with any kind of paint.

- drying speed ranges from 3 to 24 hours;

- very strong structure, reinforced with reinforcing microfibers;

- strong adhesion;

- complete absence of cracks;

- great appearance, perfectly smooth and even surface.

"Vetonit LR"

Polymer putty mixture, the specific differences of which are:

- use for wall and ceiling work;

- excellent compatibility with plastered and concrete surfaces;

- applied in one layer;

- not applicable at high humidity;

- sold in 25 kg bags.

"Vetonit VH"

The characteristic qualities of this facade finishing putty include the following features:

- The composition is used on concrete and brick surfaces.

- Do not apply it on surfaces treated with lime and water-soluble agents.

- It is better to prepare the solution using a drill with a mixing attachment.

- It should sit for about 3 hours after cooking.

- The mixture is applied in two layers no thicker than 3 millimeters, each next is applied after the previous one has dried.

- There is a high level of waterproofing.

"Vetonit KR"

Putty from organic components for the finishing stage of finishing is used in rooms with low humidity.

Other features include:

- used for walls and ceilings;

- great for drywall work before painting or wallpapering;

- average consumption with a layer of 1 mm - 1.2 / sq. m;

- does not apply for:

- floor finishing;

- on a tiled surface;

elimination of seams and cracks.

Benefits of Vetonit products

The advantages of the Vetonit collection are largely due to its composition, technical and operational characteristics.

Main advantages:

- environmentally friendly, safe composition that includes only natural ingredients;

- assumes various methods of application;

- dries quickly enough (no more than 48 hours);

- has increased adhesion to most substrates;

- economically beneficial consumption (only 1.2 kg per square meter);

- distribution on the surface excludes the presence of drops;

- subsequent grinding is done without dust;

- due to the coating with this product, the strength and performance properties of surfaces are increased;

- affordable price.

You can continue working with the prepared solution throughout the day, and drying largely depends on the thickness of the applied layer, air temperature, and its dryness.

Views

The finishing putty combines two main components. It is a filler and binder. The first is sand, limestone, cement and even marble. A special glue made of polymer compounds is usually used as a connecting link. It is designed for better adhesion and deep penetration into the surface.

The consistency of Vetonit is of two types. You can purchase the material in the form of a dry powder for mortar or a liquid mass prepared for application.

Depending on the binder present, the polymer putty made of composite plastic, cement putty, and organic composition differ. A large assortment provides a lot of possibilities for interior decoration.

There are several varieties of Vetonit, differing in composition, properties and purpose:

- "Vetonit KR" is a mixture created taking into account the use in rooms with low humidity. The mixture is made on the basis of gypsum and cement on organic glue, after leveling, it must be covered with wallpaper or paint.

- Vetonit JS is a polymer putty for all types of substrates with high adhesion and crack resistance. It contains microfiber, which gives the material extra strength. Unlike other products, it is used for sealing joints.

- Vetonit JS Plus, a crack-resistant, plastic and durable polymer mixture, is used both under tiles and under gypsum.The composition is effective for processing joints.

- At medium humidity, the mixture "Vetonit LR + silk" or "Vetonit LR +" can be used. It is a polymer material filled with finely ground marble. "Vetonit LR Fine" is designed specifically for subsequent painting.

All types of solutions are almost universal, used for construction work and repair of various types of premises.

Description and general features

You can choose from various options for finishing putty: gypsum, cement, polymer, each of which is designed for specific purposes and operating conditions.

The characteristic qualities of Vetonit products include the following features:

- The putty is made from natural ingredients.

- The composition fits easily and stretches well over the surface.

- The powdery nature of the mixture ensures a smooth and even surface.

- It is easy to sand.

- Improves the soundproofing qualities of the finished surface.

- Has a low consumption.

- According to the form of release, it happens:

- dry mix;

- ready-made pasty.

- It is sold in durable three-layer bags weighing 5 and 25 kg.